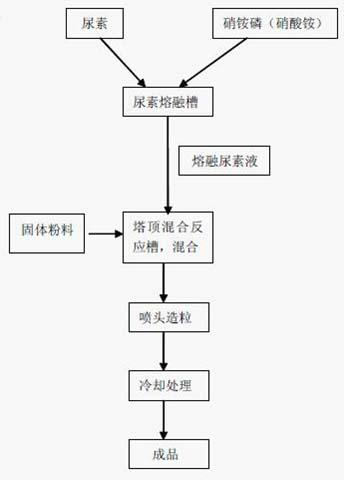

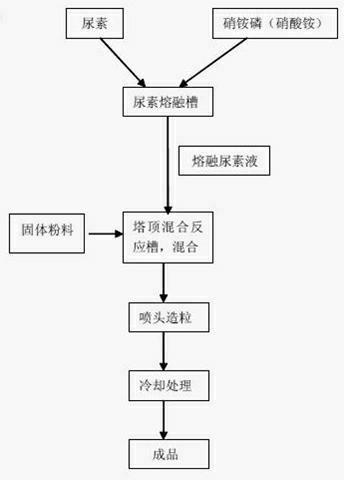

Method for producing urea-based compound fertilizer by high tower granulation

A compound fertilizer and high-tower granulation technology, which is applied to fertilizer forms, fertilizer mixtures, and fertilization devices, can solve problems such as difficulty in producing low-nitrogen or high-phosphorus compound fertilizers and high viscosity of slurry, and achieve energy consumption The effect of reducing, low viscosity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 24kg of flux ammonium nitrate and 160.9kg of urea into the urea melting tank, and melt the urea at a temperature of 117°C (the melting point of urea is 132.7°C). Other materials, containing 96kg of monoammonium phosphate, 66.7kg of potassium chloride, 52.4kg of calcium carbonate powder and return materials, mixed, the temperature of the mixed molten slurry obtained is about 102°C, and finally, the above mixed molten slurry is passed through the high tower The upper adjustable differential two-speed rotary granulation nozzle sprays into the granulation tower, and the granulation is completed under natural ventilation and cooling. The prepared compound fertilizer contains 23.1% N, P 2 o 5 12.2%, K 2 O is 10.0%, and all indicators are in line with GB15063-2001.

Embodiment 2

[0028] Add 20kg of flux ammonium nitrate and 152.7kg of urea into the urea melting tank, melt the urea at a temperature of 119°C, and the melted urea flows into the mixing reaction tank at the top of the tower after metering, and add other materials in the mixing reaction tank, including phosphoric acid Ammonium monoammonium 118.2g, potassium chloride 53.3g, calcium carbonate powder 56.2g and return material, mix, the temperature that obtains mixed molten slurry is about 110 ℃, finally, above-mentioned mixed molten slurry is passed through the adjustable The differential two-speed rotating granulation nozzle sprays into the granulation tower, and the granulation is completed under natural ventilation and cooling. The prepared compound fertilizer contains 21.9% N, P 2 o 5 15.1%, K 2 O is 7.9%, and all indicators are in line with GB15063-2001.

Embodiment 3

[0030] Add 32kg of flux ammonium phosphorus nitrate and 137.0kg of urea into the urea melting tank, and melt the urea at a temperature of 116°C. Ammonium monoammonium 38.2g, potassium sulfate 152g, calcium carbonate powder 40.7g and return materials, mixed, the temperature of the mixed molten slurry obtained is about 107°C, and finally, the above mixed molten slurry is passed through the adjustable differential in the middle and upper part of the tower. The two-speed rotating granulation nozzle sprays into the granulation tower, and the granulation is completed under natural ventilation and cooling. The prepared compound fertilizer contains 19.1% N, P 2 o 5 5.0%, K 2 O is 19.2%, and all indicators are in line with GB15063-2001.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com