Automatic packaging unit for vacuum packaging of inner bag and outer bag

An automatic packaging machine and vacuum packaging technology, applied in the field of material equipment, can solve the problems of easily contaminated materials, high cost, vacuum packaging, etc., and achieve the effect of improving the degree of automation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

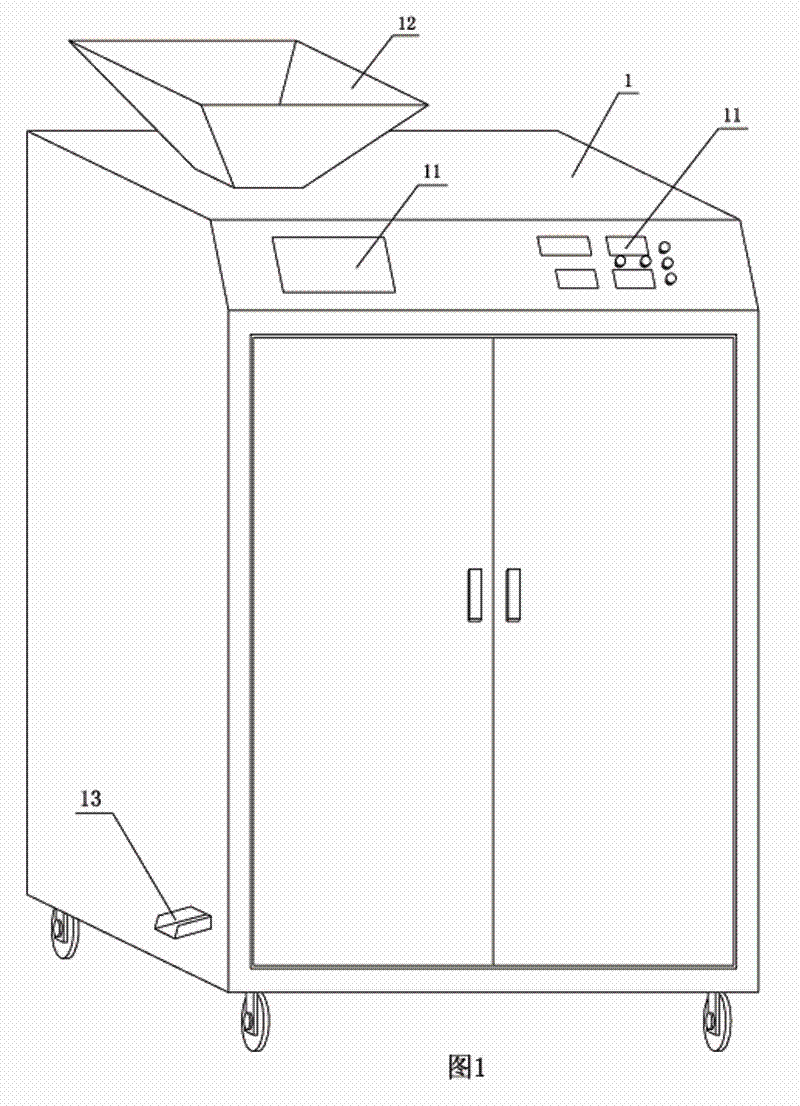

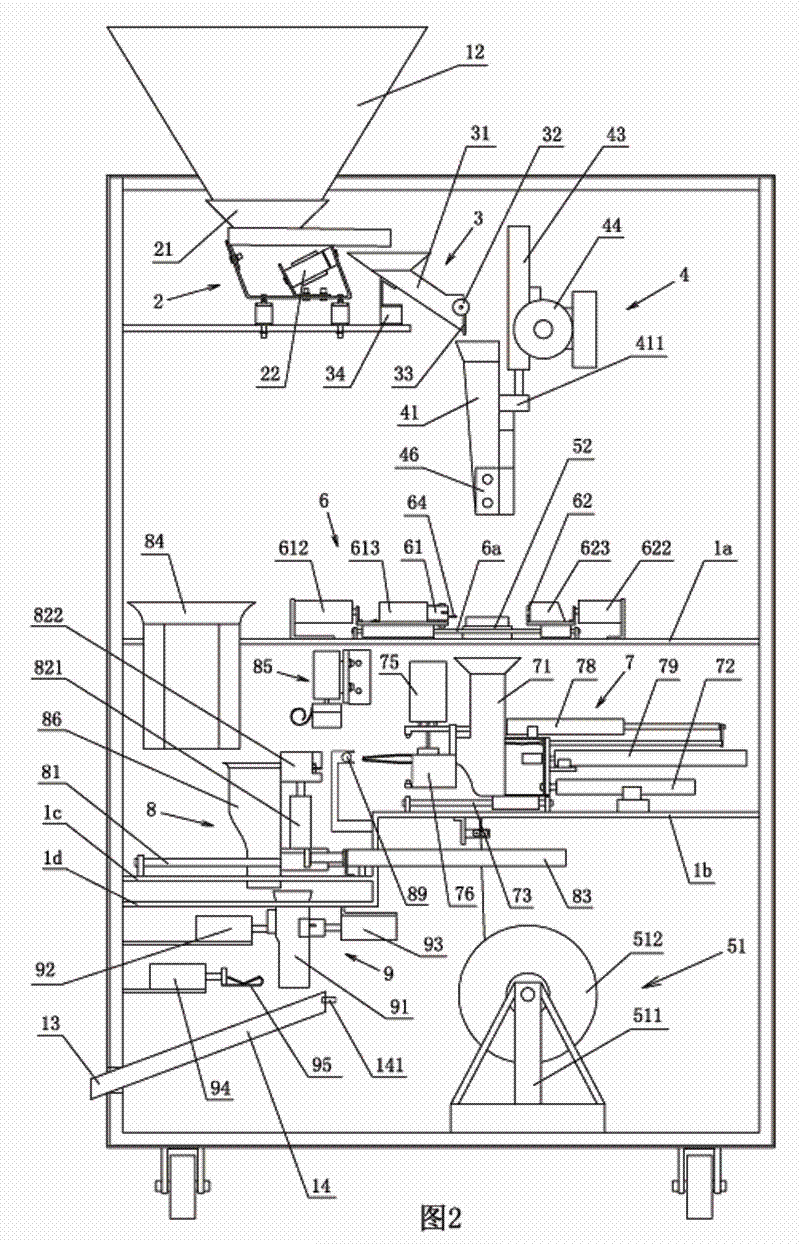

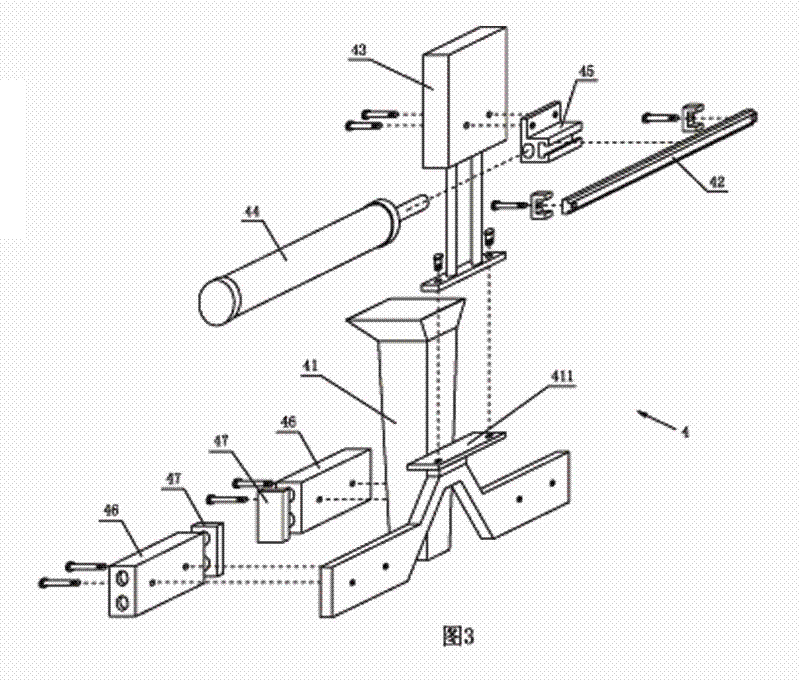

[0030] refer to figure 1 , figure 2. An automatic packaging machine for vacuum packaging of inner and outer bags, including a chassis 1 composed of a casing and a frame. The top surface of the chassis is equipped with an operation control panel 11 and built-in control electrical components. The control electrical components are reasonably arranged inside the chassis 1 (not shown in the figure) control electronics). The top of the chassis 1 is equipped with a vertically connected material hopper 12 for placing tea leaves to be packaged or other fluid solid small particle materials. The lower part of one side of the chassis 1 is provided with a finished product outlet 13, and the interior of the chassis 1 is equipped with a material hopper. 12 and the finished product discharge port 13 are successively connected from top to bottom with a feeding device 2, a metering device 3, an inner bag charging device 4, an outer bag charging device 7, an outer bag conveying device 8, a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com