Garbage refinement pretreatment system and method for garbage incineration power plant

A waste incineration and power plant technology, applied in combustion methods, chemical instruments and methods, incinerators, etc., can solve problems such as high dioxin content, incinerator failure, and low power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples and accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

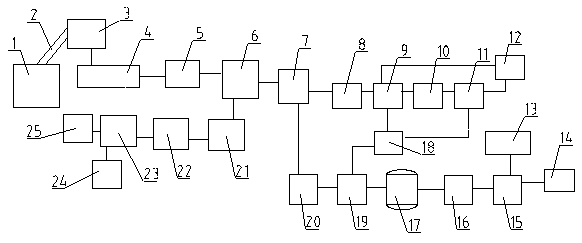

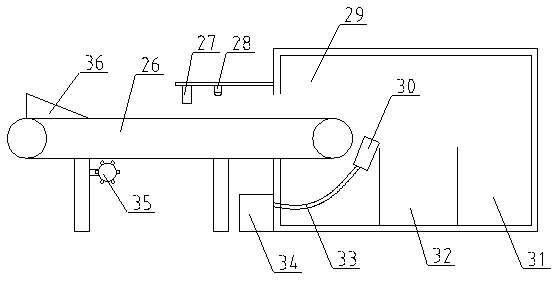

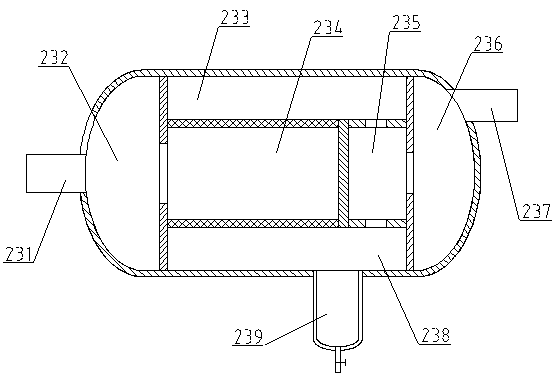

[0026] like Figure 1~3As shown, the garbage refinement pretreatment system of the garbage power plant of the present invention includes a garbage storage pool 1 and a sorting system, and is characterized in that: the sorting system includes a bag breaking machine 3, an intelligent sorting platform 4, Crusher 5 and extruder 6, a feeder 2 is arranged between the bag breaker 3 and the garbage storage pool 1, an intelligent robot is arranged on the intelligent sorting platform 4, and a dispersed The extruder 6 is provided with a slurry outlet and a solid material outlet, and the slurry outlet is connected with a slurry pool 21 and an oil-water separator 23 in turn, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com