A system for making sludge into recycled solid fuel

A solid fuel and sludge technology, which is applied in the direction of solid fuel, biofuel, fuel, etc., can solve the problems of large production equipment, low production efficiency, complex production process, etc., and achieve small footprint, simple structure, The effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

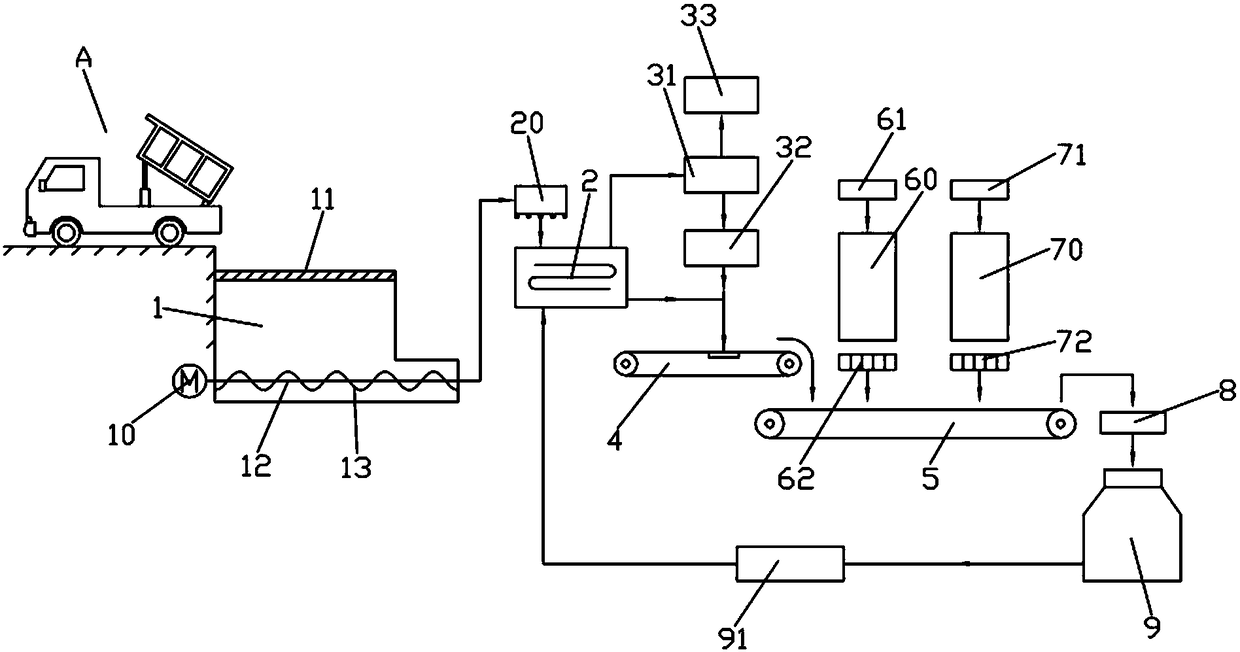

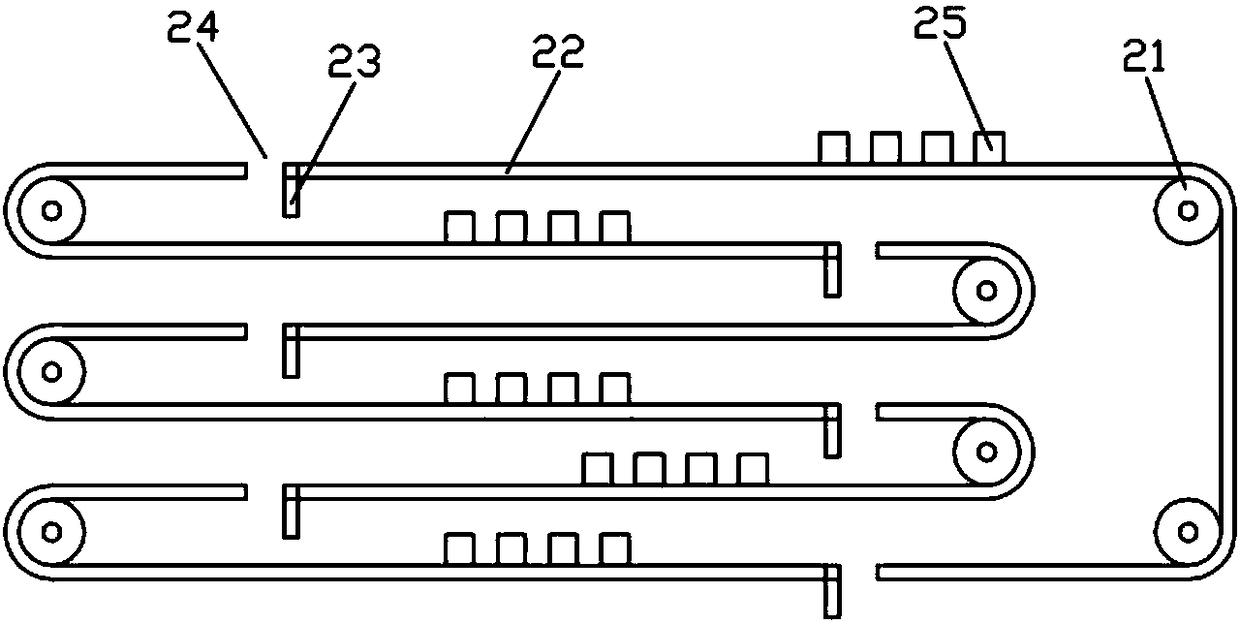

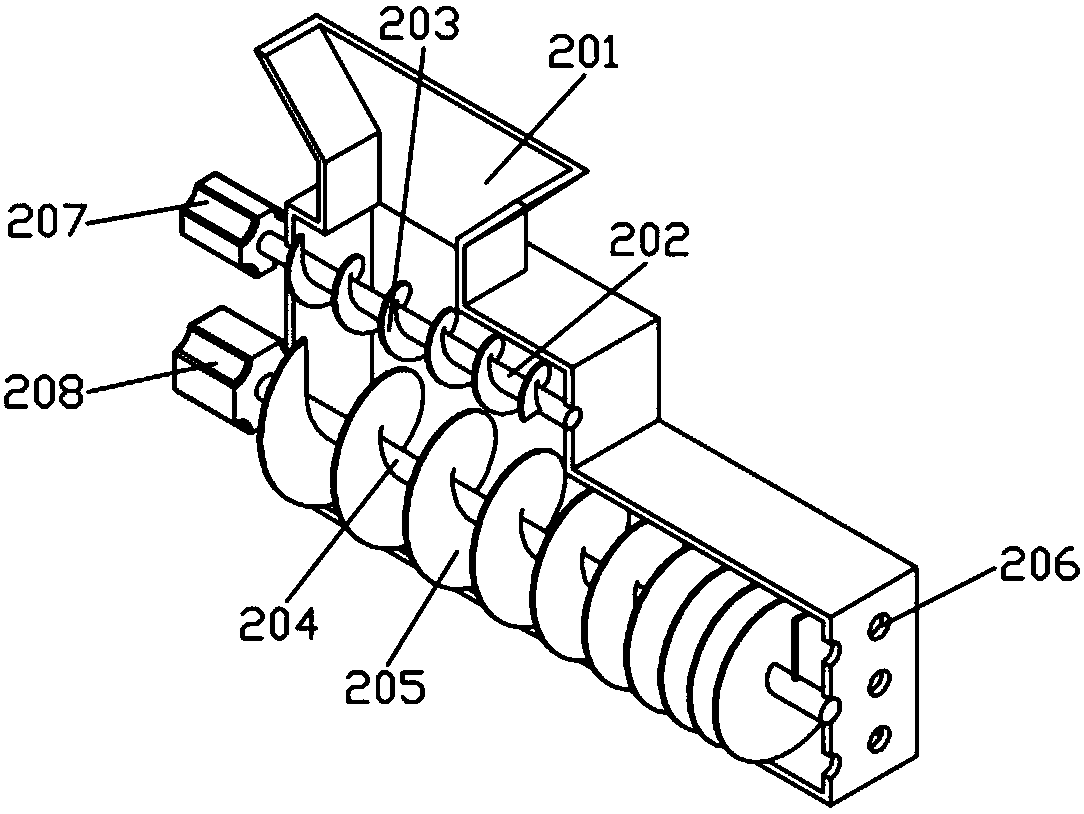

[0019] Such as figure 1 As shown, the system for making sludge into regenerative solid fuel includes a sludge storage unit 1, a drying unit 2, a weighing unit, a conveying unit 5, a granulation unit 8, and a combustion unit 9 arranged in sequence. The sludge storage unit 1 receives The sludge transported by the sludge transport vehicle A, and the sludge is transported to the extruding device 20, the sludge is extruded into granules by the extruding device 20, and put into the drying unit 2, and the drying unit 2 is equipped with multiple Layer chain plate conveyor, the sludge particles are dried and enter the weighing unit, the weighing unit is connected with the controller 40, the weighing unit sends the weighed sludge particles to the conveying unit 5, and the conveying unit 5 is arranged side by side The pulverized coal bin 60 and the rice straw bin 70, the conveying unit 5 simultaneously receives the coal powder and rice straw from the coal powder bin 60 and the rice straw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com