Alcohol base liquid fuel for alcohol base boilers and stoves and preparation method of fuel

A liquid fuel, alcohol-based technology, applied in the liquid carbon-containing fuel, fuel, petroleum industry and other directions, can solve the problem of odor, stove spit, combustion rate, pH value, low calorific value can not reach the ideal level, etc. problem, to achieve the effect of high burning value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation metering of the methanol is 45-60 tons.

[0043] In the slurrying step, hydrogen peroxide is added, and the mass-number ratio of the methanol-added hydrogen peroxide to methanol is 700-900 parts: 1.8-2.2 parts.

[0044] The additives include ferrocene, gentian violet, gasoline, and acetone, and the mass and fraction ratio of each component in the additive is ferrocene: gentian violet: gasoline: acetone=0.02-0.04 parts: 0.02-0.04 parts: 0.7-0.9 parts: 0.0018-0.0022 parts, the additive is dissolved in pure water to form a liquid additive, and the mass fraction ratio of the pure water to the additive is 180-220 parts: 0.7418-0.9822 parts.

[0045] In the stirring step, the stirring time is 100-150min.

[0046] In the standing step, the standing time is greater than 24h.

Embodiment 1

[0048] The mass fraction ratio of each component in the formula is methanol: pure water: ferrocene: gentian violet: hydrogen peroxide: gasoline: acetone = 700 parts: 180 parts: 0.02 parts: 0.02 parts: 1.8 parts: 0.7 parts: 0.0018 parts .

[0049] In the stirring step of the preparation, stir for 100 min.

[0050] In the static step of preparation, the static time is 24 hours.

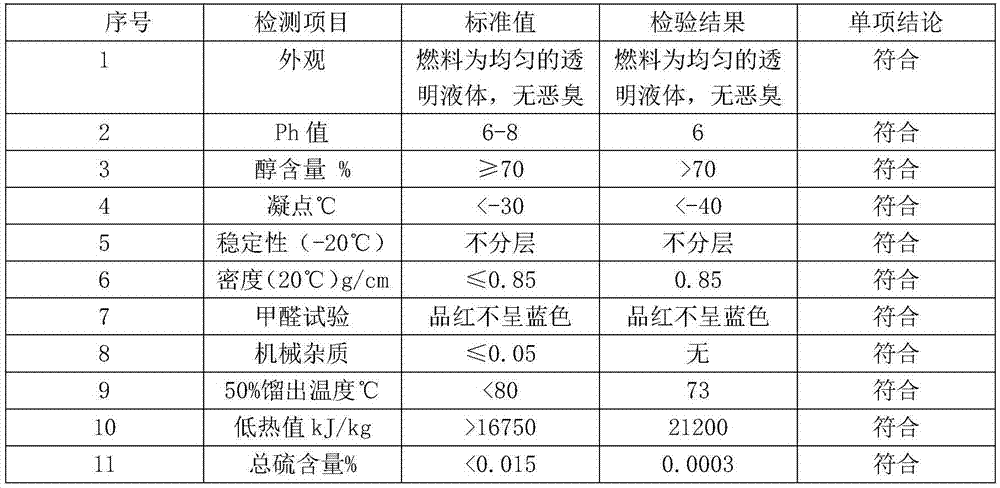

[0051] The product quality inspection parameters of the product are:

[0052]

Embodiment 2

[0054] The mass fraction ratio of each component in the formula is methanol: pure water: ferrocene: gentian violet: hydrogen peroxide: gasoline: acetone = 900 parts: 220 parts: 0.04 parts: 0.04 parts: 2.2 parts: 0.9 parts: 0.0022 parts .

[0055] In the stirring step of the preparation, stir for 130 min.

[0056] In the static step of preparation, the static time is 24 hours.

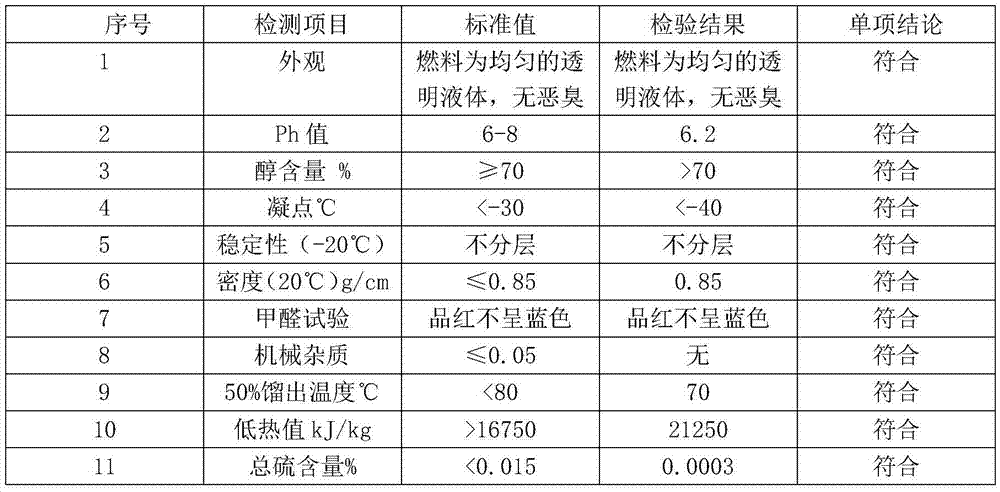

[0057] The product quality inspection parameters of the product are:

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com