Energy recycling control method for PTA device

An energy recovery and control method technology, applied in pump control, components of pumping devices for elastic fluids, non-variable-capacity pumps, etc., can solve problems such as poor energy recovery effect, loss of energy recovery, energy waste, etc. , to achieve the effect of saving steam consumption, saving energy and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

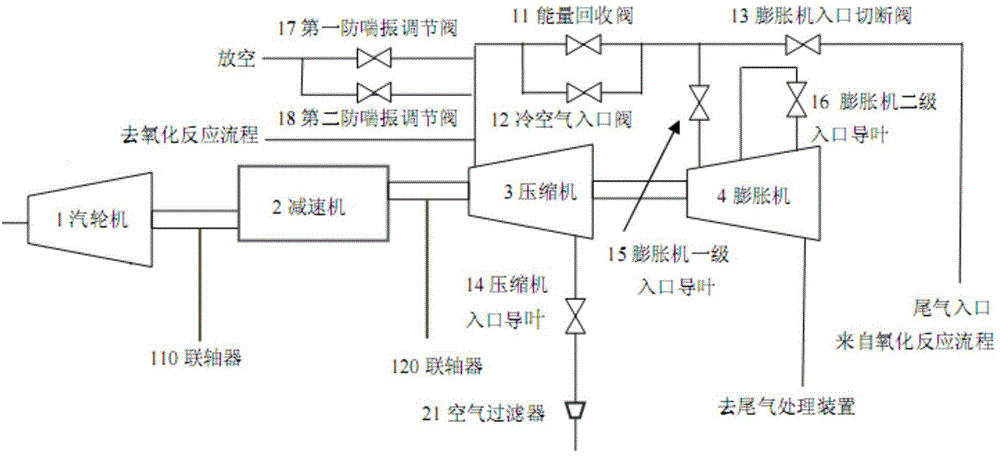

[0042] Such as figure 1 As shown, the present invention includes a steam turbine 1, a reducer 2, a compressor 3, an expander 4 and an auxiliary system to form a compressor unit; wherein, the steam turbine 1 is connected to the reducer 2 through a first coupling 110 to form a drive source unit; The reducer 2 forms a steam turbine-driven compressor unit through the second coupling 120 and the compressor 3; the compressor 3 forms an expander-driven compressor unit through the second coupling 120 and the expander 4; the steam turbine and the expander are formed through two If they are connected by a coupling, the two share the auxiliary system to complete the steam power balance of the device.

[0043] The auxiliary system includes an energy recovery valve 11, a cold air inlet valve 12, an expander inlet shut-off valve 13, a compressor inlet guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com