Environmental protection refrigerating hydrogen drying unit

A drying device and hydrogen technology, which is applied in refrigeration and liquefaction, hydrogen separation, steam condensation, etc., can solve the problems of not being able to achieve online drying, unstable operation performance, and high humidity of hydrogen in the machine, so as to prolong the contact time and increase the Heat transfer area, effect of reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

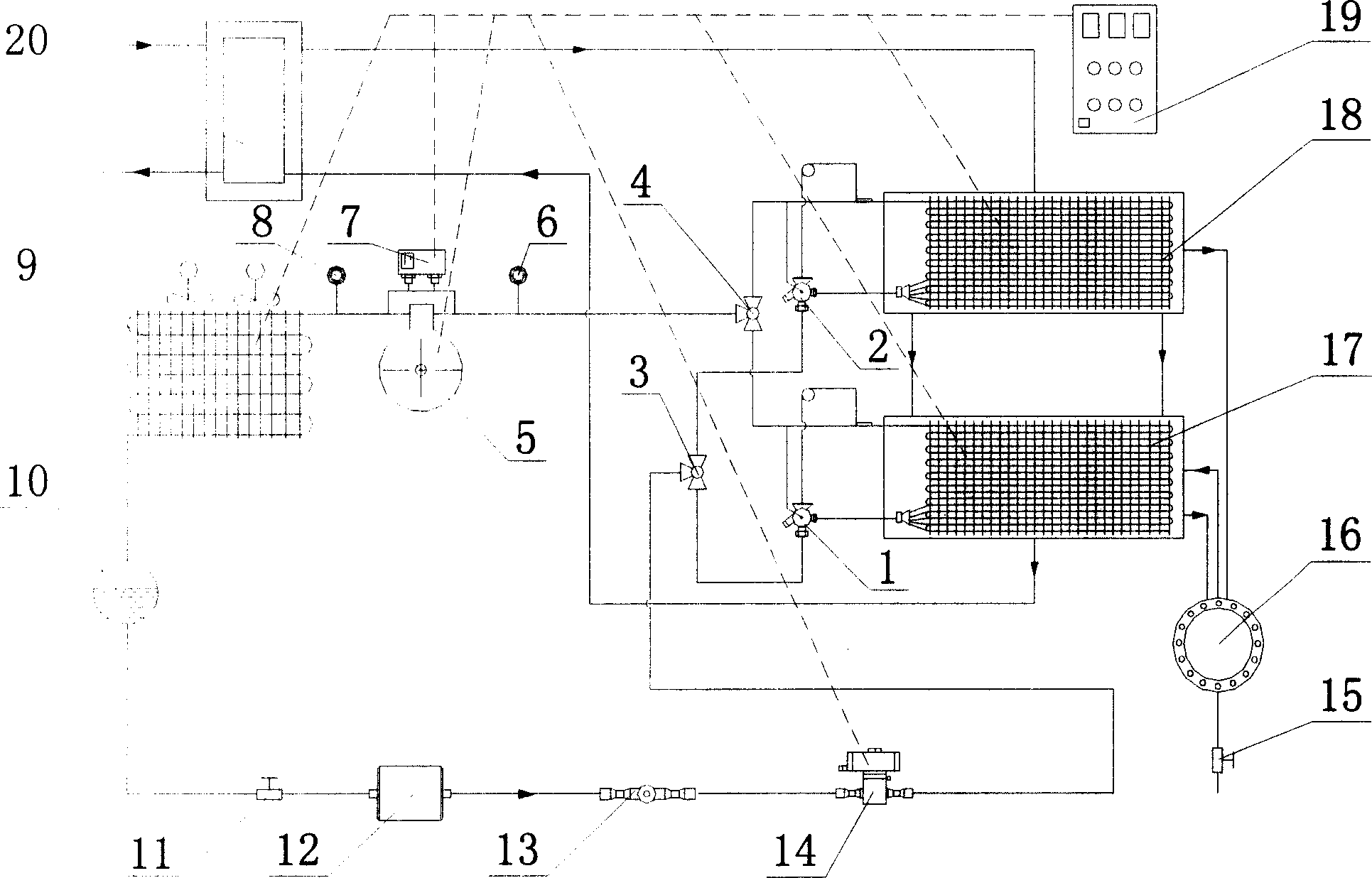

[0030] see figure 1 , the present invention comprises a cryogenic side thermal expansion valve (1), an initial cold side thermal expansion valve (2), a liquid supply three-way valve (3), a gas return three-way valve (4), a refrigeration compressor (5), a low pressure Gauge (6), pressure controller (7), high pressure gauge (8), air condenser (9), liquid storage tank (10), stop valve (11), dry filter (12), sight glass (13 ), solenoid valve (14), drain valve (15), water storage tank (16), cryogenic desiccant dryer (17), primary cooling desiccant dryer (18), electrical control cabinet (19), bypass flow Type heat exchanger (20). The bypass heat exchanger (20) is a component for heat exchange between the hot and humid hydrogen at the import and export and the cold and dry hydrogen. The cooling and dehumidifying drying of hydrogen takes place respectively in the primary cooling dehumidifying drier (18) and the deep cooling dehumidifying drier (17). The desiccant drier (18) and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com