Device for producing coarse titanium tetrachloride by low-temperature fluidizing chlorination

A crude titanium tetrachloride and boiling chlorination technology, applied in the direction of titanium halide, etc., can solve the problems of uneven residence time distribution, decreased driving force, high bed layer in the furnace, and reduce the static pressure and diffusion resistance in the furnace. Conducive to the effect of continuous operation, modification and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

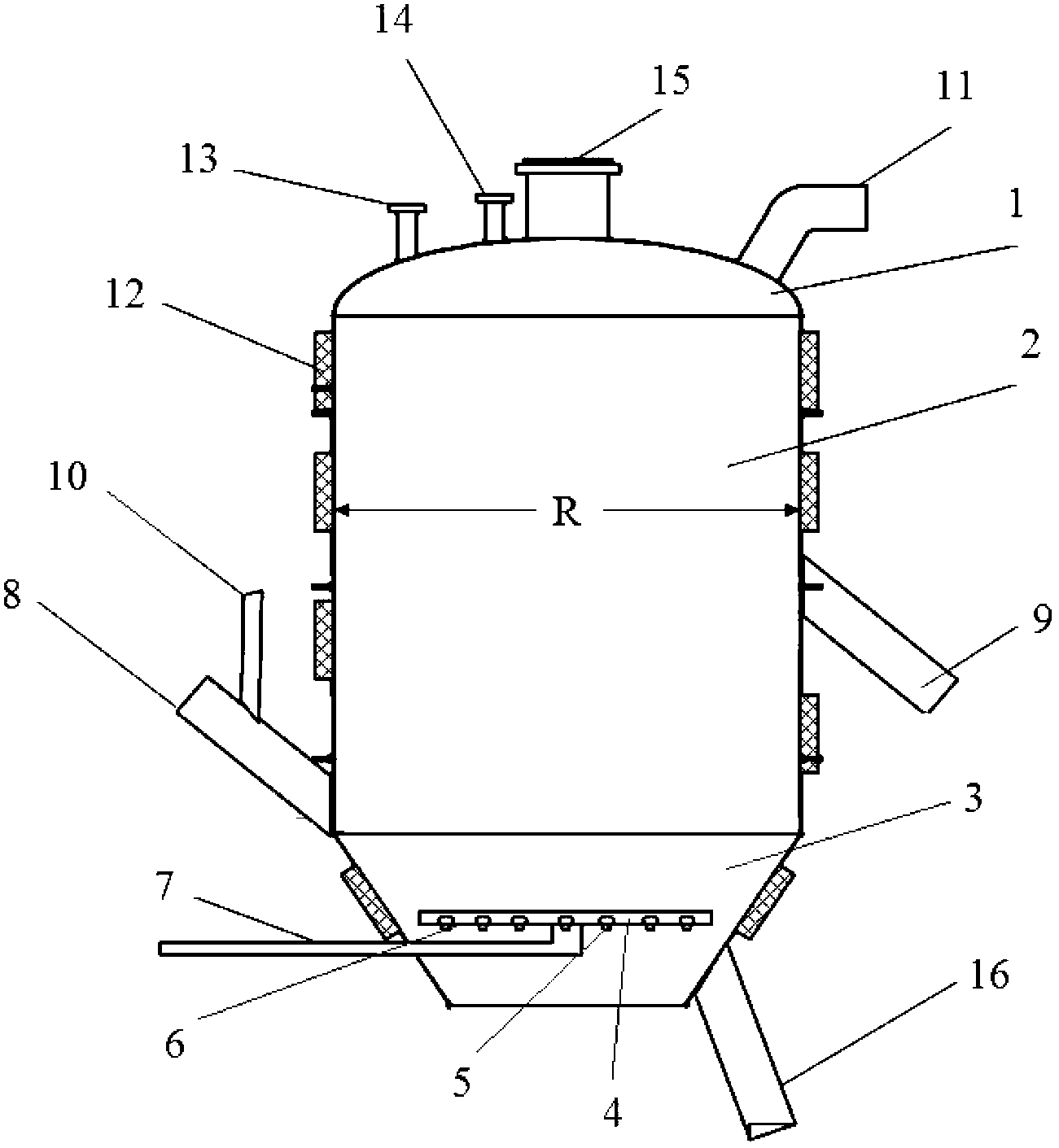

[0022] Hereinafter, exemplary embodiments of the present invention will be described in further detail with reference to the accompanying drawings.

[0023] figure 1 It is a schematic diagram of the main structure of the device for producing crude titanium tetrachloride by low-temperature boiling chlorination in an exemplary embodiment of the present invention. like figure 1 As shown, the device for producing crude titanium tetrachloride by low-temperature boiling chlorination in this embodiment includes a furnace top 1 , a furnace body 2 and a furnace bottom 3 .

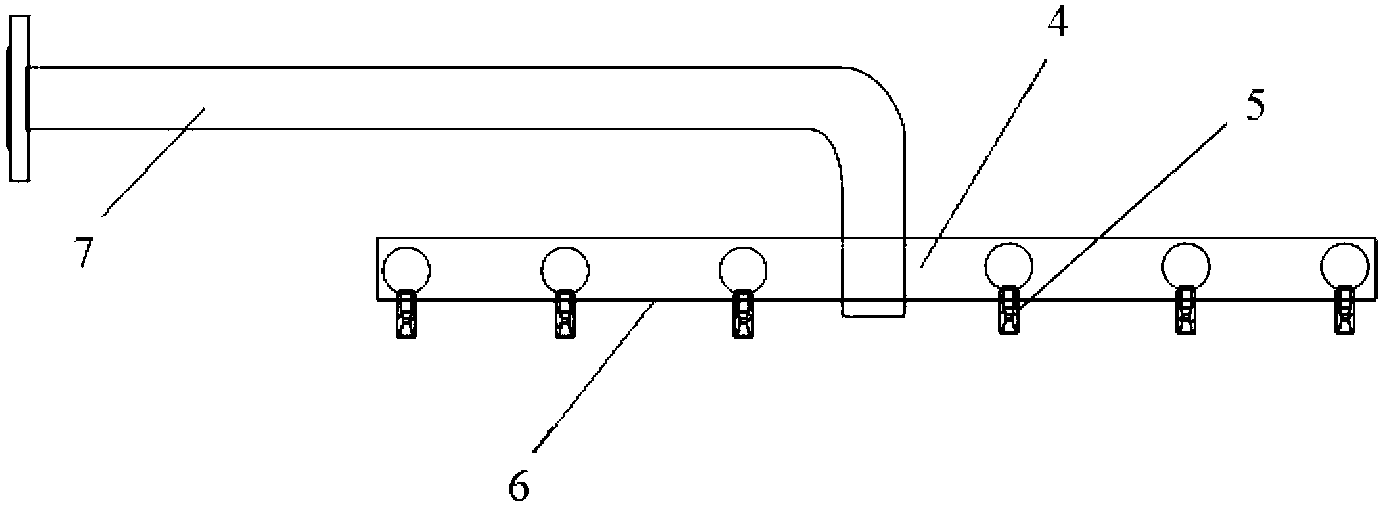

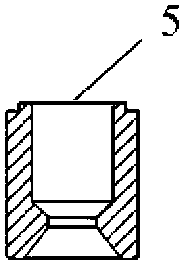

[0024] Wherein, the furnace bottom 3 is provided with a gas distributor 4, the gas distributor 4 communicates with the gas inlet pipe 7 and the gas distributor 7 includes a chassis 6 and a plurality of gas nozzles 5 evenly distributed on the chassis 6, the gas nozzles 5 with the air outlet facing upwards. The gas distributor 4 blows the reaction gas such as nitrogen or chlorine delivered by the gas inlet pipe 7 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com