Device and process for removing NOx by hyper-gravity with high efficiency

A technology of supergravity and removal, applied in the direction of separation method, dispersion particle separation, chemical instruments and methods, etc., can solve the problems of high energy consumption, low efficiency, unstable outlet concentration, etc., achieve continuous operation stability, simple process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

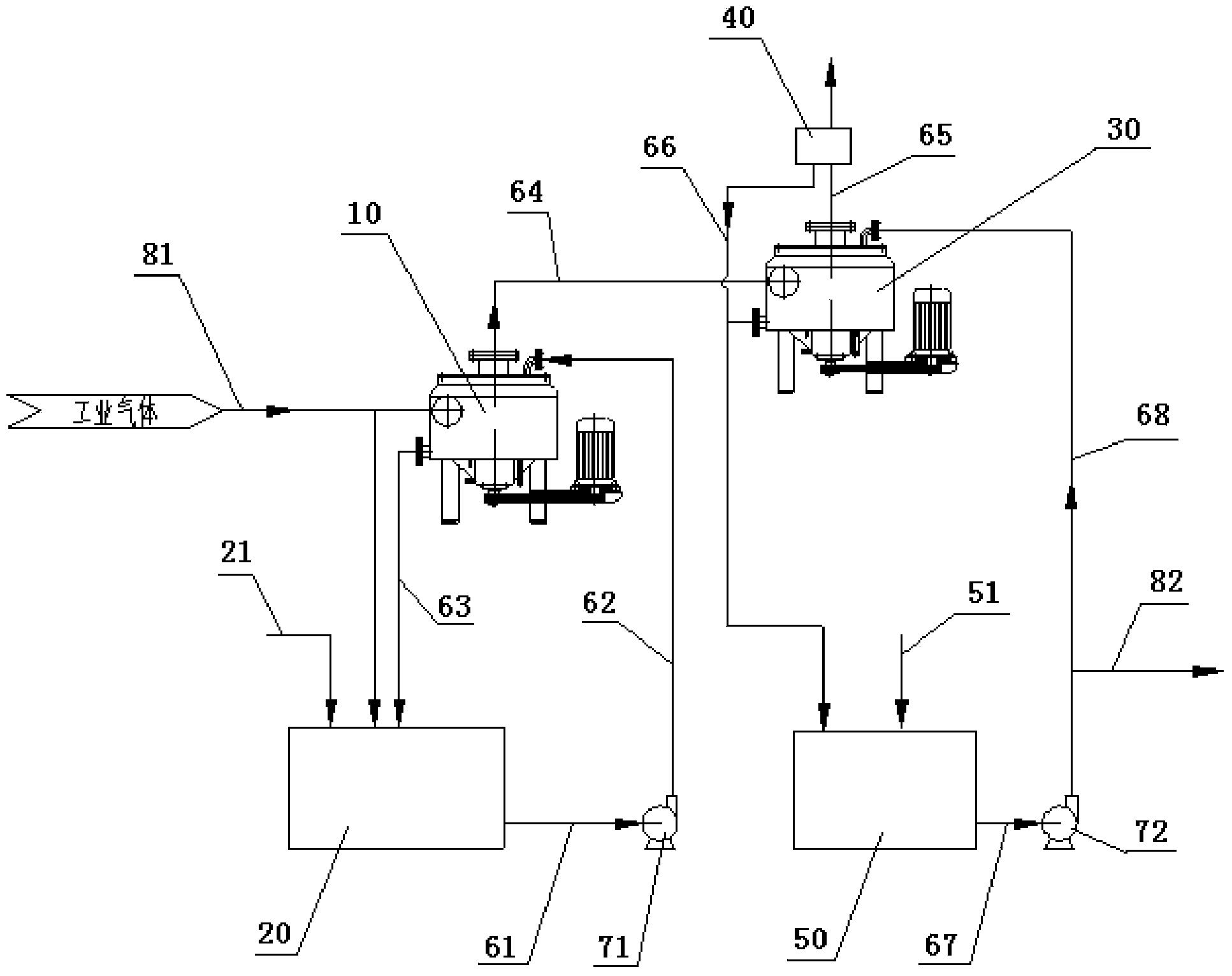

[0035] A high-efficiency removal of NO by supergravity x The device comprises high-gravity gas conditioner 10, nitric acid circulation tank 20, high-gravity lye absorber 30, mist eliminator 40 and lye tank 50;

[0036] The outlet of the nitric acid circulation tank 20 is connected to the first circulation pump 71 inlet by the first pipeline 61, and the outlet of the first circulation pump 71 is connected to the liquid inlet of the high gravity gas conditioner 10 by the second pipeline 62; The liquid outlet of the high-gravity gas conditioner 10 is connected to the nitric acid circulation tank 20 through the third pipeline 63; the gas inlet of the high-gravity gas conditioner 10 is externally connected to transport nitric acid gas or NO x industrial tail gas pipeline 81;

[0037] The gas outlet of the high-gravity gas conditioner 10 is connected to the gas inlet of the high-gravity lye absorber 30 through the fourth pipeline 64, and the gas outlet of the high-gravity lye absor...

Embodiment 2

[0058] A kind of utilizing above-mentioned device to remove NO x process, the parameter conditions are as follows:

[0059] Exhaust gas volume 30000Nm 3 / h, NOx content 3000ppm, normal temperature, pressure 0.126MPa, (of which NO accounts for 70%, NO 2 accounted for 30%), super gravity level 100g, sodium carbonate content 15% (w / w), nitric acid circulation volume 30m 3 / h, alkali suction circulation is 40m 3 / h. NO after conditioning 2 / NO is 1.1:1, after the tail gas is absorbed by lye, NO x The content is less than 200ppm.

Embodiment 3

[0061] A kind of technology that utilizes above-mentioned device to remove NOx, parameter condition is as follows:

[0062] Exhaust gas volume 10000Nm 3 / h, the temperature is normal temperature, the pressure is 0.12Mpa, and the supergravity NOx content is 2000ppm (of which the NO content is 60%, the NO 2 content 40%), supergravity level 200g, sodium carbonate content 15% (w / w), nitric acid circulation volume 10m 3 / h, alkali suction circulation is 20m 3 / h,. NO after conditioning 2 / NO is 1.3:1, and the NOx content of tail gas is less than 100ppm after being absorbed by lye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com