Machine integrating tea weighing with film inner bag making and loading

An all-in-one machine and automatic weighing device technology, applied in the field of material equipment, can solve the problems of low production efficiency and achieve the effects of improving production efficiency, high degree of automation, and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

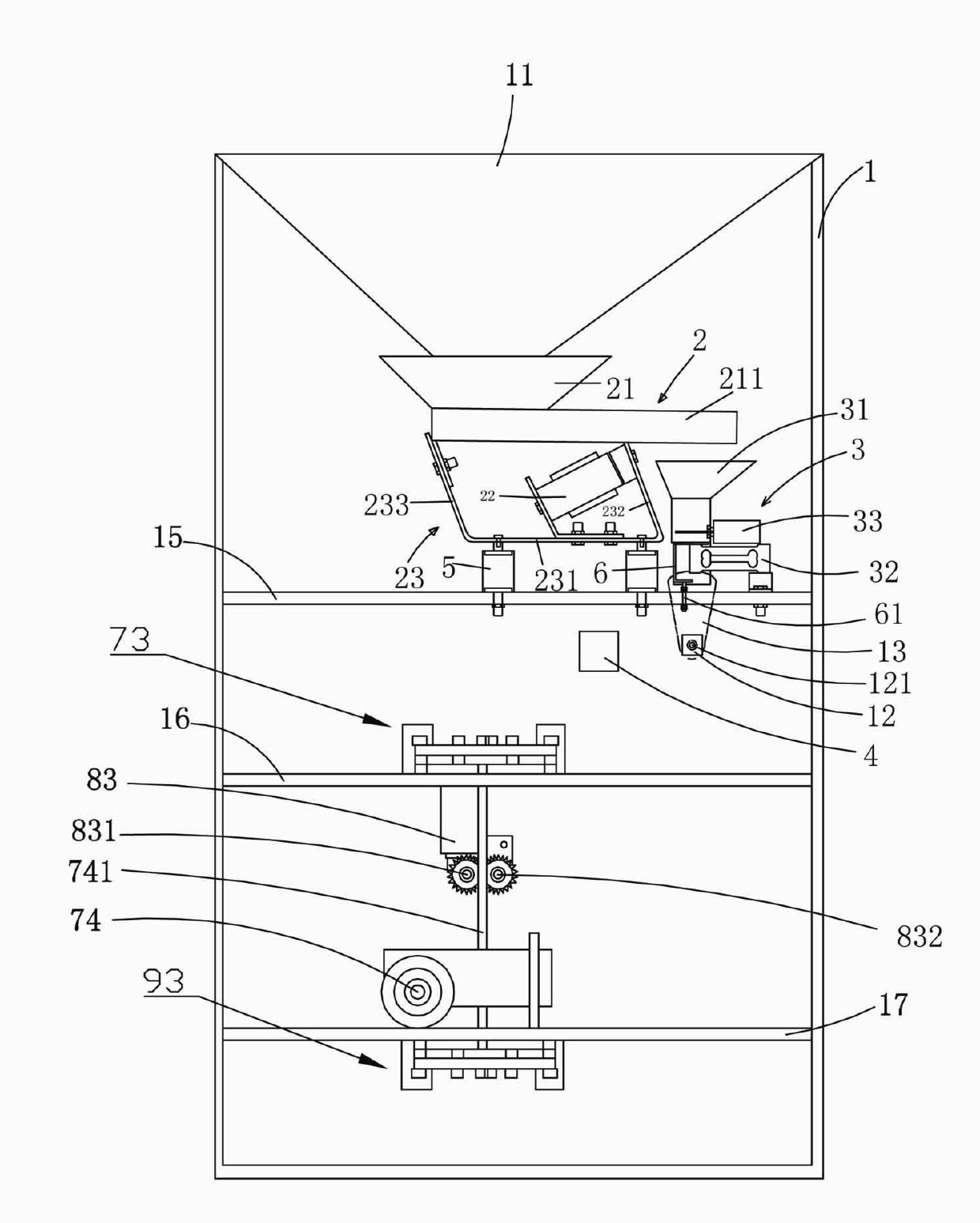

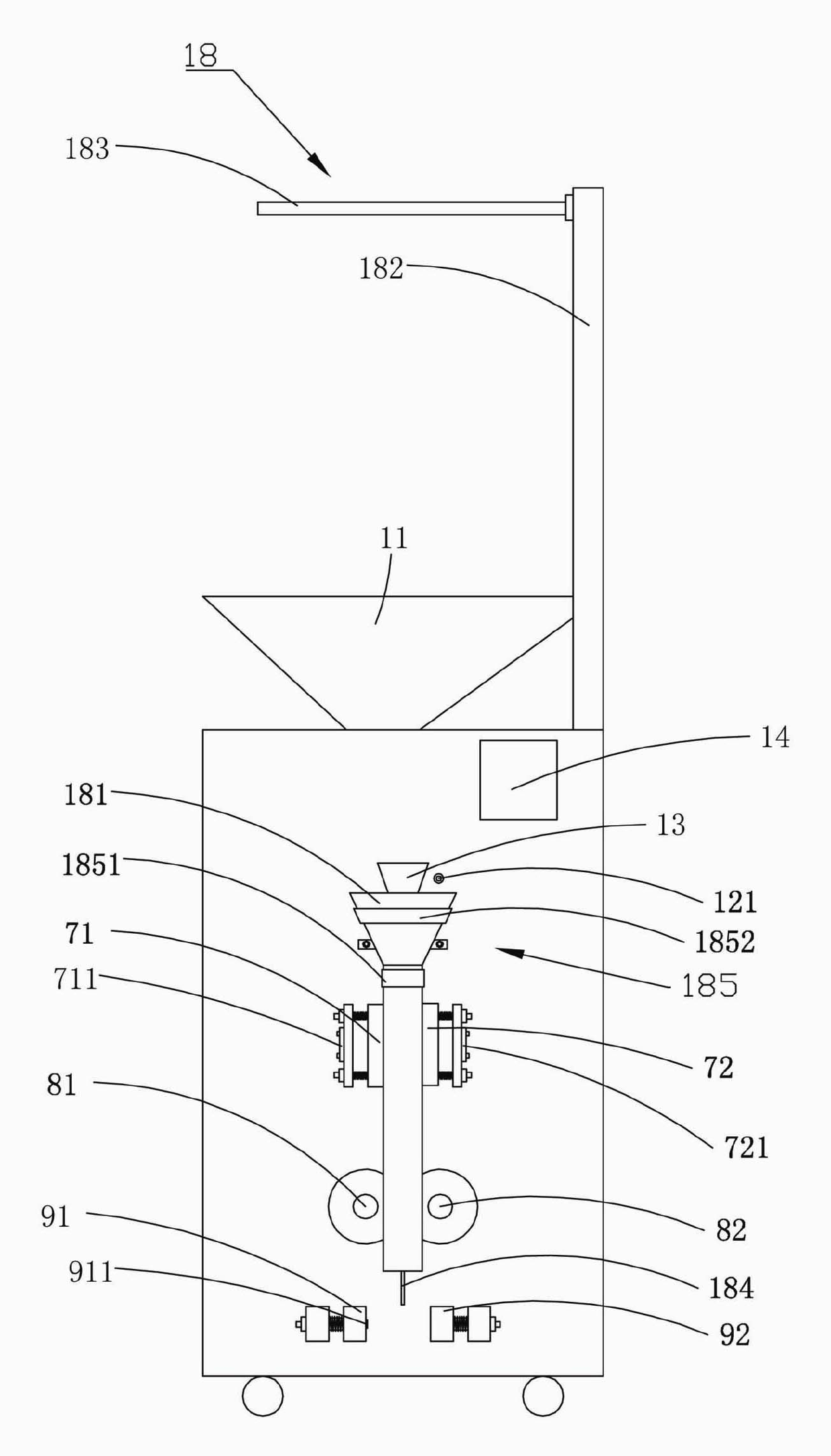

[0018] like figure 1 , figure 2 As shown, an integrated machine for tea weighing and film inner bag making and bag filling includes a casing 1, a reel device 18 fixed on the casing for installing a film reel for making an inner bag, and a reel device 18 arranged on the machine casing. The shell 1 has a top-to-top tea precision automatic weighing device and a film inner bag-making and bag-filling device.

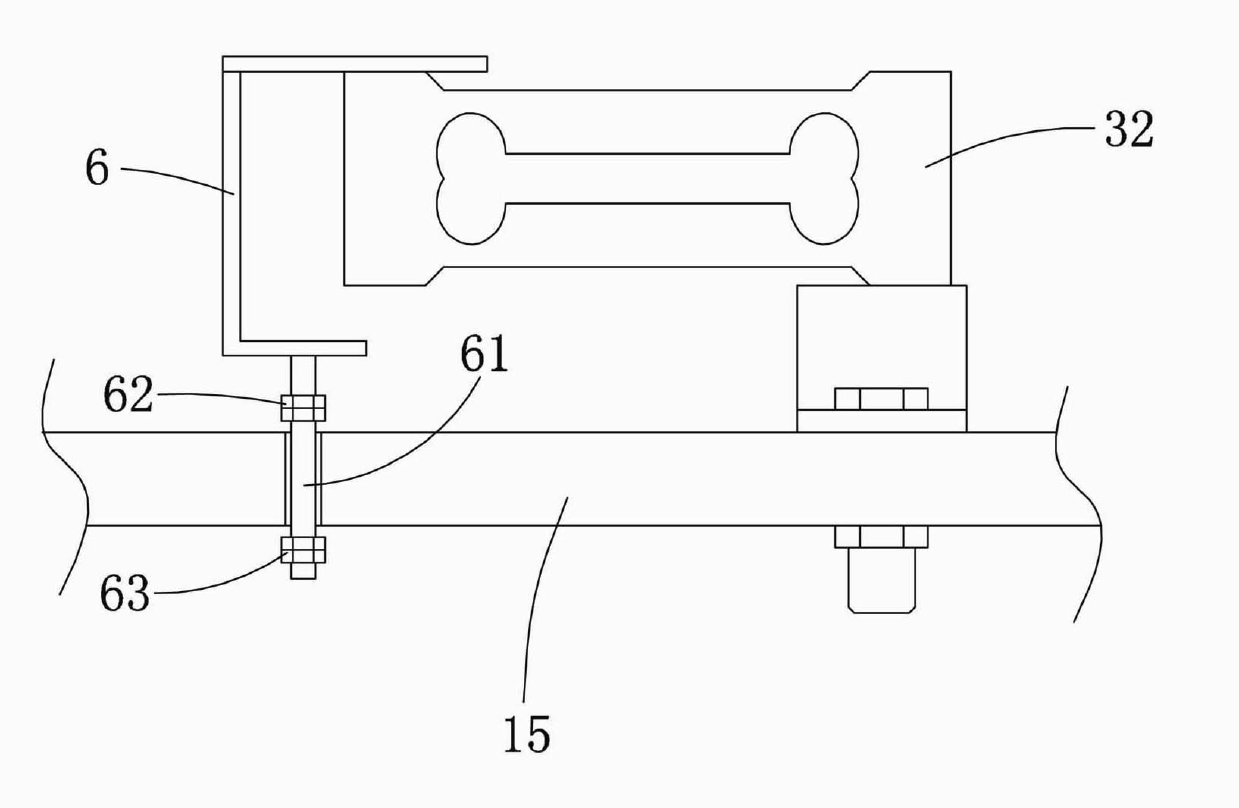

[0019] refer to figure 1 , figure 2 , the tea precision automatic weighing device includes a feeding storage mechanism 11 arranged on the casing 1, an infrared sensor 12, a discharge cylinder 13, a control panel 14 and a vibrating feeding mechanism 2 installed inside the casing 1, Measuring mechanism 3, controller 4. The feeding and storage mechanism 11 is a vertically penetrating feeding cylinder arranged on one side of the top surface of the casing 1; The discharge port of bucket 31 is connected. The infrared sensor 12 is fixed in the casing 1, and its infrared sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com