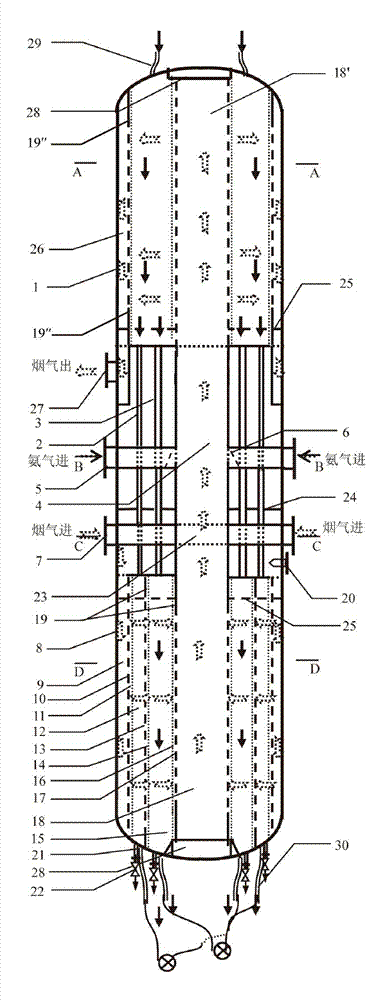

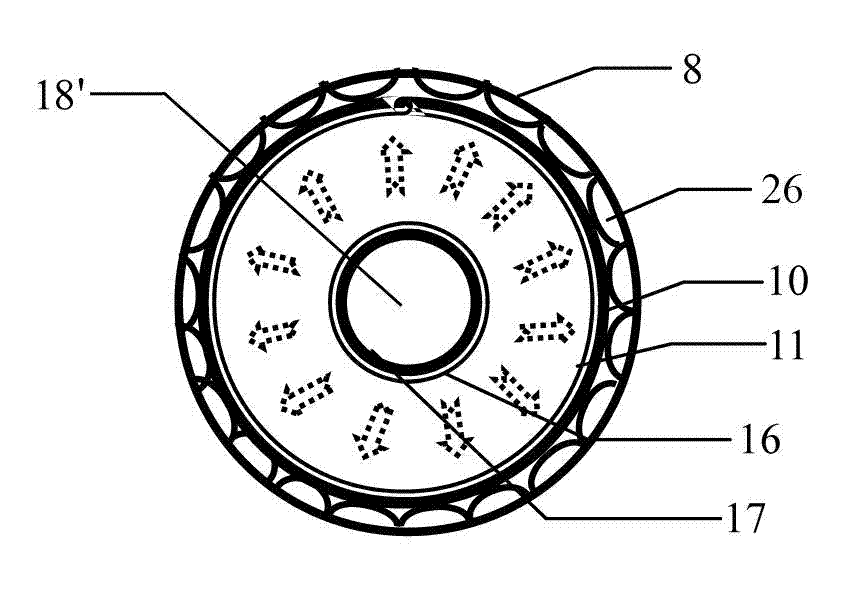

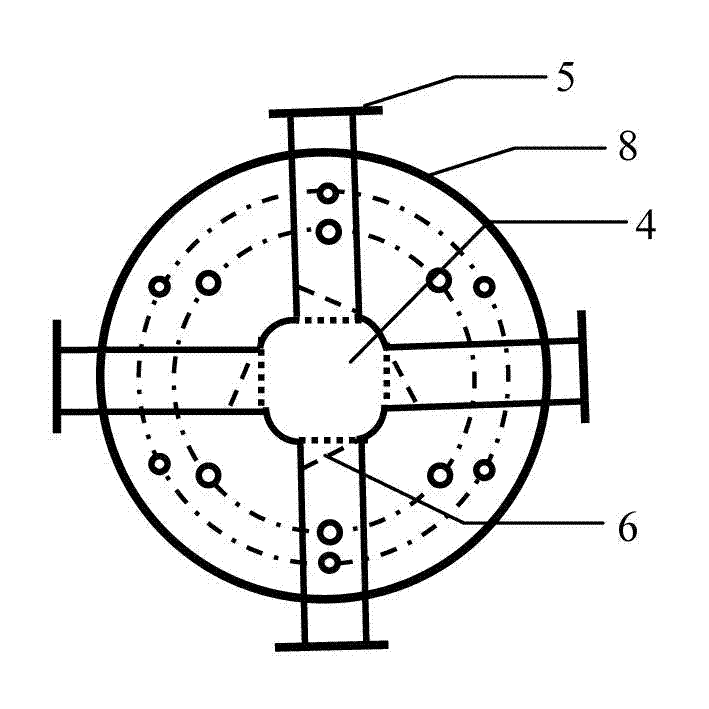

Axial and radial cross flow moving bed reactor and activated coke flue gas desulfurization and denitration technology thereof

A technology for desulfurization, denitrification, and activated coke, which is applied in air quality improvement, chemical instruments and methods, and dispersed particle separation, etc. It can solve the problems of inefficient and reasonable activated coke stratification, low combined performance of upper and lower sections, and insufficient gas-solid contact. , to achieve the effect of saving equipment investment and operating costs, sufficient gas-solid contact, and continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The flue gas purification and sulfur recovery system designed in this example can be used for the desulfurization and denitration flue gas of a single-unit 1000MW ultra-supercritical coal-fired thermal power unit in a coal-fired power plant, a 600-square-meter large smelting and sintering machine, a large coal-fired boiler or other non-ferrous metallurgical tail gas Purify the field. Designed to handle flue gas volume 3.0×10 6 m 3 / h, depending on the situation, use a single adsorption reactor or multiple adsorption reactors in parallel for processing, and the designed flue gas space velocity is 300~500h -1 . SO in flue gas components 2 The volume fraction is 1000~4000×10 -6 , NO x The volume fraction is 200~800×10 -6 , Also contains some toxic heavy metal ions mercury, cadmium, etc., harmful smoke and dust. The adsorption temperature is 80-130°C; the adsorption catalyst used is a columnar desulfurization and denitration activated coke with qualified performance and econ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com