A wet-type integrated desulfurization, denitrification, mercury removal tower and process for PM2.5 removal

A desulfurization, denitrification, mercury removal, and removal tower technology, which is applied in the field of wet integrated desulfurization, denitrification, mercury removal, and PM2.5 removal towers and processes, to achieve the effects of improving efficiency, saving floor space, and ultra-low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

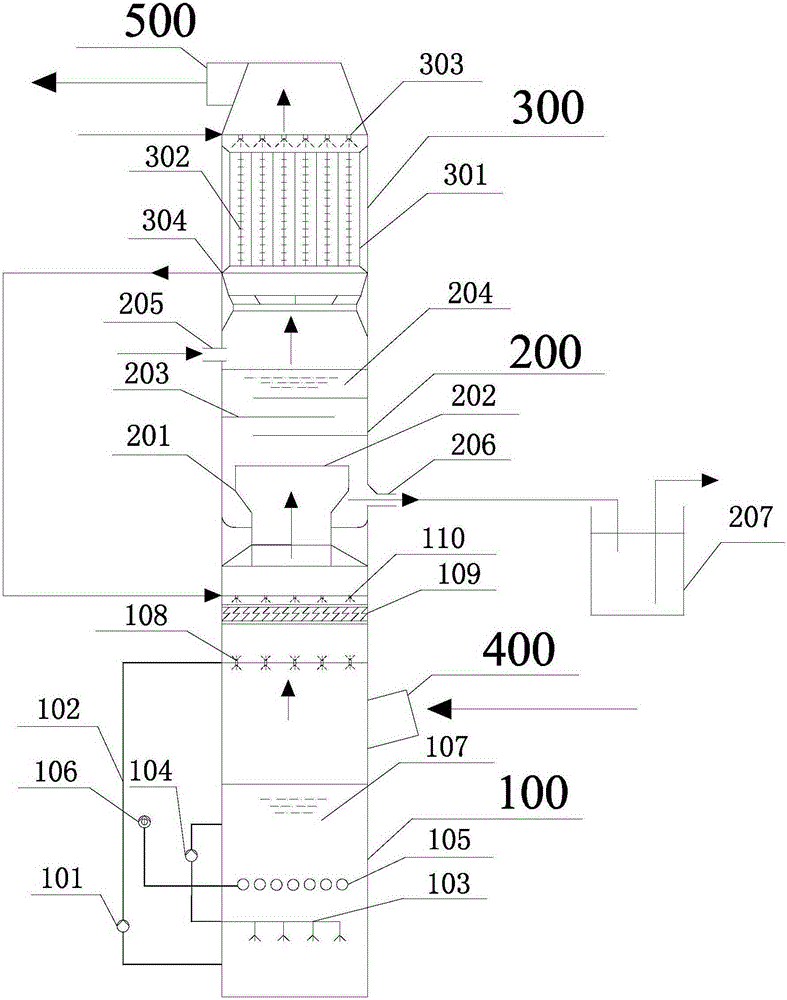

[0045] figure 1 It is a structural schematic diagram of a wet-type integrated desulfurization, denitrification, demercuration, and PM2.5 removal tower of the present invention. Such as figure 1 As shown, a wet-type integrated desulfurization, denitrification, mercury, and PM2.5 removal tower proposed in this embodiment is provided with a wet desulfurization section 100 and an oxidation, denitrification, and mercury removal section 200 from bottom to top in the removal tower. and the wet electrostatic precipitator section 300 , the flue gas inlet 400 is arranged on the wet desulfurization section 100 , and the clean flue gas outlet 500 is arranged on the wet electrostatic precipitator section 300 .

[0046] Specifically, the wet desulfurization section 100 includes a tower bottom slurry pool 107 and a desulfurizer slurry spray layer 108, the desulfurizer slurry spray layer 108 is arranged above the tower bottom slurry pool 107, and the flue gas inlet 400 channel is set in the ...

Embodiment 2

[0063] This example proposes a wet-type integrated desulfurization, denitrification, mercury removal, and PM2.5 removal process. The wet-type integrated desulfurization, denitrification, mercury, and PM2.5 removal tower described in Example 1 is used for flue gas purification treatment. As shown in the figure, the following steps are included:

[0064] Step S101, wet desulfurization stage: introduce the flue gas to be treated into the wet desulfurization section 100 through the flue gas inlet 400, start the desulfurizer slurry spray layer 108 to spray the flue gas to be treated, and complete the wet desulfurization process. Desulfurization.

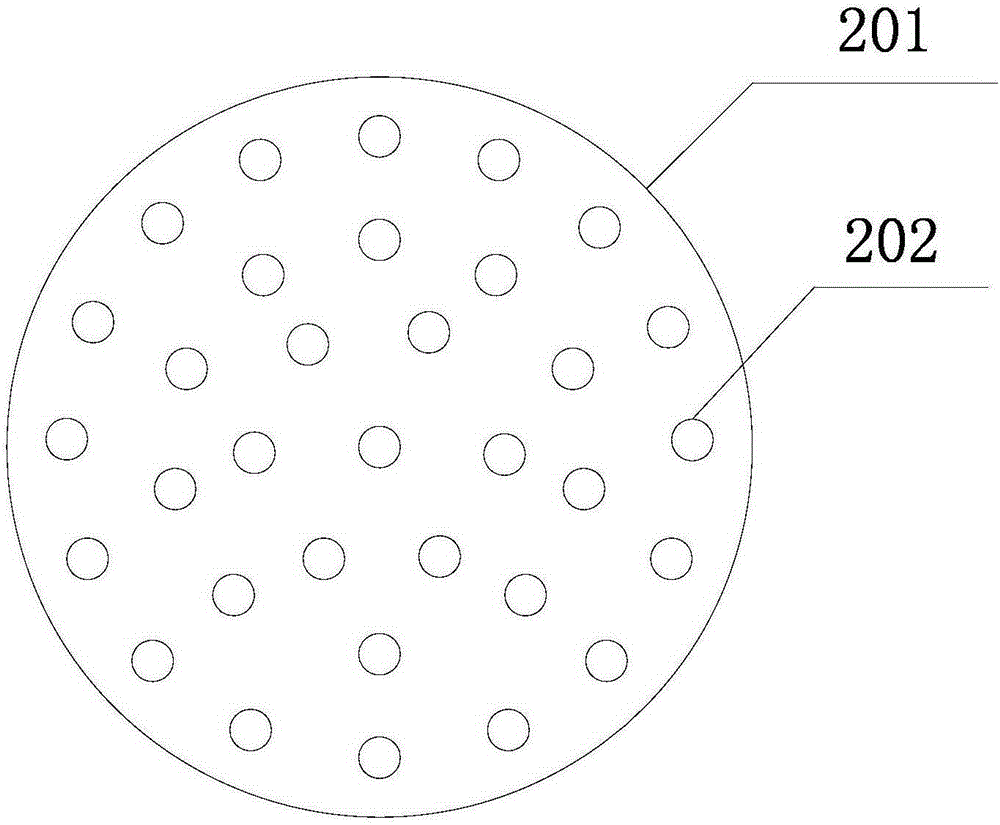

[0065] Step S102, denitrification and demercury stage: the flue gas to be treated after desulfurization enters the oxidative denitrification and demercuration section 200, passes through the flue gas uniform distribution device 201 and the flue gas distribution plate 203, and The oxidant solution 204 fully contacts and reacts to oxidize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com