Wet electric dust remover

A wet electrostatic precipitator and electrode plate technology is applied in the field of flue gas dust removal to achieve the effects of increasing the degree of turbulence, uniform current density and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

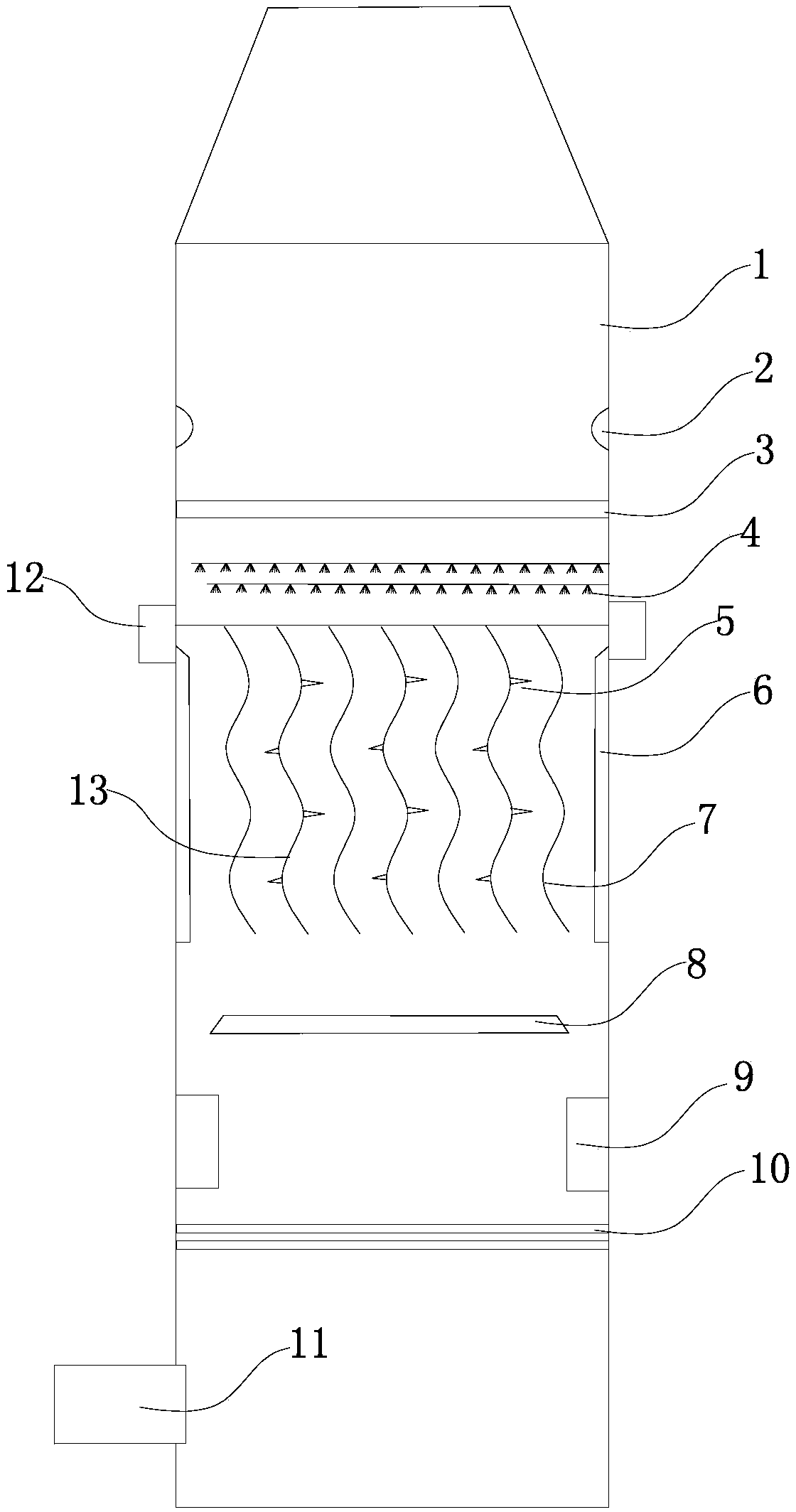

[0016] like figure 1 As shown, the wet electrostatic precipitator of the present invention includes a tower body 1 and a pole plate area in the tower body 1. An insulator chamber 12 is arranged above the pole plate area to fix the broken end of the cathode wire suspension frame. A smoke uniform distribution plate 3 is arranged at the entrance of the smoke gas, and a plurality of through holes are arranged on the smoke gas uniform distribution plate 3. It is installed on the inner wall of the tower, which includes a pair of sub-ring plates that support each other, which can be welded on the inner wall of the tower to concentrate the airflow to the middle, increase the turbulence of the flue gas, optimize the flow field, promote local micro-mixing, and promote the flow of smoke. The fine particles carried by the air collide and condense to impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com