Multi-layer screen mesh structure

A technology of sieve mesh and sieve hole, applied in the direction of sieve, solid separation, grid, etc., can solve the problem that the effect needs to be improved, and achieve the effect of improving the sieving effect, increasing the degree of disorder, and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

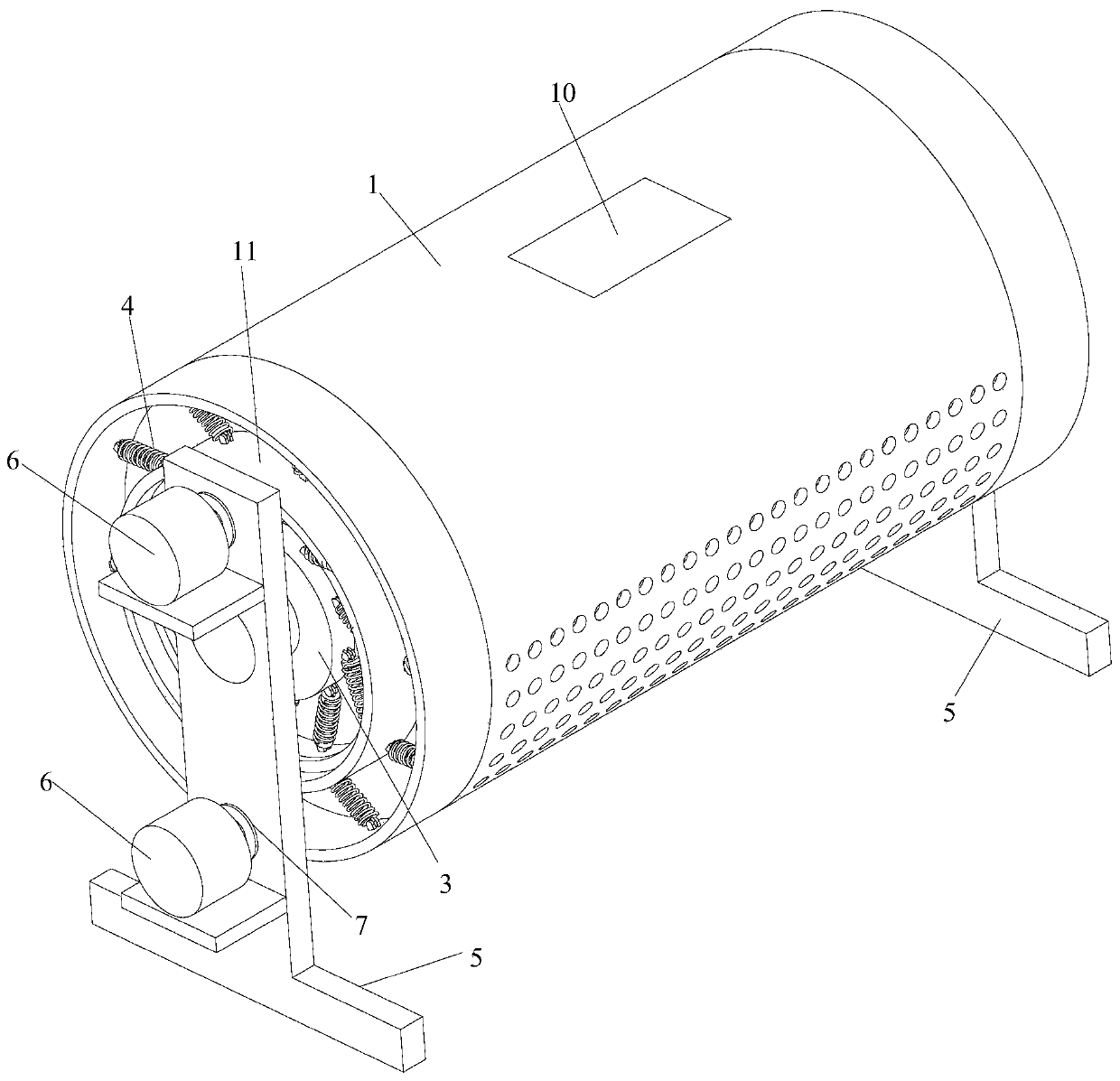

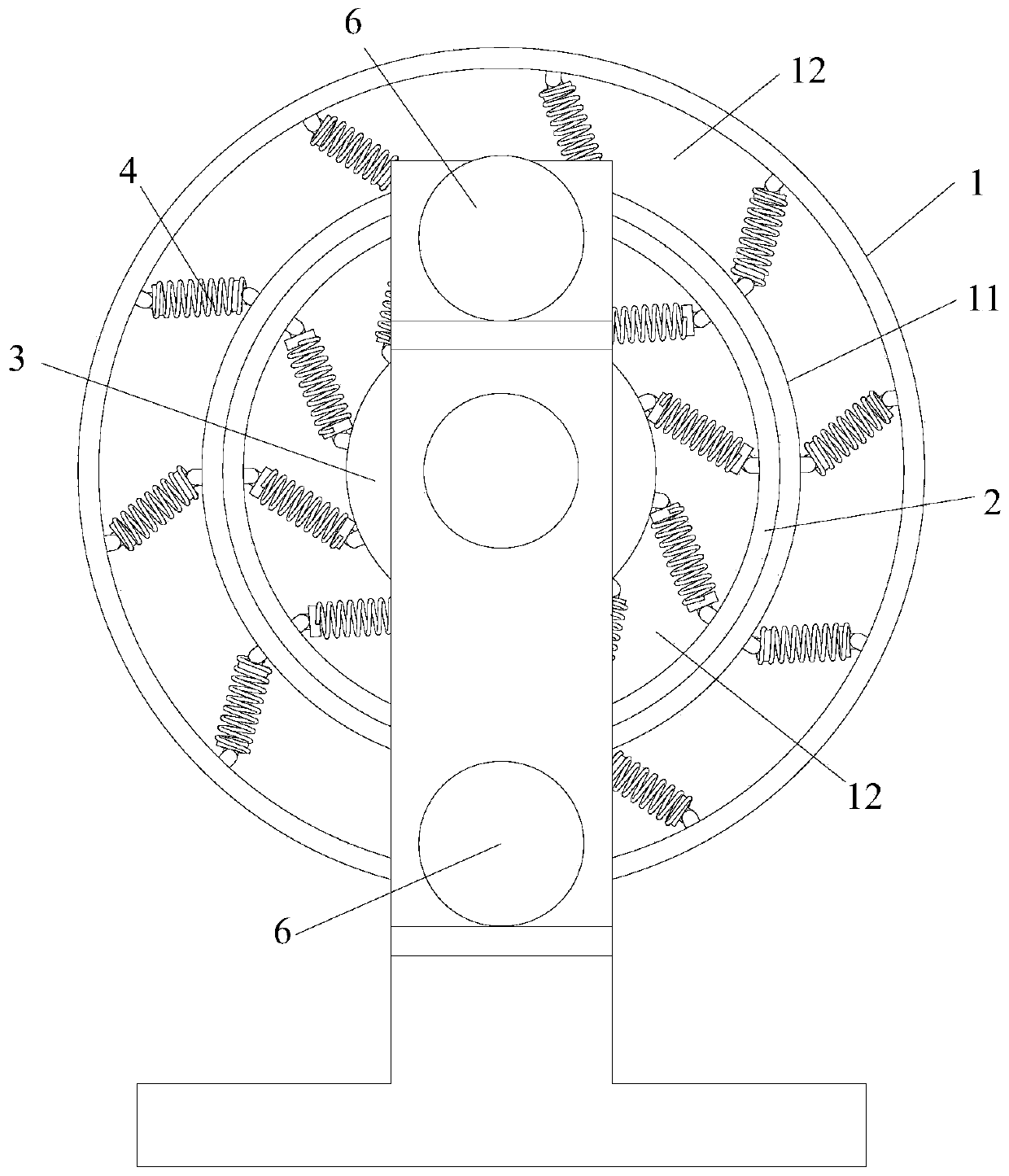

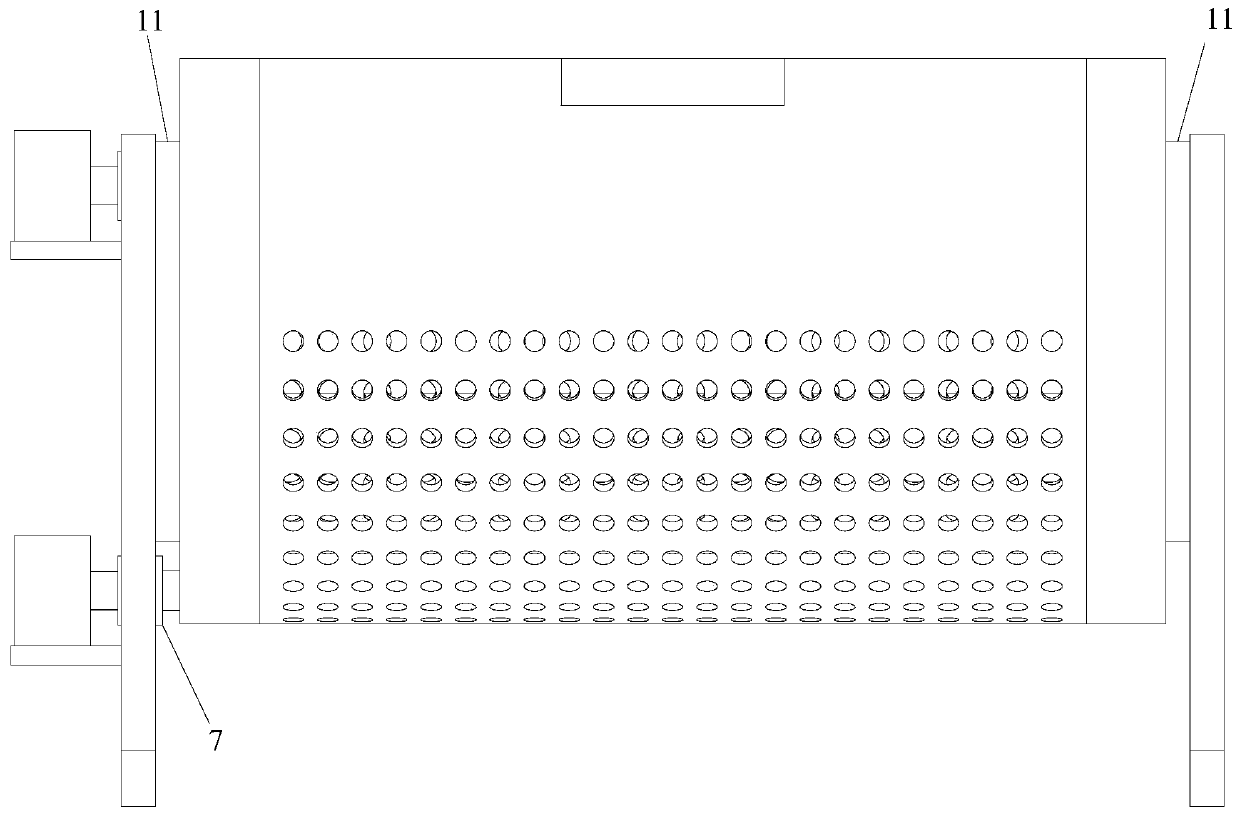

[0037] Such as figure 1 As shown, the present invention provides a multi-layer screen structure, including several nested screens, the number of screens is greater than or equal to 2, and the sieve apertures of these screens decrease successively from the inside to the outside, these The screens are all cylindrical and coaxial, and these screens can rotate freely, that is, each screen is a free end;

[0038] The innermost sieve is set on the support 5 through a main shaft 3, and the sieve can rotate in the circumferential direction relative to the main shaft 3; there are two support 5, located at both ends of the sieve respectively.

[0039] The rotation of each screen is reciprocating, and the rotation angles in both directions (because the screen rotates in the circumferential direction, so the two directions are forward rotation and reverse rotation) are all acute angles, that is, the screen is in reciprocating motion. The angle of one-way swing is an acute angle; the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com