Patents

Literature

77results about How to "Increase screening speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

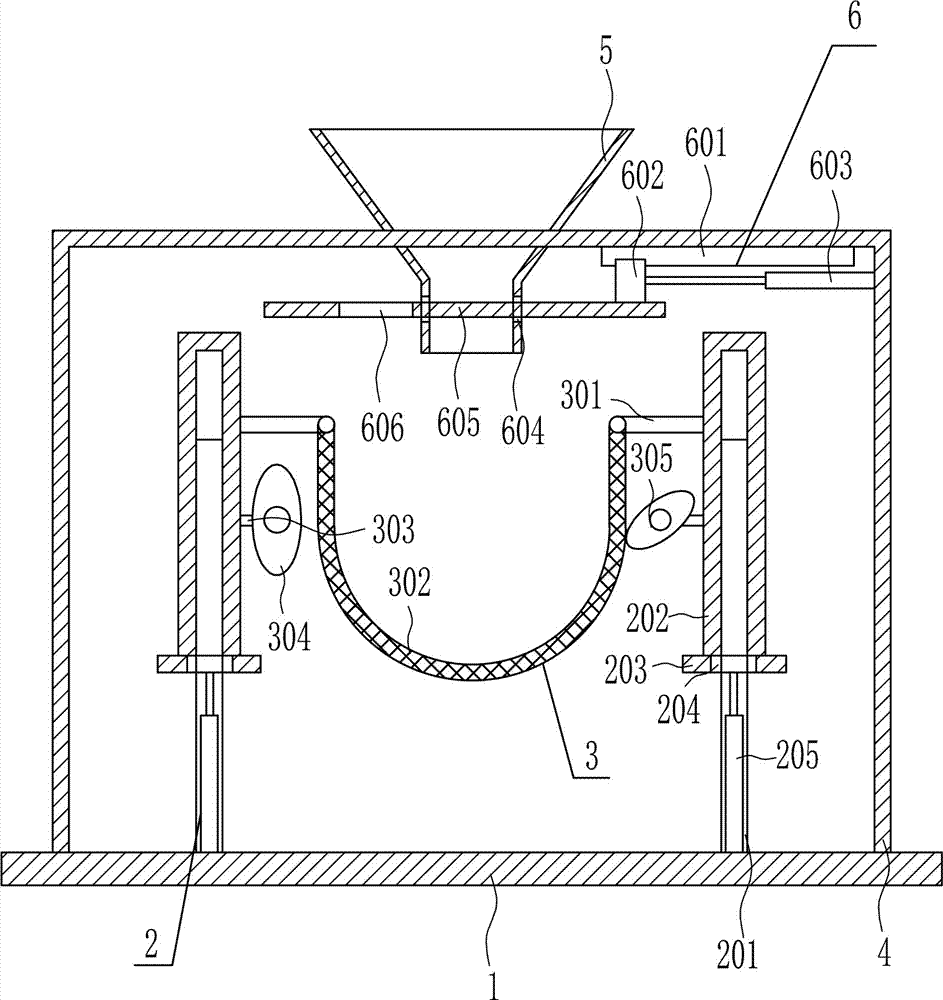

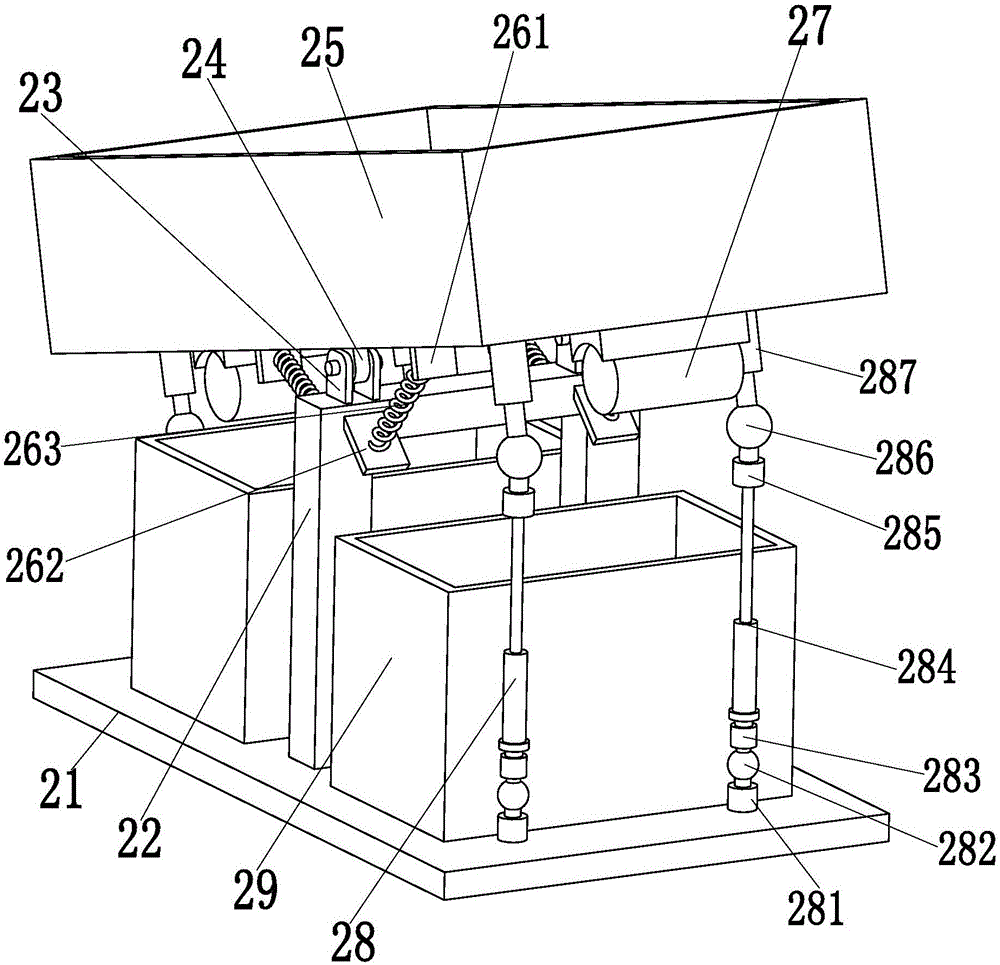

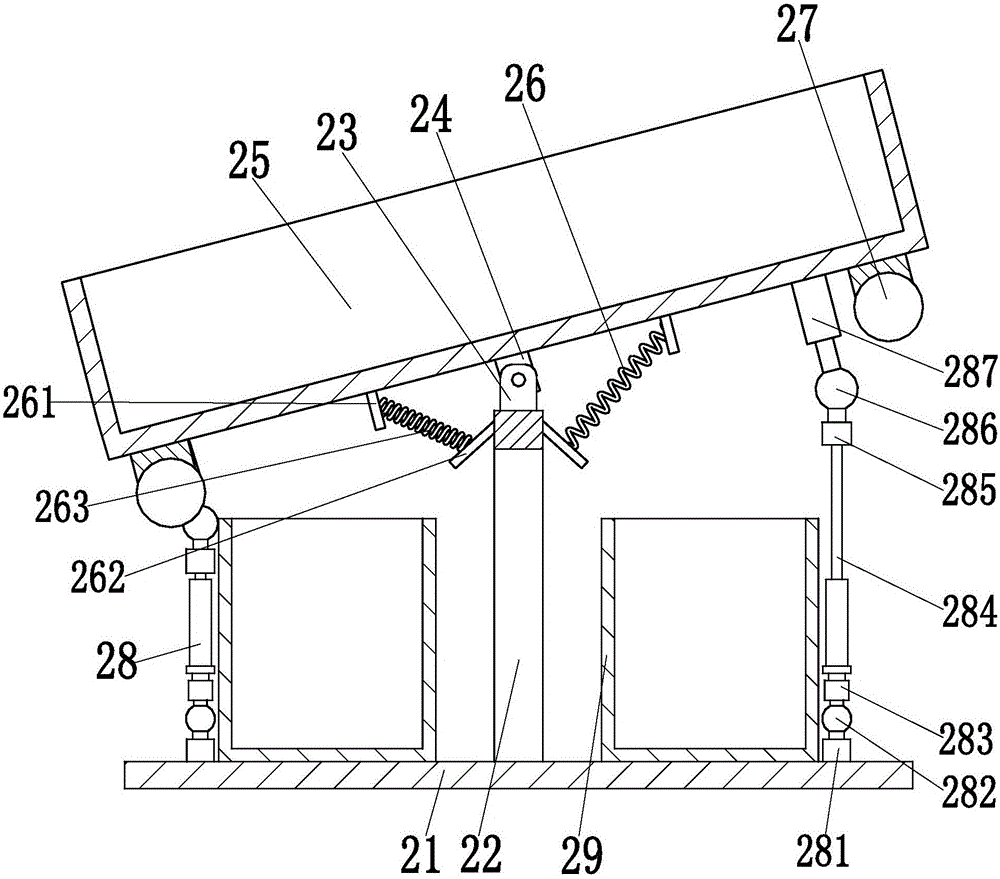

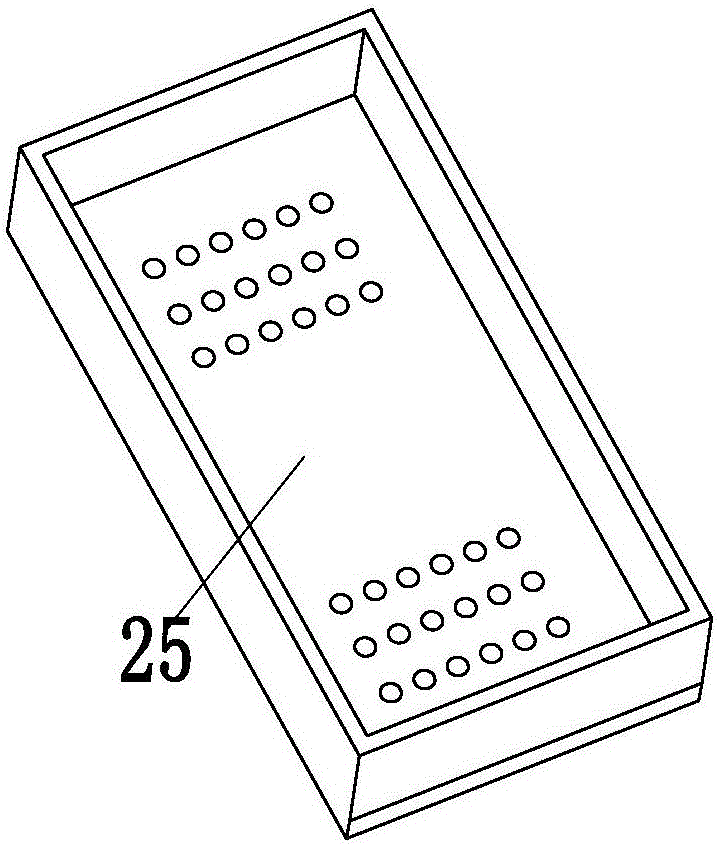

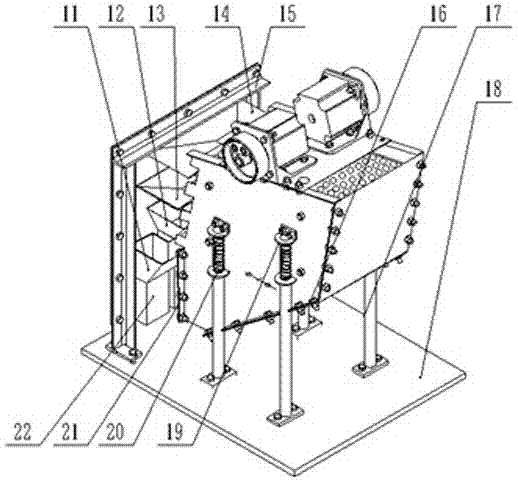

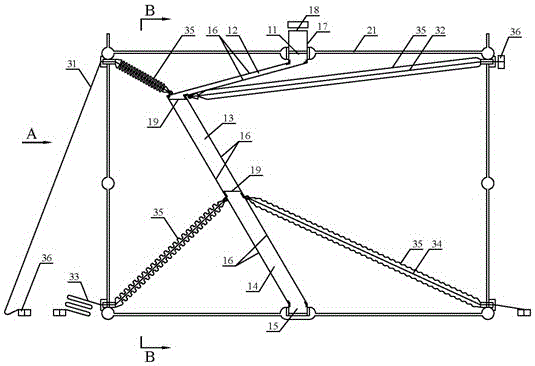

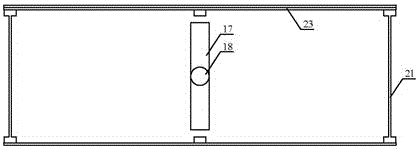

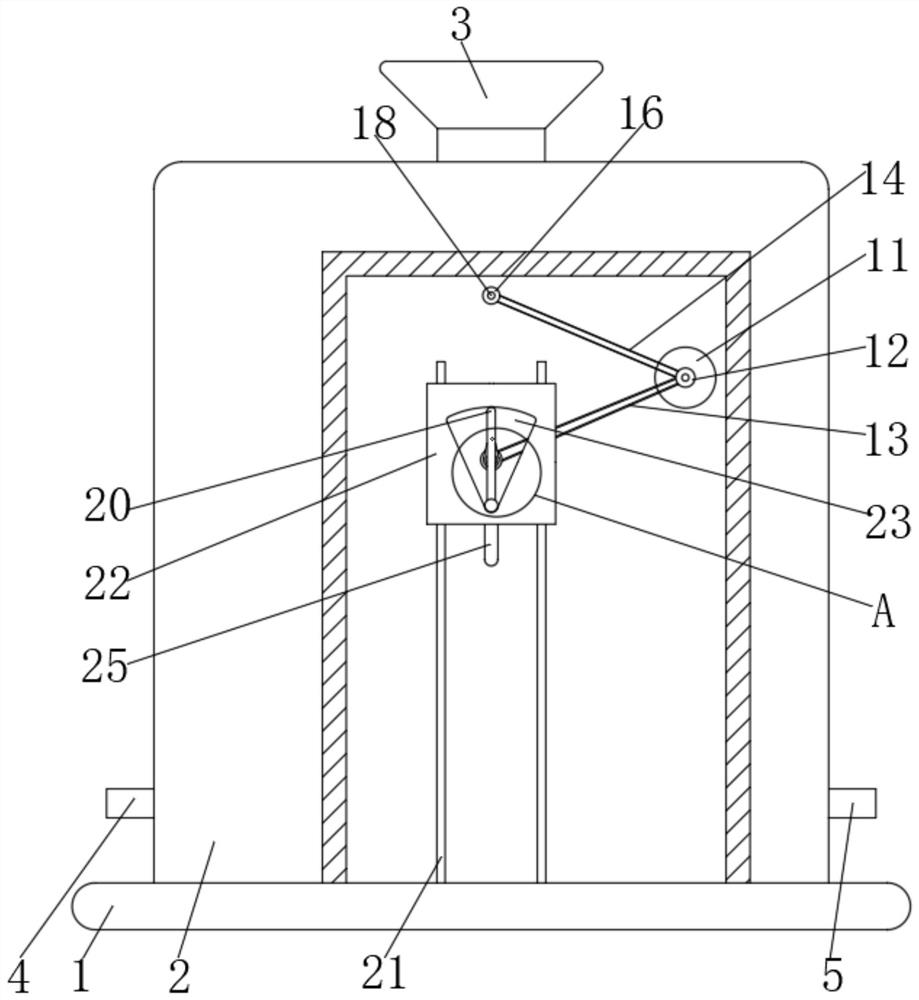

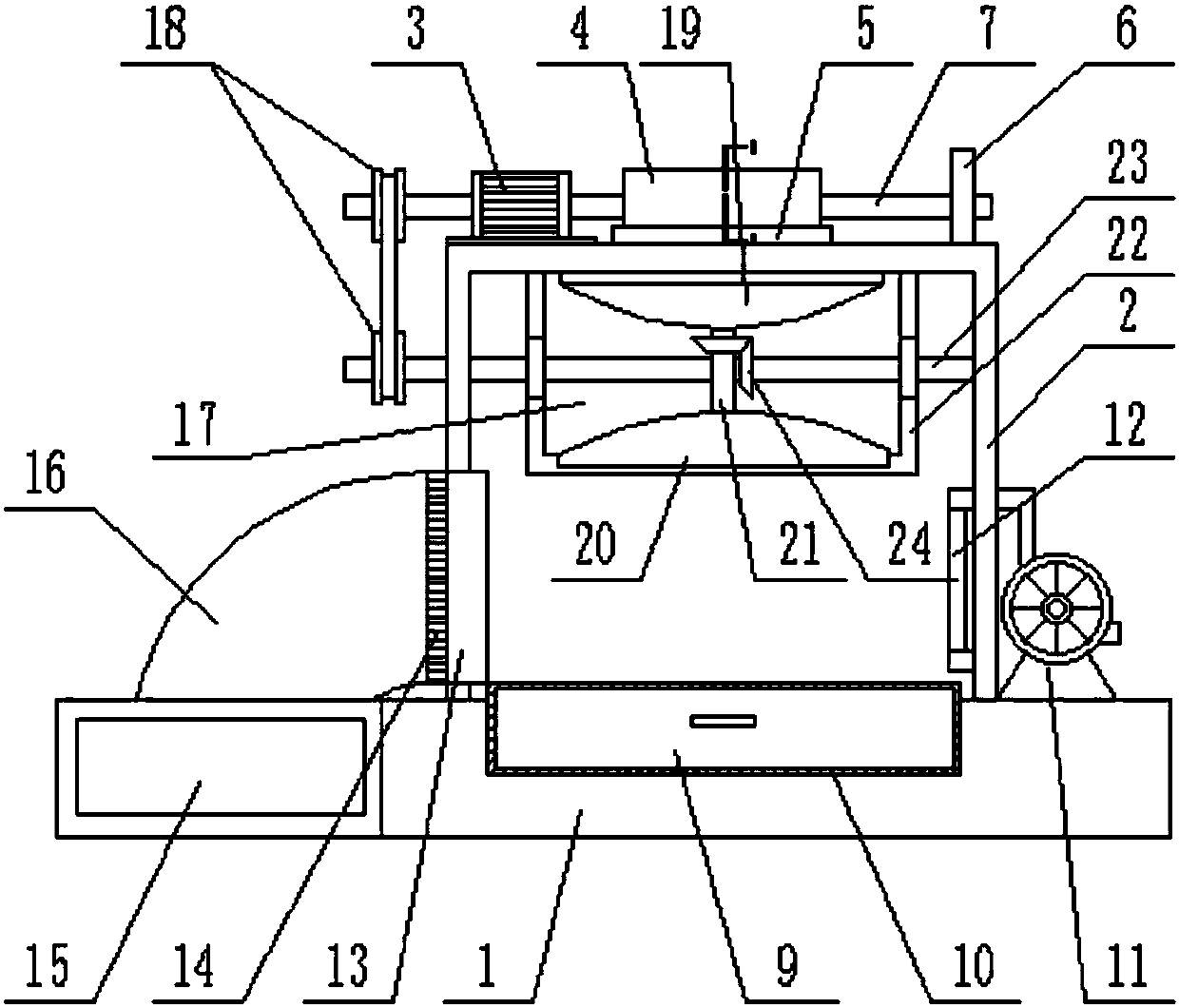

Sand screening device for construction

InactiveCN108421703AImprove screening effectIncrease screening speedSievingScreeningScreening effectReciprocating motion

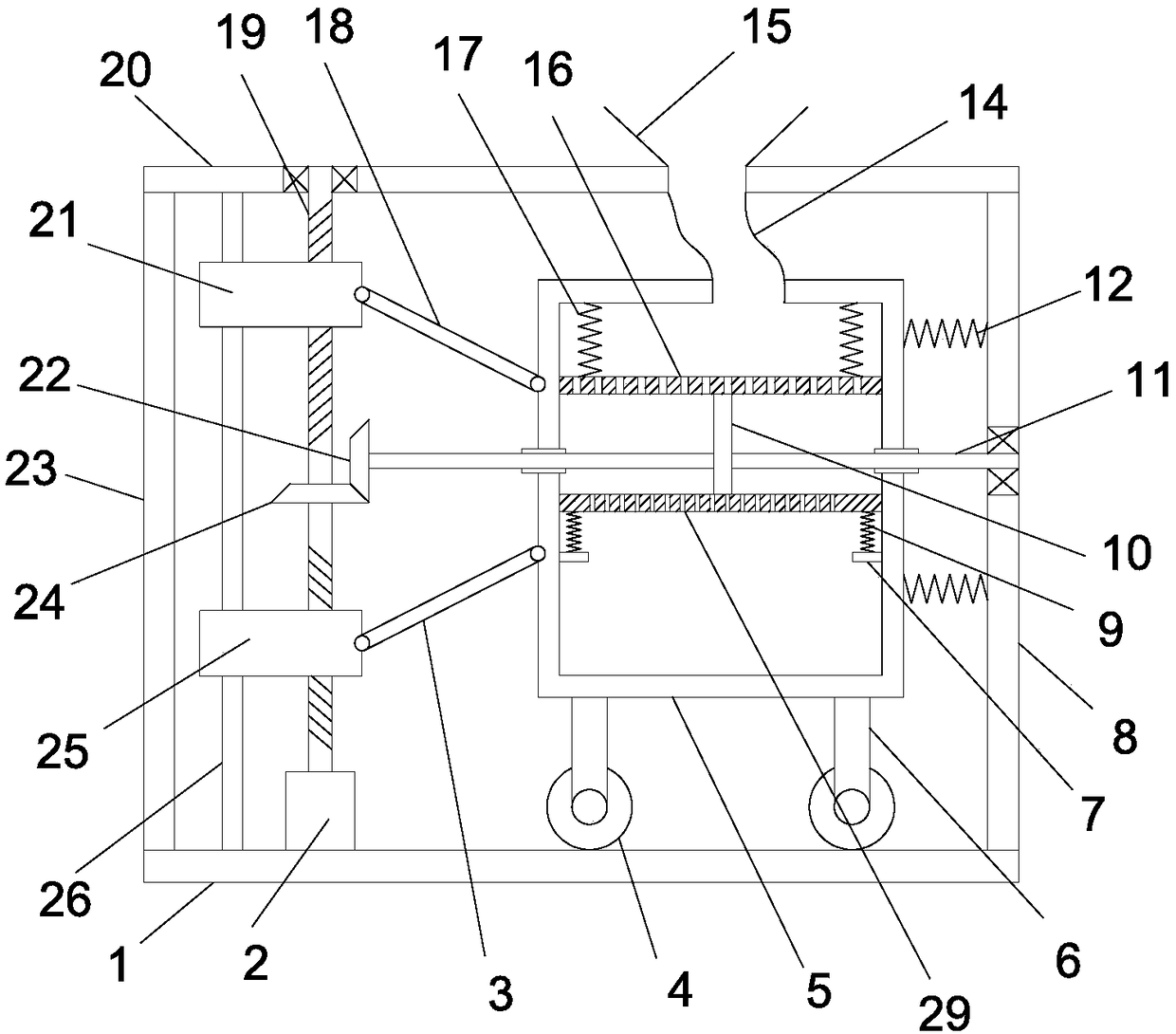

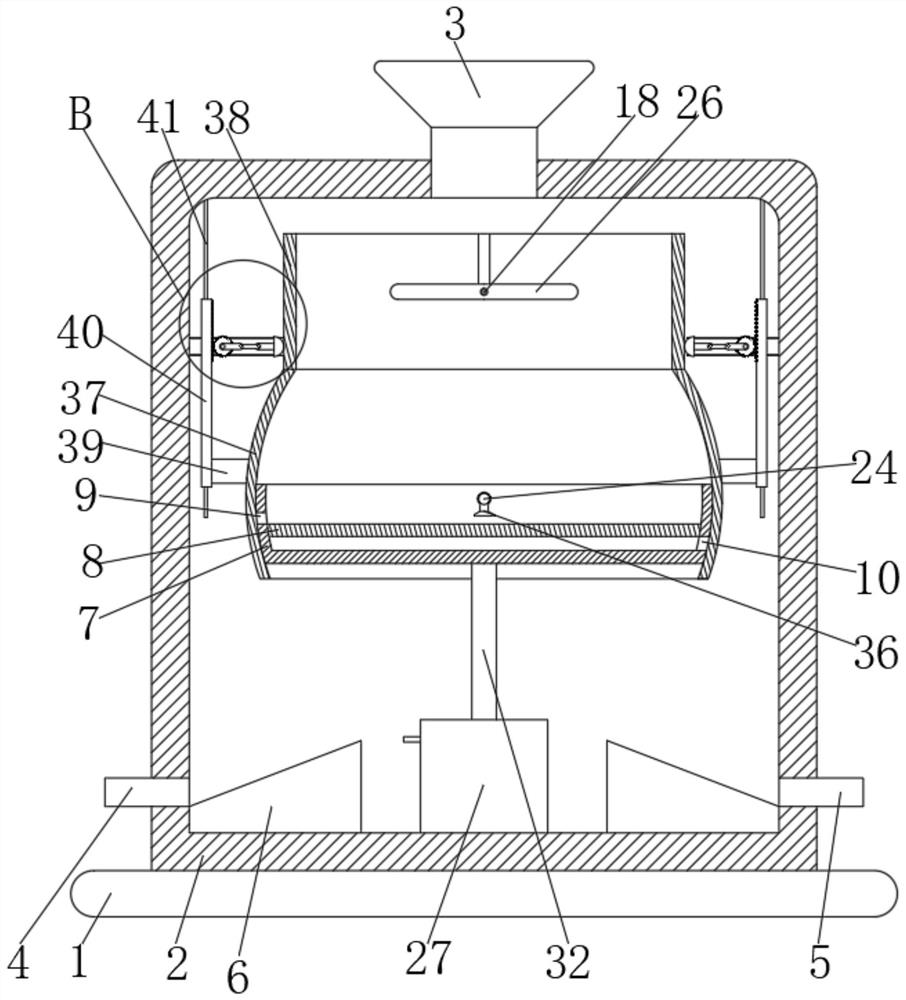

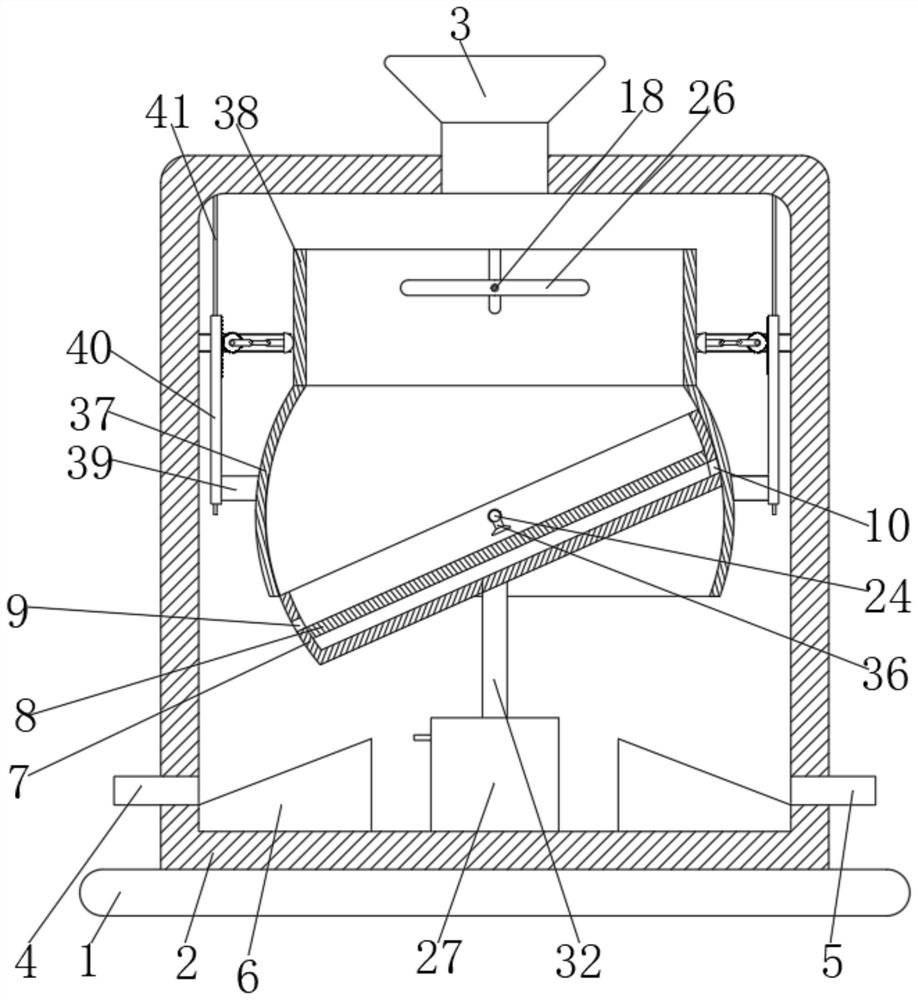

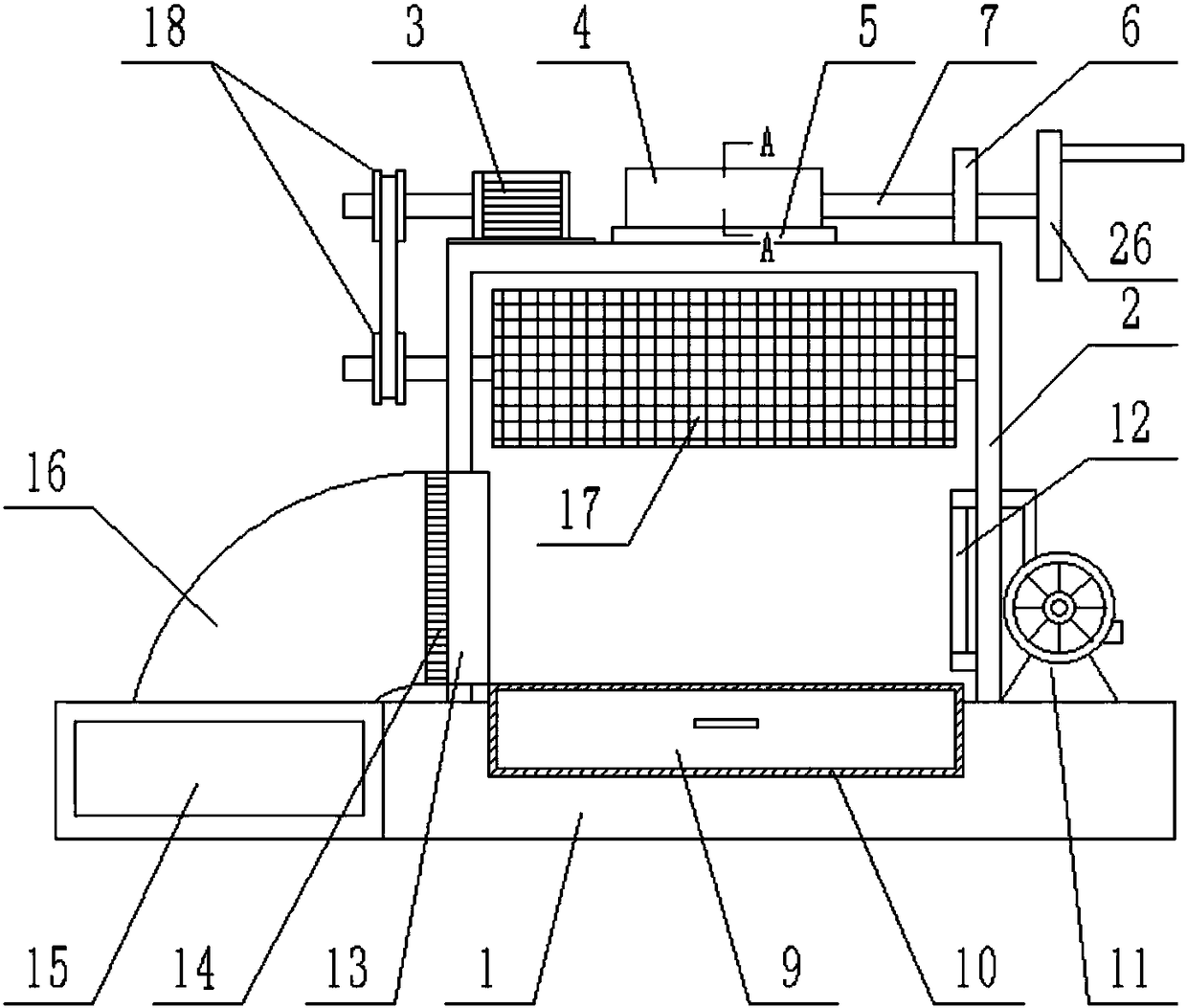

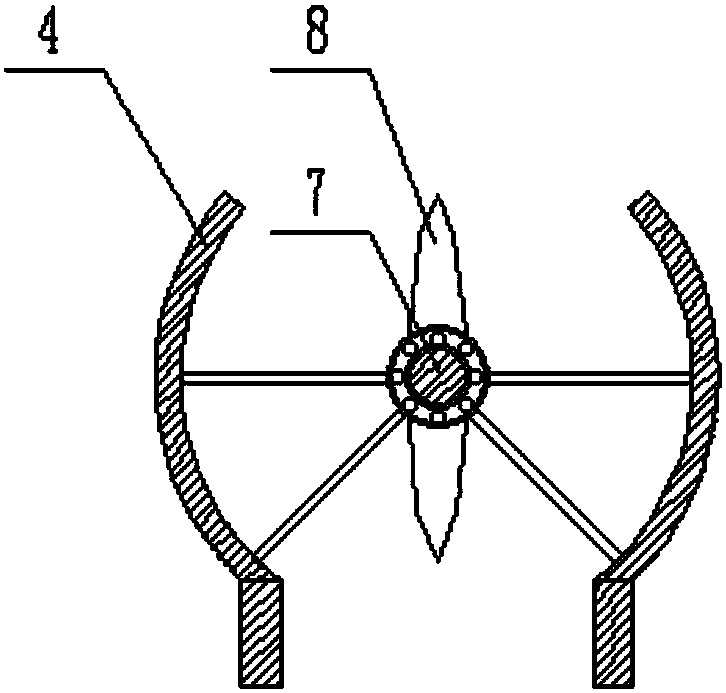

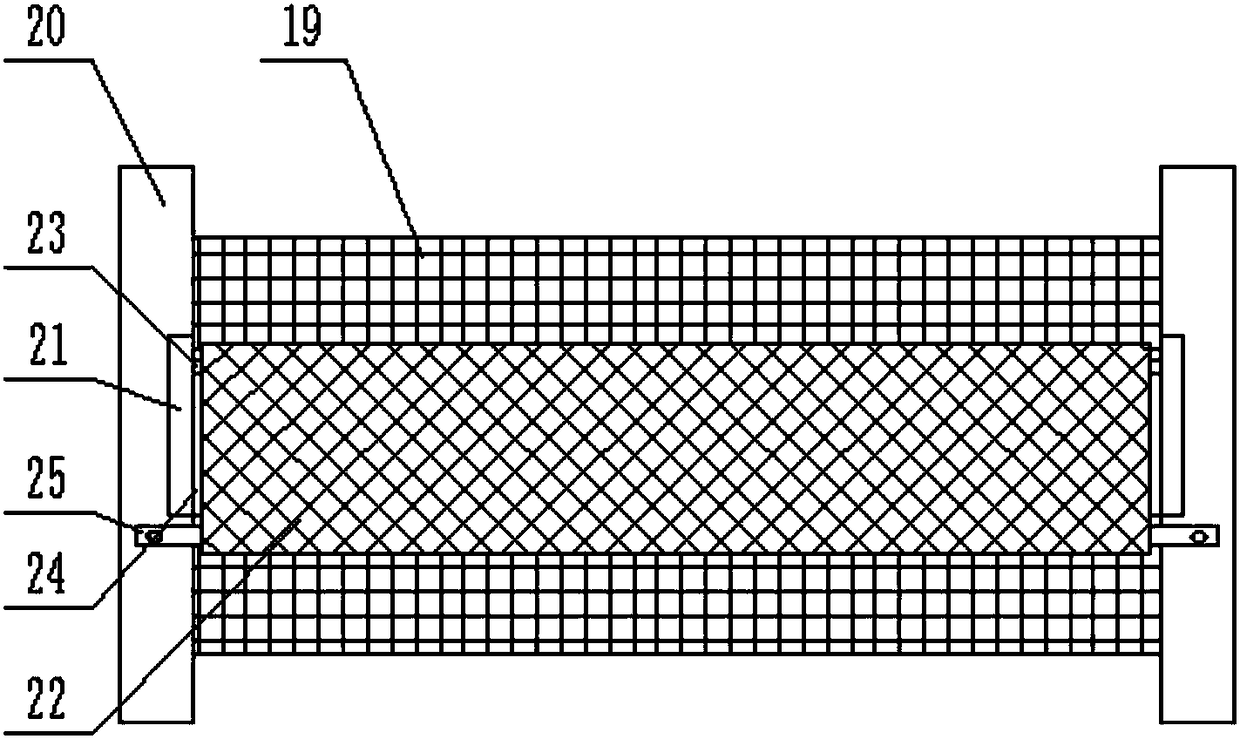

The invention discloses a sand screening device for construction. The sand screening device comprises a bottom plate and a screening box. A left vertical plate and a right vertical plate are vertically and fixedly mounted on the bottom plate. A top plate is horizontally and fixedly mounted on the left vertical plate and the right vertical plate. Supporting legs are vertically and fixedly mounted at the bottom of the screening box. A feeding pipe is mounted on the top plate and communicates with the interior of the screening box through a flexible connecting pipe. Damping springs are fixedly connected between the screening box and the left side wall of the right vertical plate. The sand screening device has the obvious advantages that the screening effect on sand is good, and the screeningspeed is high; the screening box is driven through a second connecting rod and a first connecting rod to do left-and-right reciprocating motion under the elastic acting force of the damping springs,shaking of the sand in the screening box is promoted, and the sand screening rate is increased; and through rotation of an oval cam, a first screening plate and a second screening plate are driven tovibrate up and down under the elastic action of second limiting springs, and the screening speed of the first screening plate and a second screening plate on the sand is further increased.

Owner:重庆峰创科技有限公司

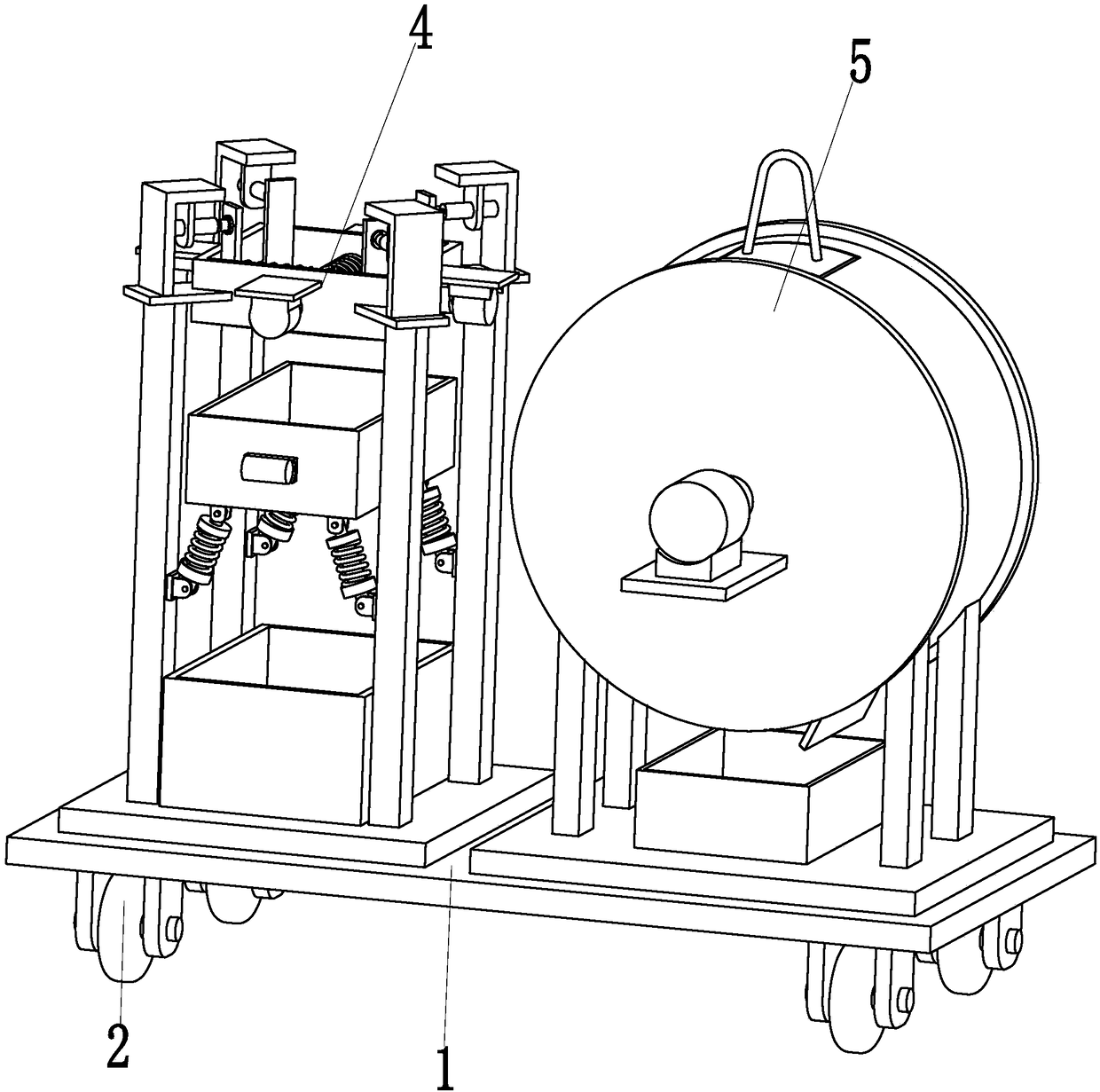

Full-automatic processing equipment for reutilization of capsules

ActiveCN106269477AEasy to moveImprove stabilitySievingScreeningScreening effectAutomatic test equipment

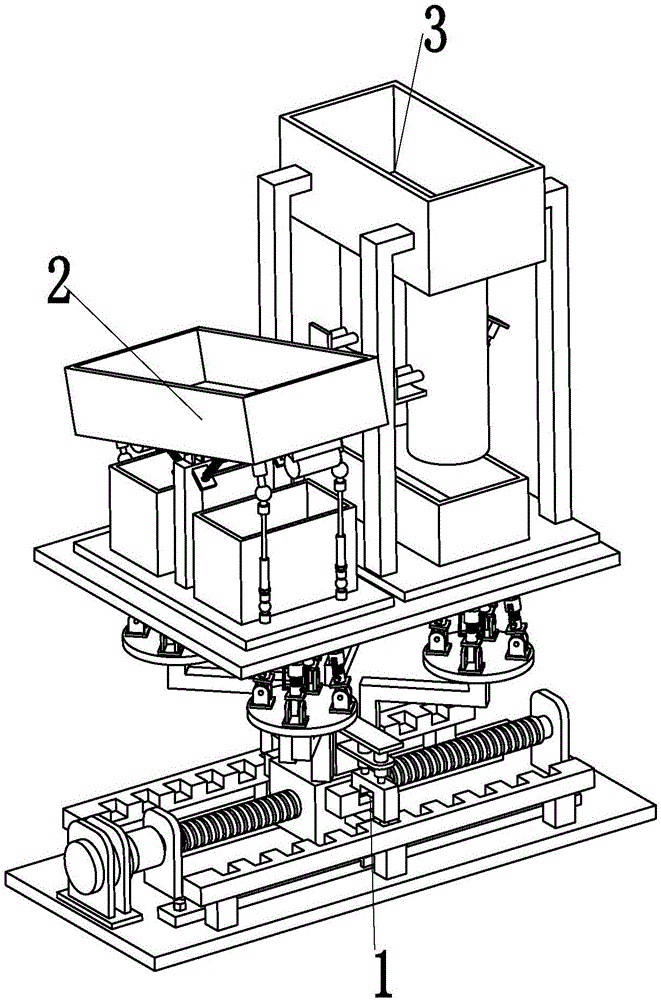

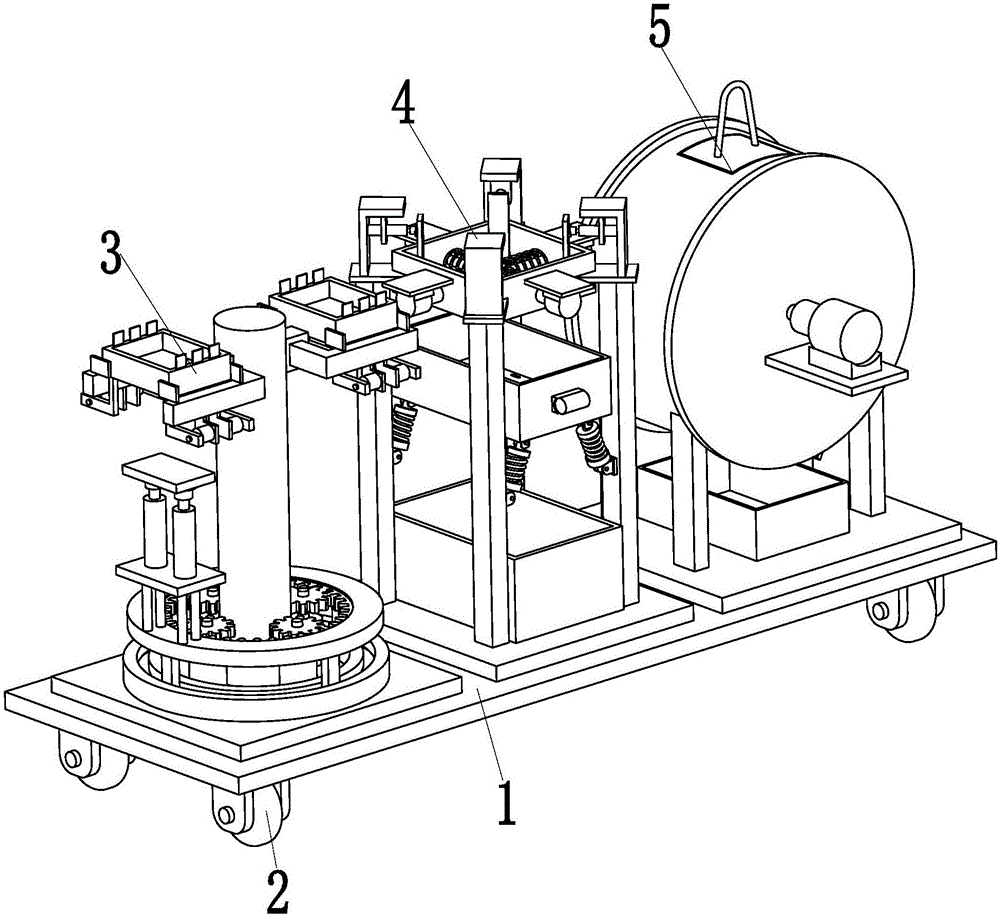

The invention relates to full-automatic processing equipment for reutilization of capsules. The full-automatic processing equipment comprises a positioning and moving device which can achieve a precise capsule movable-collecting function, manual picking is not needed, the automation degree is high, and work efficiency is high. A capsule screening device is mounted on the left side of the upper end face of the positioning and moving device and can achieve an automatic unqualified-capsule screening function, and a capsule crushing device is mounted on the right side of the upper end face of the positioning and moving device and can achieve an automatic unqualified-capsule crushing and reutilizing function. According to the full-automatic processing equipment, the precise capsule movable-collecting function, the automatic unqualified-capsule screening function and the automatic unqualified-capsule crushing and reutilizing function can be achieved, and the full-automatic processing equipment for reutilization of capsules has the advantages that manual back-and-forth picking is not needed, the shaking condition is avoided in the movable picking process, and the equipment is good in mobility; manual screening of unqualified capsules is not needed, the screening time is short, the screening speed is high, and the screening effect is good; and unqualified capsules can be recycled, and work efficiency is high.

Owner:九江昂泰胶囊有限公司

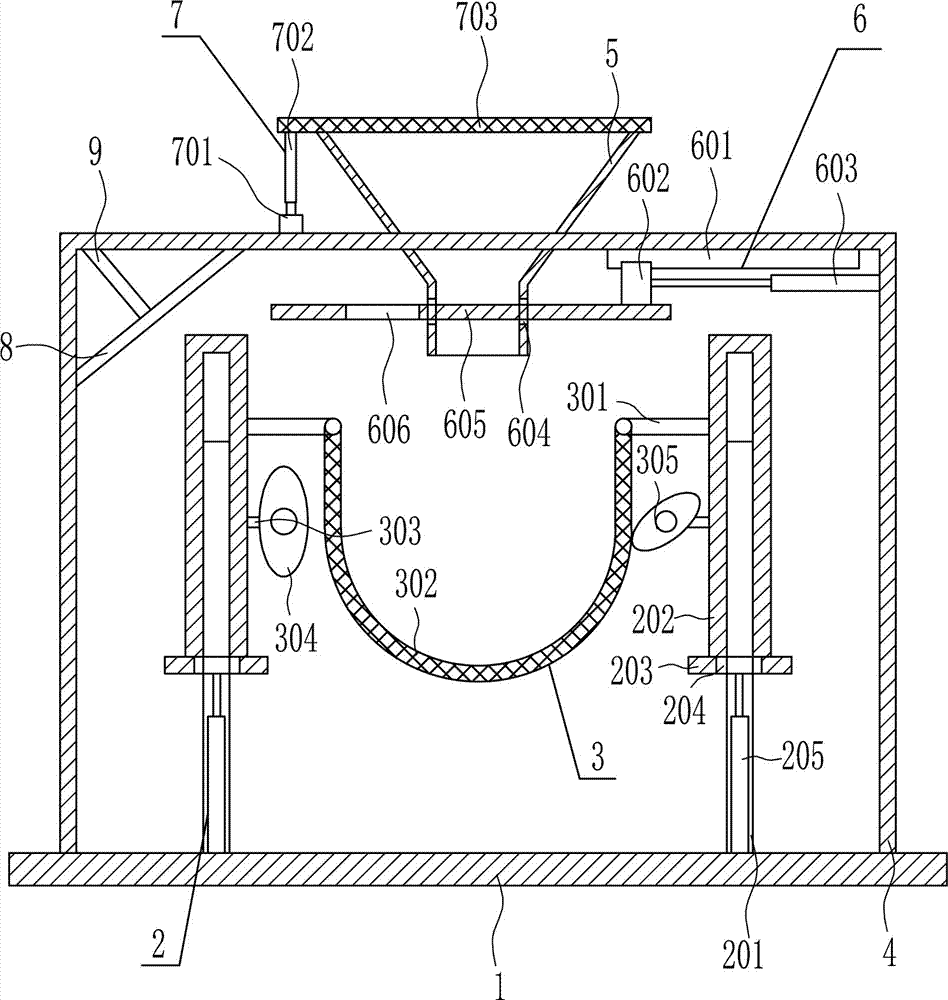

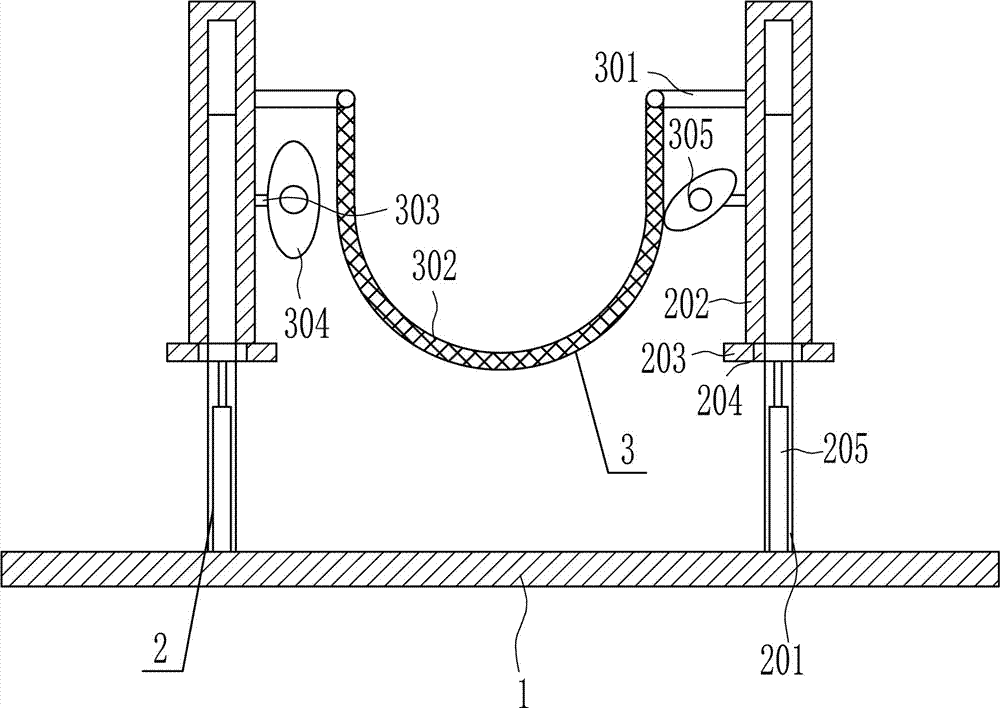

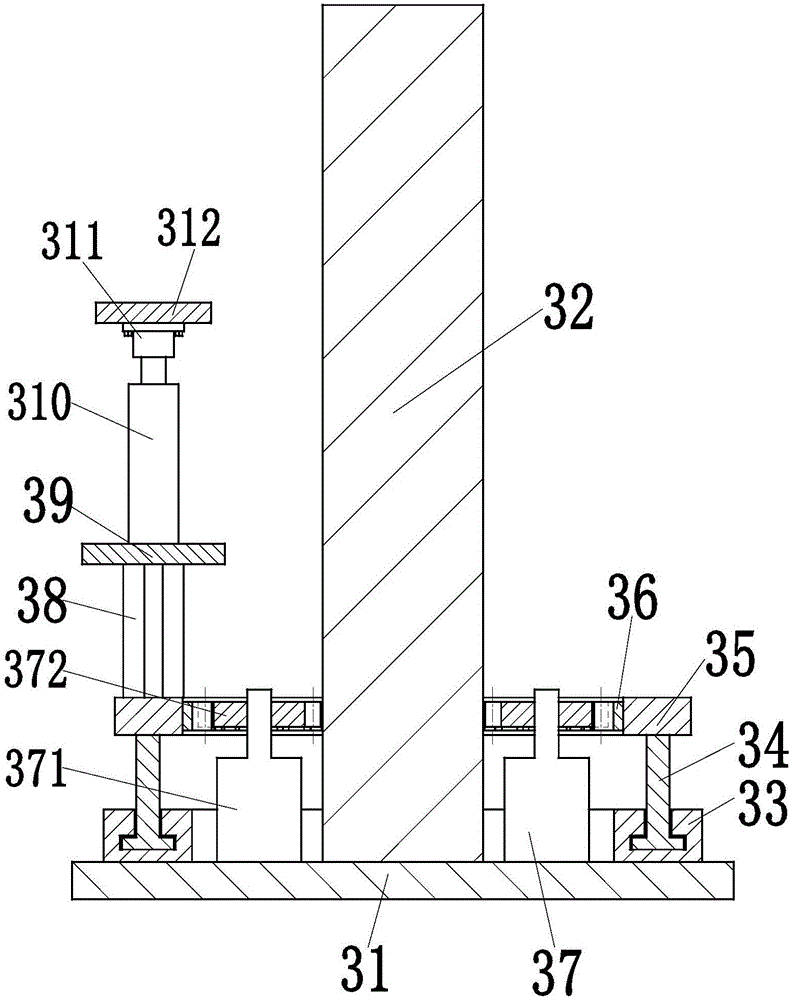

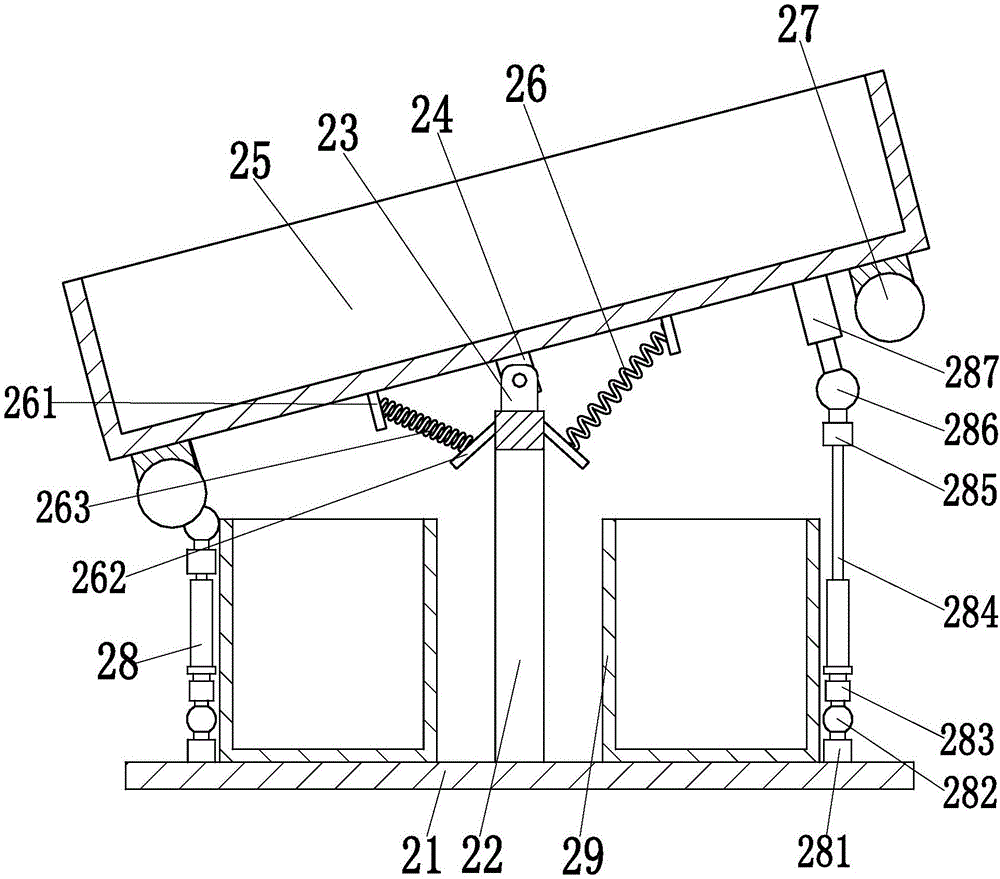

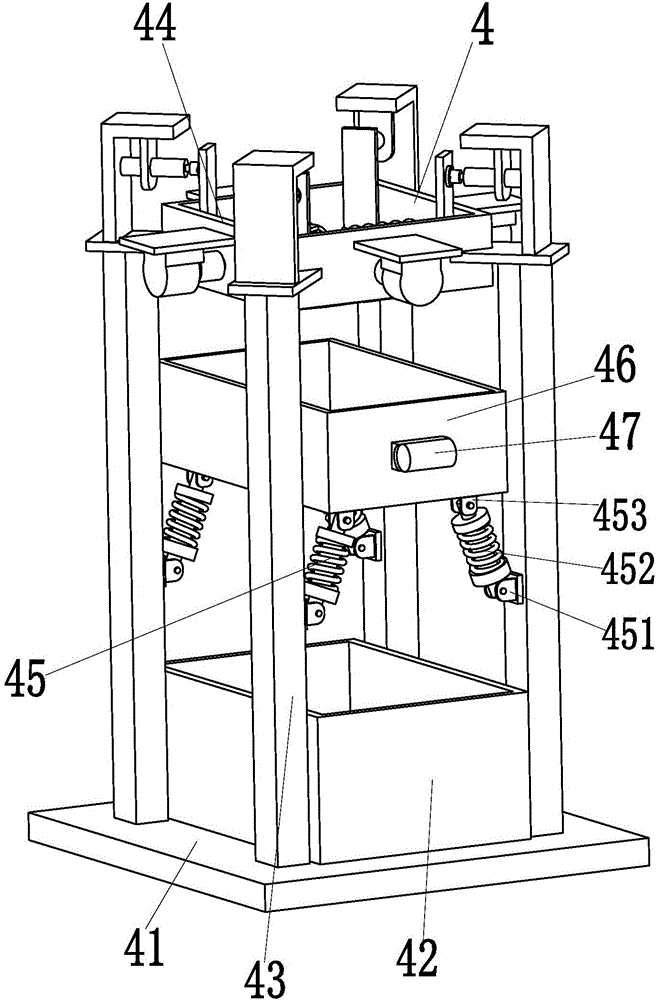

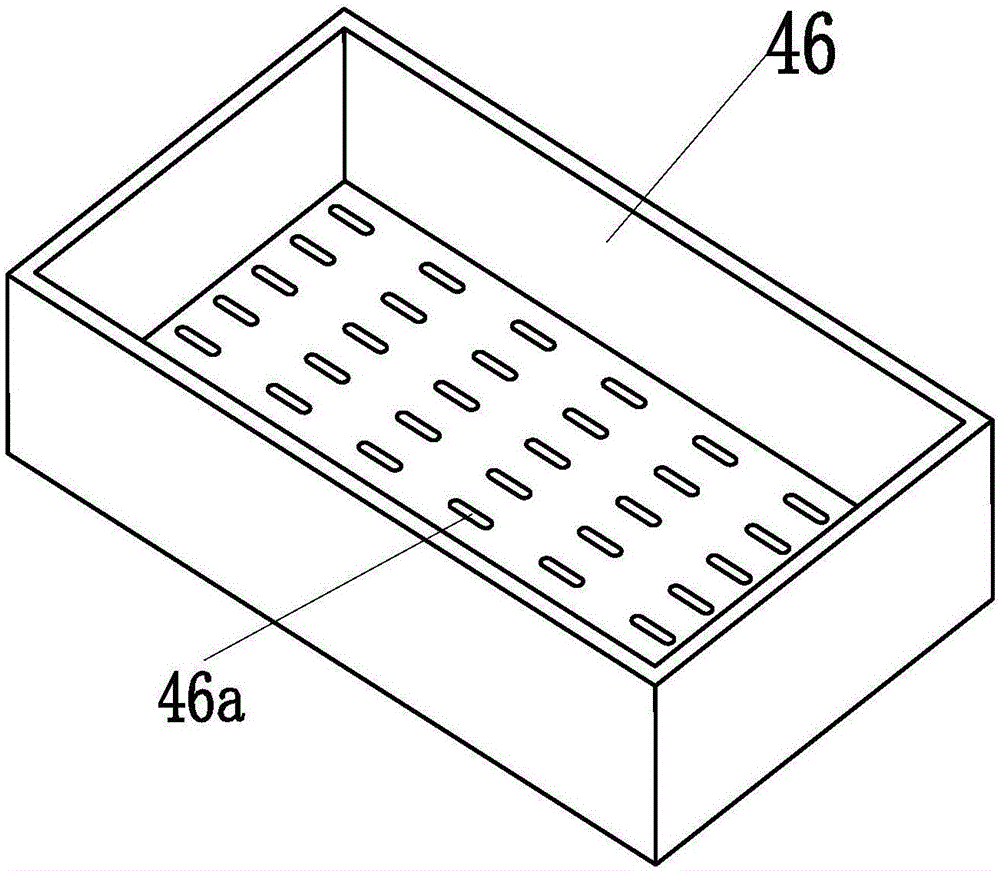

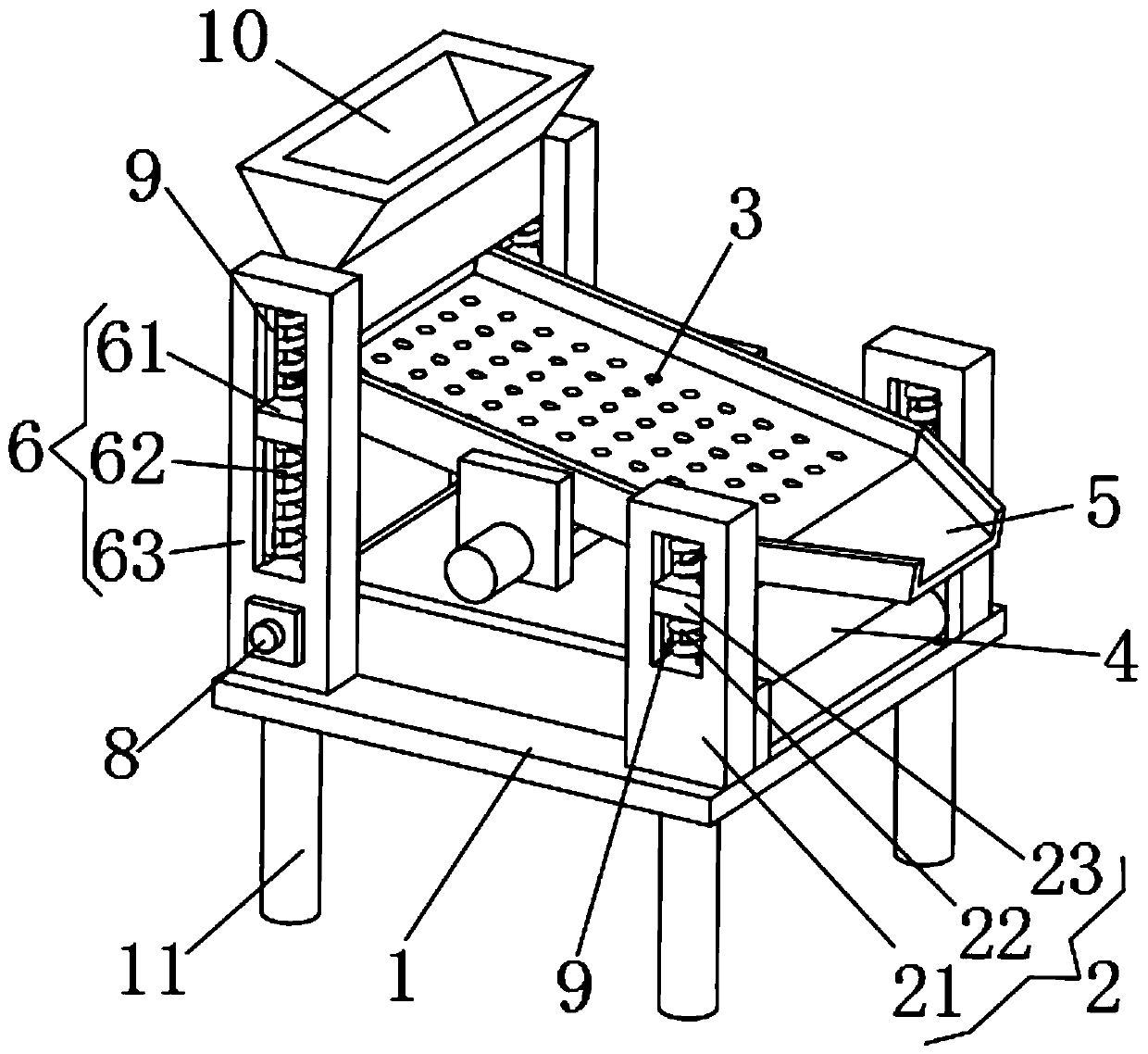

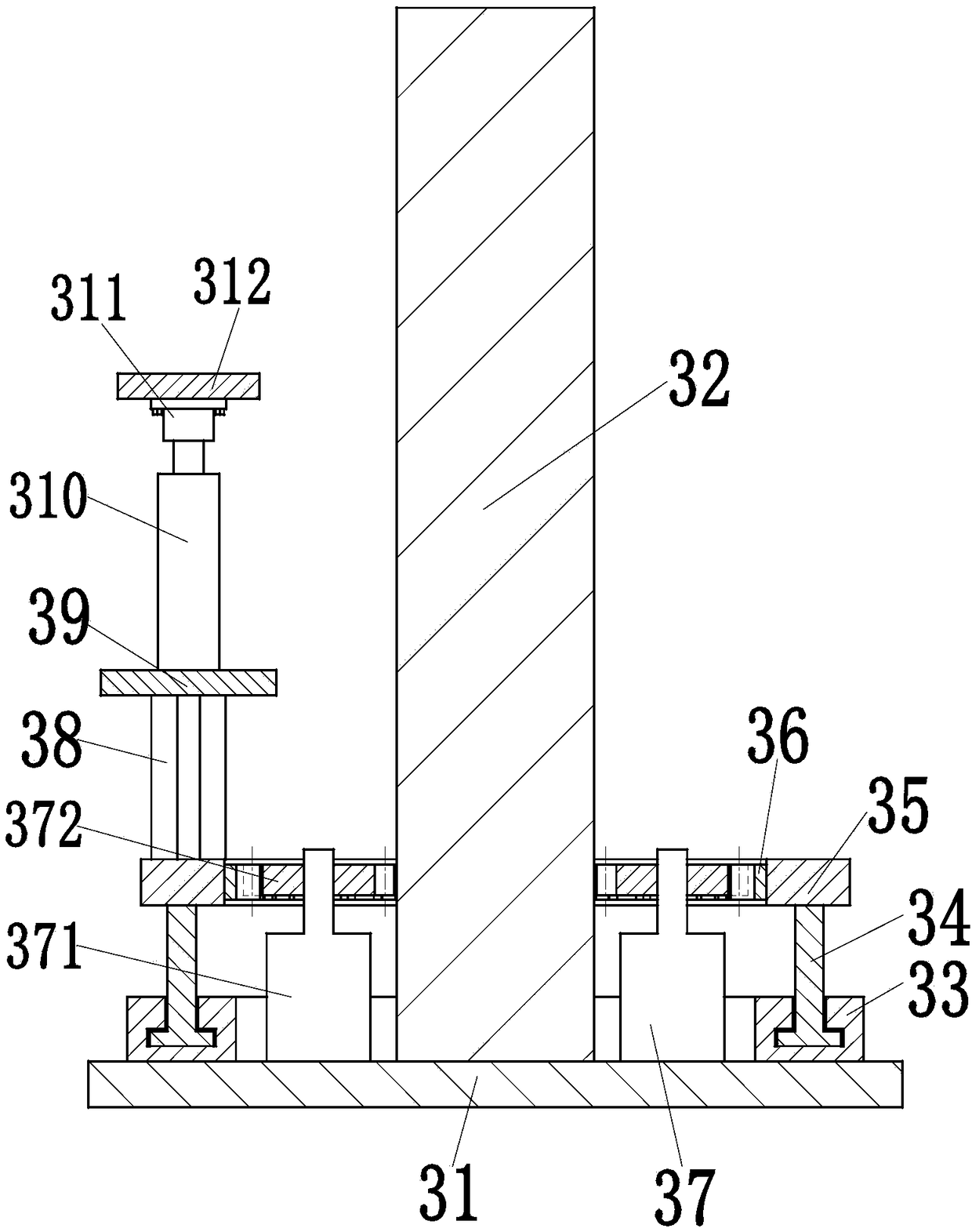

Efficient sand screening device for municipal engineering construction

ActiveCN107282420APrevent fallingHigh strengthSievingScreeningArchitectural engineeringUltimate tensile strength

The invention relates to a sand screening device, in particular to an efficient sand screening device for municipal engineering construction and aims to provide an efficient sand screening device capable of saving time and labor and reducing labor intensity, high in sand screening speed and used for municipal engineering construction. For solving the technical problem, the efficient sand screening device for municipal engineering construction comprises a base plate and the like. Vertical movement devices are symmetrically arranged on the left side and the right side of the top of the base plate, and sand screening devices are arranged at the upper portions of the inner sides of the vertical movement devices. The efficient sand screening device can screen sand through the vertical movement devices and the sand screening devices, and accordingly achieves the advantages of saving time and labor, reducing the labor intensity and being high in sand screening speed.

Owner:君奕纺织科技有限公司

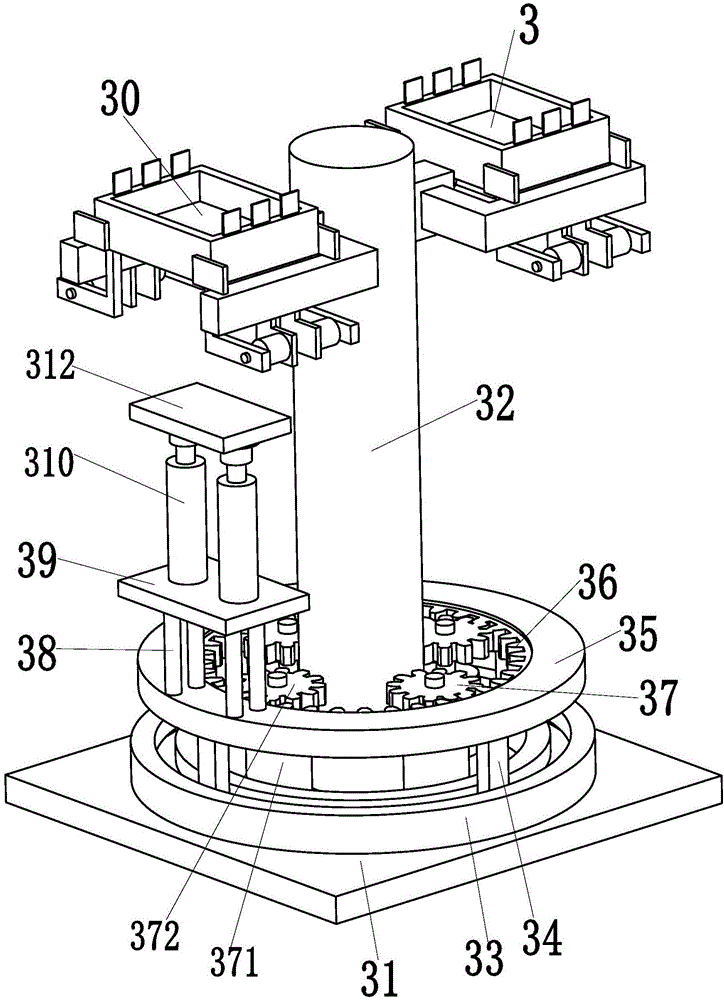

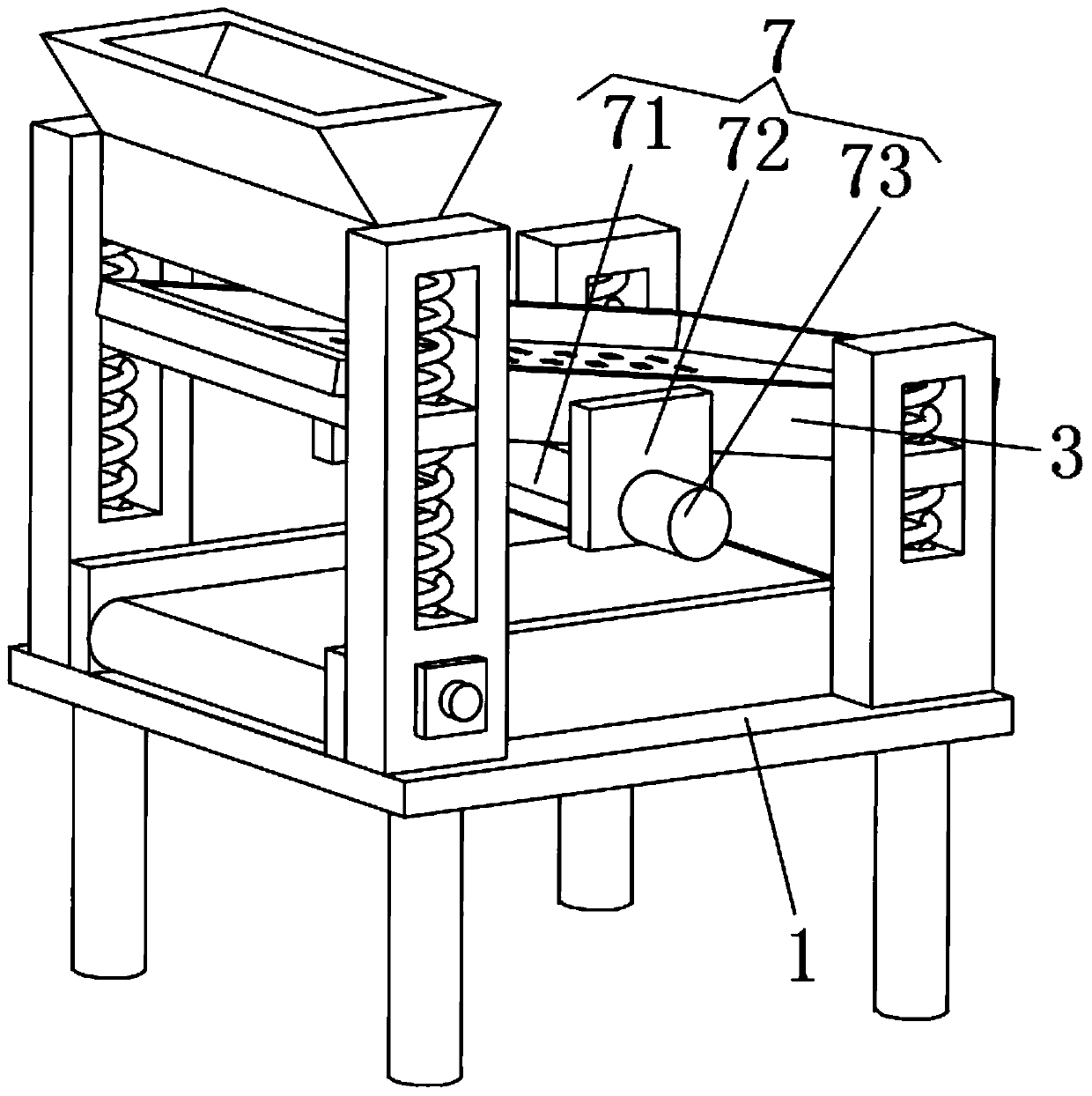

Precise capsule screening device

InactiveCN106111525ARealize automatic screening functionImprove screening effectSievingScreeningEngineering

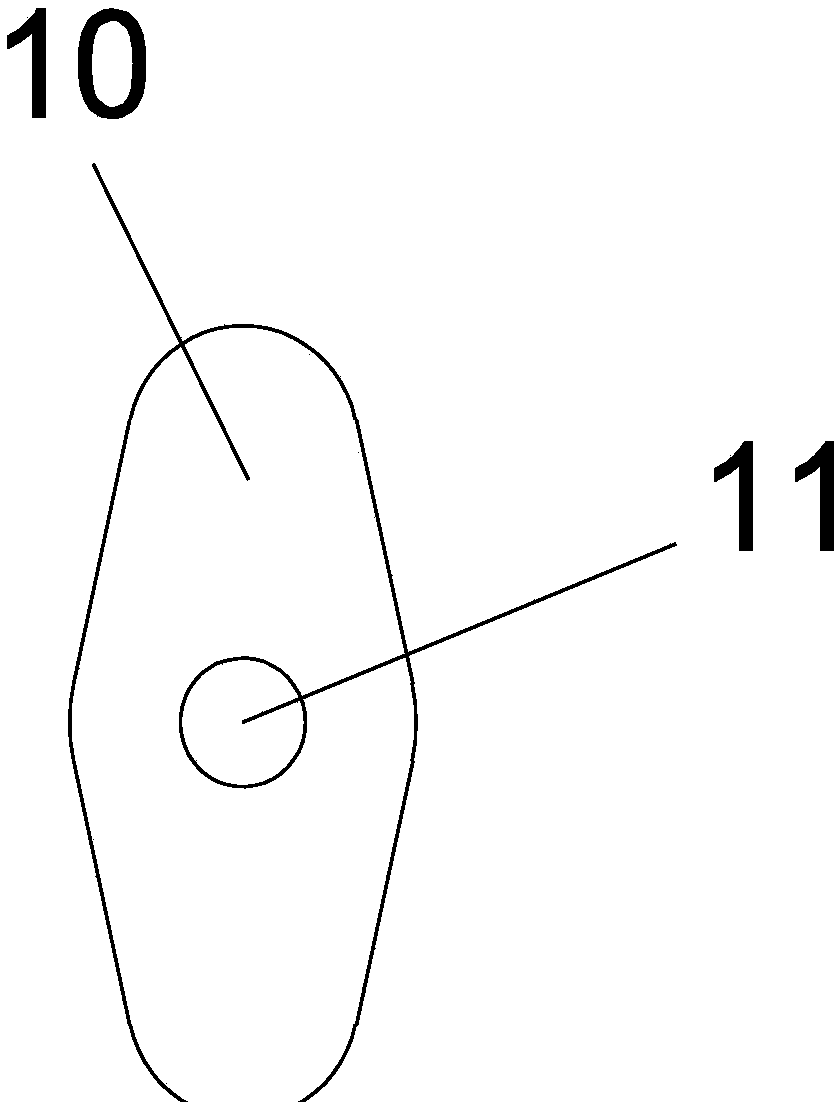

The invention relates to a precise capsule screening device. The precise capsule screening device comprises a screening support plate; a screening frame is mounted at the middle part of the screening support plate; two pairs of fixed lugs are symmetrically arranged on the upper end surface of the screening frame; rotating lugs are mounted between the two pairs of fixed lugs through pin shafts; two rotating lugs between the two pairs of fixed lugs are symmetrically arranged at the middle part of the lower end surface of a screening box; the screening frame can rotate on two pairs of fixed lugs through the two rotating lugs; four limiting branch chains are respectively mounted between two sides of the screening box and two side walls of the screening frame; and when the screening box continuously rotates up and down, the four limiting branch chains symmetrically distributed on two sides of the screening box achieve an excellent limiting effect, so that the screening box is helped to quickly recover to the middle position, and the up-down rotating amplitude of the screening box is limited. The precise capsule screening device can realize an automatic screening function of unqualified capsules.

Owner:XUCHANG UNIV

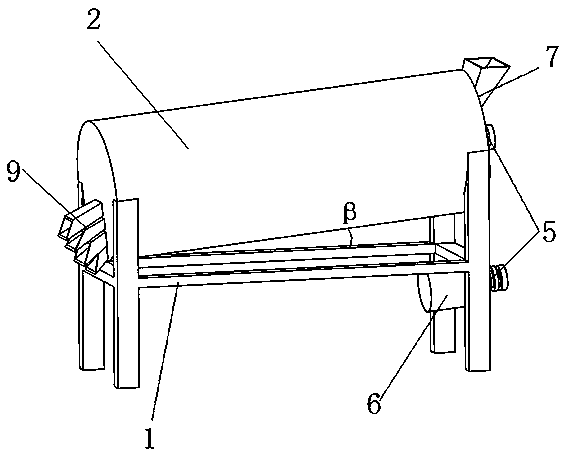

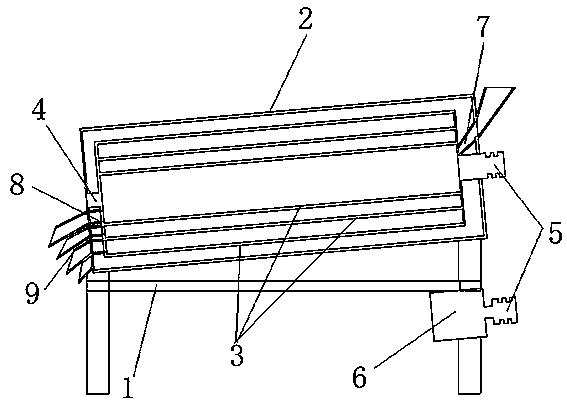

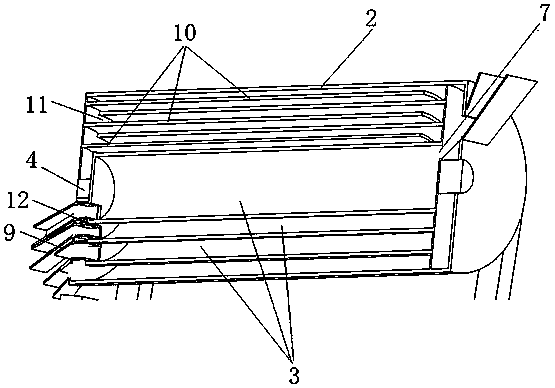

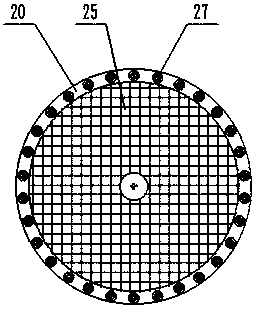

Automatic and efficient multistage rotary sand sieving machine and production method thereof

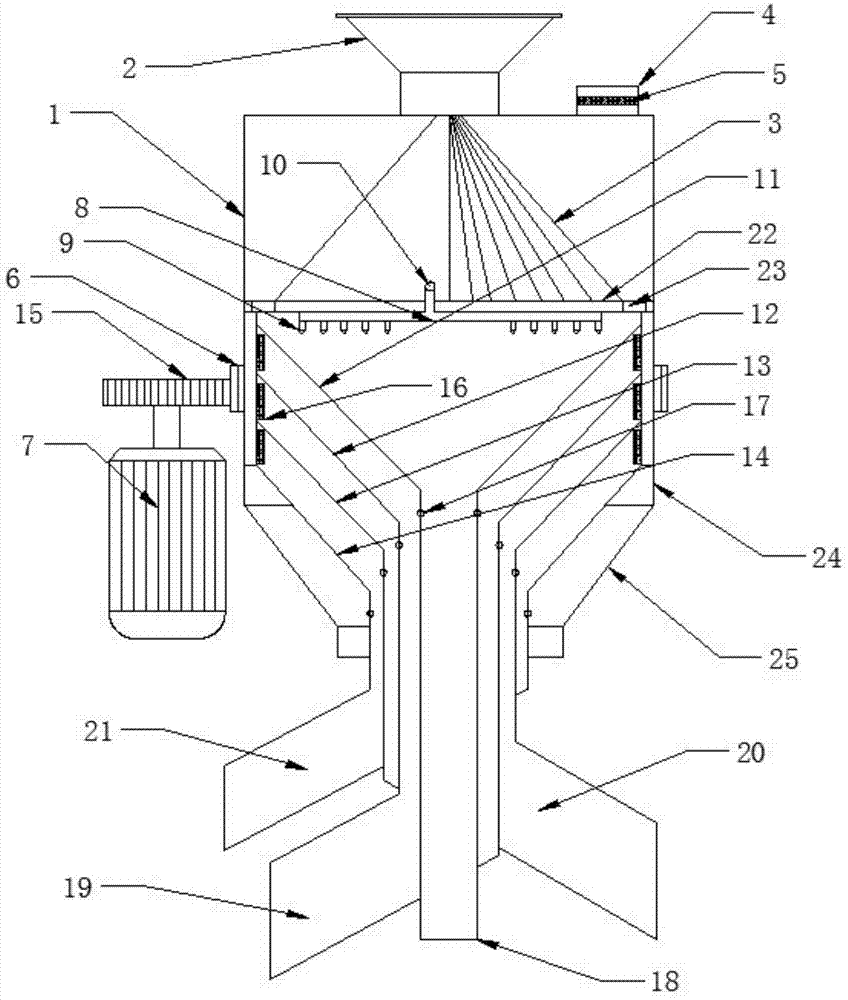

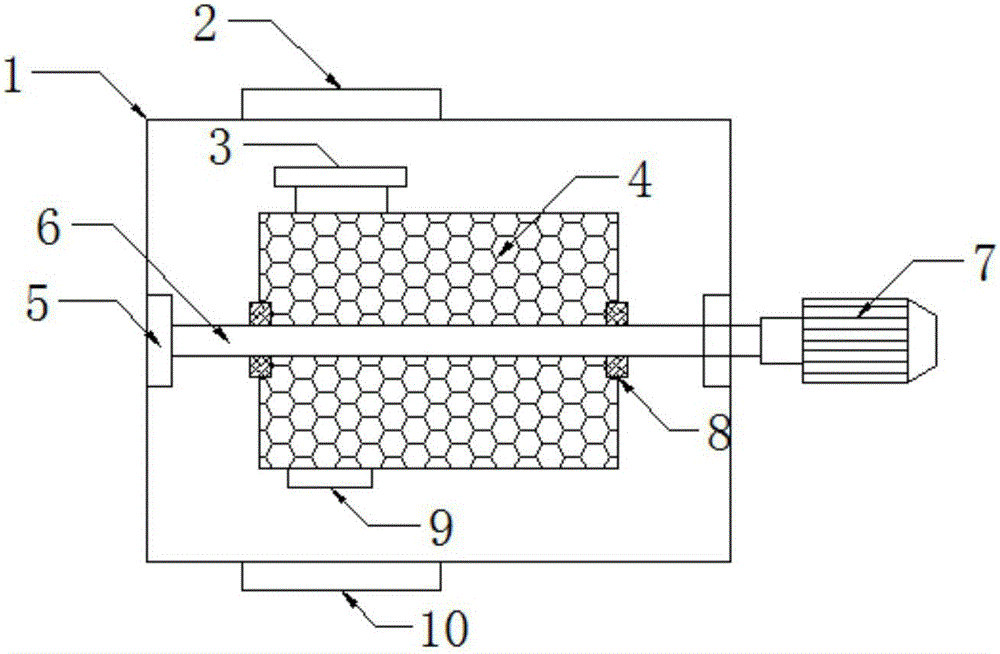

The invention discloses an automatic and efficient multistage rotary sand sieving machine which comprises a barrel body, a material distribution base and a control motor. A rotary barrel and a conical barrel are mounted at the lower end of the barrel body in sequence. A material distribution board is arranged between the material distribution base in the barrel body and a feeding hopper which is located at the top end of the material distribution base. A filter screen is arranged in an air outlet pipe located at the top end of the barrel body. A rotary sleeve wheel located on the rotary barrel is connected with the control motor through a driving wheel. A plurality of sand outlet barrels are arranged in the conical barrel from inside to outside in sequence and are fixedly connected onto mesh sieves and sliding boards which are both located on the inner wall of the rotary barrel through rotary joints respectively, a plurality of vibrating boards are arranged on the inner wall of the rotary barrel, and a pneumatic pipe located at the lower end of the material distribution base is connected with an air nozzle and an air inlet pipe. The automatic and efficient multistage rotary sand sieving machine is simple to operate and can conduct multistage sieving on mixed sand automatically without blocking sieving holes easily; has a high sieving efficiency and fast sieving speed and small pollution, thereby effectively improving the working environment .

Owner:SUZHOU SESINCH MECHANICAL ELECTRICAL TECH

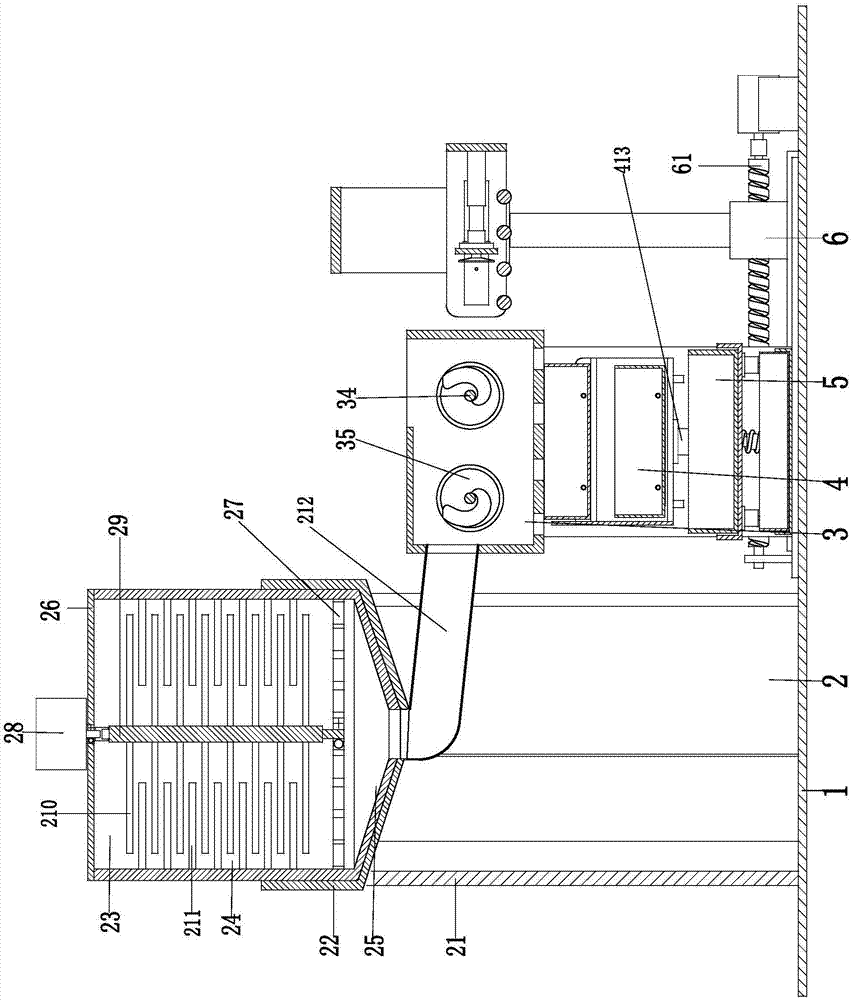

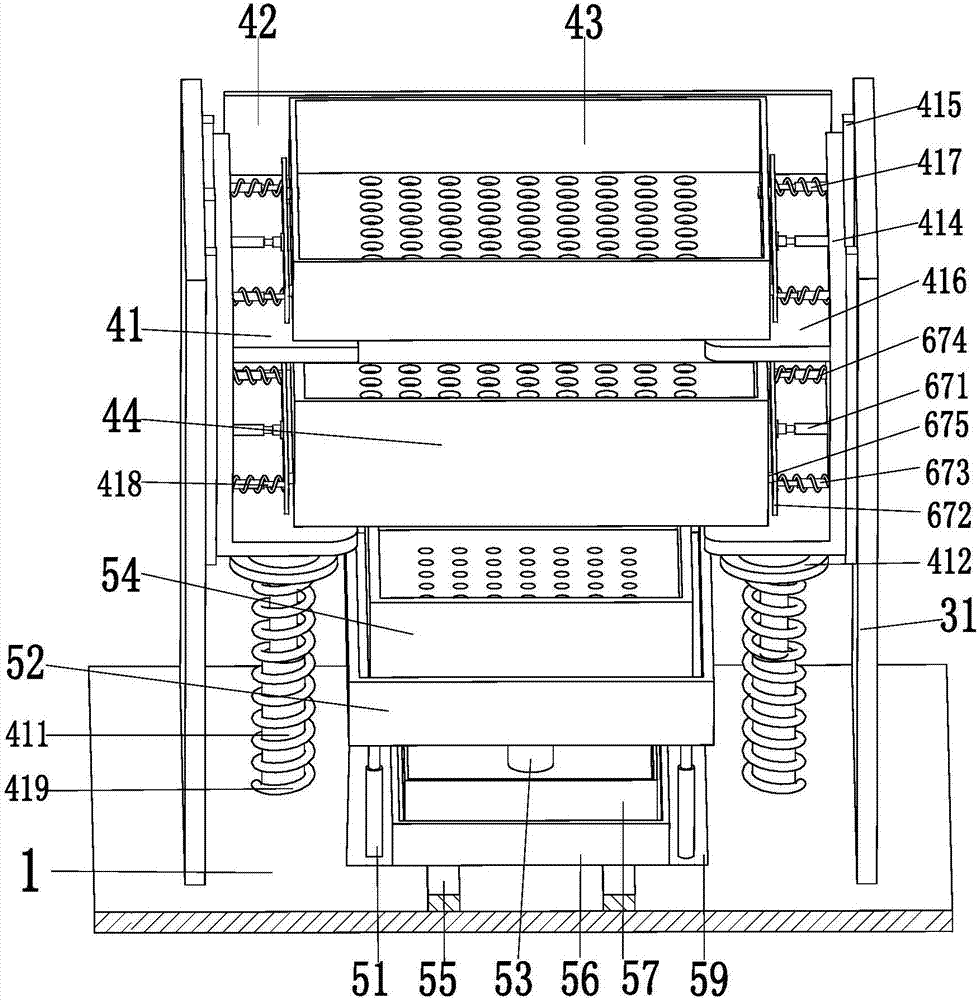

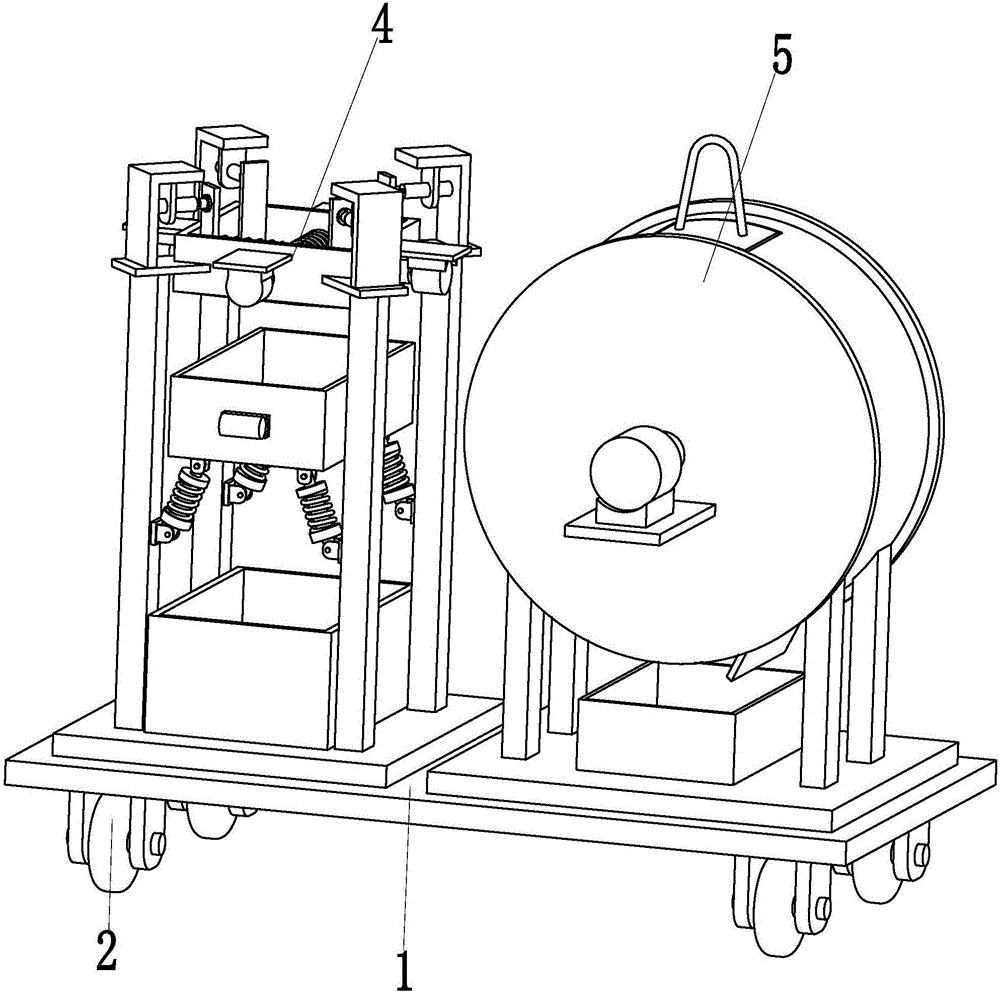

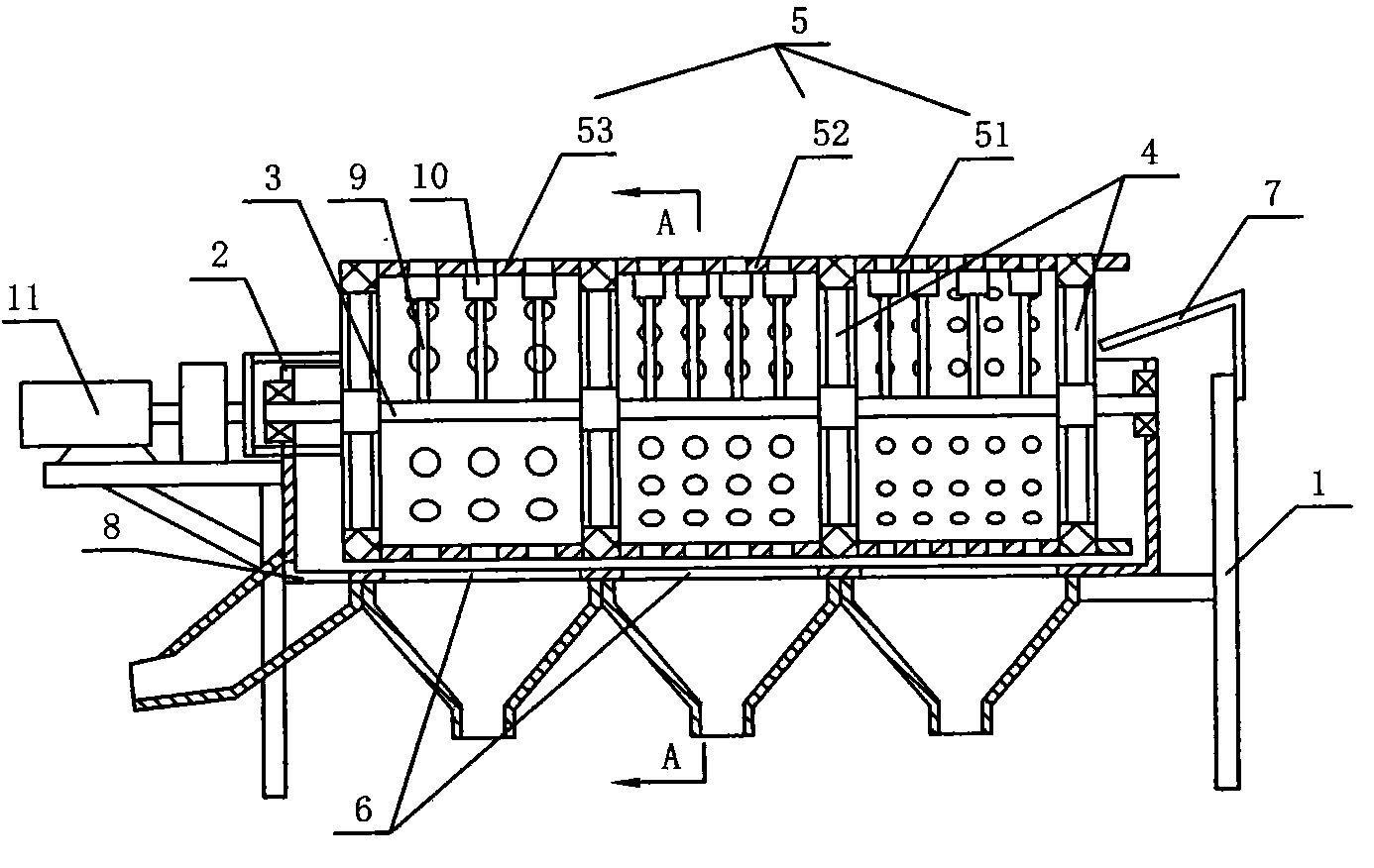

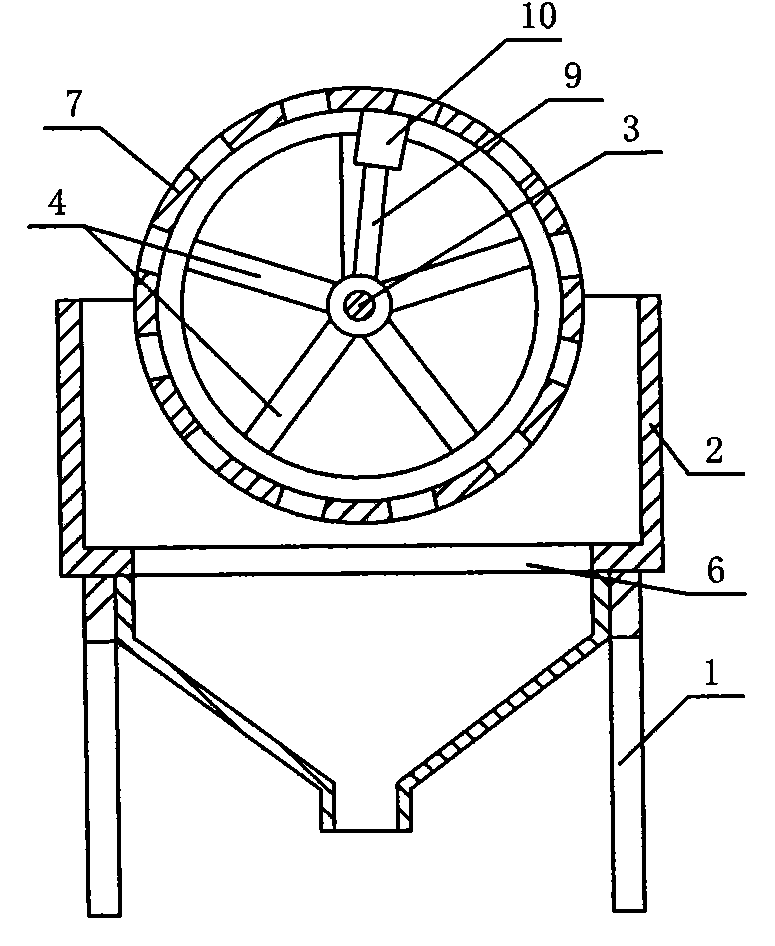

Integrated tea leaf tedding and screening machine

ActiveCN106269518AUniform transmission forceGood transmission effectSievingGas current separationScreening effectEngineering

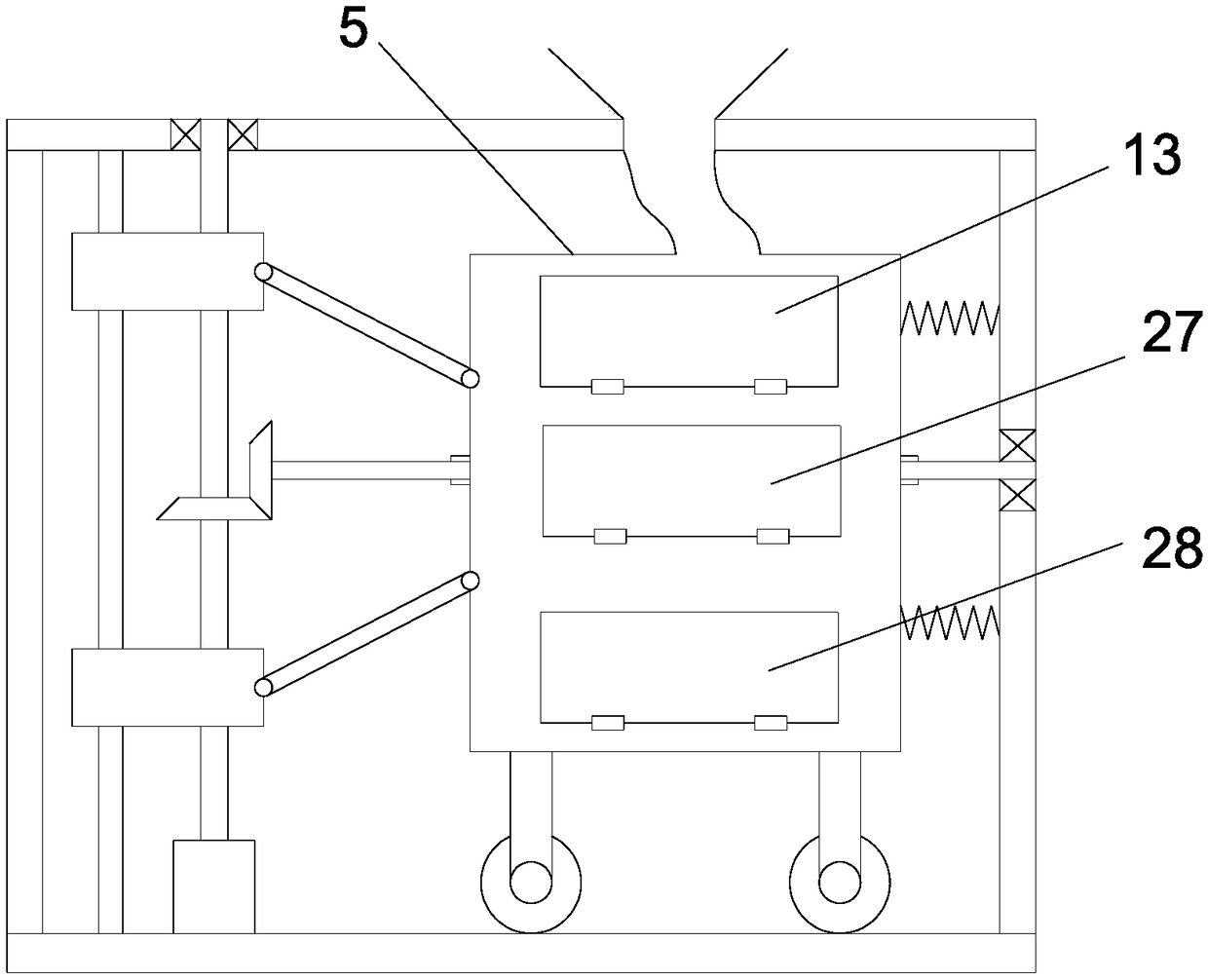

The invention relates to an integrated tea leaf tedding and screening machine which comprises a bottom plate, four universal wheels are symmetrically installed on the lower end face of the bottom plate, the integrated tea leaf tedding and screening machine is moved to a processing position through the four universal wheels, a condensation tedding device is installed on the left side of the upper end face of the bottom plate and achieves the function of condensing light and rapidly tedding tea leaves, the tedding time is greatly shortened, the tedding speed is high, and the tedding effect is good; a multilevel screening device is installed on the right side of the upper end face of the bottom plate and achieves the function of automatically screening the tea leaves at multiple levels, the screening time is short, the screening speed is high, and the screening effect is good; the condensation tedding device comprises a tedding support plate installed on the left side of the upper end face of the bottom plate, an installation cylinder is welded at the middle part of the upper end face of the tedding support plate, and an annular limit groove is installed on the upper end face of the tedding bottom plate. The integrated tea leaf tedding and screening machine achieves the functions of integrally automatically tedding and screening the tea leaves, no manual operation is needed, the operation is simple and convenient, and the degree of automation is high.

Owner:岳阳县洞庭春纯天然茶叶有限公司

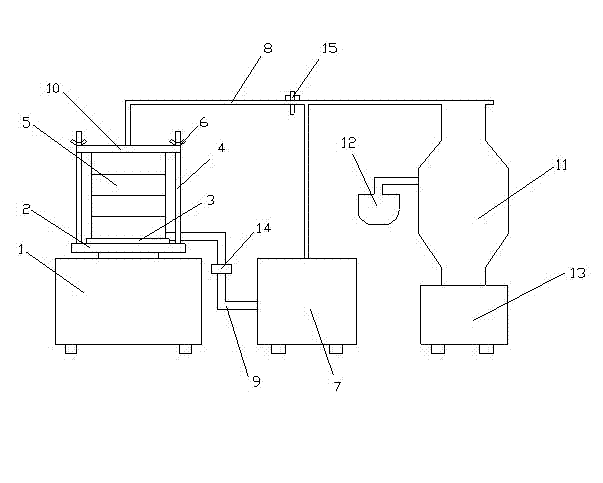

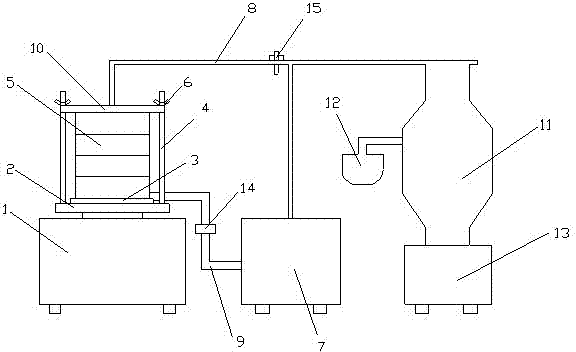

Pneumatic screening device

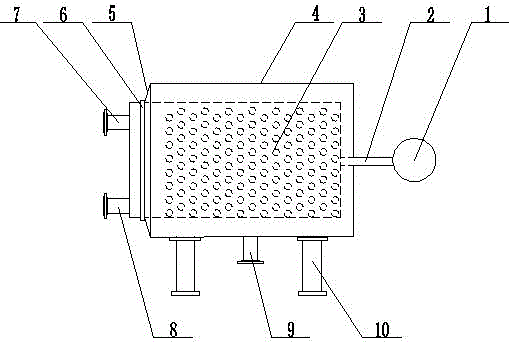

InactiveCN102580926AReduce noiseSieve evenlySievingGas current separationWorking environmentAgricultural engineering

The invention discloses a pneumatic screening device, which comprises a screening device, an air blower and an exhaust device. The air blower is connected with the screening device respectively via an air inlet pipe and an air outlet pipe, and one end of the air inlet pipe is connected with the exhaust device. The pneumatic screening device is capable of screening in a graded manner according to different mesh numbers of the material. A sampling sieve is connected with the air blower so that the material can be evenly and quickly screened. In the mean time, the arrangement of the exhaust device saves raw material and reduces costs. The pneumatic screening device is in a closed structure, dust-proof and low in noise so that the surrounding working environment cannot be affected.

Owner:常州宏泰摩擦材料有限公司

Material screening and collecting device based on sample preparation and detection

The invention relates to the field of general machinery, in particular to a novel linear vibrating screen and matched hoppers, and is mainly applied to the fields of foods, coal, medicinal materials and the like. The novel linear vibrating screen device and matched sample collecting device aim to overcoming the shortages of a screening device which is specially used for sample preparation at present and the defects in the prior art, and are used for efficiently and accurately screening coal powder, flour, medicinal material powder and the like. The novel linear vibrating screen device and the matched sample collecting device solve the problems that screening is not sufficient, screening efficiency is low, sample preparation time is long, screening devices are heavy and the like, and have the advantages of being convenient to carry, rapid in screening, accurate in screening, simple to manufacture, convenient to operate and the like.

Owner:ZHONGBEI UNIV

Wood shaving board raw material automatic machining equipment for furniture manufacturing

ActiveCN107116653AUniform cutting efficiencyRealize the function of automatic processingSievingScreeningMachining processRaw material

The invention relates to wood shaving board raw material automatic machining equipment for furniture manufacturing. The wood shaving board raw material automatic machining equipment for furniture manufacturing comprises a bottom plate, a cutting device is mounted at the front end of the bottom plate, and a crushing device is mounted on the rear side of the lower end of the cutting device; a screening device is mounted at the lower end of the crushing device, a collecting device is mounted at the lower end of the screening device, and a circulating converting device is mounted at the rear end of the bottom plate; and the cutting device, the crushing device, the screening device, the collecting device and the circulating converting device are mutually matched to complete the technique of wood shaving board raw material automatic machining. According to the wood shaving board raw material automatic machining equipment for furniture manufacturing, the difficult problems that in the existing wood shaving board raw material machining process, the cutting efficiency of wood shaving board raw materials is low, cutting is uneven, the consumed time for crushing is long, screening efficiency is low, screening stability is poor, manpower is needed for sorting out the wood shaving board raw materials not meeting the requirements to conduct secondary machining, the labor intensity is large, and working efficiency is low can be solved, and the function of wood shaving board raw material automatic machining can be achieved.

Owner:日照市澳思柏恩装饰材料有限公司

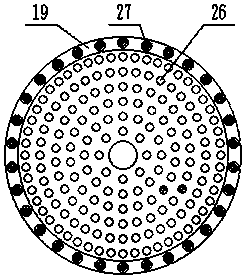

Efficient tea screening device

InactiveCN109261486AReduce noiseExtended service lifeSievingPre-extraction tea treatmentEngineeringTea leaf

The invention discloses an efficient tea screening device. The device comprises a rack, a screening cylinder and multiple screen cylinders, wherein the screen cylinders are coaxially arranged and sequentially sleeved with one another from inside to outside; the screening cylinder is fixedly mounted on the rack, one end of each screen cylinder is rotatably mounted on the rack through a rotating shaft, the apertures of mesh holes of the multiple layers of screen cylinders are sequentially decreased from inside to outside, a feeding port communicated with the exterior of the screening cylinder isformed in the upper end of the innermost screen cylinder, and discharge openings communicated with the exterior of the screening cylinder are formed in the bottoms of the lower ends of the screeningcylinder and screen cylinders respectively. No vibration is caused, the operation is stable, the noise is small, and the service life of the device is long; compared with the traditional tea circularscreening machines, the tea screening device has the advantages of being simple in structure, small in occupied space, high in screening speed and efficiency and large in working load; meanwhile, teascreening is conducted from inside to outside, the screening effect is great, and the efficiency is high.

Owner:赖小琴

An automatic processing equipment for tea screening and coarse frying

InactiveCN106311586BRealize multi-level automatic screening functionShort sieving timeSievingPre-extraction tea treatmentEngineeringAutomatic processing

Owner:广州香雪海贸易有限公司

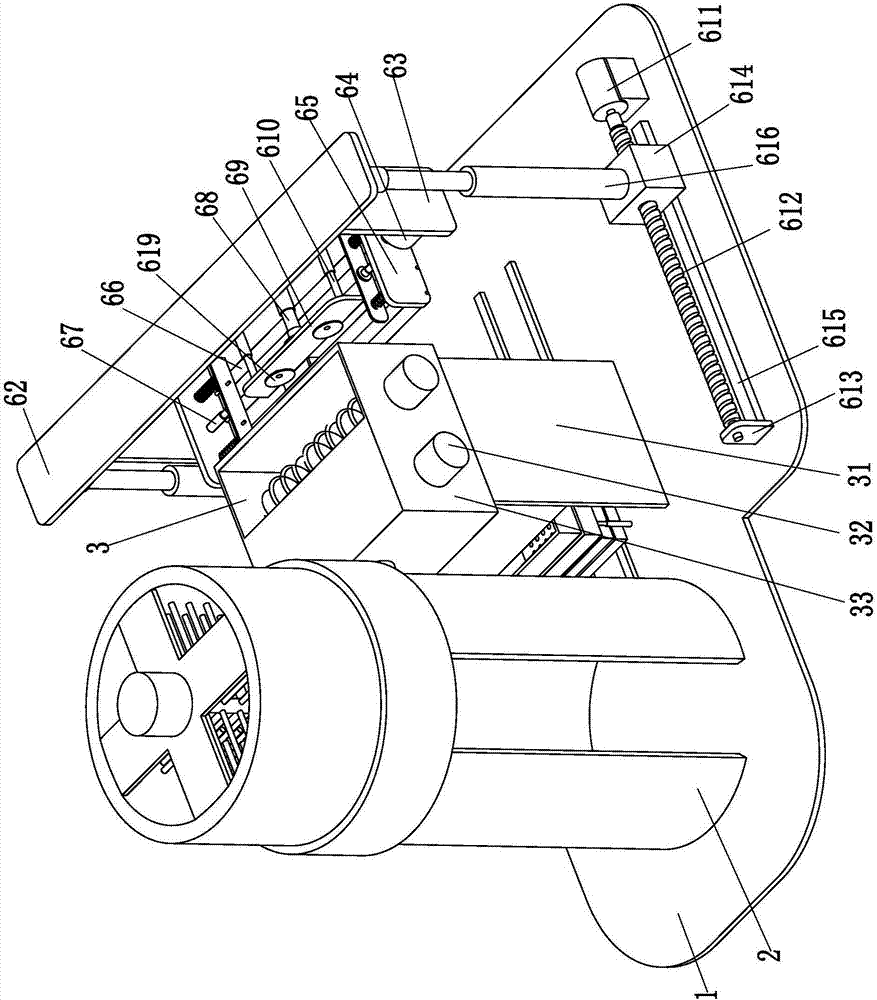

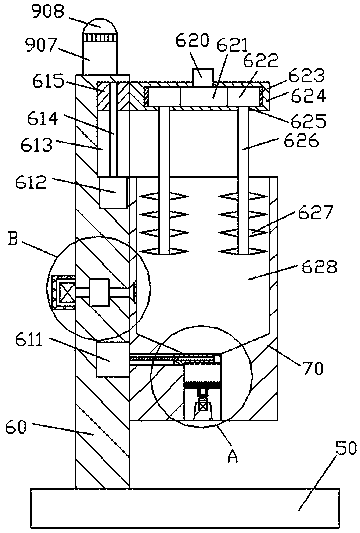

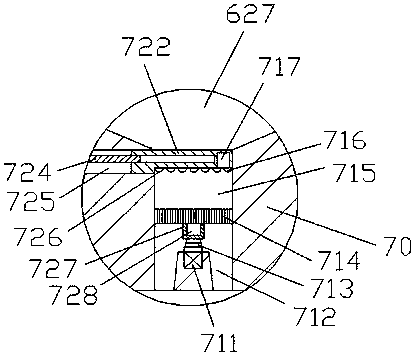

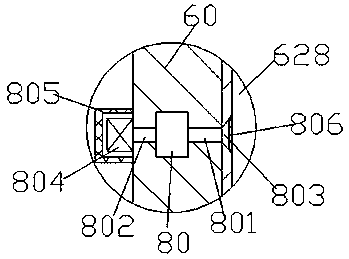

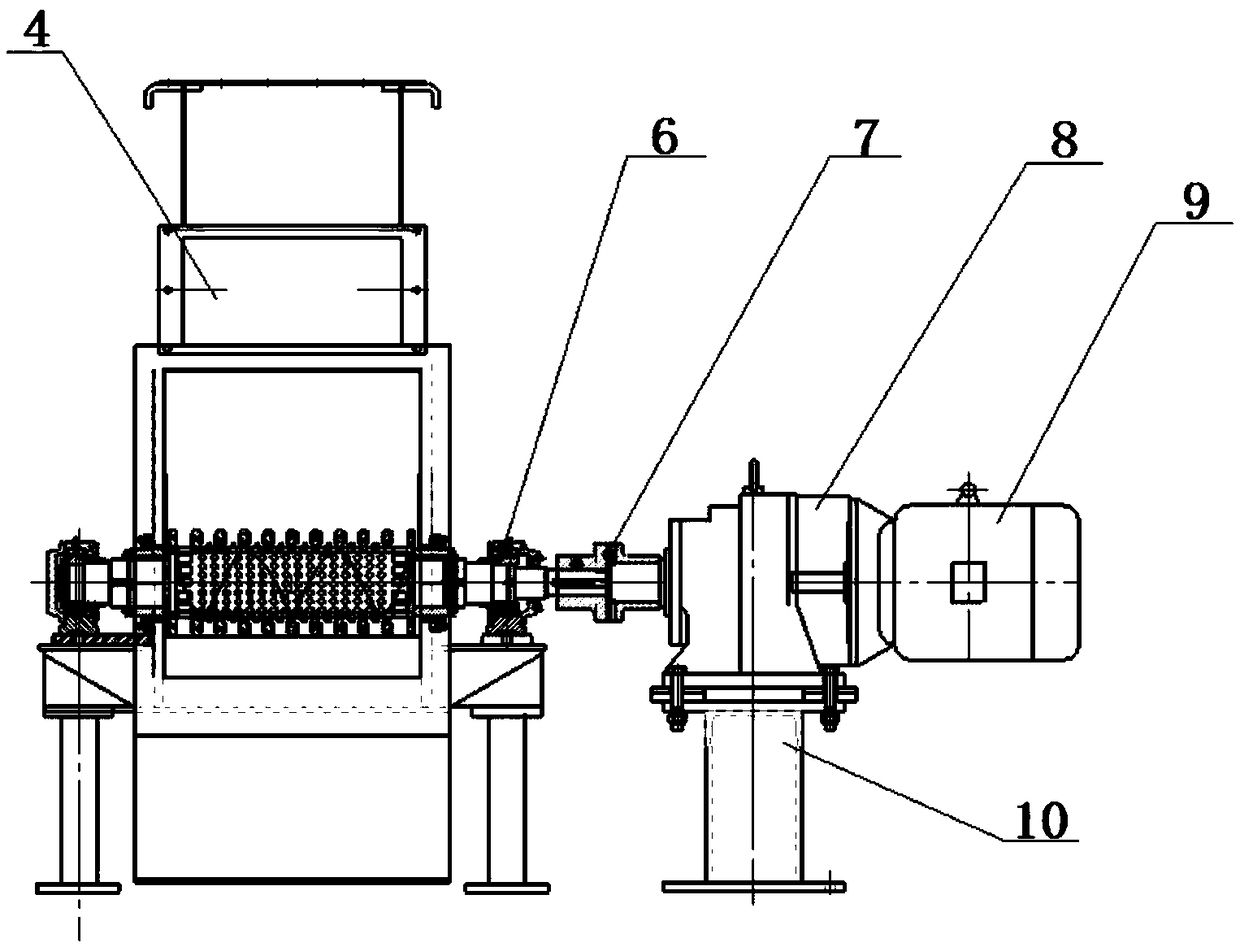

Screening and crushing integrated machine for capsules

ActiveCN106269478ARealize automatic screening functionImprove screening effectSievingScreeningEngineering

The invention relates to a screening and crushing integrated machine for capsules. The device comprises a base plate, wherein a capsule screening device is arranged on the left side of the upper end face of the base plate; the capsule screening device can realize a function of automatically screening the unqualified capsules; a capsule crushing device is arranged on the right side of the upper end face of the base plate; the capsule crushing device can realize the function of automatically crushing and reusing the unqualified capsules; the capsule screening device comprises a screening branch plate which is arranged on the left side of the upper end face of the base plate; a screening frame is arranged in the middle of the screening branch plate; two pairs of fixing lugs are symmetrically arranged on the upper end face of the screening frame; a rotating lug is arranged between each pair of fixing lugs through a pin shaft; the two rotating lugs arranged between the two pairs of fixing lugs are symmetrically arranged on the middle part of the lower end face of a screening box respectively; and the screening frame is capable of rotating on the two pairs of fixing lugs through two rotating lugs. The screening and crushing integrated machine for capsules can realize the functions of automatically screening, crushing and reutilizing the unqualified capsules.

Owner:徐州科悦电子科技有限公司

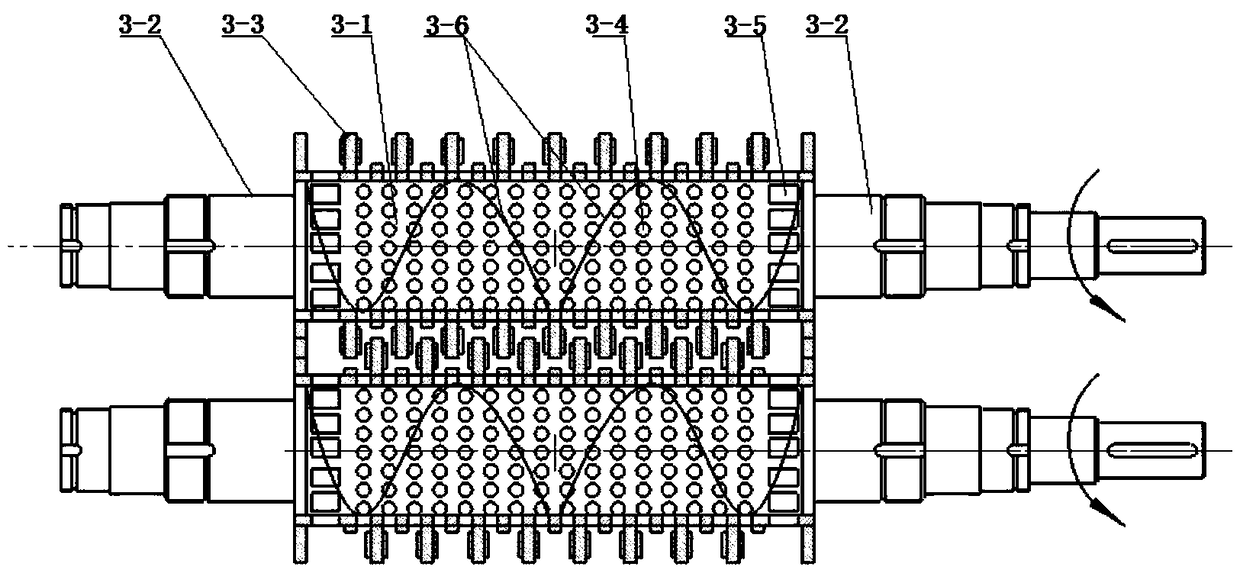

Bracing wire type hanging and folding screen

The invention discloses a bracing wire type hanging and folding screen for tests and belongs to the field of test room analyzing tools. The bracing wire type hanging and folding screen for tests comprises a screen cavity combined body, a screen box and a bracing wire mechanism. The screen cavity combined body comprises an upper static cavity, an upper swinging screen cavity, a shaking screen cavity, a lower swinging screen cavity and a lower static cavity. The double side faces of each screen cavity of the screen cavity combined body are provided with screen frames and screen nets. When the screen cavities of the screen cavity combined body are pulled left and right, variable-angle turning can be achieved, and the screen cavity combined body is fixed in the screen box. The bracing wire mechanism is used for controlling all the screen cavities in the screen box to shake from the outside of the screen box, so that the screen faces of all the screen cavities face upwards and face downwards alternately. When the bracing wire type hanging and folding screen is used for wet type screening, left and right alternate pulling is used for overturning pulp layers in the screen cavities, and the screen box is overturned vertically to improve the penetrating screening efficiency. The test tool has the beneficial effects of being free of power supply, capable achieving clean manual screening and capable of facilitating feeding and taking.

Owner:KUNMING UNIV OF SCI & TECH

Improved biomass fuel treatment device

The invention discloses an improved biomass fuel treatment device. The improved biomass fuel treatment device comprises a stand fixedly mounted on the bottom end surface of a support column, and a boxshell fixedly mounted on the right side end surface of the support column; a lifting device is arranged in the right side end surface of the support column on the upper side of the box shell; a cavity is formed in the top end surface of the box shell; the bottom wall in the cavity communicates with a push rising cavity; a first slide cavity penetrating out of the left side end surface of the boxshell is formed in the left side end surface of the box shell between the push rising cavity and the cavity; a baffle plate is slidingly matched and mounted in the first slide cavity; a first screw rod is matched and mounted in the left side end surface of the baffle plate; a first motor is in power fit installation at the extension tail end of the left side of the first screw rod; the first motoris fixedly mounted in the right side end surface of the support column; a concave groove is formed in the right side end of the baffle plate; and multiple sets of grinding teeth are fixedly mounted on the bottom end surface of the concave groove.

Owner:珠海句宸光电科技有限公司

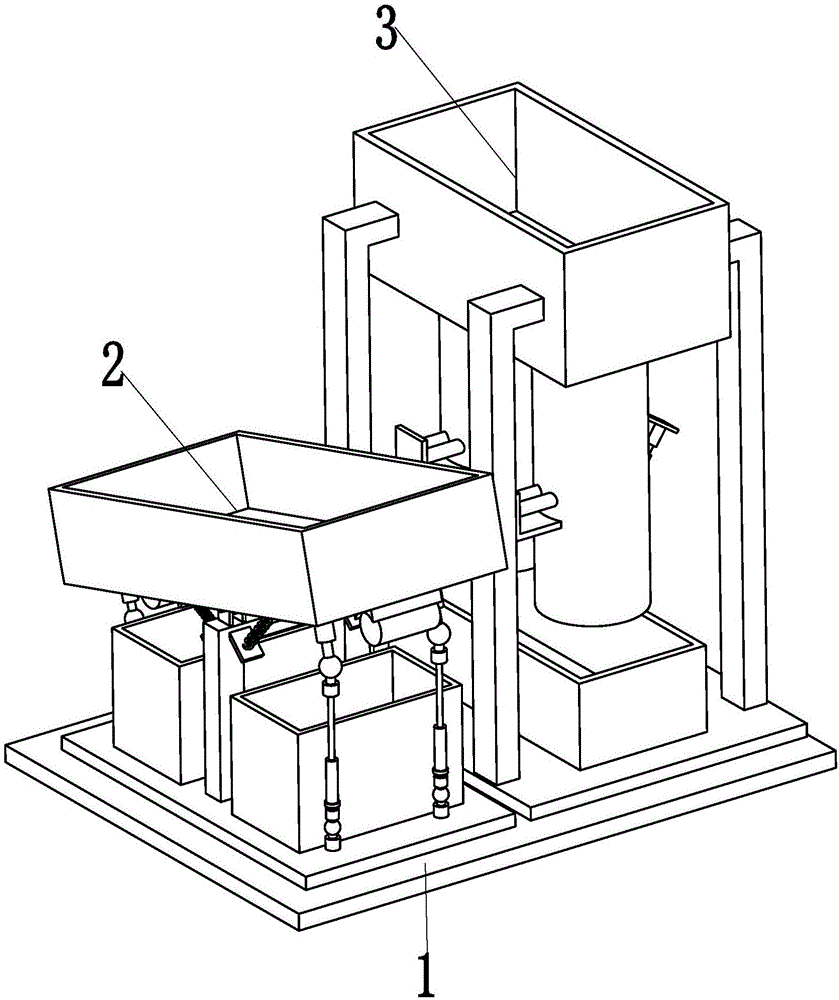

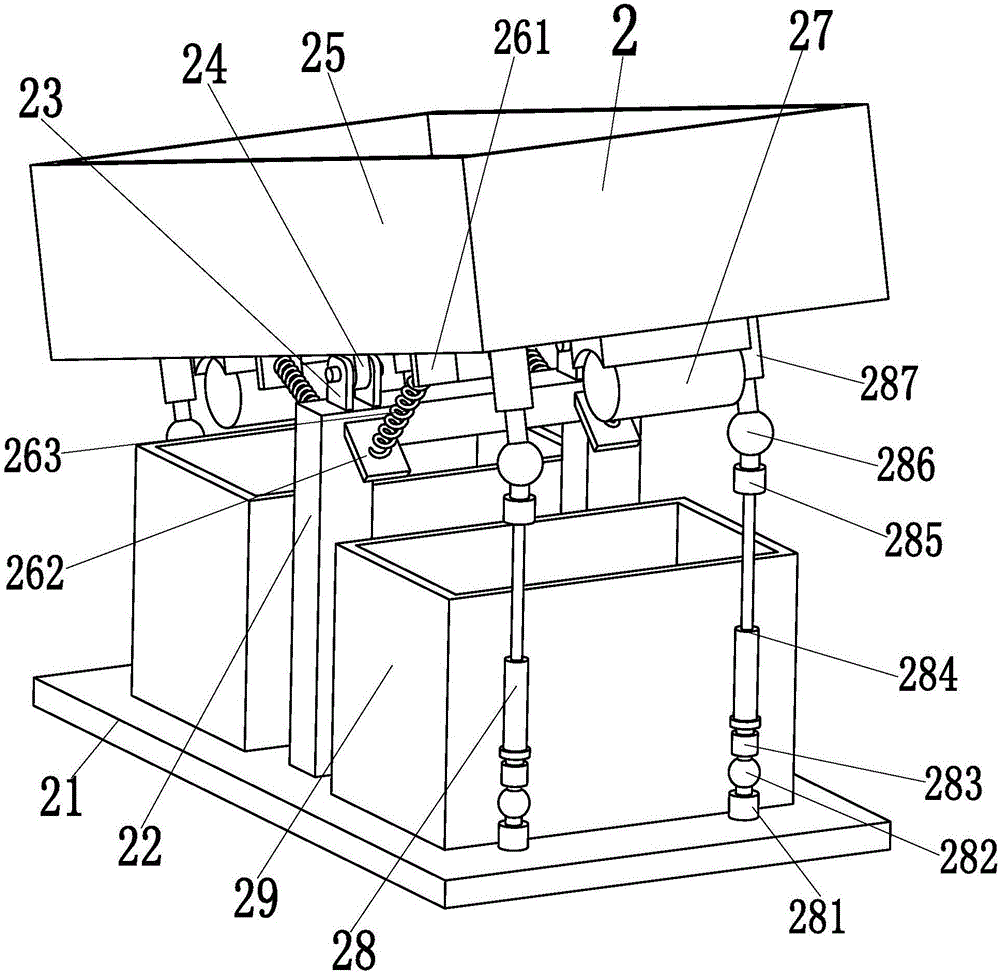

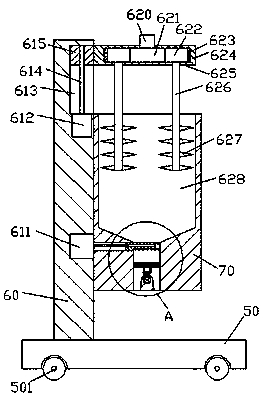

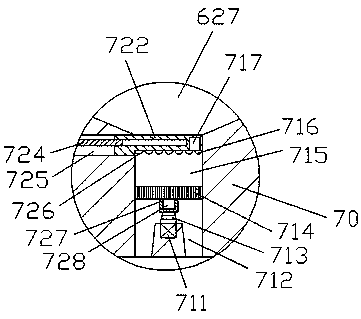

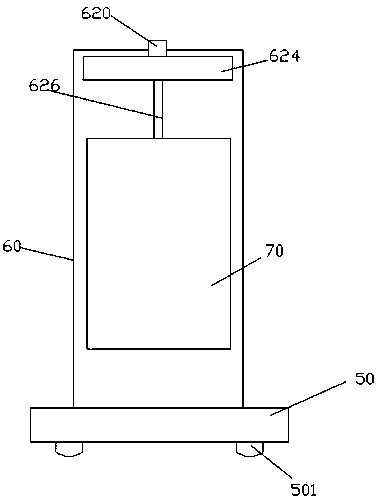

Automatic tea leaf screening and rough-frying processing device

InactiveCN106311586ARealize multi-level automatic screening functionShort sieving timeSievingPre-extraction tea treatmentEngineeringAutomatic processing

The invention relates to an automatic tea leaf screening and rough-frying processing device. The automatic tea leaf screening and rough-frying processing device comprises a base plate. Four universal wheels are symmetrically installed on the lower end face of the base plate; the automatic tea screening and rough-frying processing device can be moved to a processing position through the four universal wheels; a multi-grade screening device is installed at the left side of the upper end face of the base plate and can achieve an automatic multi-grade screening function of tea leaves; a controllable rough-frying device is installed at the right side of the upper end face of the base plate and can achieve a controllable quick rough-frying function of the tea leaves; and rough-frying time is largely shortened by adopting an annular processing mode. The multi-grade screening device comprises a screening supporting plate installed at the left side of the upper end face of the base plate; a collecting box is installed in the middle of the upper end face of the screening supporting plate and has a function of collecting the screened tea leaves; four screening supporting posts are symmetrically installed at the upper end face of the screening supporting plate; and a screening mechanism is installed on the tops of the four screening supporting posts. The automatic tea screening and rough-frying processing device can achieve the integral automatic processing function of screening and rough-frying of the tea leaves, does not need to be operated manually, and is convenient to operate.

Owner:广州香雪海贸易有限公司

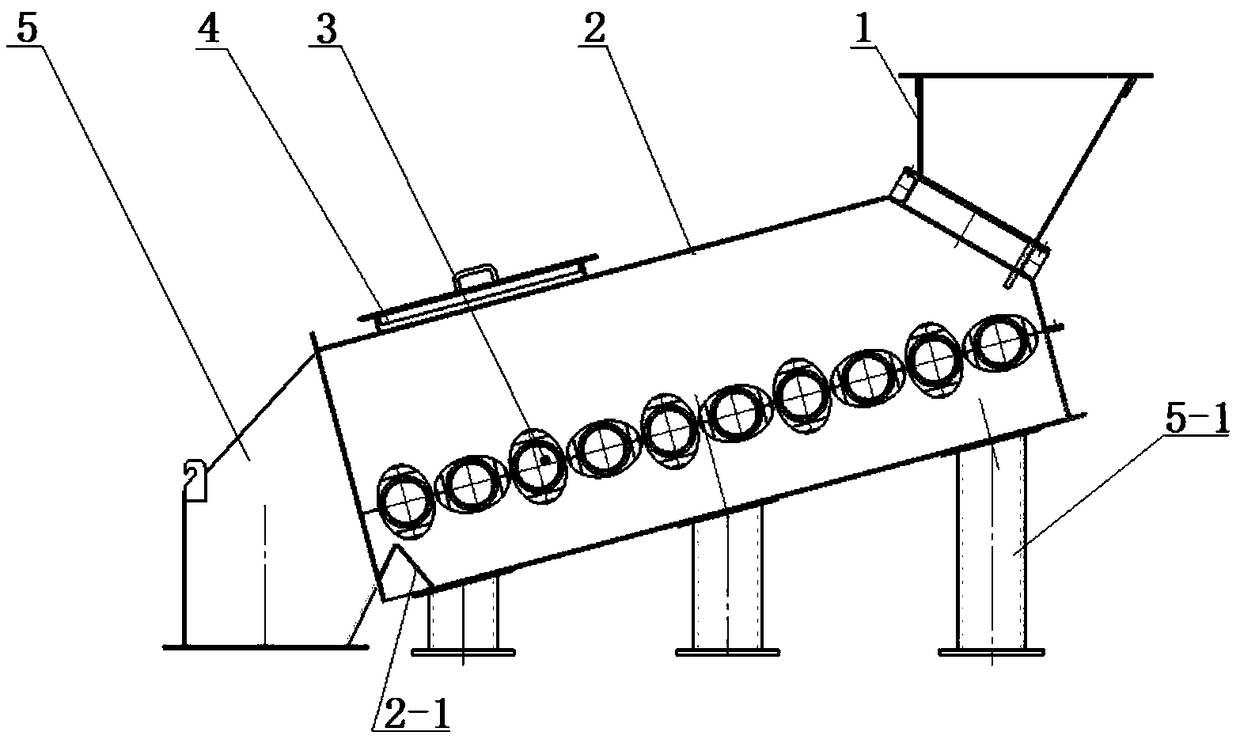

Particle material sieving machine

The invention discloses a particle material sieving machine, comprising a rack; a spindle is arranged on the rack and is rotationally connected with an electric motor-driven sieve drum by a rotary cover and a support arm, wherein openings are formed in two ends of the sieve drum; the opening in the front end of the sieve drum is a charging opening; the opening in the rear end of the sieve drum is a discharging opening; the spindle and the sieve drum are obliquely downwards arranged from front to back; sieve meshes are formed in the drum wall of the sieve drum; the sieve drum is divided into a fine sieve section, a middle sieve section and a thick sieve section from front to back; the sieve meshes in the fine sieve section are smaller than those in the middle sieve section; the sieve meshes in the thick sieve section are larger than those in the middle sieve section; three material outlets arranged by respectively corresponding to the fine sieve section, the middle sieve section and the thick sieve section are formed in the bottom of a material box; the spindle is provided with a cleaning arm extending to the inner wall of the sieve drum. The cleaning arm is provided with a cleaning head capable of cleaning the sieve meshes. The particle material sieving machine has the advantages of high sieving efficiency and good sieving effect.

Owner:秦健

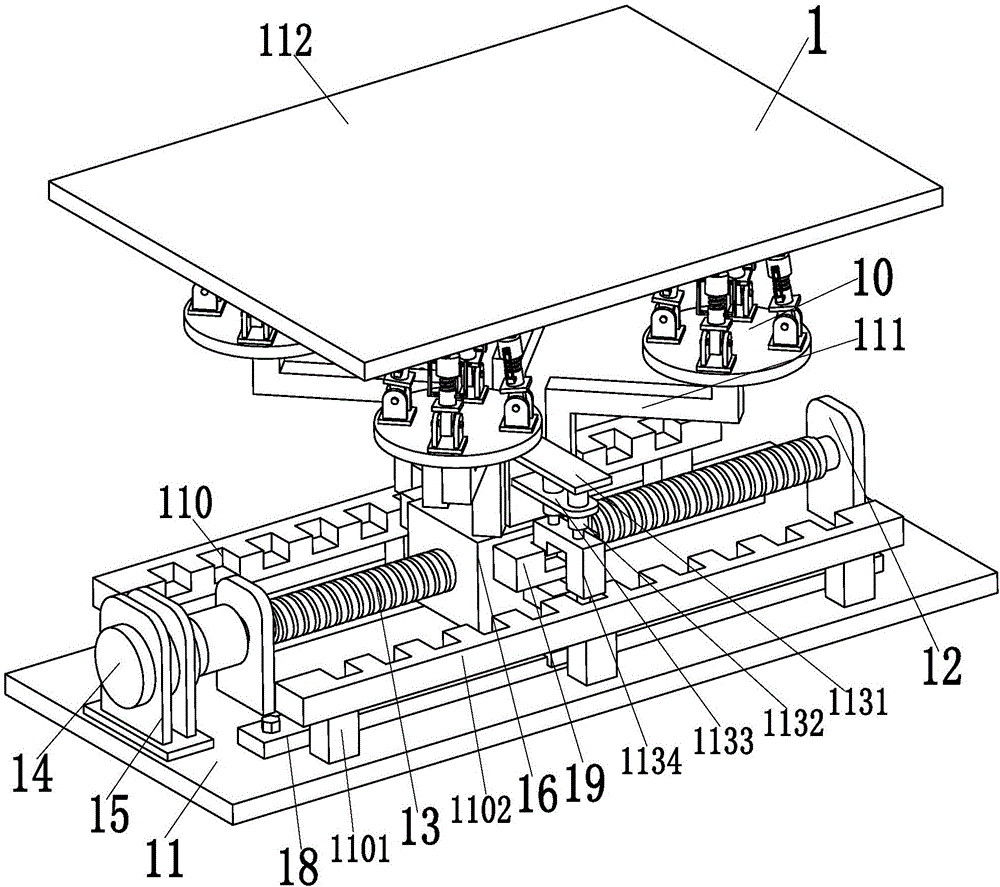

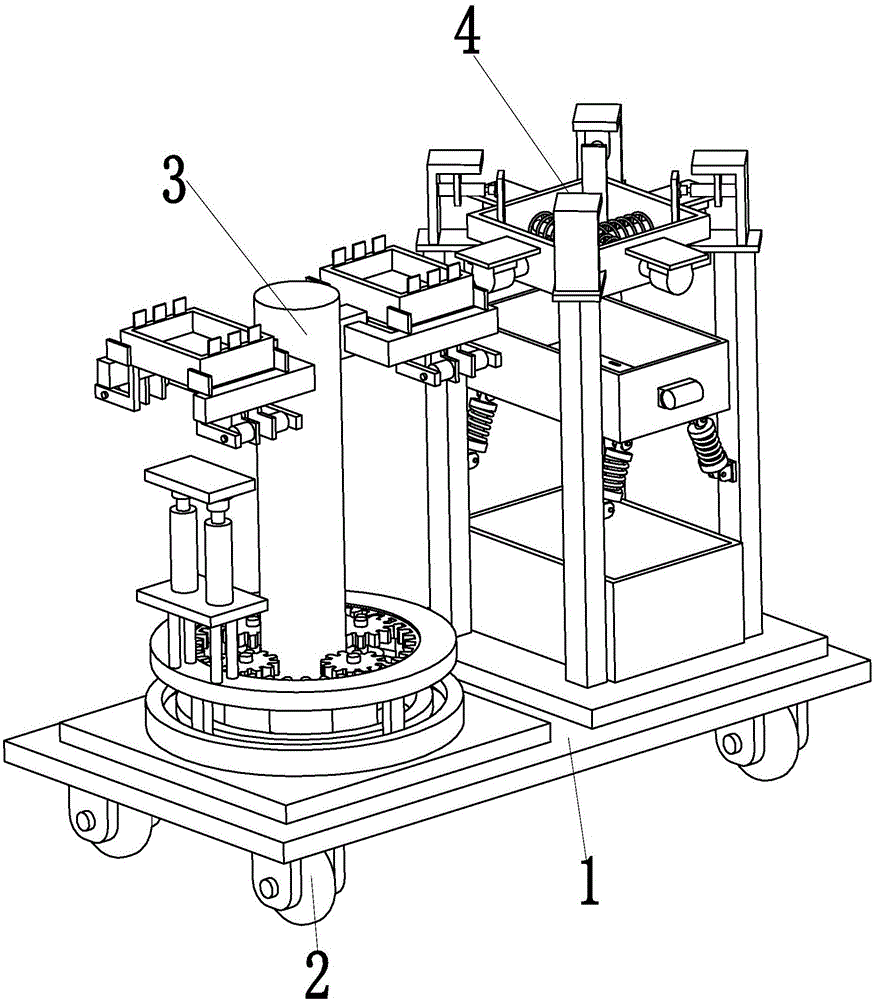

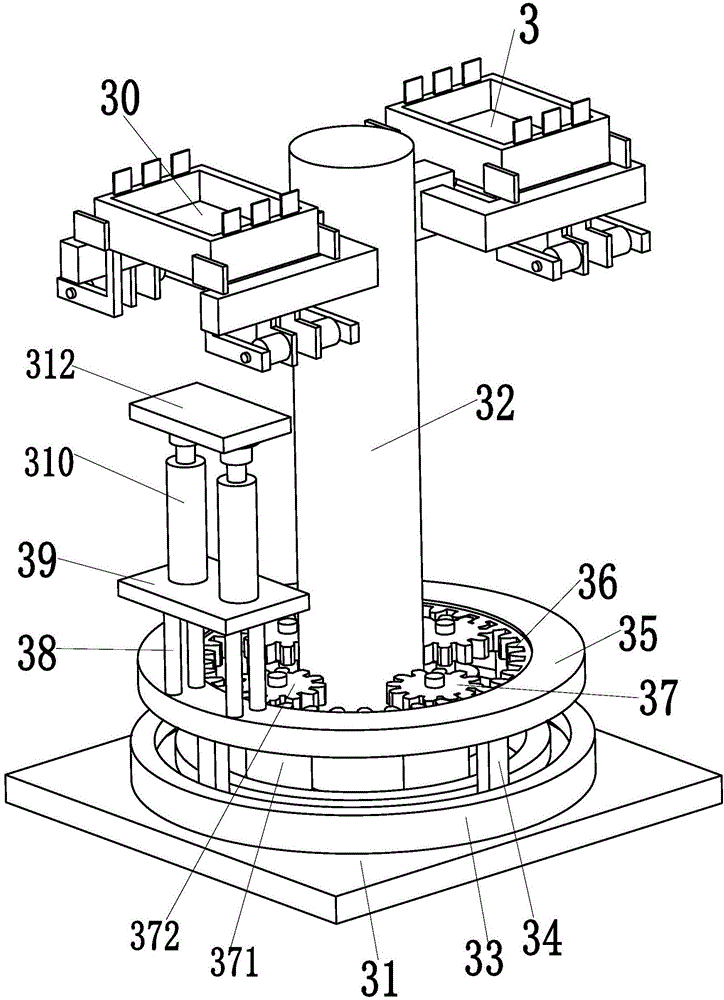

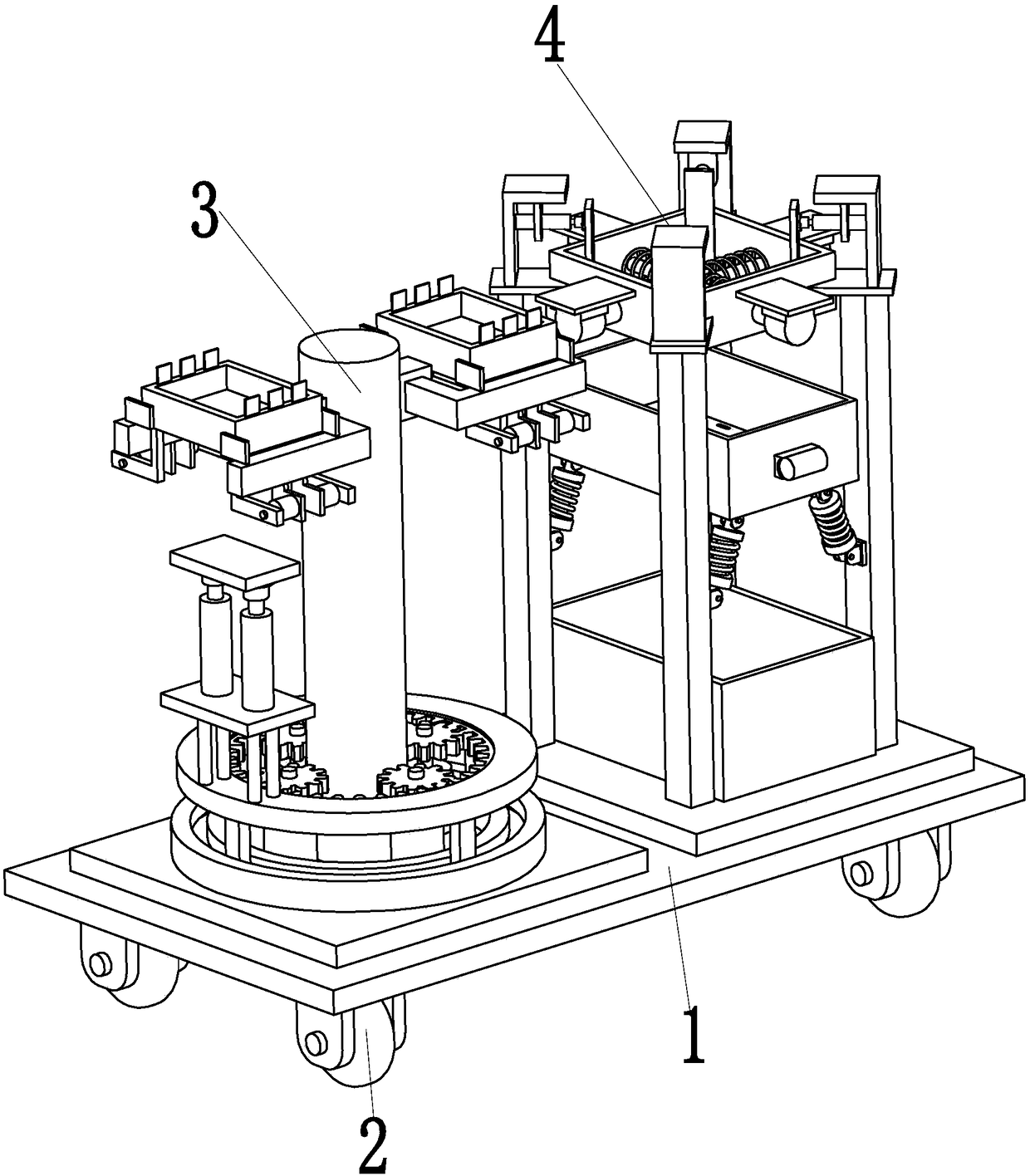

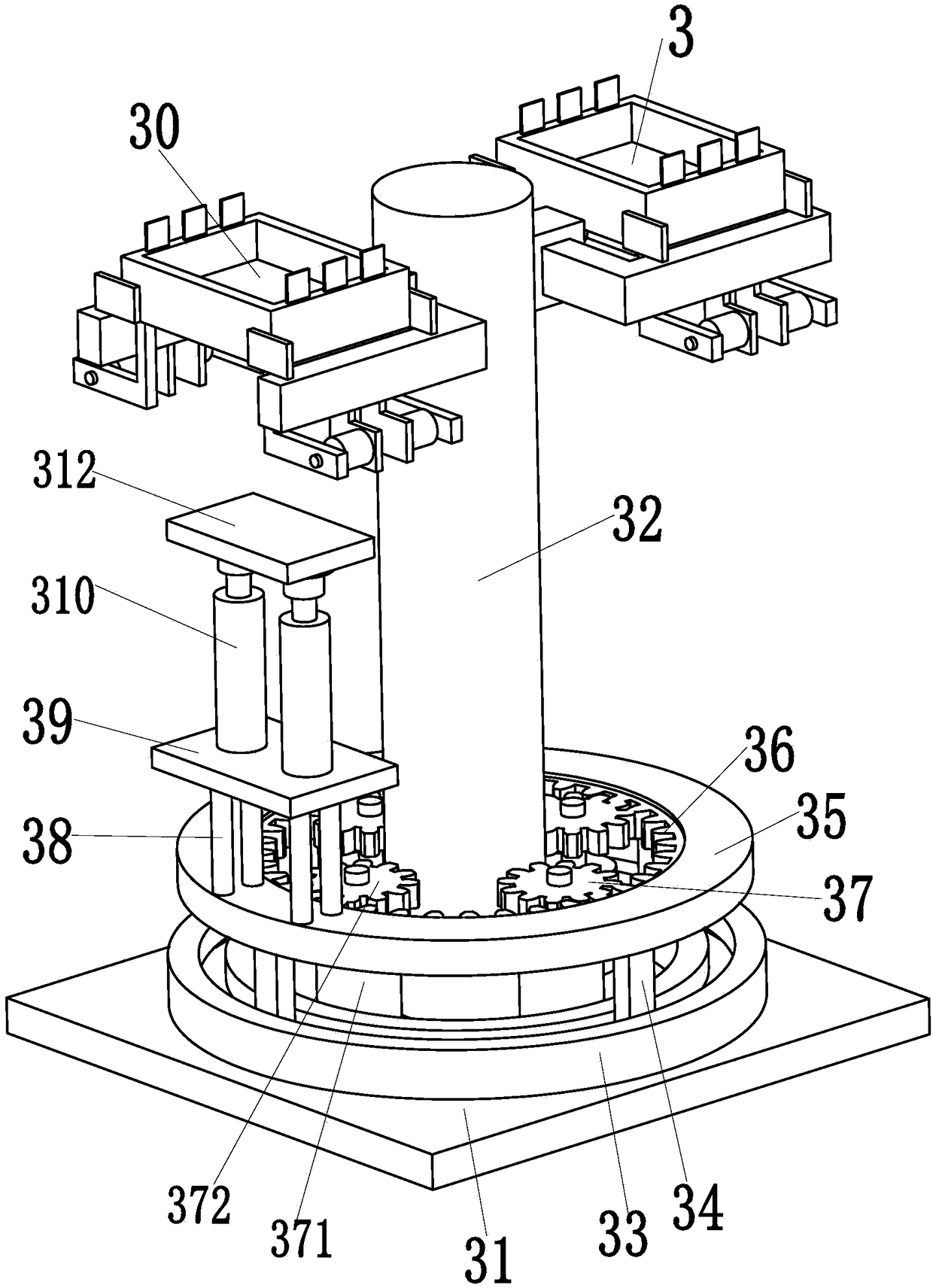

Capsule sieving machine capable of moving precisely

ActiveCN106269479AAccurate Mobile CollectionGood mobile performanceSievingScreeningEngineeringCoupling

The invention relates to a capsule sieving machine capable of moving precisely. The capsule sieving machine comprises a positioning moving device. The positioning moving device can achieve precise moving and collecting functions on capsules, manual taking is not needed, and working efficiency is high. A capsule sieving device is installed on the upper end face of the positioning moving device and can achieve an automatic sieving function on disqualified capsules. The positioning moving device comprises a bottom plate, and two installing lugs are arranged on the upper end face of the bottom plate; and a lead screw is installed between the two installing lugs through bearings, a moving motor is installed at the left end of the lead screw through a coupler, and the moving motor is installed on a motor support. The precise moving and collecting functions on the capsules can be achieved, the automatic sieving function on the disqualified capsules can also be achieved, and the beneficial effects that manual back-and-forth taking is not needed, no shake status exists in the moving and taking process, and equipment mobility performance is good; and the disqualified capsules do not need to be manually sieved, the sieving time is short, the sieving speed is high, the sieving effect is good, and working efficiency is high are achieved.

Owner:山东润安生物科技有限公司

Vibrating type feed powder shaking device for livestock breeding and powder shaking method

ActiveCN113198723ASpeed up sievingEasy to separateSievingFeeding-stuffAnimal scienceLivestock breeding

The invention discloses a vibration type feed powder shaking device for livestock breeding and a powder shaking method, and relates to the technical field of feed powder shaking. Under the action of two vibration parts, feed in powder shaking parts continuously shakes, the inner wall of a powder shaking box is fixedly connected to a guide plate, the problems that an existing feed screening mode is generally simple in structure, so that a screen is only provided, a vibration mode matches and the feed is screened by inflow water, the mode possibly has many defects, the screening effect on impurities gathered together on the screen is possibly poor through the pure vibration mode, the quality of the feed obtained after screening is reduced due to the fact that the feed at the edge position of the screen cannot be effectively screened at the same time, and due to long-time screening, the impurities on the surface of the screen are too many and cannot be synchronously discharged, and the powder shaking efficiency and effect are poor are solved.

Owner:GUANGDONG OCEAN UNIVERSITY

Fully-automatic processing device for tea leaves

ActiveCN106172939AUniform transmission forceGood transmission effectPre-extraction tea treatmentScreening effectEngineering

The invention relates to a fully-automatic processing device for tea leaves. The fully-automatic processing device comprises a base plate, wherein the lower end surface of the base plate is symmetrically provided with four universal wheels; the fully-automatic processing device is moved to the position of processing through the four universal wheels; the left side of the upper end surface of the base plate is provided with a spotlighting tedding unit which can realize the function of rapid spotlighting tedding of the tea leaves, greatly shortens tedding time and has rapid tedding speed and good tedding effect; the central part of the upper end surface of the base plate is provided with a multistage screening unit which can realize the function of multistage automatic screening of the tea leaves and has short screening time, rapid screening speed and good screening effect; and the right side of the upper end surface of the base plate is provided with a controllable rough stir-frying unit which can realize the function of rapid controllable rough stir-frying of the tea leaves, greatly shortens rough stir-frying time by adopting a circular processing manner and has good effect of crude tea leaves. The fully-automatic processing device for the tea leaves provided by the invention can realize integrated automatic processing functions of tedding, screening and rough stir-frying of the tea leaves, does not need manual operation, is simple and convenient to operate, and has high degree of automation.

Owner:武汉大雾山茶业有限公司

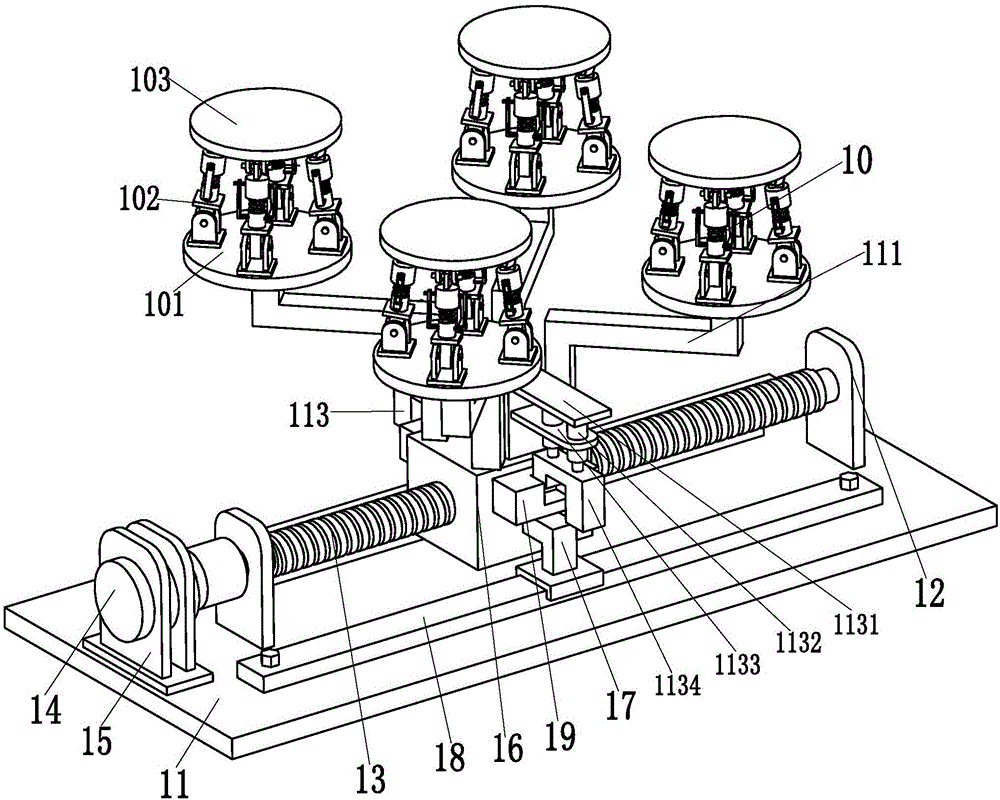

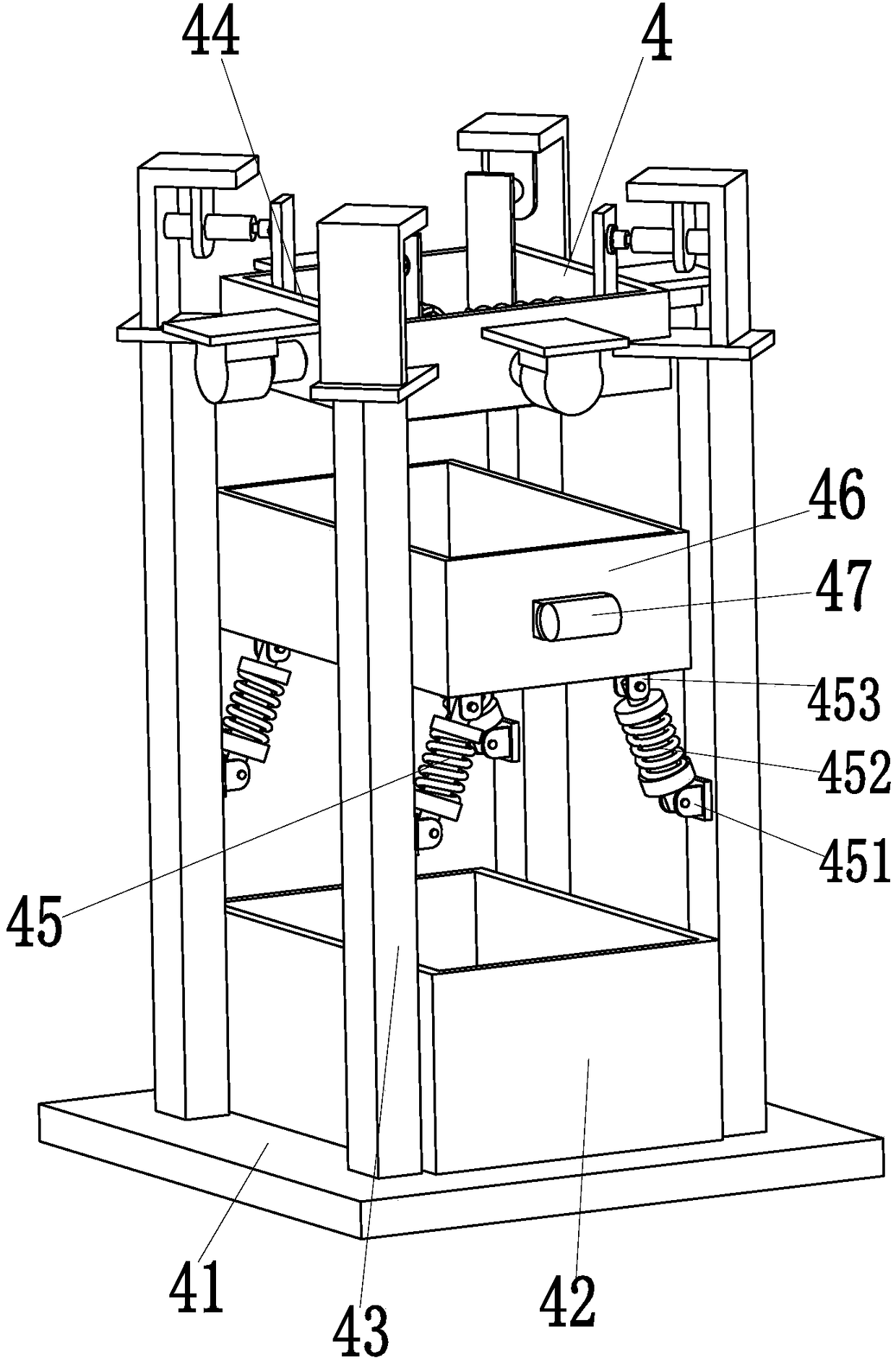

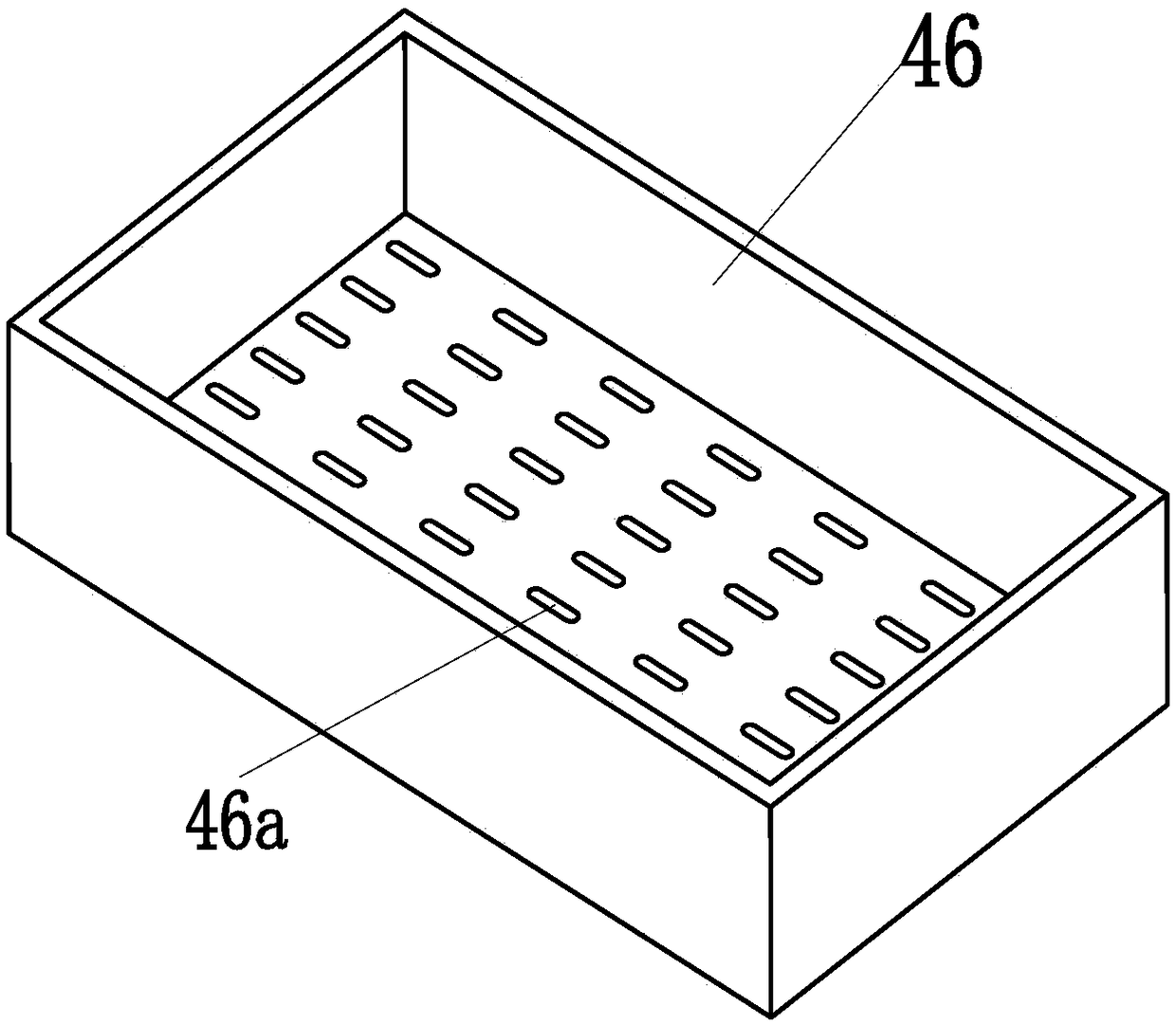

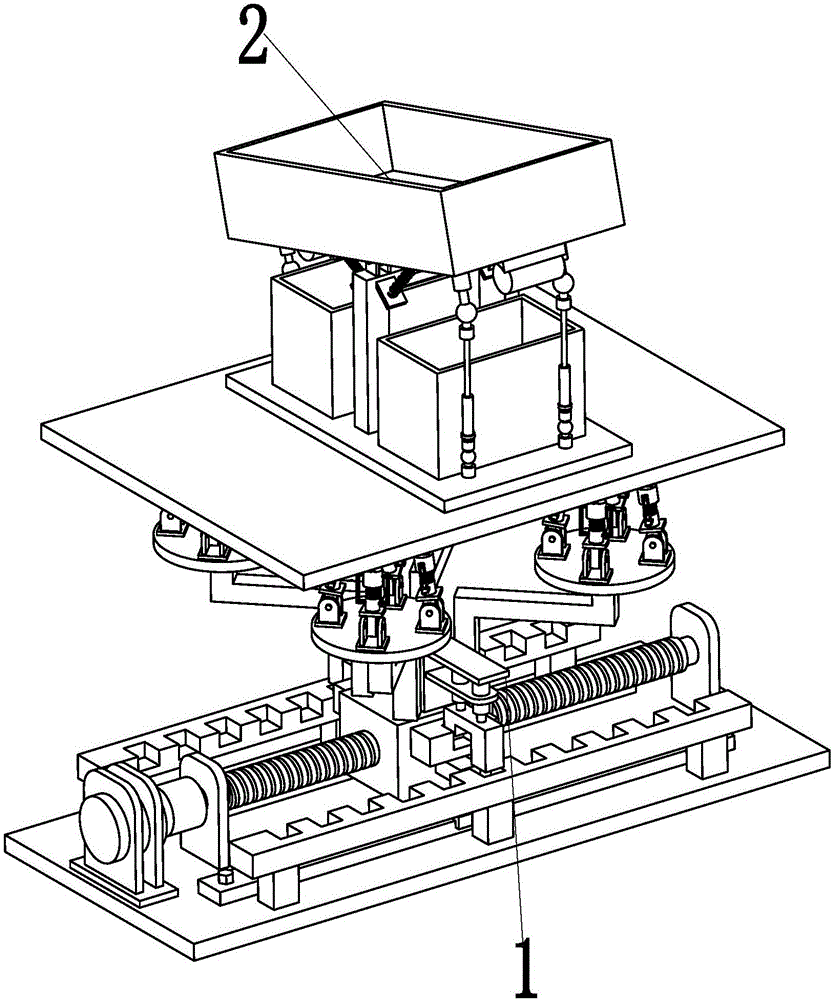

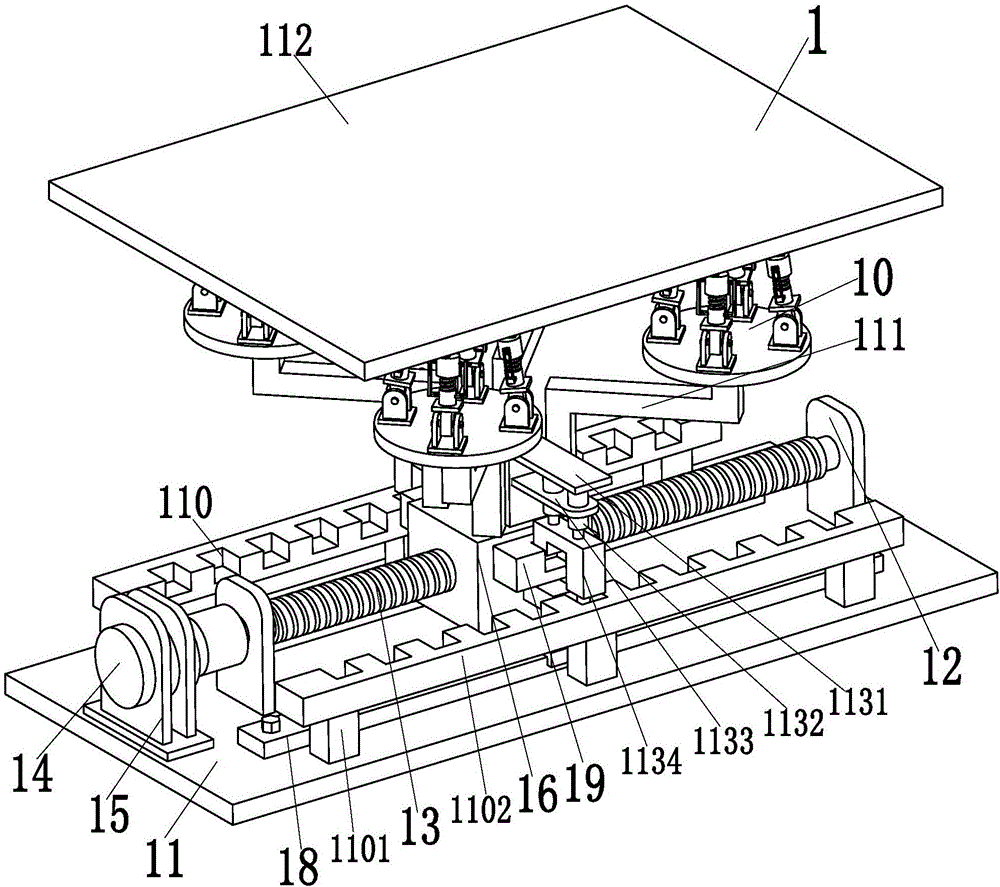

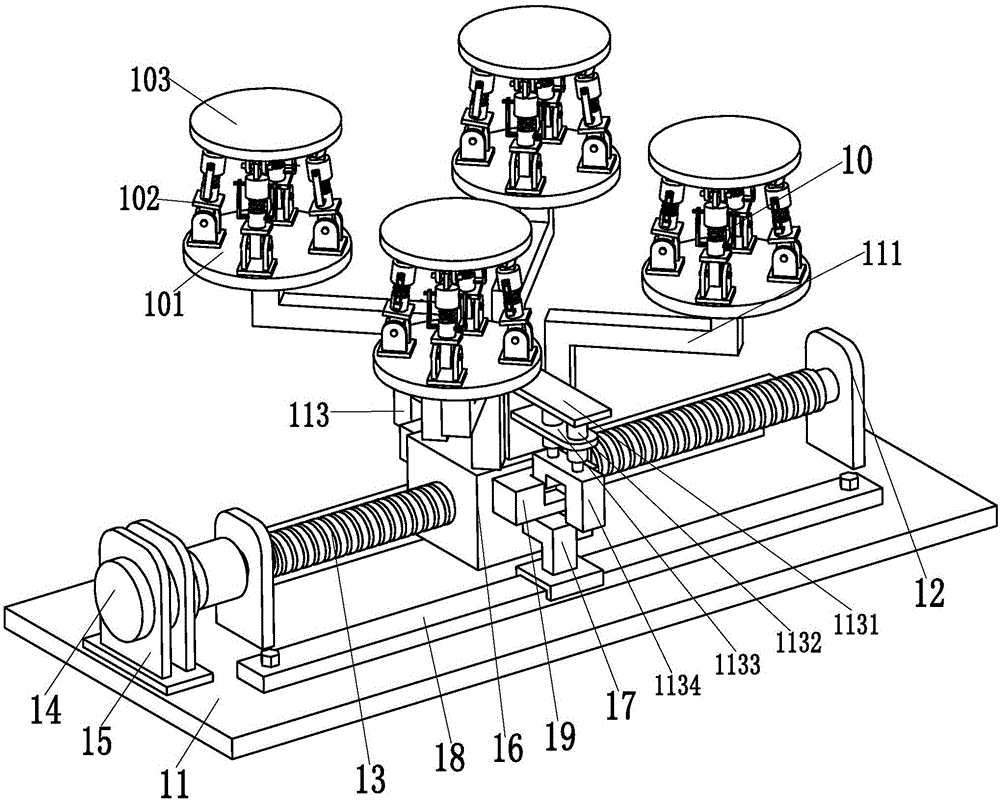

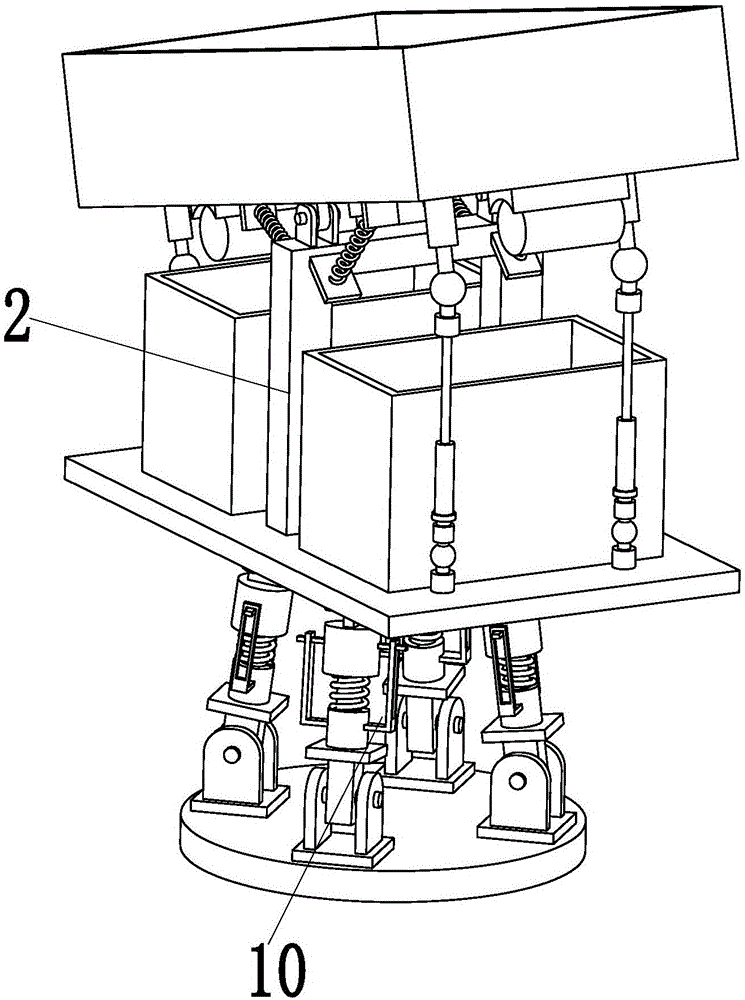

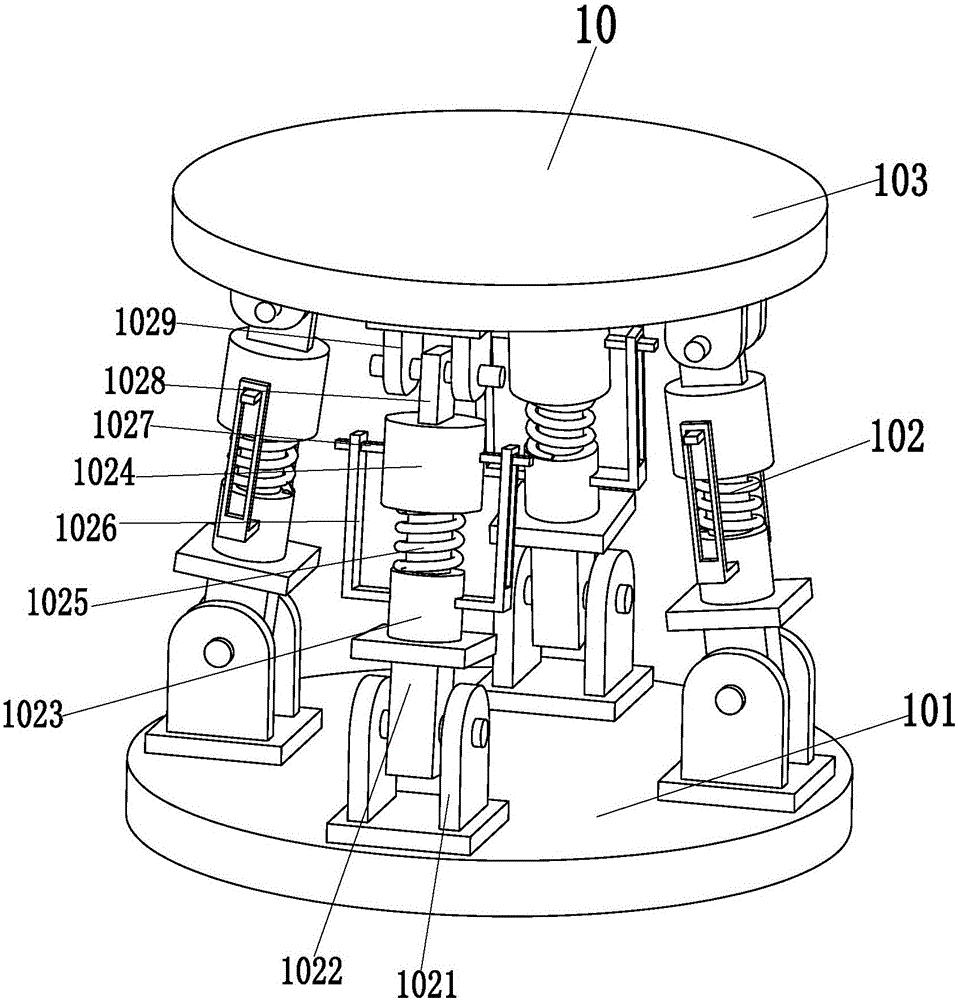

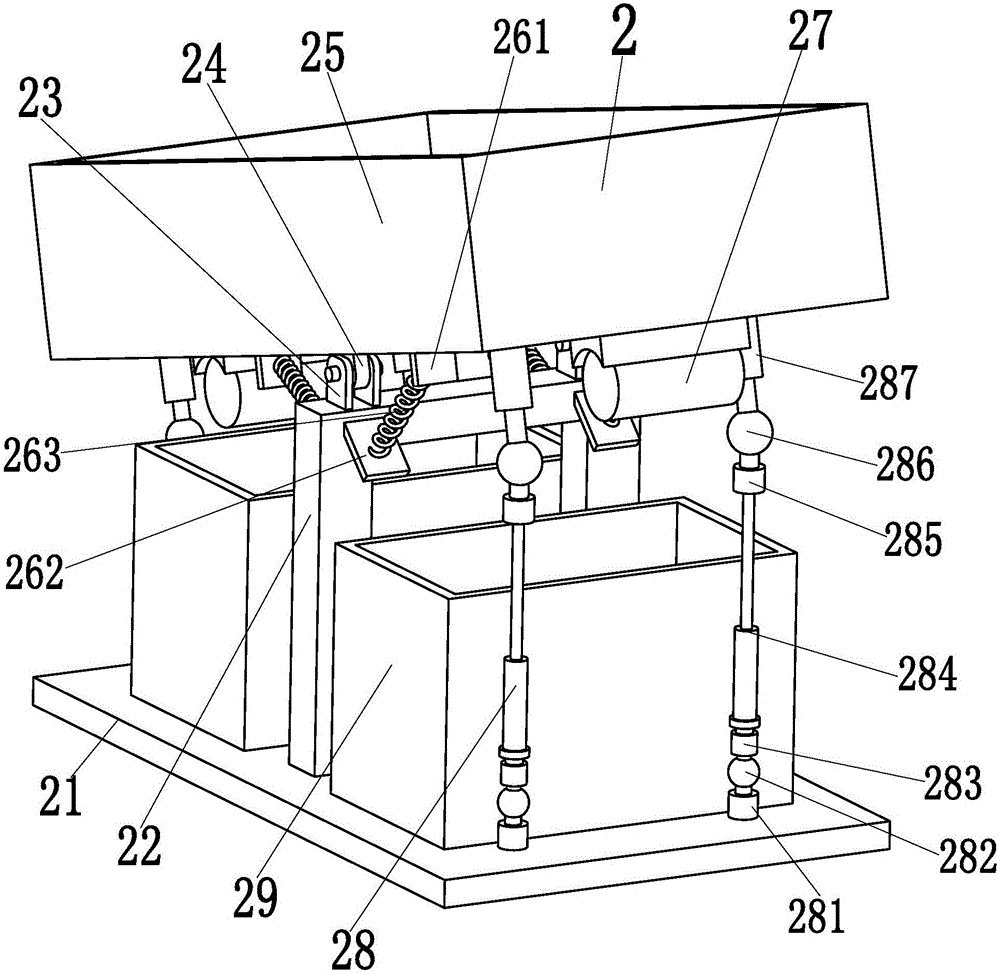

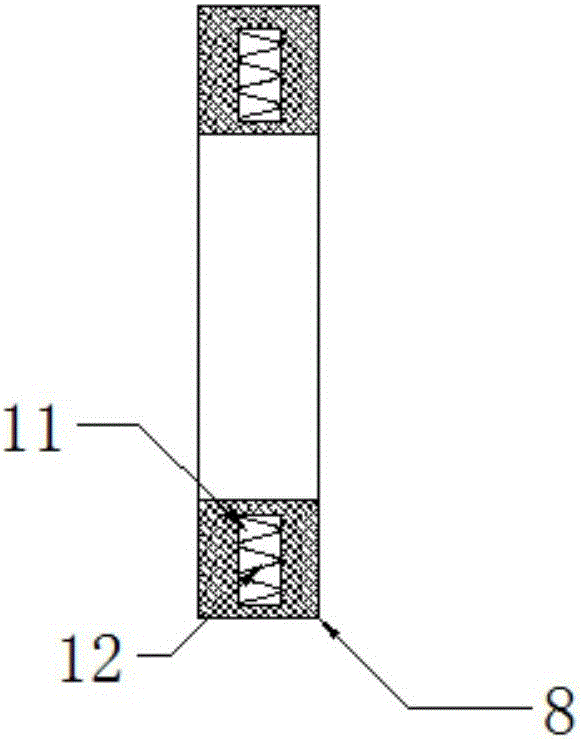

Capsule screening mechanism based on parallel mechanism

ActiveCN106311597AImprove stabilityImprove dynamic performanceSievingScreeningScreening effectDamping function

The invention relates to a capsule screening mechanism based on a parallel mechanism. The capsule screening mechanism comprises a damping mechanism with good damping effect; a capsule screening device is mounted on the upper end surface of the damping mechanism, and can realize an automatic screening function of unqualified capsules; the damping mechanism comprises a lower damping table; the upper end surface of the lower damping table is uniformly equipped with four damping branched chains in the axial direction; the top ends of the four damping branched chains are mounted on the lower end surface of the upper damping table; and the four damping branched chains are uniformly distributed between the lower damping table and the upper damping table, so that the damping mechanism achieves a uniform damping function on the capsule screening device. The capsule screening mechanism based on the parallel mechanism can realize the stable automatic screening function of unqualified capsules without manual operation, and has the advantages that a shaking condition is avoided in a working process, the unqualified capsules do not needed to be manually screened, screening time is short, screening speed is high, screening effect is good, working efficiency is high and the like.

Owner:JIANGXI YINTAO PHARMACEUTICAL CO LTD

Drum type dry corn kernel screening device for agriculture

InactiveCN108080269ASimple structureGood screening effectSievingGas current separationDrive motorAgriculture

The invention discloses a drum type dry corn kernel screening device for agriculture. The drum type dry corn kernel screening device comprises a device body. A base is arranged on the bottom of the device body. A screening cavity is formed above the base. A drive motor is arranged on the top of the screening cavity. A feeding opening is formed in the top of the screening cavity. The device body isprovided with a material collecting bin. A fan is arranged on the base. A dust collecting bin is arranged on the left side of the device body. The device body is provided with a screening mechanism.The drum type dry corn kernel screening device is simple in structure, materials are screened in a rolling manner, the screening effect is good, the screening speed is high, the positions of the materials in a drum change fast, the good screening effect is achieved, moreover, in the screening and feeding process, by means of the effect of discharging paddles, blocking of the feeding opening is effectively avoided, moreover, dust in the materials are treated in the whole process, the quality obtained after screening is improved, the use effect is good, and practicality is high.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Material jamming preventing rotary screen

InactiveCN106179943AIncrease screening speedSimple structureSievingRotating vibration suppressionCouplingDrive shaft

The invention provides a material jamming preventing rotary screen. The material jamming preventing rotary screen comprises a shell, a feeding port, a screen opening, a rotary screen drum, vibration-preventing bearings, a transmission shaft, a servo motor, damping washers, a vibration generator, a discharging port, damping cavities and damping springs. The feeding port is formed in the top end of the shell, and the discharging port is formed in the bottom end of the shell. The coaxial transmission shaft is arranged in the shell. The transmission shaft is assembled in the shell through the vibration-preventing bearings, and the end portion of the transmission shaft is fixed to an output shaft of the servo motor through a coupler. The rotary screen drum is fixed to the transmission shaft and can rotate along with rotation of the transmission shaft. The vibration generator is arranged on the rotary screen drum. The damping washers are arranged between the rotary screen drum and the transmission shaft. The damping cavities extending in the radial direction are evenly arranged in the damping washers. Each damping cavity is internally provided with the corresponding damping spring. The material jamming preventing rotary screen has the beneficial effects that material jamming is prevented, and the running stability is high.

Owner:TIANJIN SHIYIDE FERTILIZER

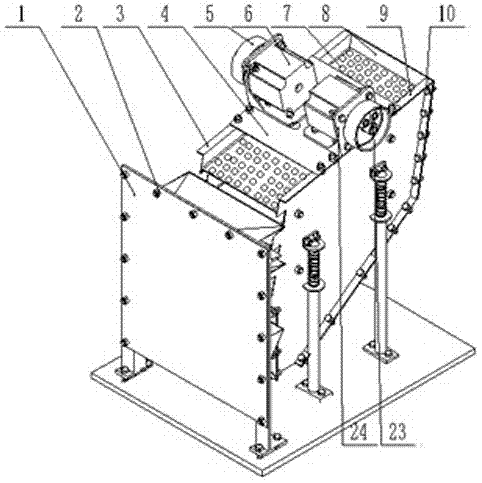

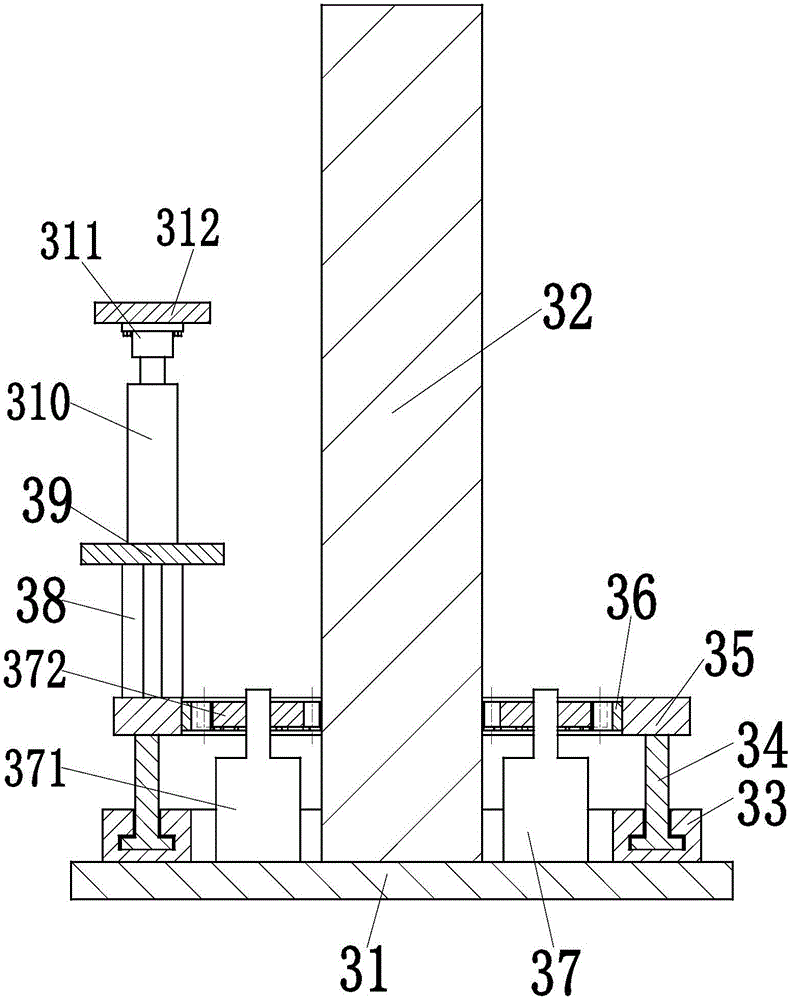

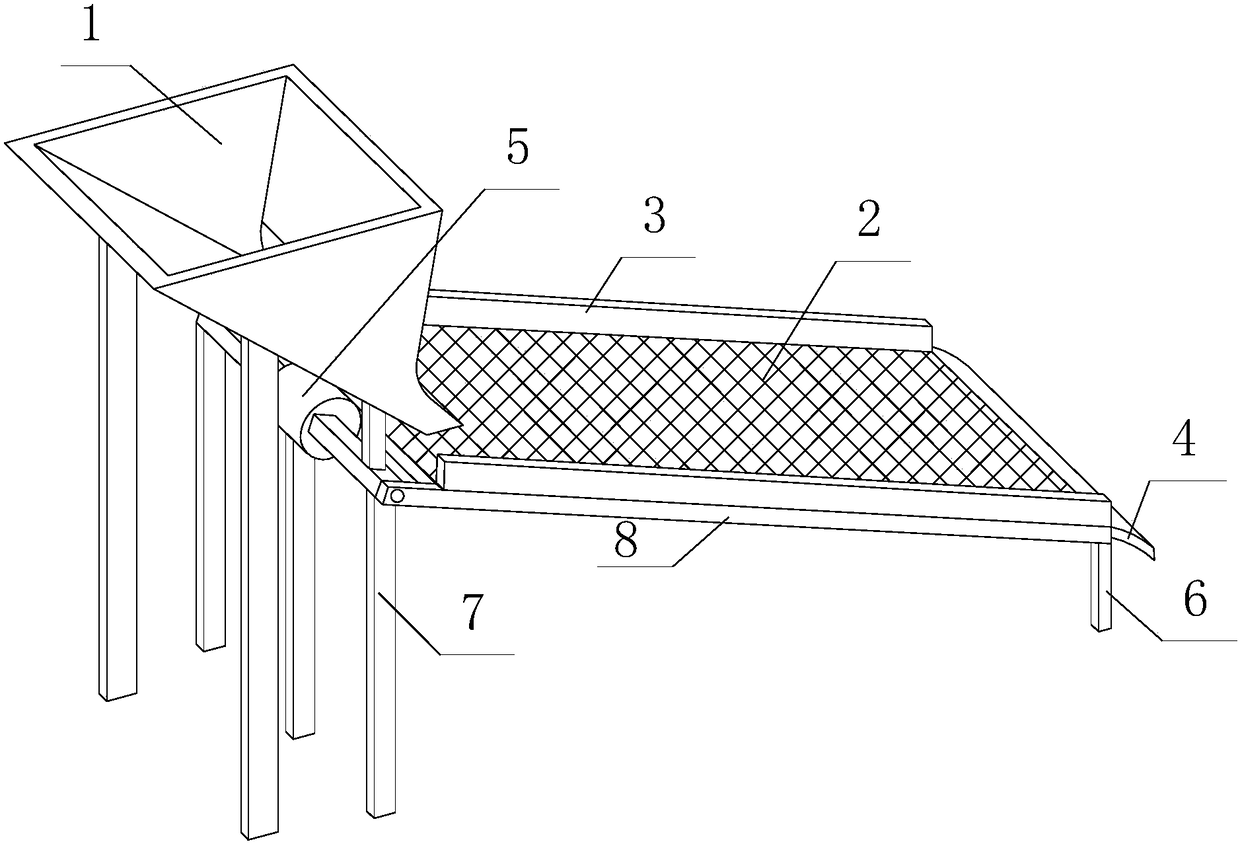

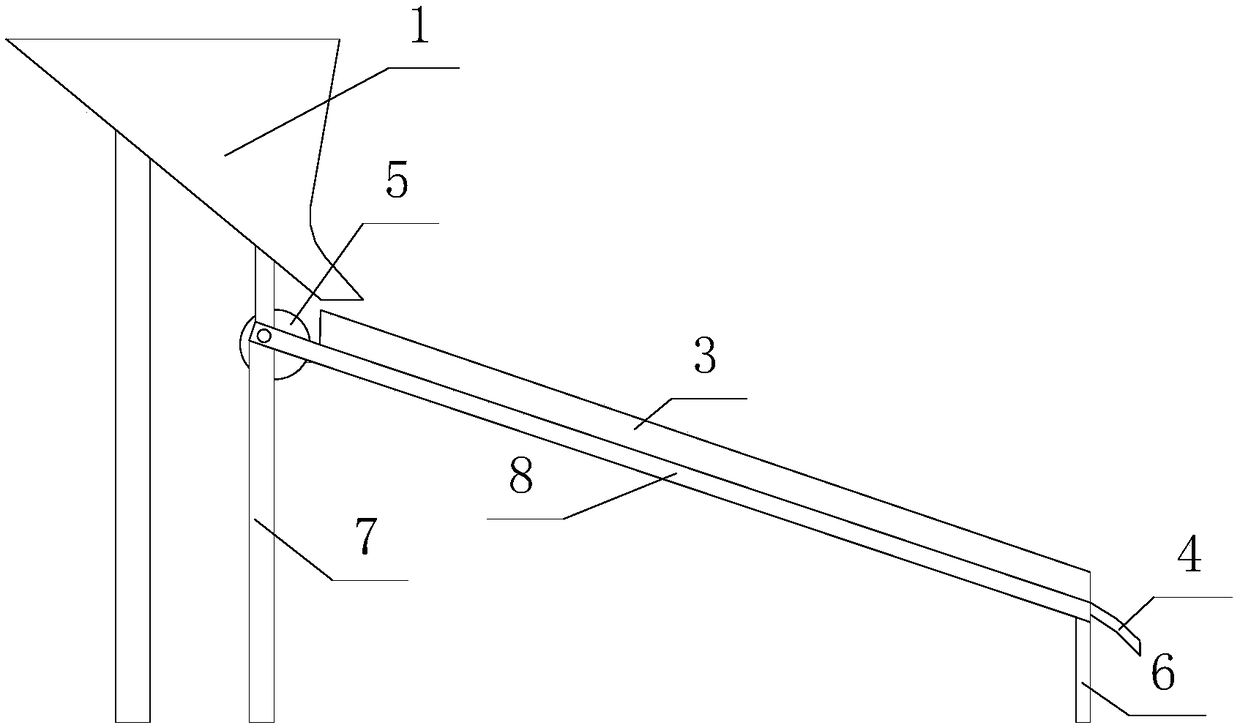

Sand sieving machine for constructional engineering

InactiveCN108325816ASimple structureScreening speed is fastSievingScreeningReciprocating motionArchitectural engineering

The invention provides a sand sieving machine for constructional engineering. The sand sieving machine for constructional engineering comprises a telescopic rod, a rack and a frame. The frame is arranged inclinedly; a sieve screen is arranged on the surface of the frame; the left end of the frame is hinged to the upper end of the rack; the telescopic rod is arranged on the lower side of the rightend of the frame; a feeding hopper and a vibration motor are arranged at the upper end of the rack; the vibration motor is located under the feeding hopper and is arranged at the left end of the sievescreen; the left end surface and the right end surface of the feeding hopper are an inclined surface and an arc-shaped surface; and a discharge hole of the feeding hopper is arranged inclinedly. Thesand sieving machine for constructional engineering provided by the invention is simple in structure, and a screen frame can move left and right in a reciprocating way during work so as to be used forautomatically sieving sand, so that a large number of labor force is saved, the sand sieving quality is improved, and a foundation is laid for the next step of procedure.

Owner:方芳

Agricultural funnel type screening device for dried corn kernels

InactiveCN107913851ABig change in positionAvoid cloggingSievingGas current separationScreening effectDrive shaft

The invention discloses an agricultural funnel type screening device for dried corn kernels. The device comprises a device body; a base is arranged at the bottom of the device body; a screening chamber is arranged above the base; a driving motor is arranged at the top of the screening chamber; a driving shaft is arranged at the output end of the driving motor; the device body is provided with a collecting bin; a fan is arranged on the base; a dust collecting bin is arranged on the left side of the device body; the device body is provided with a screening mechanism; and the screening mechanismcomprises an upper screening structure and a lower screening structure. The device is simple in structure, materials are screened by the aid of the funnel type structure, the screening effect is good,the screening speed is high, the positions of the materials are changed greatly by the aid of the double screening mechanism, and the very good screening effect is realized; besides, blockage of a feeding opening is effectively avoided under the effect of discharging paddles during screening feeding; in addition, in the whole process, dust in the materials is processed, so that the quality afterscreening is improved; and the device is good in use effect and high in practicability.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Sand-stone sieve plate device for industry

InactiveCN110479586AImprove screening effectIncrease screening speedSievingScreeningEngineeringPower unit

The invention discloses a sand-stone sieve plate device for the industry. The sand-stone sieve plate device for the industry comprises a bottom plate, a first vibration unit, a sieve frame, a second vibration unit and a power unit, wherein the first vibration unit comprises first fixed plates, first springs and first slide tables; two first fixed plates are arranged, and arranged at the front sideand the rear side of the right end of the upper surface of the bottom plate separately, and through grooves are formed in the side surfaces of the two first fixed plates separately; two first slide tables are arranged; the side surfaces of the two first slide tables are slidably connected with the sidewalls of the through grooves in the side surfaces of the two first fixed plates separately; fourfirst springs are arranged; the upper ends of the two first springs at the upper side are fixedly connected with the tops of the through grooves in the side surfaces of the two first fixed plates separately; and the lower ends of the two first springs at the upper side are fixedly connected with the upper surfaces of the two first slide tables separately. The sand-stone sieve plate device for theindustry is good in sieving effect and low in sieving efficiency, and thorough sand-stone separation after sieving is achieved.

Owner:桑田

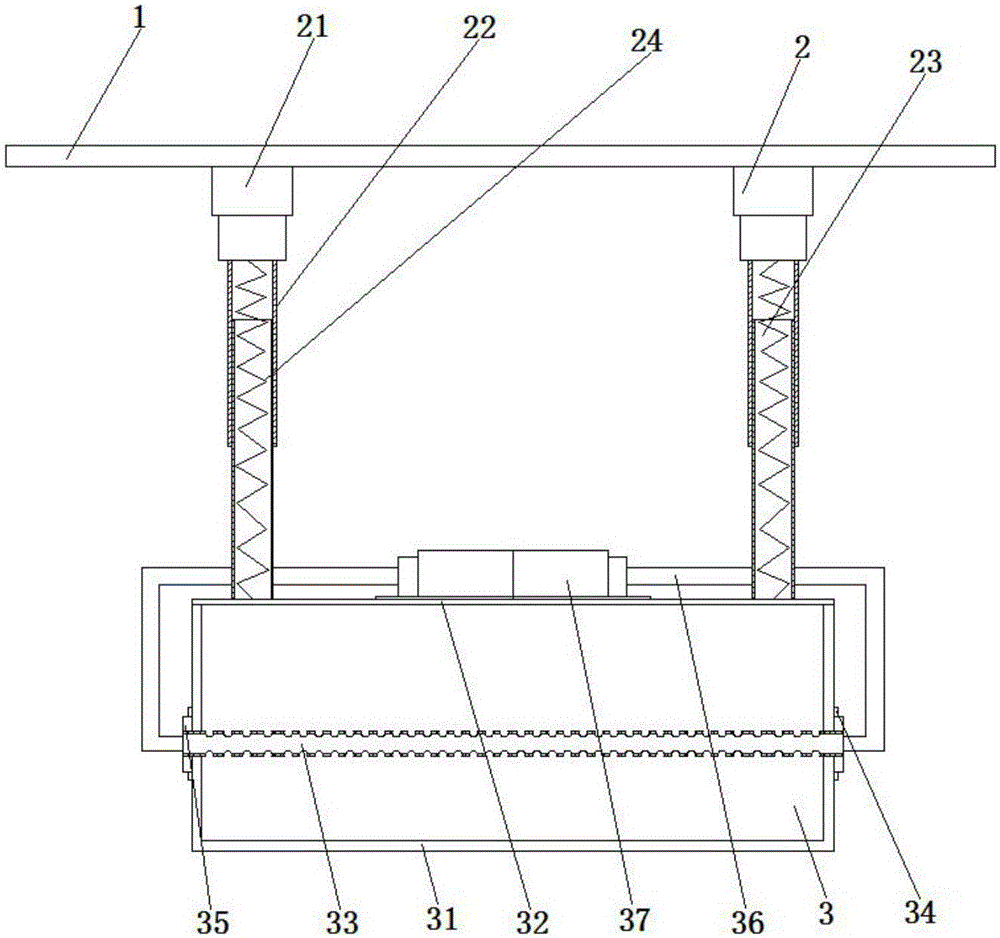

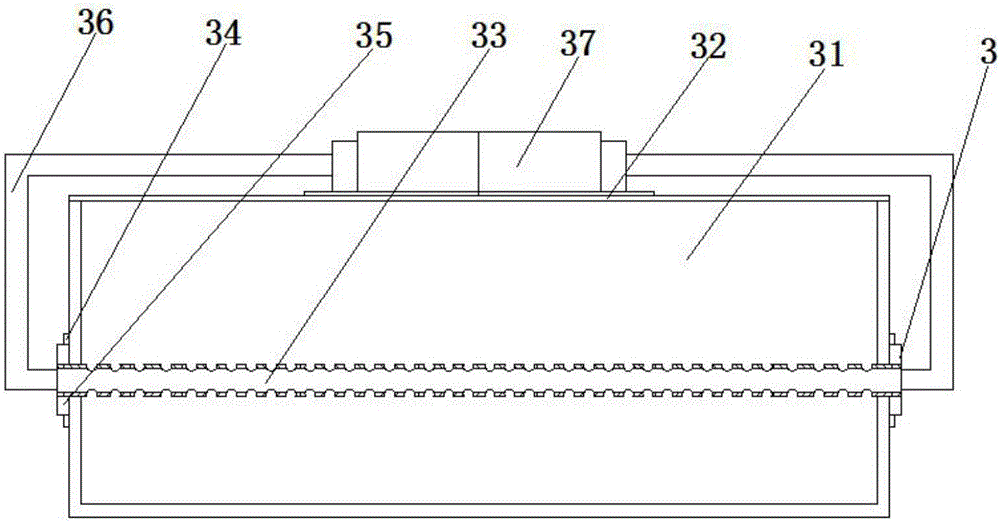

Vertical reciprocating reverse-vibrating type hog bristle screening machine

InactiveCN106513305AImprove cleanlinessFacilitate subsequent processingSievingScreeningBristleAgricultural engineering

The invention relates to a vertical reciprocating reverse-vibrating type hog bristle screening machine which comprises a fixing plate, four reciprocating reverse-vibrating support chains and a screening device. The fixing plate is of a rectangular flat-plate-shaped structure. Threaded installing holes are formed in the fixing plate and are symmetrical with respect to the transverse central axis of the fixing plate. The reciprocating reverse-vibrating support chains are located between the fixing plate and the screening device. The upper ends of the reciprocating reverse-vibrating support chains are connected with the four vertex corners of the fixing plate correspondingly. The lower ends of the reciprocating reverse-vibrating support chains are connected with the screening device. According to the vertical reciprocating reverse-vibrating type hog bristle screening machine, vibrating and stirring are adopted for screening hog bristles, impurities and dust doped in the hog bristles can be removed, the cleanliness of the hog bristles is improved, and convenience is provided for subsequent processing of the hog bristles; and the screening speed is high, operation is easy, and the impurity removing effect is good.

Owner:ANHUI MINGSHAN ORGANIC AGRI TECH DEV

Automated tedding-screening machine for tea manufacturing and processing

ActiveCN108311387APlay a role in concentrating lightSpeed up the tetheringSievingGas current separationScreening effectEngineering

The invention relates to an automated tedding-screening machine for tea manufacturing and processing. The automated tedding-screening machine comprises a baseplate, wherein four universal wheels are symmetrically mounted on the lower end surface of the baseplate; through the universal wheels, the automated tedding-screening machine can be moved to a processing position; a light-concentrating tedding device is mounted on the left side of the upper end surface of the baseplate; through the light-concentrating tedding device, the light-concentrating quick tea tedding function can be achieved; thetedding time is greatly shortened, the tedding speed is high, and the tedding effect is good; a multi-stage screening device is mounted on the right side of the upper end surface of the baseplate; through the multi-stage screening device, the multi-stage automatic tea screening function can be achieved; the screening time is short, the screening speed is high, and the screening effect is good; the light-concentrating tedding device comprises a tedding support plate mounted on the left side of the upper end surface of the baseplate; a mounting cylinder is welded with the middle of the upper end surface of the tedding support plate; and a ring-shaped limiting slot is mounted on the upper end surface of the tedding support plate. By adoption of the automated tedding-screening machine provided by the invention, the tea tedding-screening integrated automatic processing function can be achieved; no manual operation is needed, the operation is simple and convenient; and the degree of automation is high.

Owner:湖南瑶园生态农业科技发展有限公司

Coal slurry sieving equipment

The invention discloses coal slurry sieving equipment. A motor is connected to a sieve drum through a transmission shaft; the left side of the outer surface of the sieve drum is not provided with a sieve pore; the rest positions of the outer surface of the sieve drum are uniformly distributed with sieve pores; the sieve drum and the center shaft of a fine-particle coal slurry collecting barrel are on the same straight line; the fine-particle coal slurry collecting barrel sleeves the outer part of the sieve drum; the left side of the fine-particle coal slurry collecting barrel extends out of the sieve drum; the left side of the fine-particle coal slurry collecting barrel is provided with an anti-leakage plate; the left side of the anti-leakage plate is provided with a sealing ring; the bottom of the fine-particle coal slurry collecting barrel is provided with a fine-particle coal slurry outlet; a slurry inlet and a coarse-particle coal slurry outlet are formed in the cylindrical side plate at the left side of the sieve drum; and a valve is separately arranged on the slurry inlet, the coarse-particle coal slurry outlet and the fine-particle coal slurry outlet.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

Screening machine with large screening area

PendingCN108636754AIncrease the screening areaGood screening effectSievingScreeningPower controlEngineering

The invention discloses a screening machine with a large screening area. The screening machine comprises a machine body and a power control machine; the machine body comprises a feeding inlet, a screening cavity, a coarse material discharging outlet and a plurality of fine material discharging outlets; the screening cavity is internally provided with a plurality of screening rollers, and the multiple screening rollers are obliquely arranged from the top end to the bottom end of the screening cavity; the included angle between every two adjacent screening rollers is 90 degrees; each screening roller comprises a screening barrel, a plurality of first screening holes, a rotary shaft, a plurality of elliptical screening sheets, a plurality of second screening holes and a guide sheet; and the top of the screening cavity is provided with a plurality of automatic material distribution devices. According to the screening machine with the large screening area, compared with traditional screening machines, the screening area is larger, the material blockage, locking and adhesion possibility is reduced, the screening efficiency and quality are improved, and noise is lowered.

Owner:四川皇龙智能破碎技术股份有限公司

Activated carbon breaking plant

InactiveCN108212486APerform shreddingEfficient shreddingGrain treatmentsActivated carbonGRINDING TOOTH

The invention relates to an activated carbon breaking plant which comprises a seat body fixedly installed on the end face of the bottom of a strut and a material box fixedly installed on the end faceof the right side of the strut. Rolling wheels are arranged at the bottom of the seat body in a rolling manner, a jacking device is arranged at the position, in the end face of the right side of the strut, of the upper side of the material box, a material cavity is arranged in the end face of the top of the material box, a pushing cavity is arranged on the inner bottom wall of the material cavityin a communicating manner, a first sliding connection cavity penetrating out of the end face of the left side of the material box is arranged in the end face of the left side of the material and arrange between the pushing cavity and the material cavity, a shielding plate is installed in the first sliding connection cavity in a sliding connection fit manner, a first spiral rod is installed on theend face of the left side of the shielding plate in a matched manner, a first motor is installed on a left-side extending tip of the first spiral rod and is fixedly installed on the end face of the right side of the strut, a sinking hole is formed in the right side of the shielding plate, and a plurality of grinding teeth are fixedly installed on the end face of the bottom of the sinking hole.

Owner:广州峥航机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com