Patents

Literature

47results about How to "Sieve evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

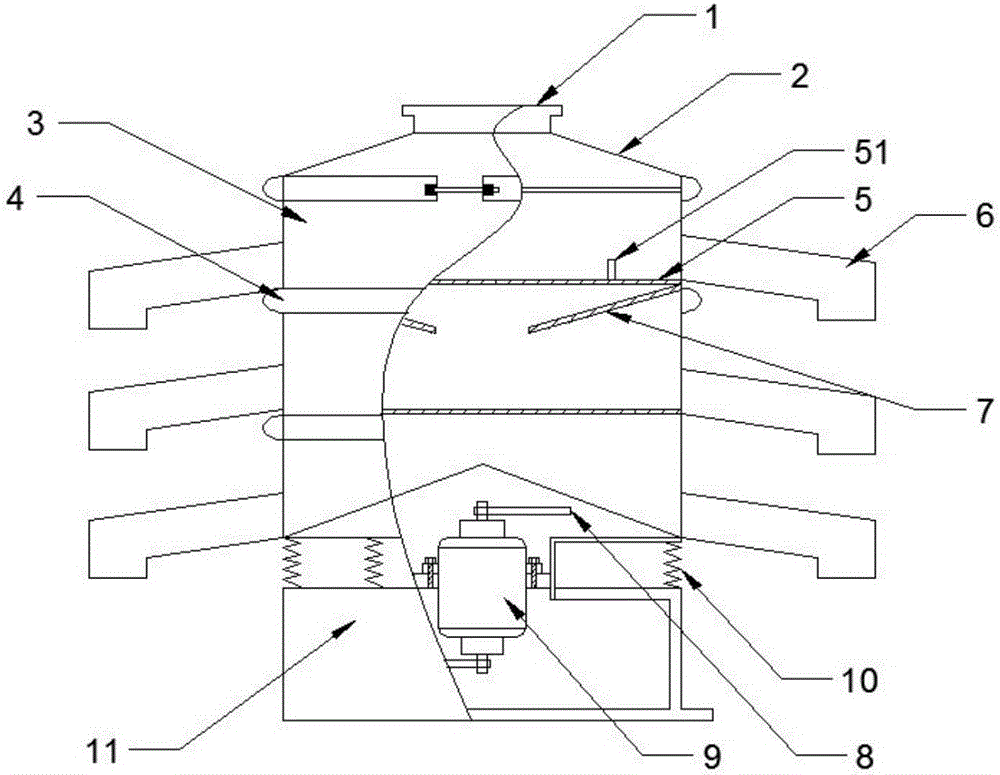

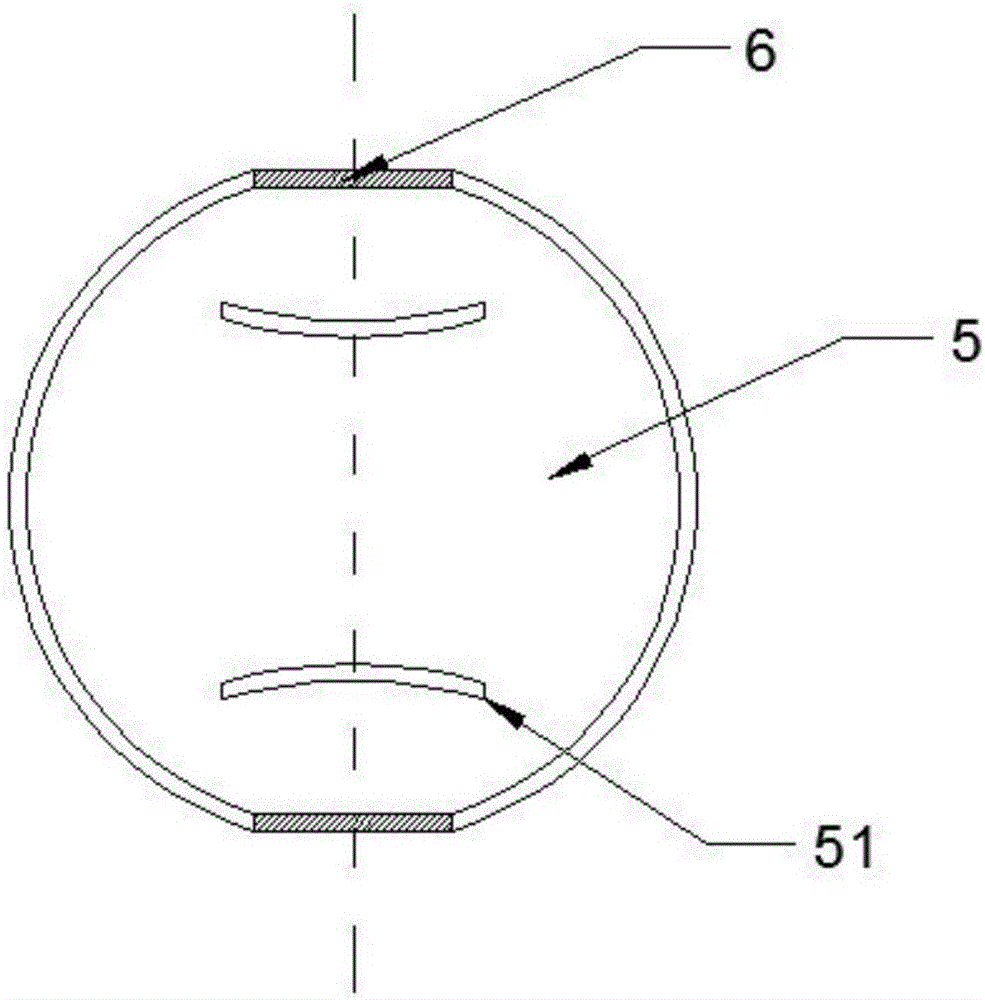

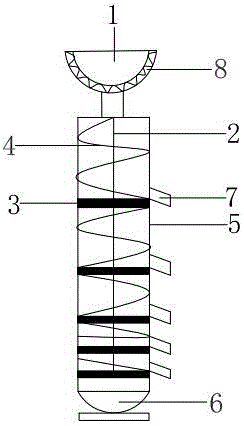

Rotary vibrating screen

InactiveCN106076829AReduce the problem of excessive movement stroke gapEasy dischargeSievingScreeningPhysicsFunnel shape

Owner:CHIZHOU JIULONGPU ECO AGRI COMPREHENSIVE DEV CO LTD

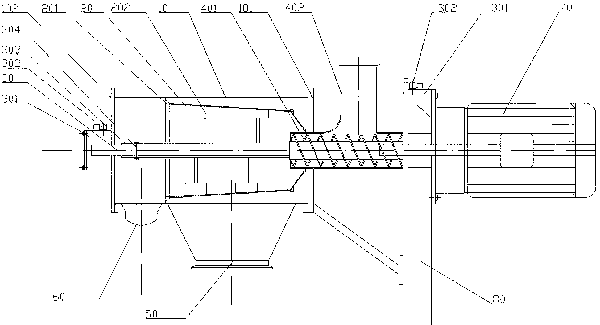

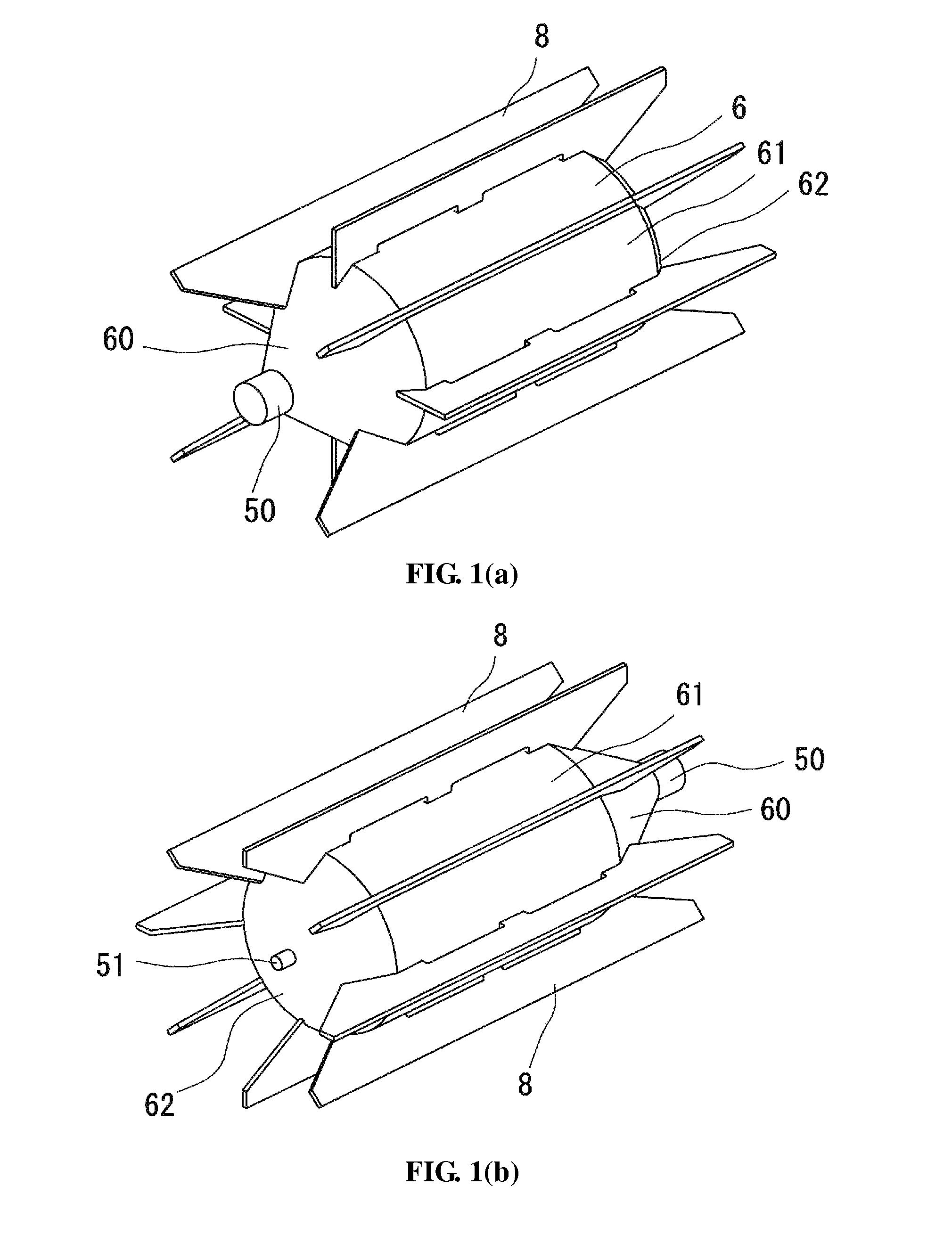

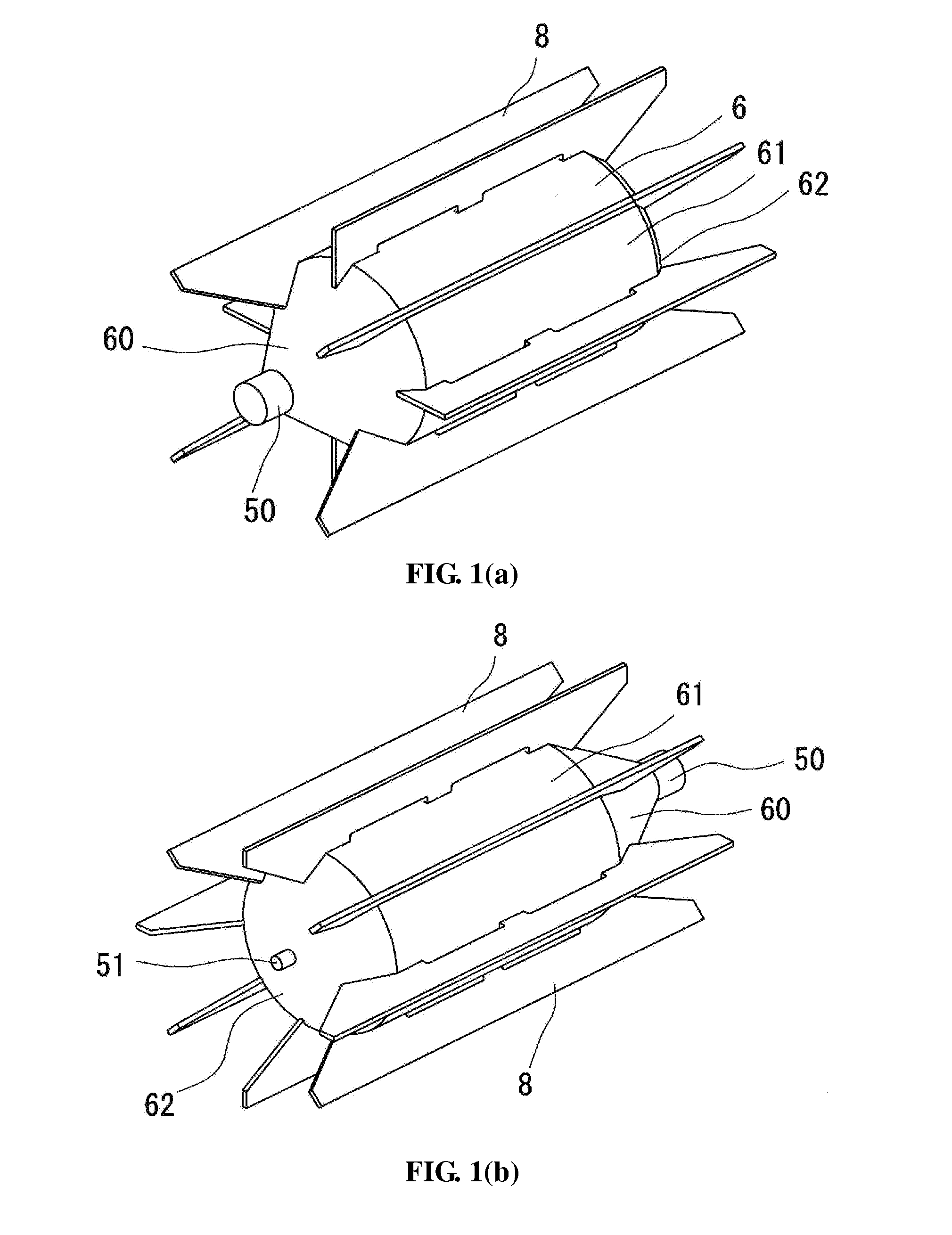

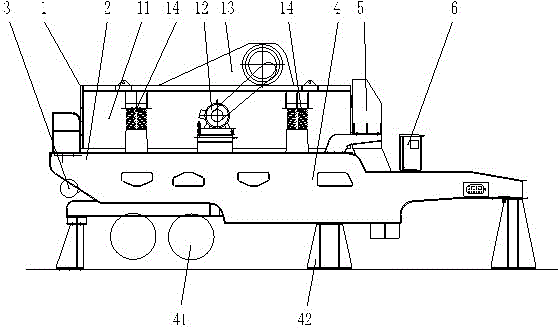

Rotary screening machine

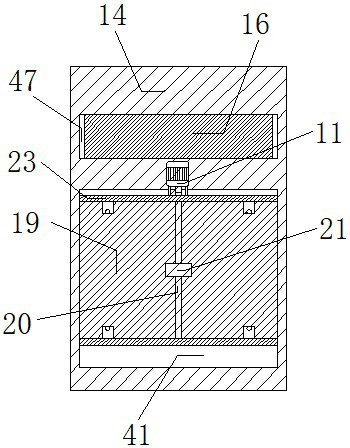

InactiveCN103170452ASieve evenlyLarge screening energySievingScreeningSmall footprintMechanical engineering

The invention discloses a rotary screening machine which is used for grading materials according to particle sizes. The rotary screening machine mainly comprises a machine frame, a screen frame, a screen net, a feeding pipe, a gear motor and a central shaft, wherein the screen net can rotate with the central shaft. The rotary screening machine is mainly characterized in that a feeding screw is placed inside the feeding pipe, screen barrel spoilers are placed on a section, locating inside the screen net, of the central shaft, and both the feeding screw and the central shaft are driven by the gear motor. The screen barrel spoilers face towards the direction of the feeding pipe and are slantly and sequentially installed on the central shaft from top to bottom in a stagger mode. When the feeding screw rotates, the materials are continuously delivered into the screen net along the direction of screwing, and the materials do axial motion and at the same time rotate around the central shaft inside the screen net with the screen barrel spoilers. The rotary screening machine is large in screening energy and screened materials are even. The rotary screening machine is simple and compact in structure and small in floor space.

Owner:赛铂(广州)机电科技有限公司

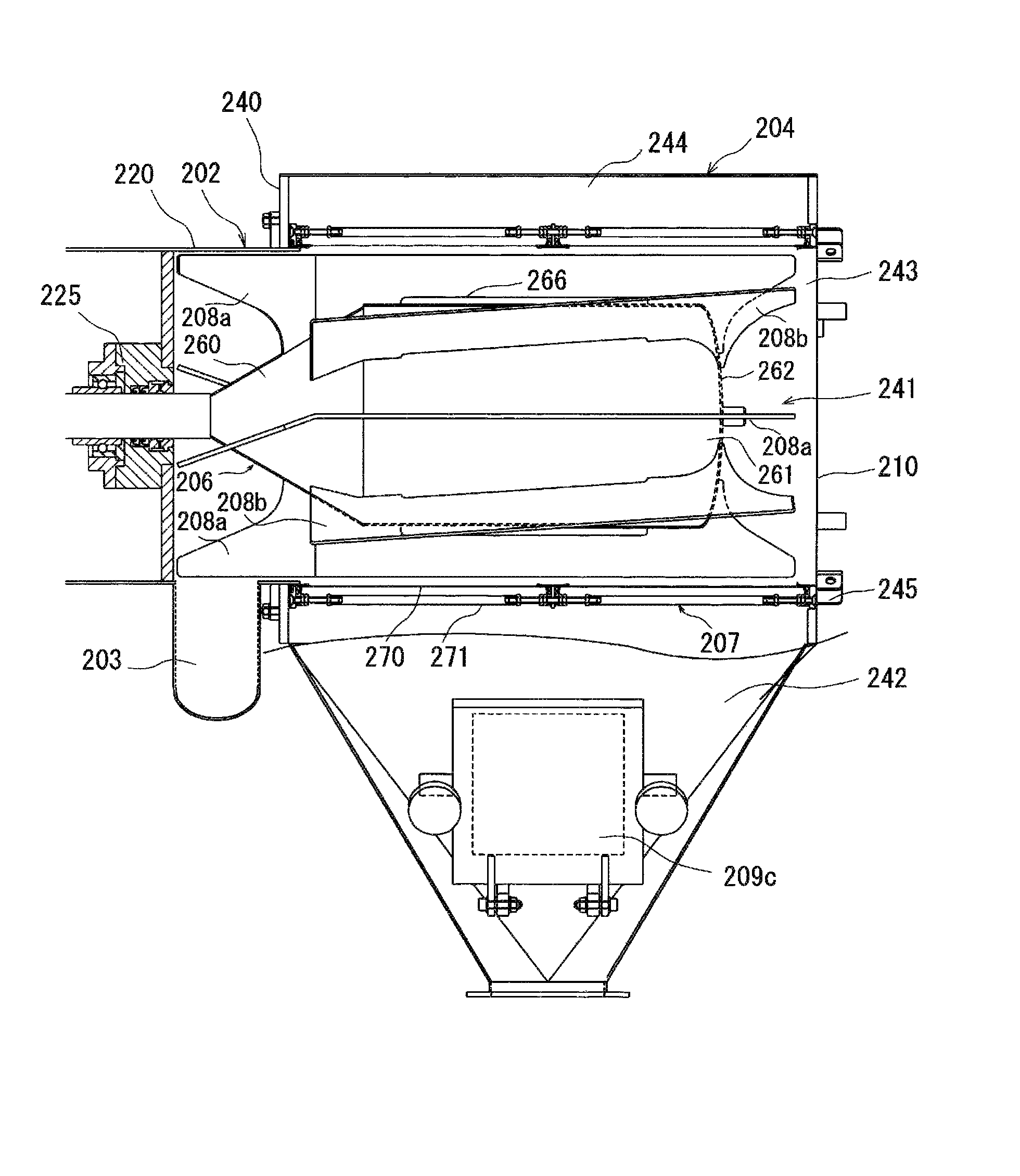

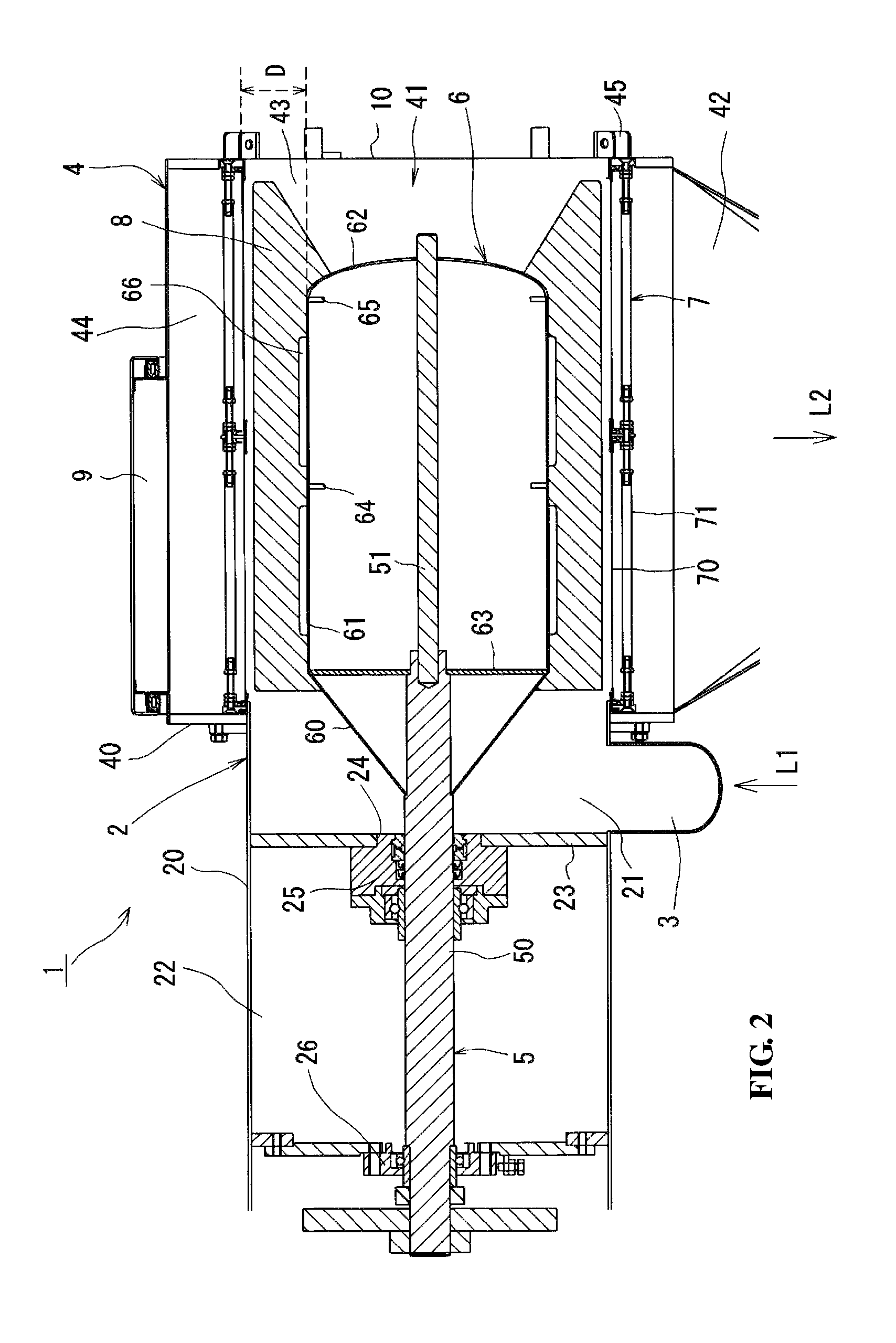

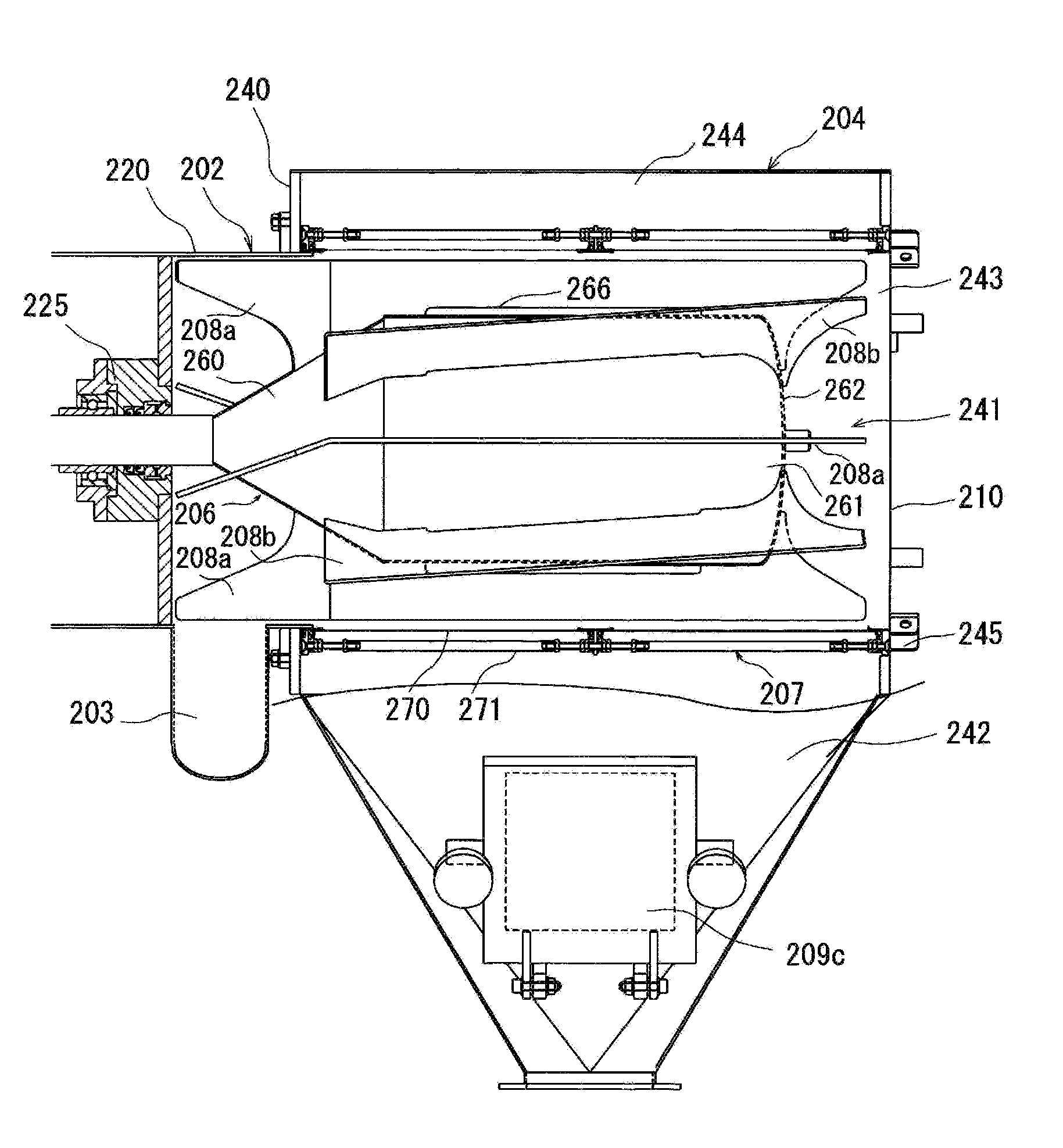

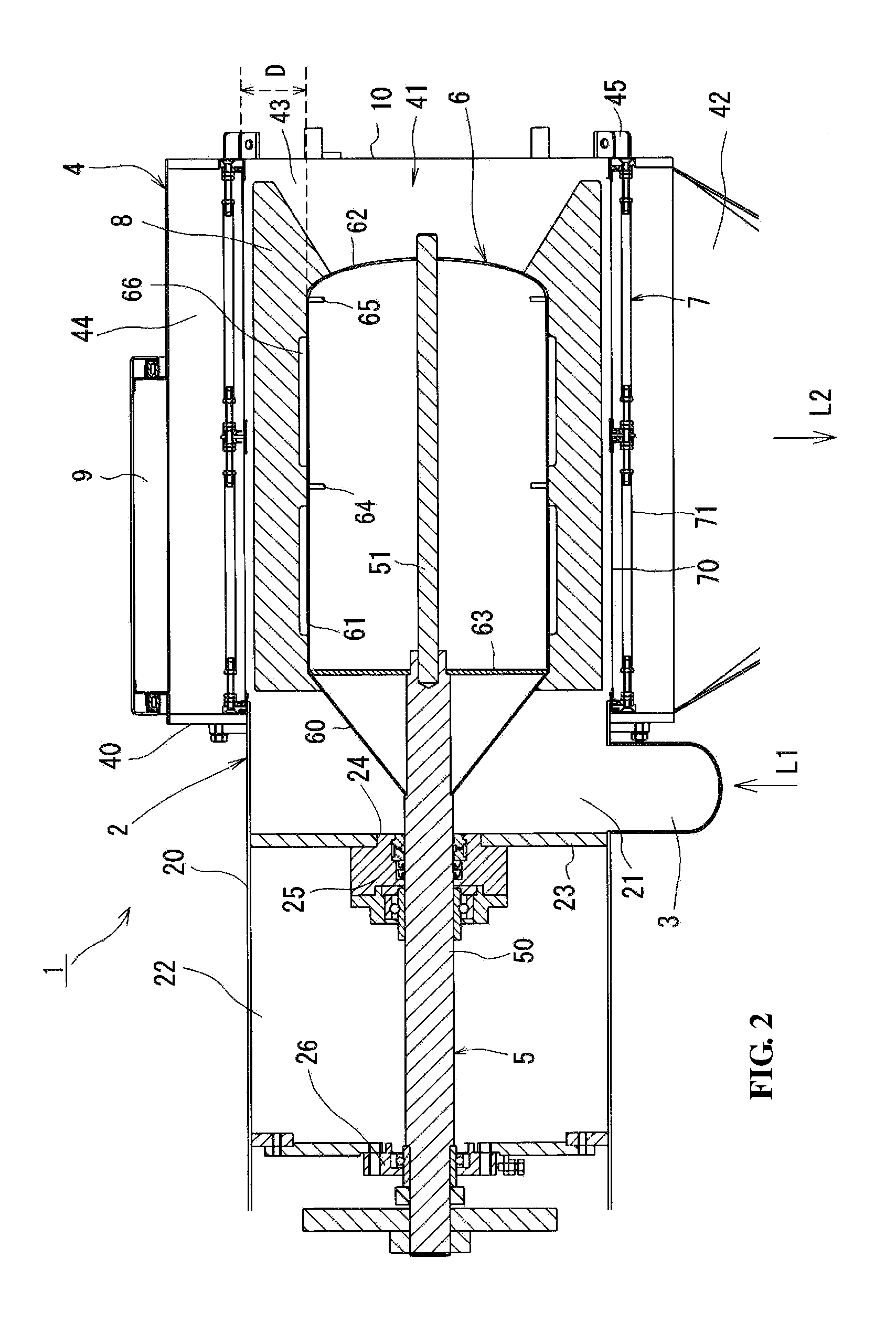

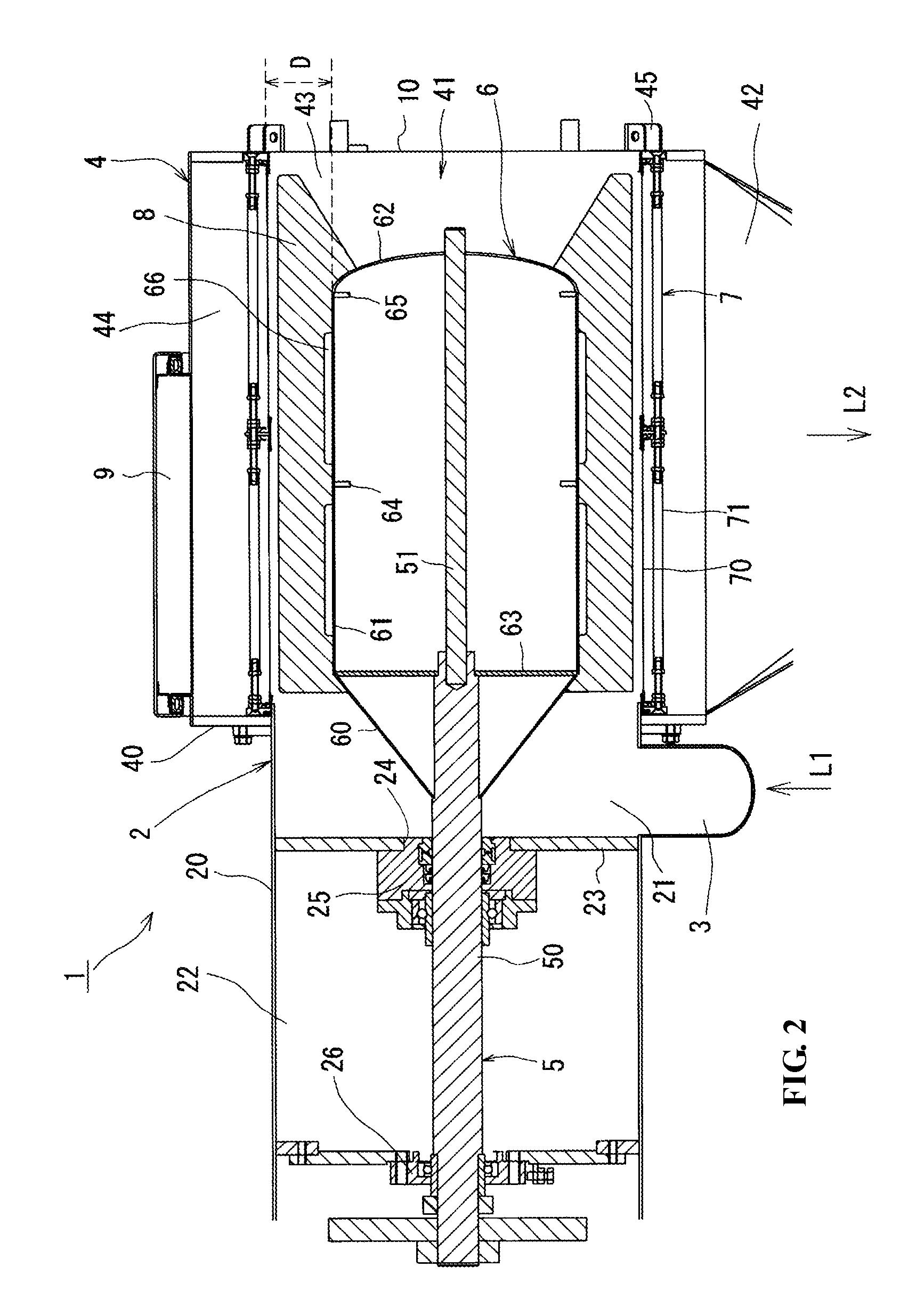

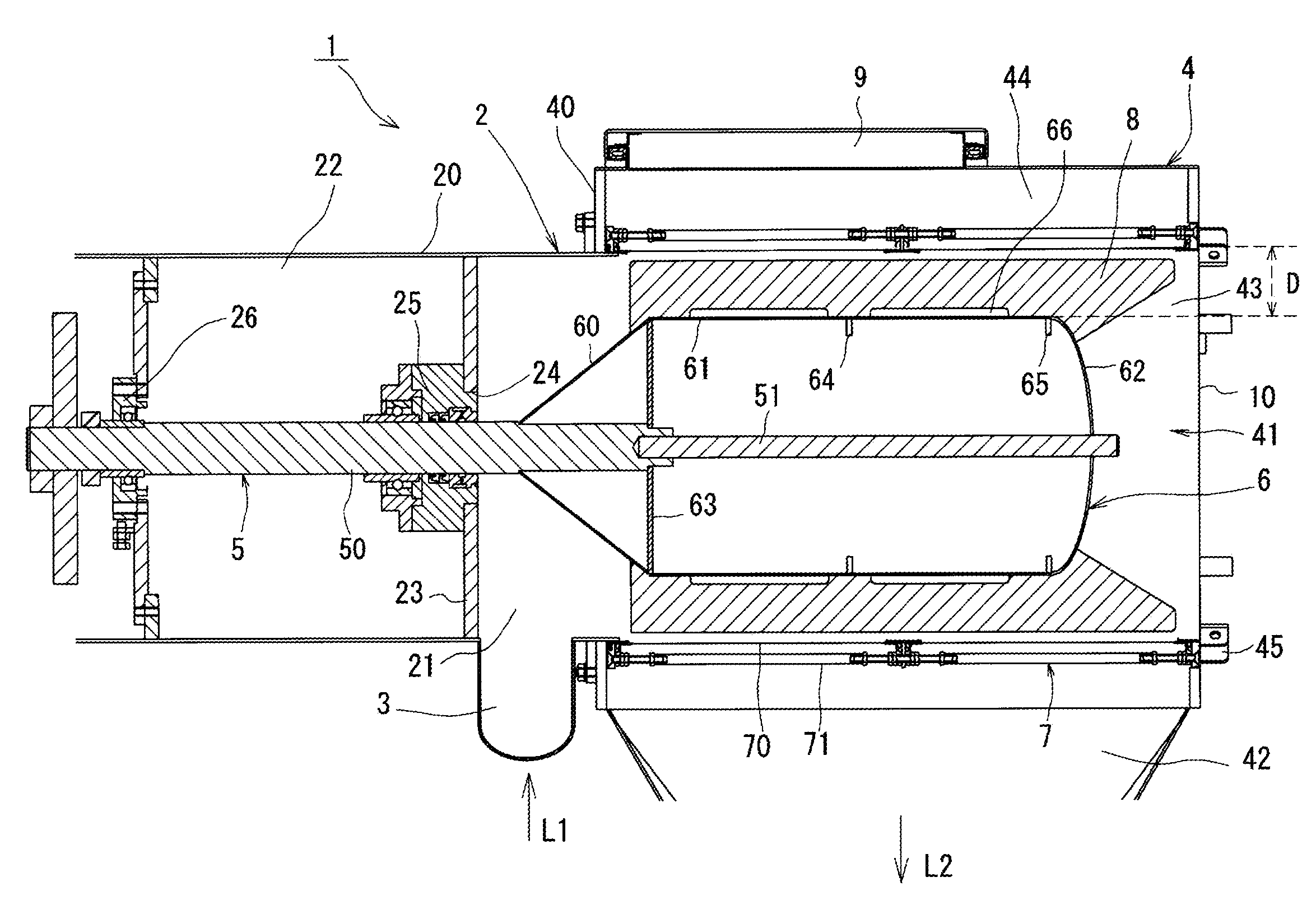

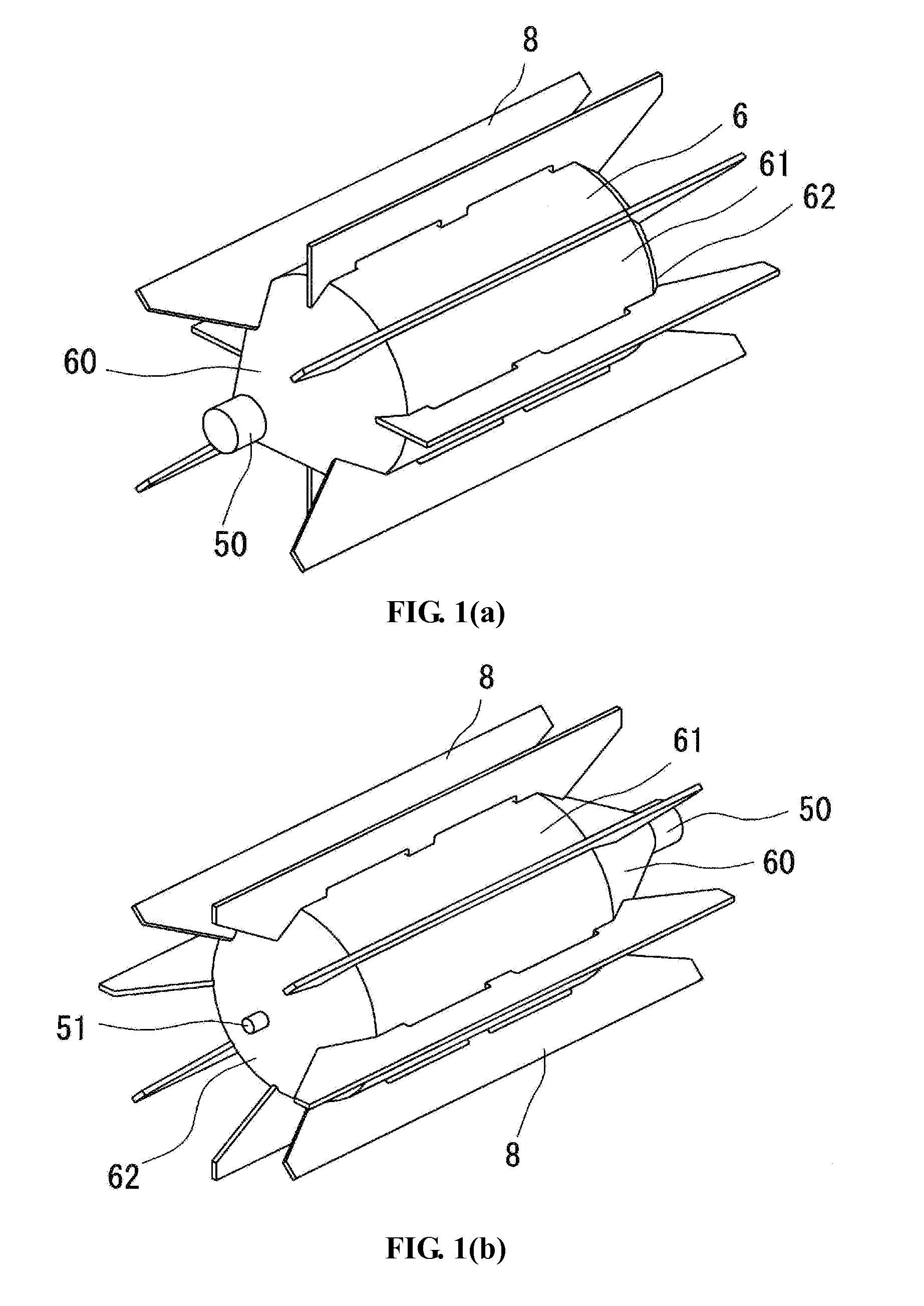

Sifter

ActiveUS7896163B2Reduce the amount requiredIncrease the screening areaSievingGas current separationEngineeringMechanical engineering

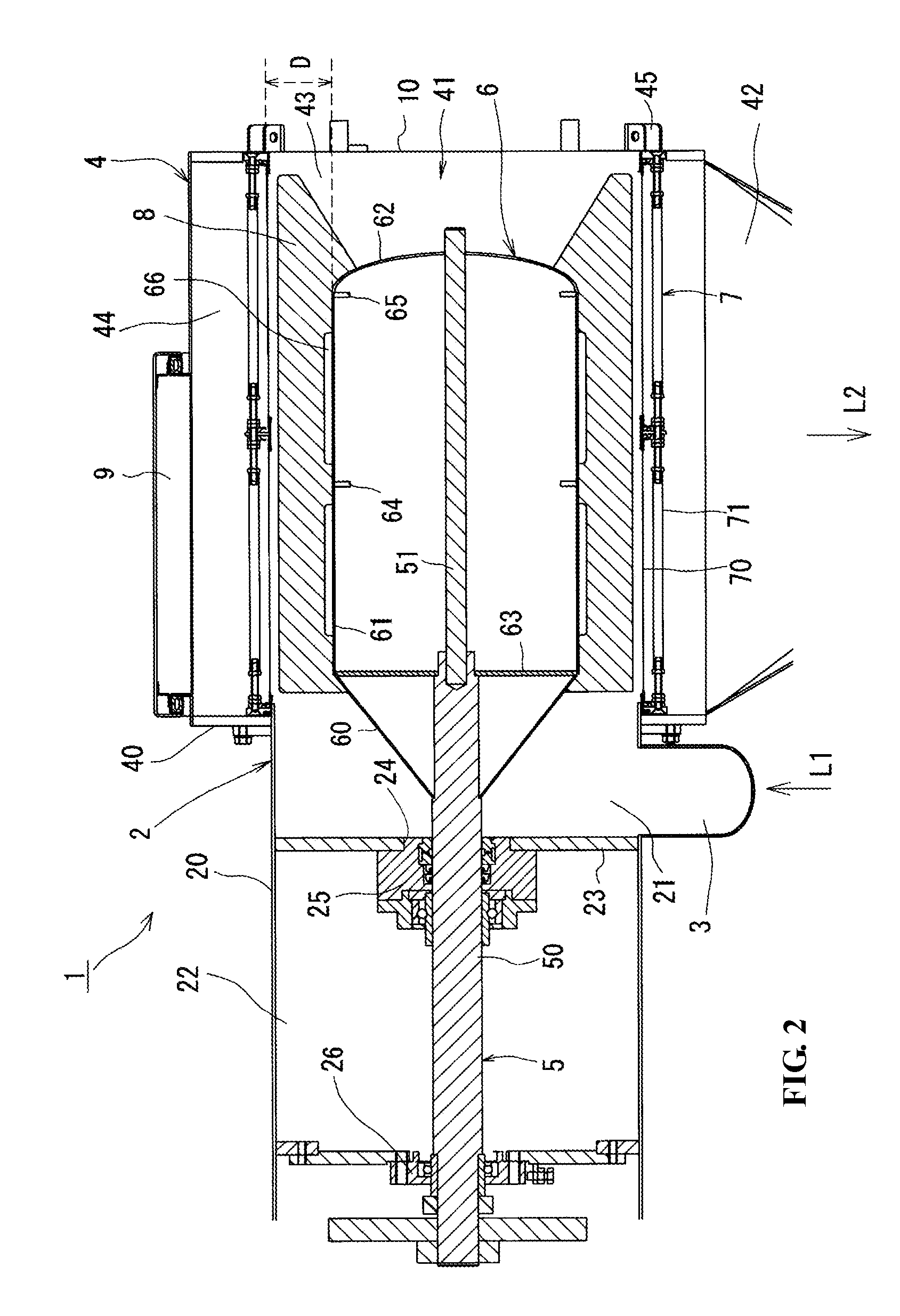

A sifter comprising: a receiver having a supply chamber; a sieve assembly having a sieving chamber coupled to the supply chamber; a rotator having a rotating shaft laterally arranged to pass through the supply chamber and the sieving chamber; a drum having a circular cross-section and having a larger diameter than the diameter of the rotating shaft, the drum being extended in at least space of the sieving chamber and arranged coaxially with the sieve; a cylindrical sieve located inside the sieving chamber and arranged coaxially with the rotating shaft; a stirring rotor located in an inner area of the sieving chamber inside the sieve comprising a rotating blade attached to the rotating shaft; an extraction member; and an outlet for discharging powder passing through the sieve from the inner area to the outer area.

Owner:TSUKASA

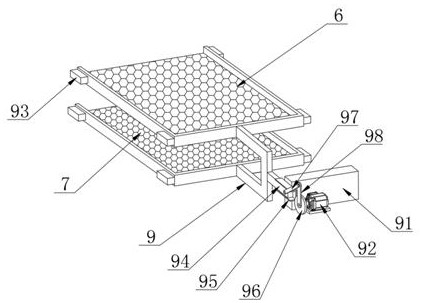

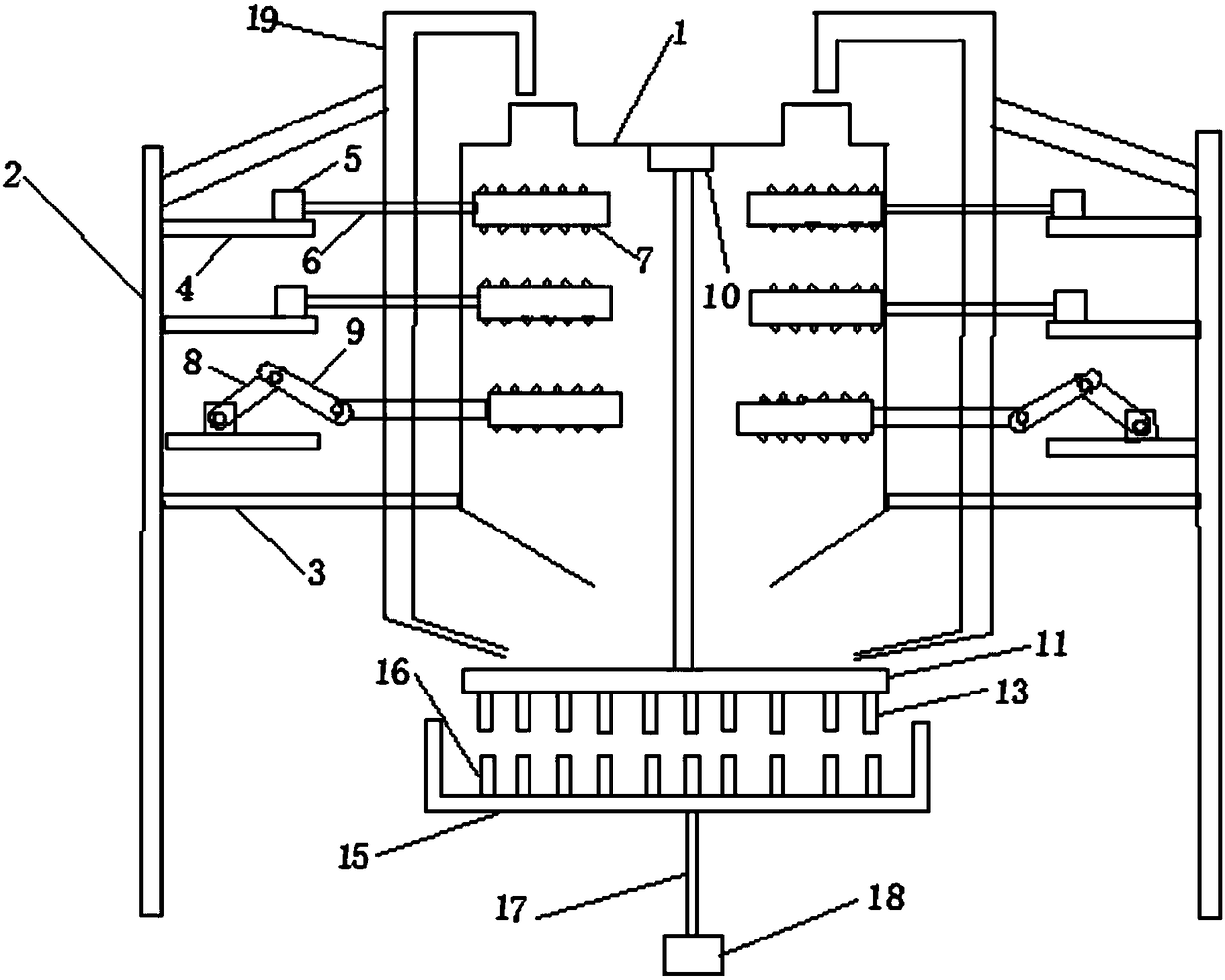

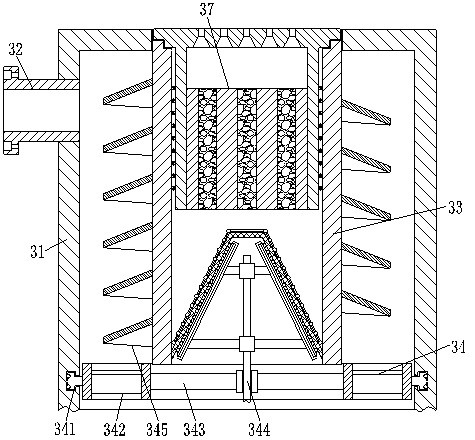

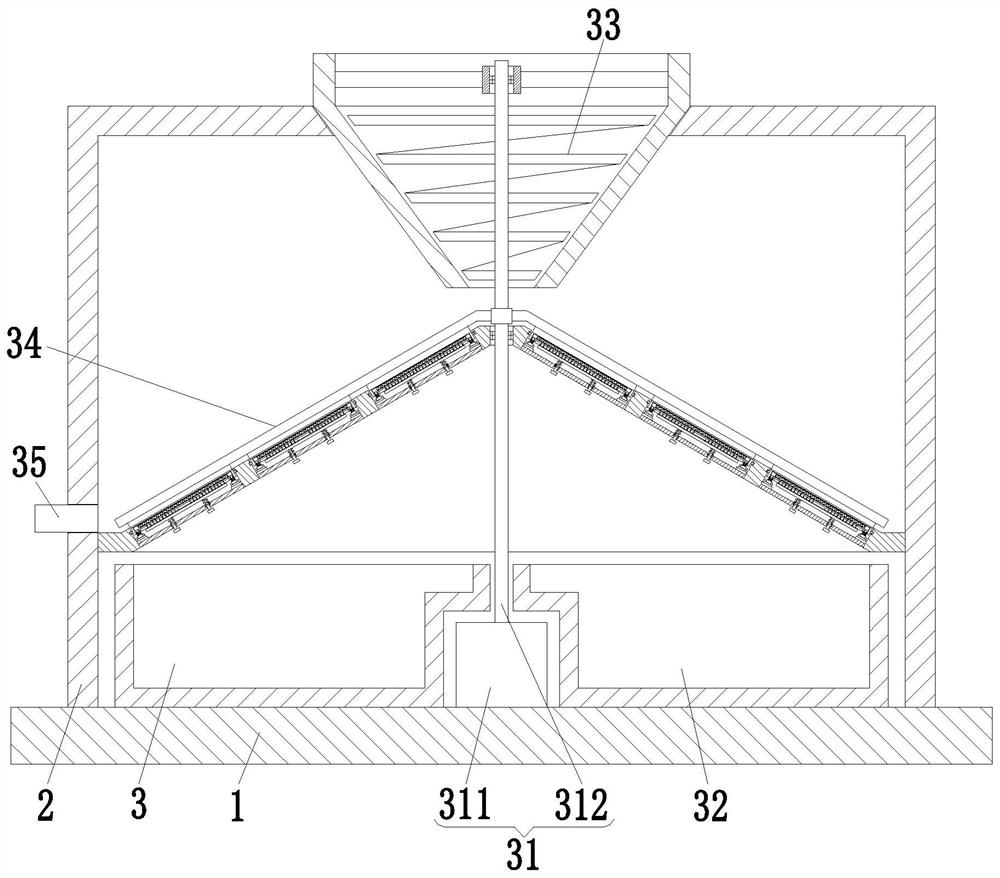

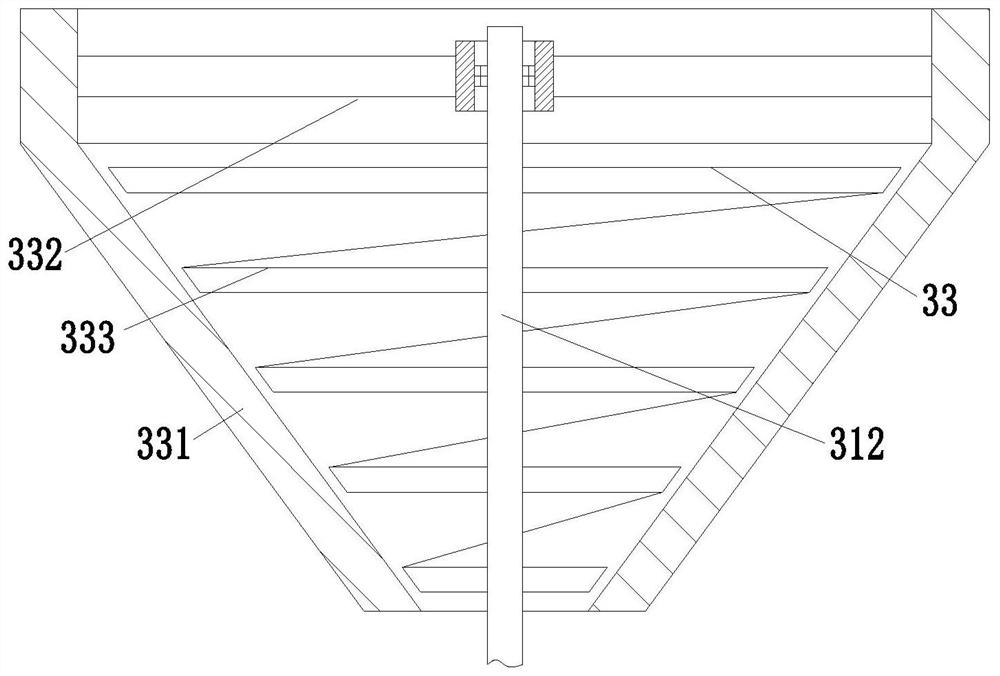

Treatment device and method for efficient solid waste treatment

InactiveCN112718086AImprove the power of reciprocating linear screenEvenly dispersedSievingScreeningReciprocating motionEnvironmental engineering

The invention relates to the technical field of cement waste, and discloses an efficient solid waste treatment device. The efficient solid waste treatment device comprises two vertical plates arranged correspondingly, wherein a crushing mechanism is mounted above one ends of the two vertical plates, an upper sieve plate and a lower sieve plate are arranged between the two vertical plates up and down in parallel, a receiving hopper is arranged at the bottom between the two vertical plates, and a slag receiving hopper is arranged between the two vertical plates and located under one end of the upper sieve plate and one end of the lower sieve plate, the middles of the rear surfaces of the upper sieve plate and the lower sieve plate are jointly connected with a reciprocating motion mechanism, and sweeping mechanisms are arranged in the positions, corresponding to the upper sieve plate and the lower sieve plate, of the inner sides of the vertical plates. When the crushed waste is screened, the waste can fall onto the screen plate to be more rapidly and uniformly dispersed, so that the screening efficiency of the screen plate on the waste is improved; and moreover, the screened impurities and metal substances can be classified, so that the solid waste treatment efficiency is further improved.

Owner:辽宁银盛水泥集团有限公司

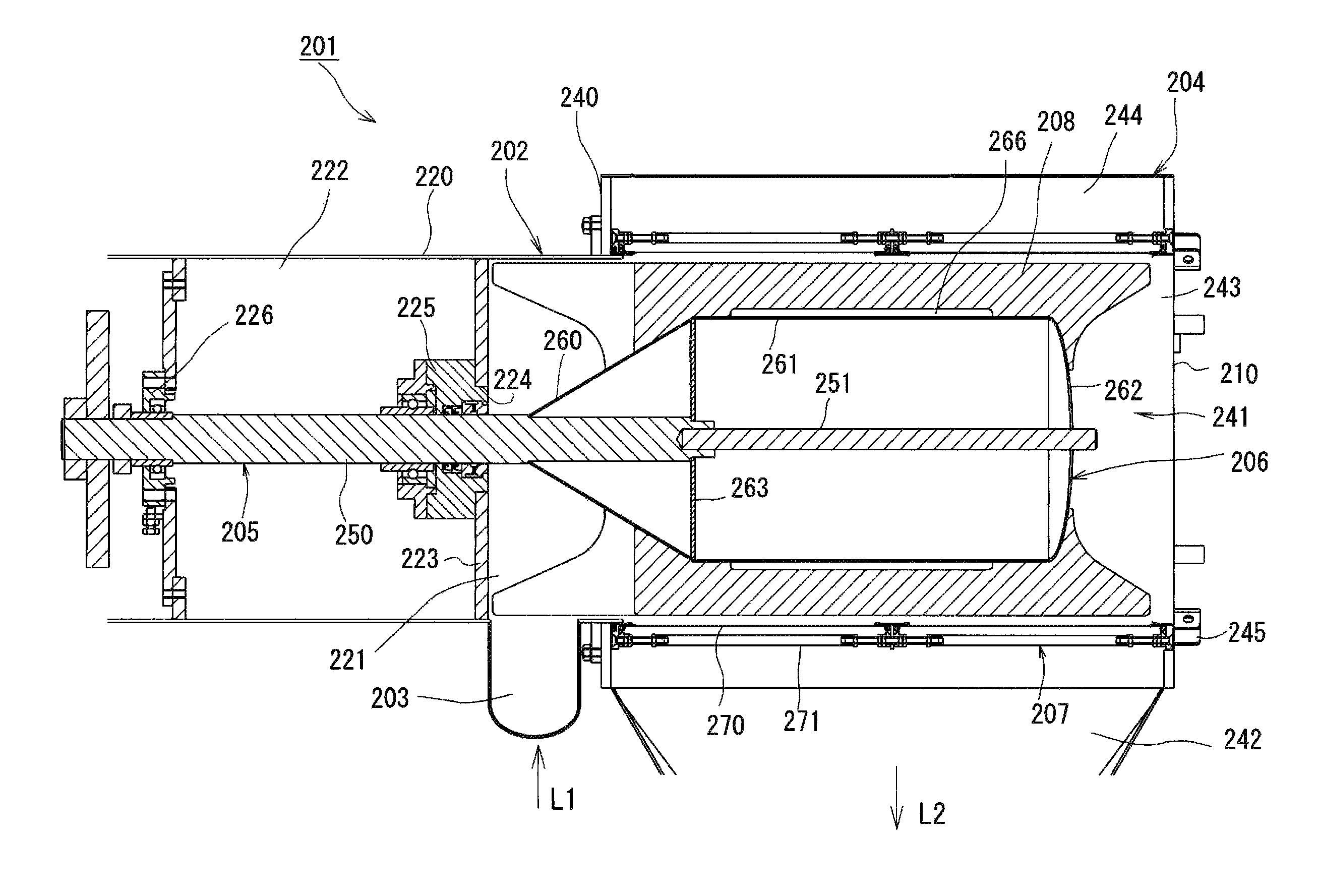

Sifter

ActiveUS20080308469A1Lower potentialReduce pressure lossSievingGas current separationRotational axisEngineering

A sifter comprising: a receiver having a supply chamber; a sieve assembly having a sieving chamber coupled to the supply chamber; a rotator having a rotating shaft laterally arranged to pass through the supply chamber and the sieving chamber; a drum having a circular cross-section and having a larger diameter than the diameter of the rotating shaft, the drum being extended in at least space of the sieving chamber and arranged coaxially with the sieve; a cylindrical sieve located inside the sieving chamber and arranged coaxially with the rotating shaft; a stirring rotor located in an inner area of the sieving chamber inside the sieve comprising a rotating blade attached to the rotating shaft; an extraction member; and an outlet for discharging powder passing through the sieve from the inner area to the outer area.

Owner:TSUKASA

Pneumatic screening device

InactiveCN102580926AReduce noiseSieve evenlySievingGas current separationWorking environmentAgricultural engineering

The invention discloses a pneumatic screening device, which comprises a screening device, an air blower and an exhaust device. The air blower is connected with the screening device respectively via an air inlet pipe and an air outlet pipe, and one end of the air inlet pipe is connected with the exhaust device. The pneumatic screening device is capable of screening in a graded manner according to different mesh numbers of the material. A sampling sieve is connected with the air blower so that the material can be evenly and quickly screened. In the mean time, the arrangement of the exhaust device saves raw material and reduces costs. The pneumatic screening device is in a closed structure, dust-proof and low in noise so that the surrounding working environment cannot be affected.

Owner:常州宏泰摩擦材料有限公司

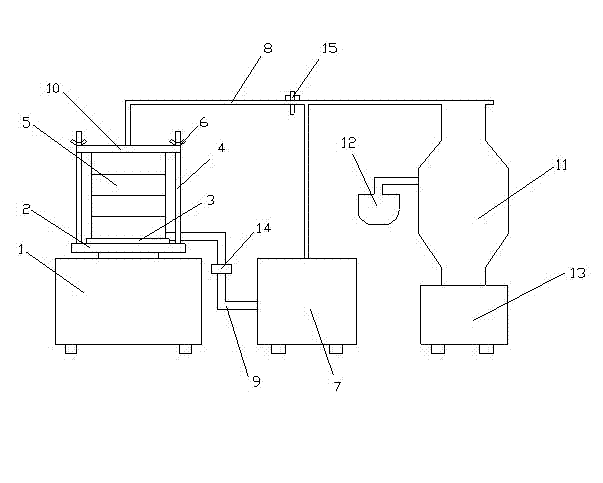

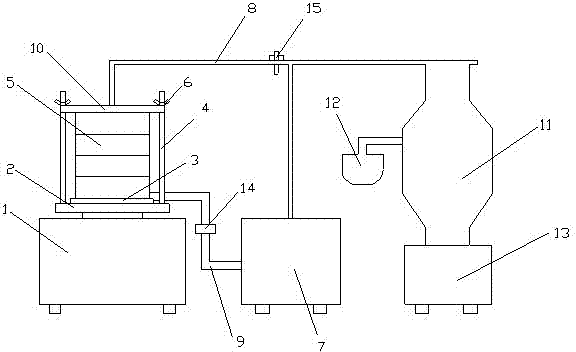

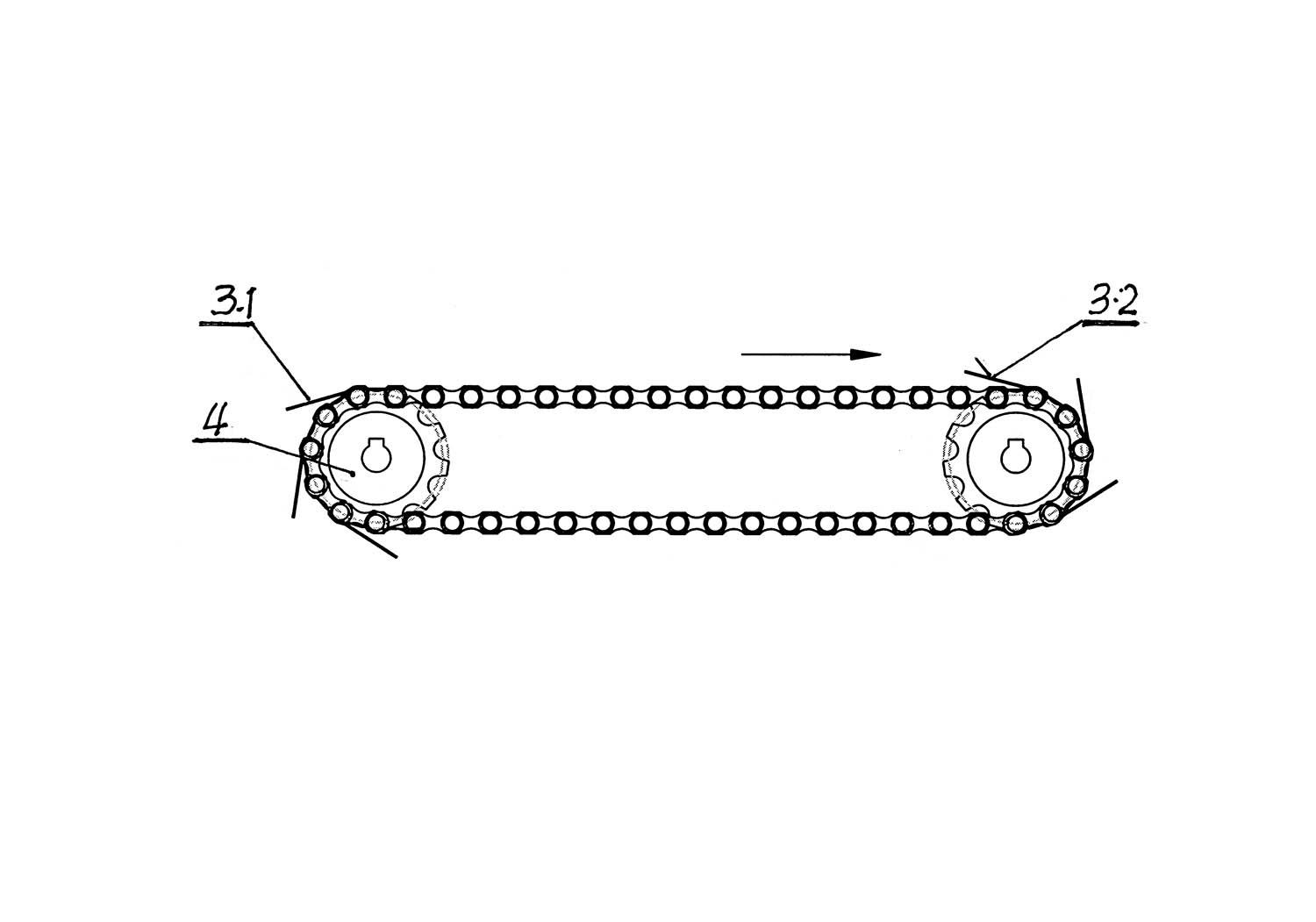

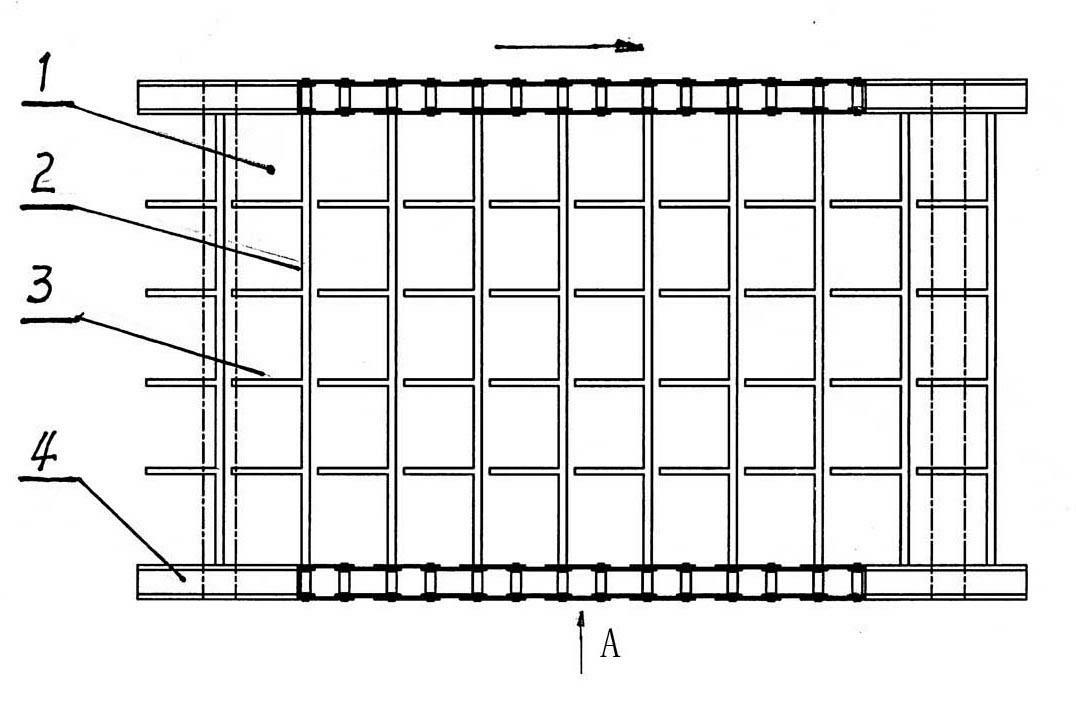

Annular movement sieve

InactiveCN102179364AReduce blockingImprove production and screening efficiencySievingScreeningEngineeringSieve

The invention belongs to the field of screening devices, and provides an annular movement sieve. The annular movement sieve is mainly characterized in that: the conventional sieve is greatly improved, a longitudinal grid and a horizontal grid of the sieve are connected in a T shape; two ends of the horizontal grid are connected with a link plate of a link chain driving mechanism to form an annular sieve so as to realize annular movement operation; therefore, the material can be charged continuously and can be sieved uniformly, material blockage is reduced, the sieving efficiency and output are improved, energy consumption is reduced, soft impurities can be removed, and the annular movement sieve has obvious advantages.

Owner:张玉伟

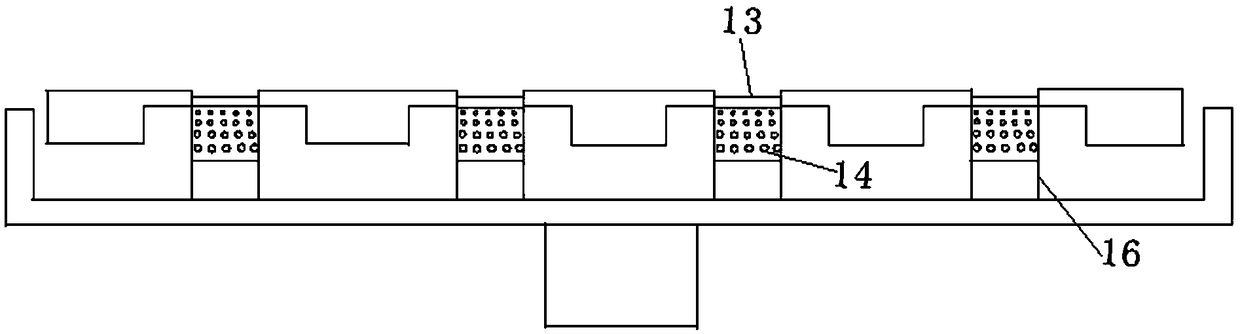

Screening net adjusting and anti-blocking device

A screening net adjusting and anti-blocking device comprises a feeding device, a breaking device, a supporting device, a screening device and an anti-blocking and adjusting device. Adjusting columns are arranged below screening columns, screening holes in the screening columns can be blocked when the adjusting columns ascend, and therefore the opening and closing number of the multiple screening holes can be adjusted in the screening process at any time. Due to the fact that the radii of the screening holes formed in the screening columns from top to bottom are gradually increased, the particle size of screened materials can be adjusted. The positions of the adjusting columns are decided by the particle size of the materials which need to be screened, the adjusting columns ascend to pass through leaking holes to arrive at the position above a screening plate and can push out the large-particle-size materials which block the screening holes, and therefore the large-particle-size materials are prevented from blocking the leaking holes. The purposes of adjusting the size of the screening holes and preventing the leaking holes from being blocked are achieved by the same device, the structure is simple, and operation is convenient.

Owner:灵璧县浩翔信息科技有限公司

Construction waste crushing and screening equipment

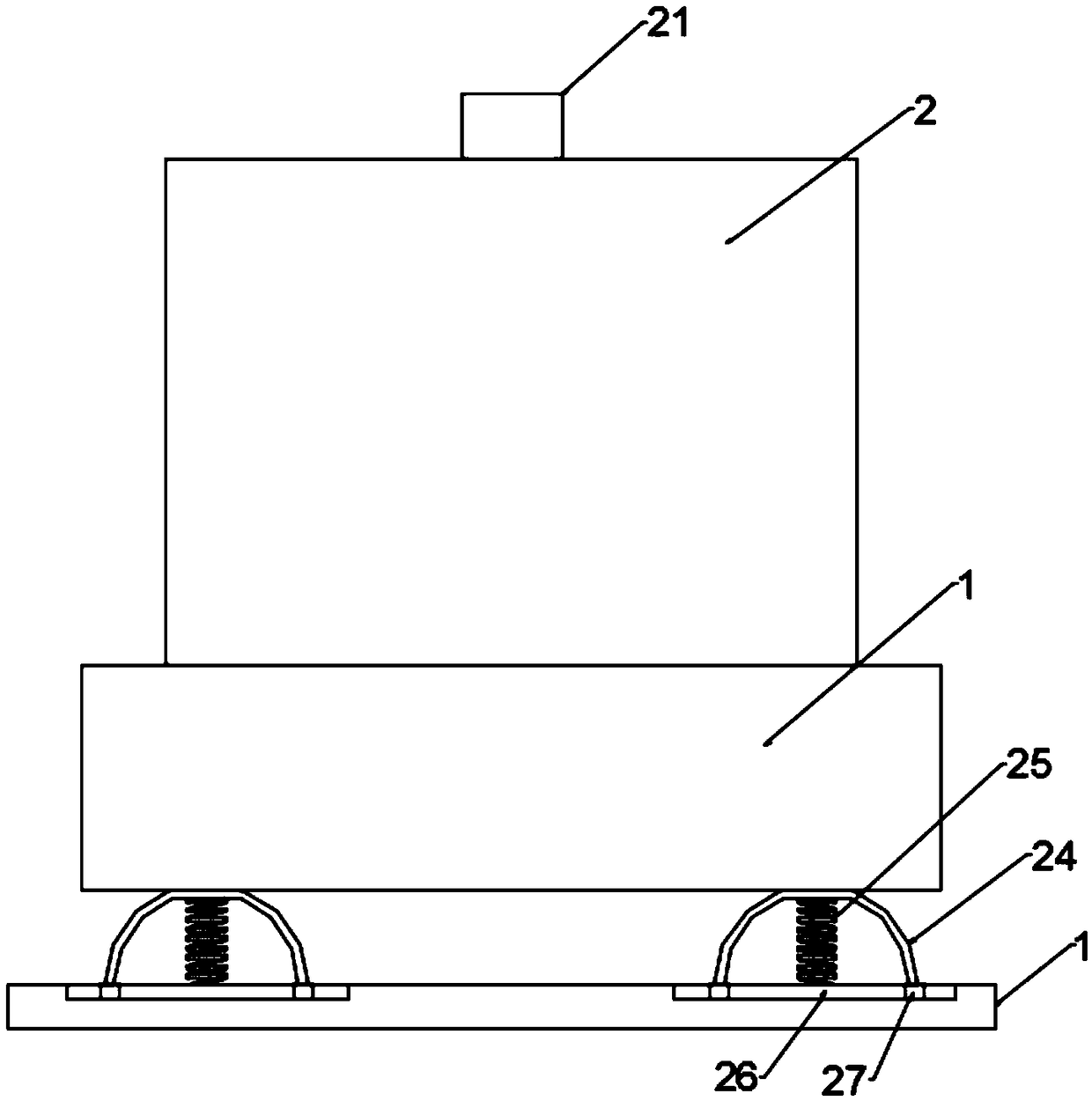

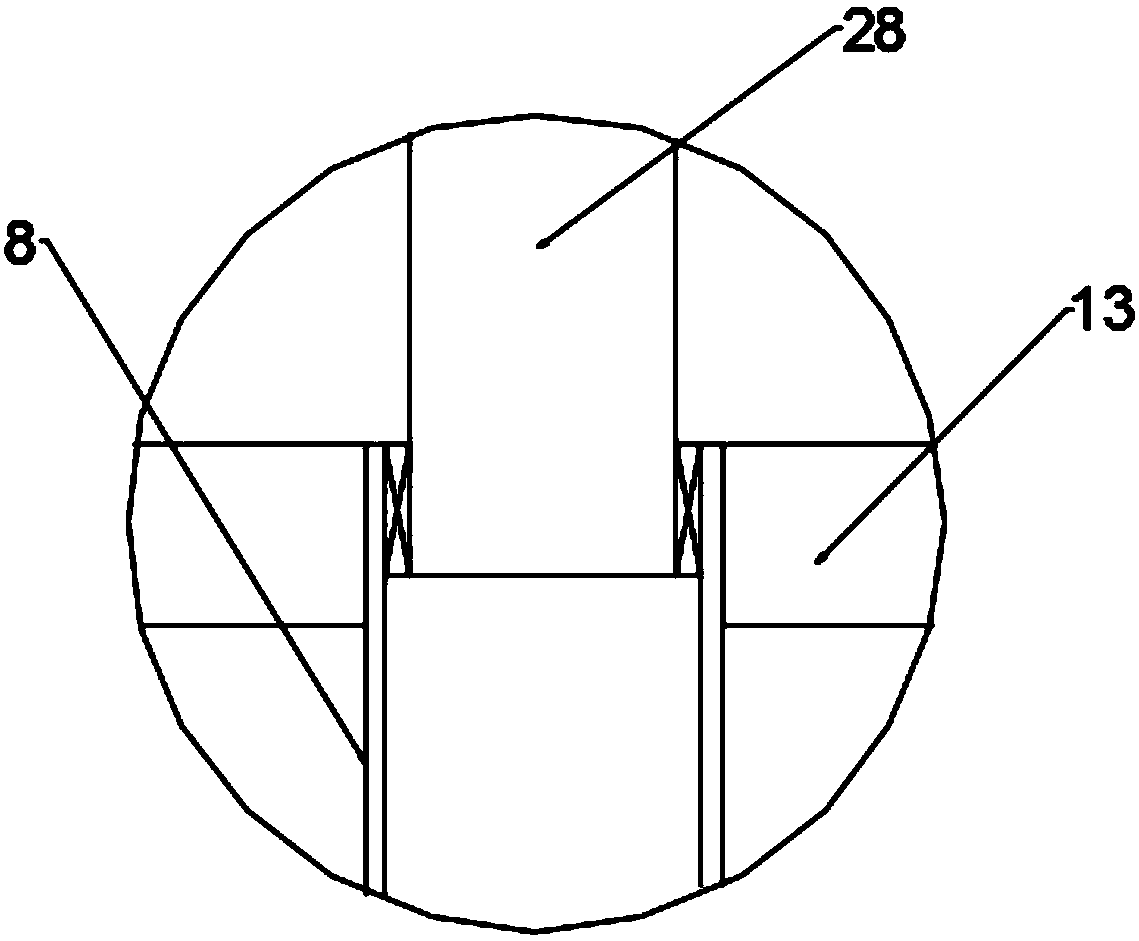

InactiveCN112844580ASieve evenlyImprove filtration strokeSievingScreeningArchitectural engineeringSupport plane

The invention relates to construction waste crushing and screening equipment. The equipment comprises a bottom plate, support frames, a screening device and a crushing device, wherein the support frames are evenly installed in the middle of the upper end of the bottom plate; the screening device is installed between the upper ends of the support frames; a feeding hole is formed in the upper end of the screening device; and the crushing device is installed on the feeding hole. The equipment can solve the problems that existing equipment is poor in crushing effect and uneven in crushing when crushing construction wastes, more large particle substances exist in the crushed construction wastes and follow-up recycling of the construction wastes is not facilitated, and meanwhile, the existing equipment is poor in screening effect when crushing the construction wastes and cannot effectively screen the construction wastes, and large particle impurities usually block meshes in a screen easily to affect the screening efficiency of the construction wastes.

Owner:孙庆虎

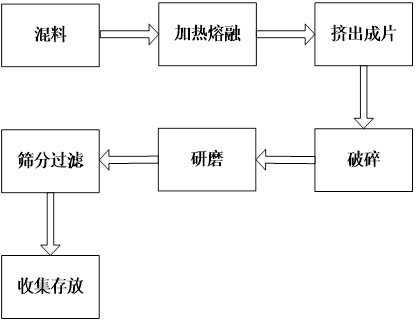

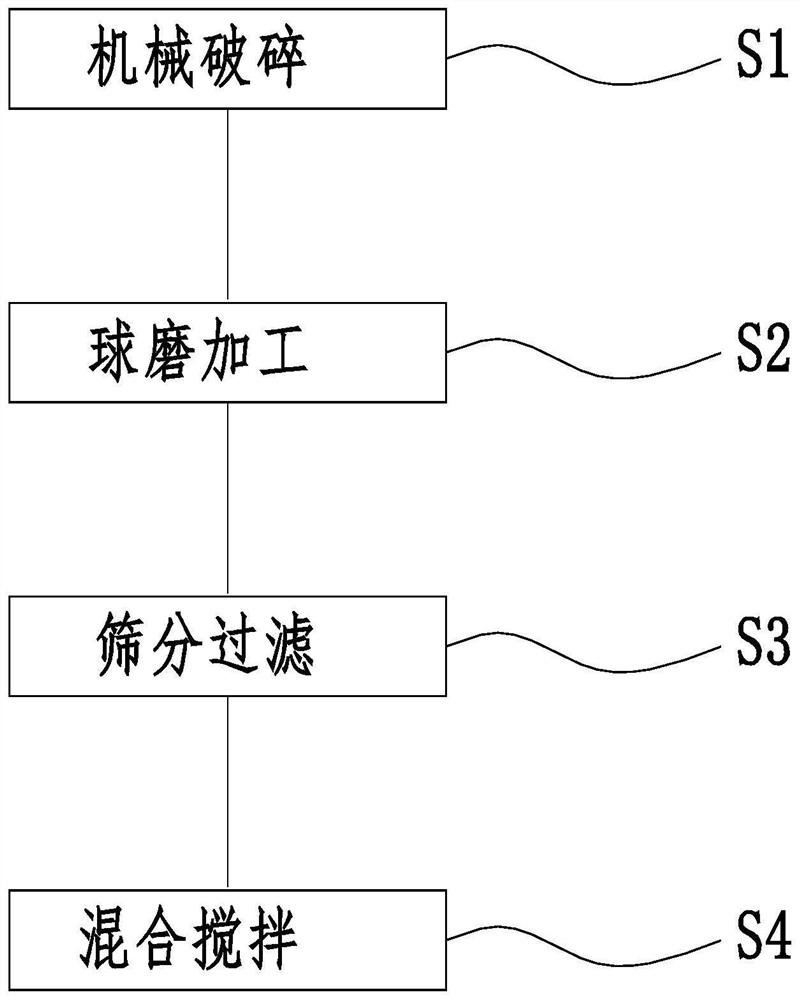

Mineral powder coating production and preparation process

ActiveCN112246403AAvoid inclusionsAvoid cloggingGas current separationPowdery paintsPowder coatingCeramic materials

The invention relates to a mineral powder coating production and preparation process. A bottom plate, supporting frames and a screening device are included, wherein the supporting frames are symmetrically installed at the upper end of the bottom plate, and the screening device is installed between the upper ends of the supporting frames. According to the process, the problem that the preparation effect of coatings is affected because the screening effect is poor, screening is uneven, and ultrafine powder particles in the powder coatings cannot be effectively removed when the powder coatings are screened through existing equipment, and the problem that the air environment is prone to being affected as the ultrafine powder particles in the airflow are prone to diffusing into the air becauseultrafine powder in airflow usually cannot be effectively collected or filtered when the powder coatings are processed through the existing equipment can be solved.

Owner:贵州贵毅宏祥环保材料有限公司

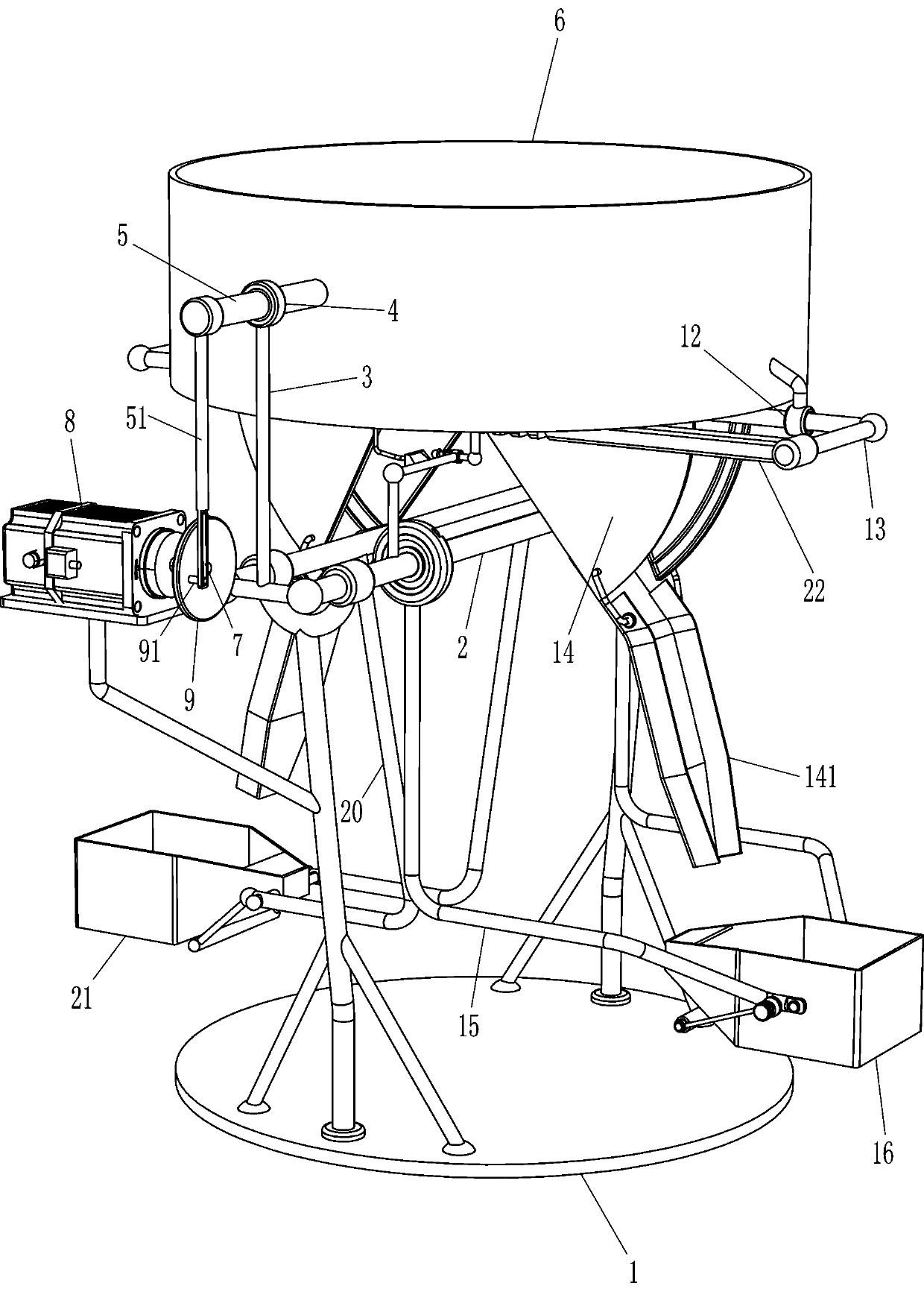

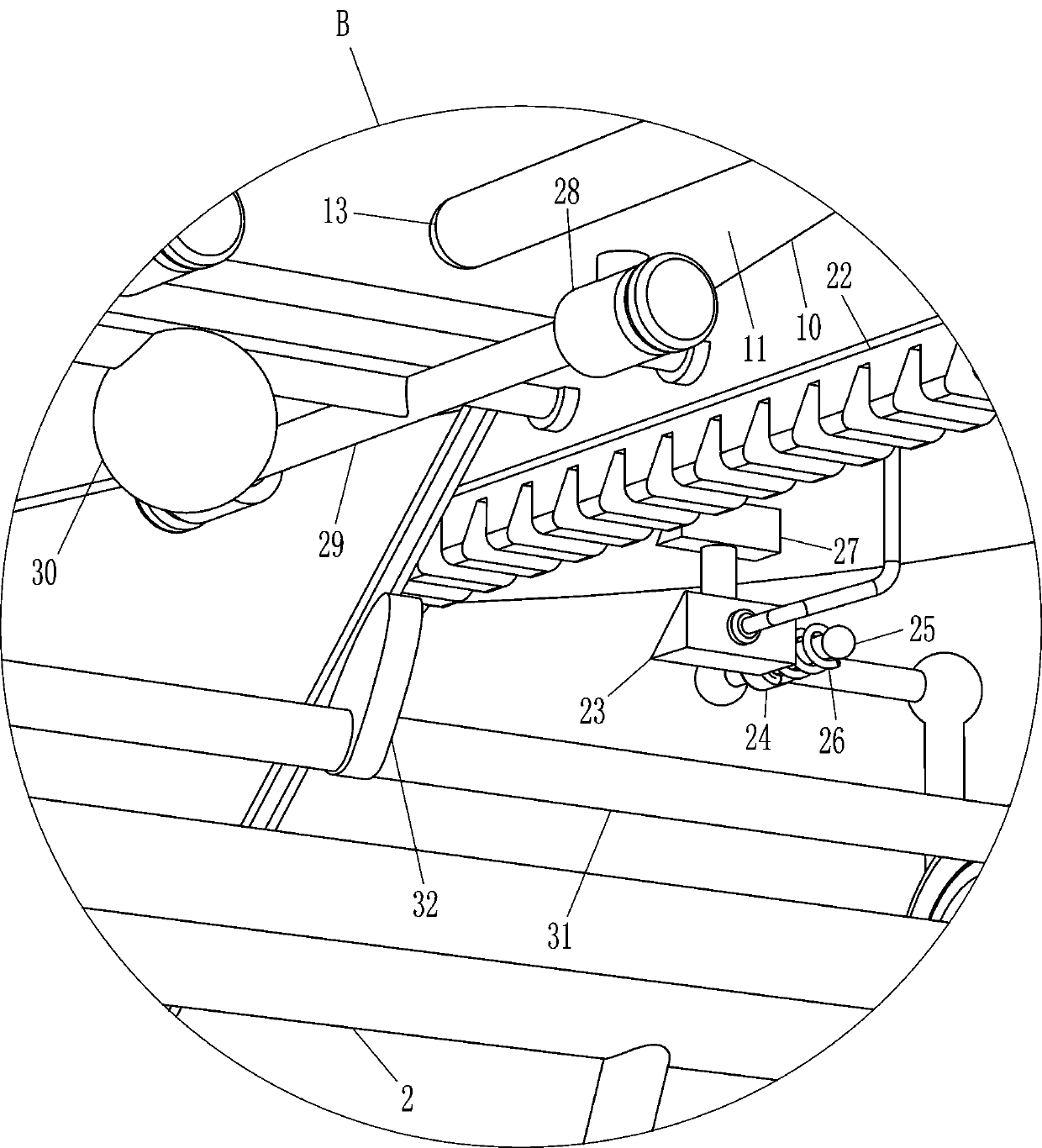

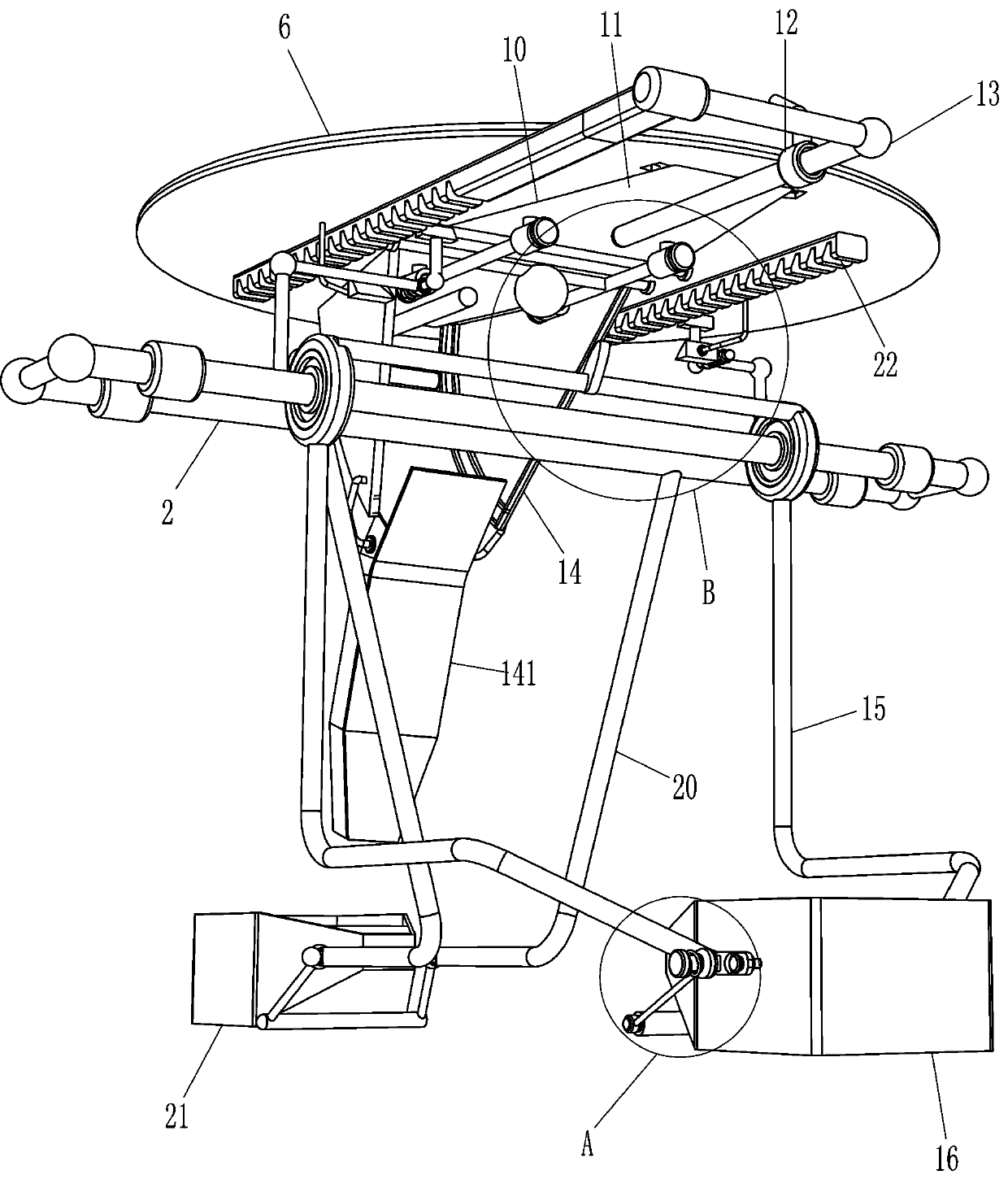

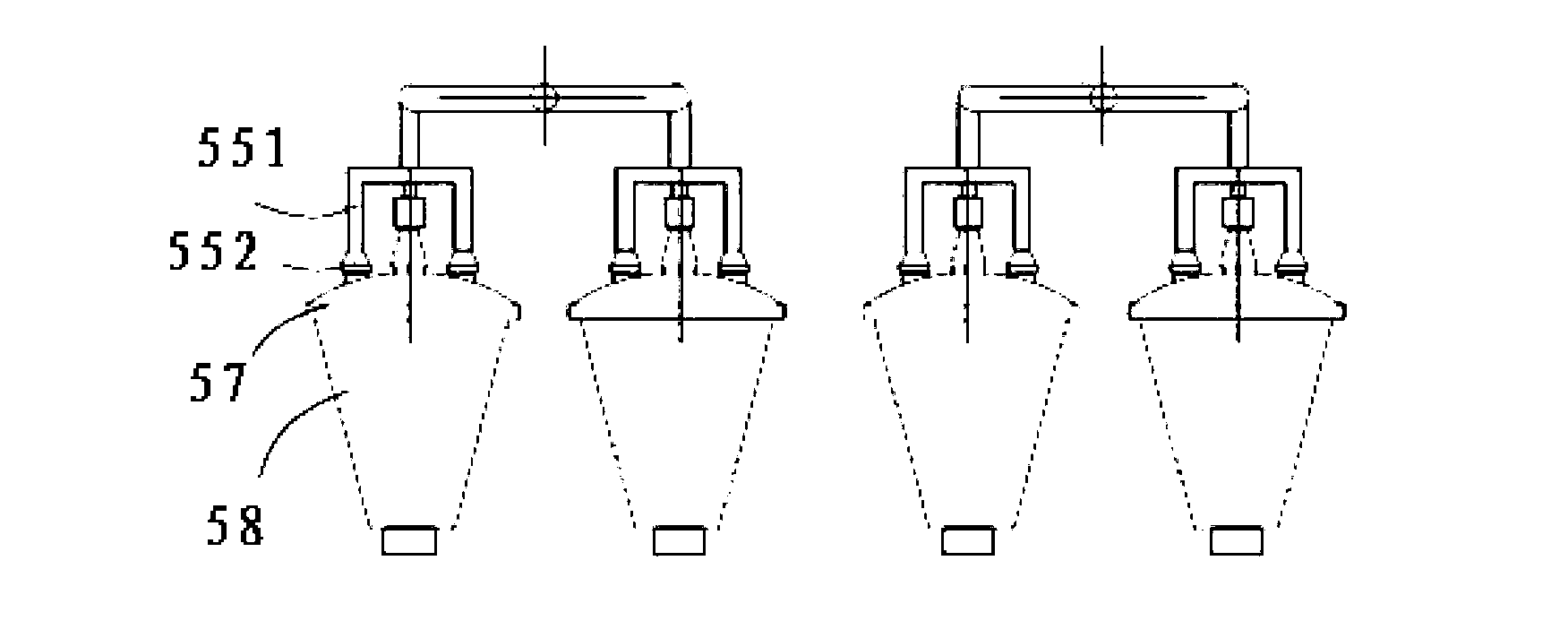

Fertilizer sampling and screening device

InactiveCN111570263ASieve evenlyAvoid wastingSievingScreeningAgricultural scienceAgricultural engineering

The invention relates to a screening device, in particular to a fertilizer sampling and screening device. The fertilizer sampling and screening device is uniform in screen and improves the detection accuracy. The fertilizer sampling and screening device comprises a mounting frame, a square rod, vertical rods, a shaking assembly, a discharging assembly, a collecting assembly and the like; the square rod is installed on the mounting frame; the vertical rods are arranged on the front side and the rear side of the square rod; the vertical rods on the front side and the rear side are provided withthe shaking assembly for shaking in a front-and-back moving mode; the bottom of the shaking assembly is provided with the discharging assembly for discharging in a rotary mode; and the mounting frameis provided with the collecting assembly for collecting in a rotary mode. Fertilizers are screened through the shaking assembly, so that the fertilizers are screened more uniformly, and the fertilizers are discharged through the discharging assembly, so that waste caused when the fertilizers fall from the two sides in the falling process can be prevented.

Owner:刘强

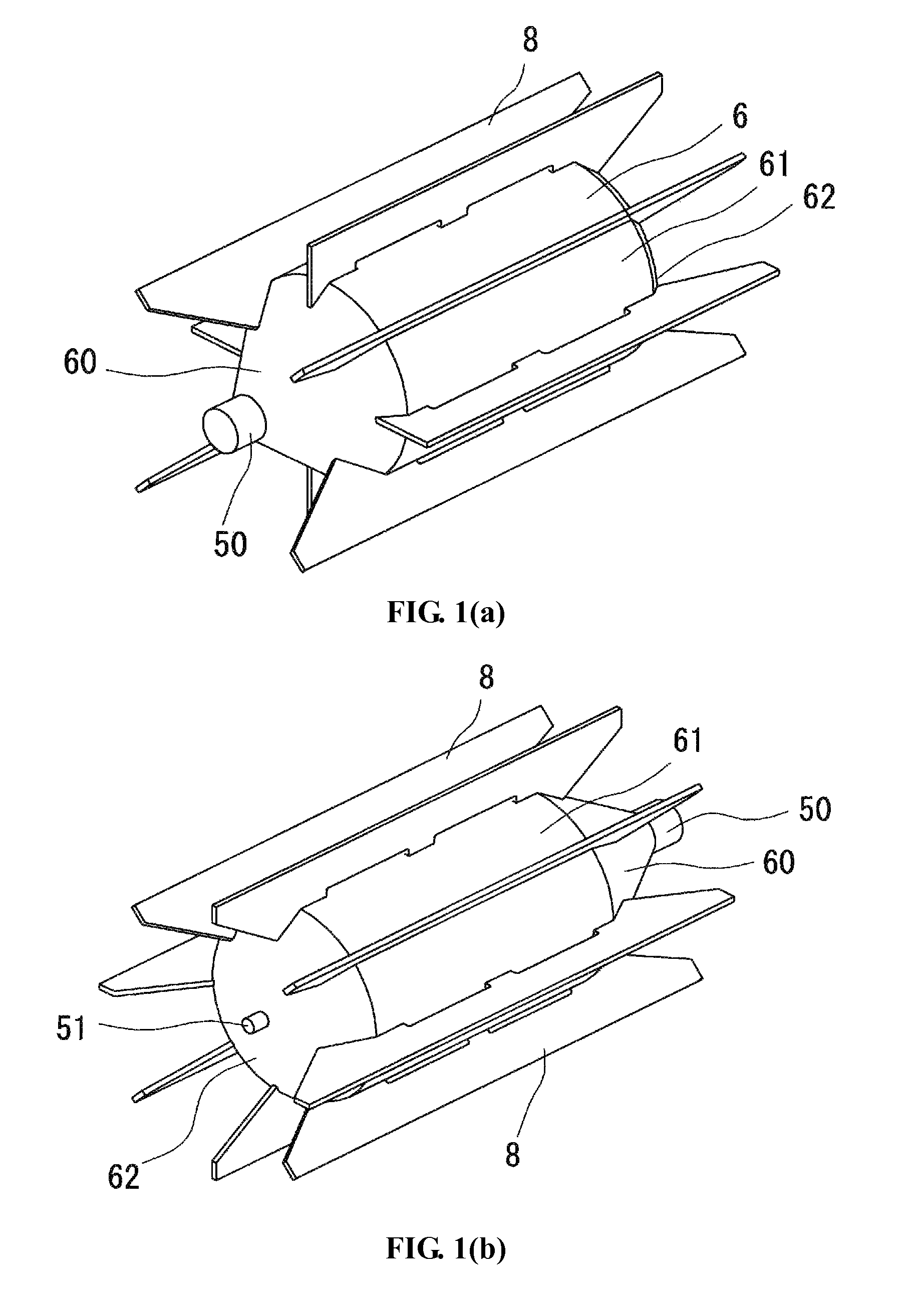

Sifter

ActiveUS8240481B2Reduce the amount requiredIncrease the screening areaSievingGas current separationEngineeringMechanical engineering

A sifter comprising: a receiver having a supply chamber; a sieve assembly having a sieving chamber coupled to the supply chamber; a rotor having a rotating shaft laterally arranged to pass through the supply chamber and the sieving chamber; a drum having a circular cross-section and having a larger diameter than the diameter of the rotating shaft, the drum being extended in at least space of the sieving chamber and arranged coaxially with the sieve; a cylindrical sieve located inside the sieving chamber and arranged coaxially with the rotating shaft; a stirring rotor located in an inner area of the sieving chamber inside the sieve comprising a rotating blade attached to the rotating shaft; an extraction member; and an outlet for discharging powder passing through the sieve from the inner area to the outer area.

Owner:TSUKASA

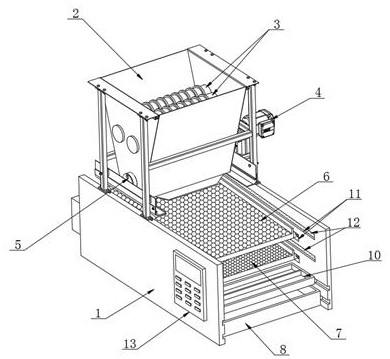

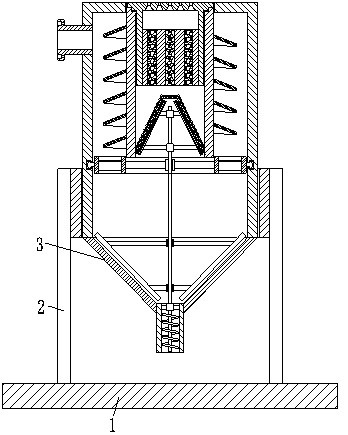

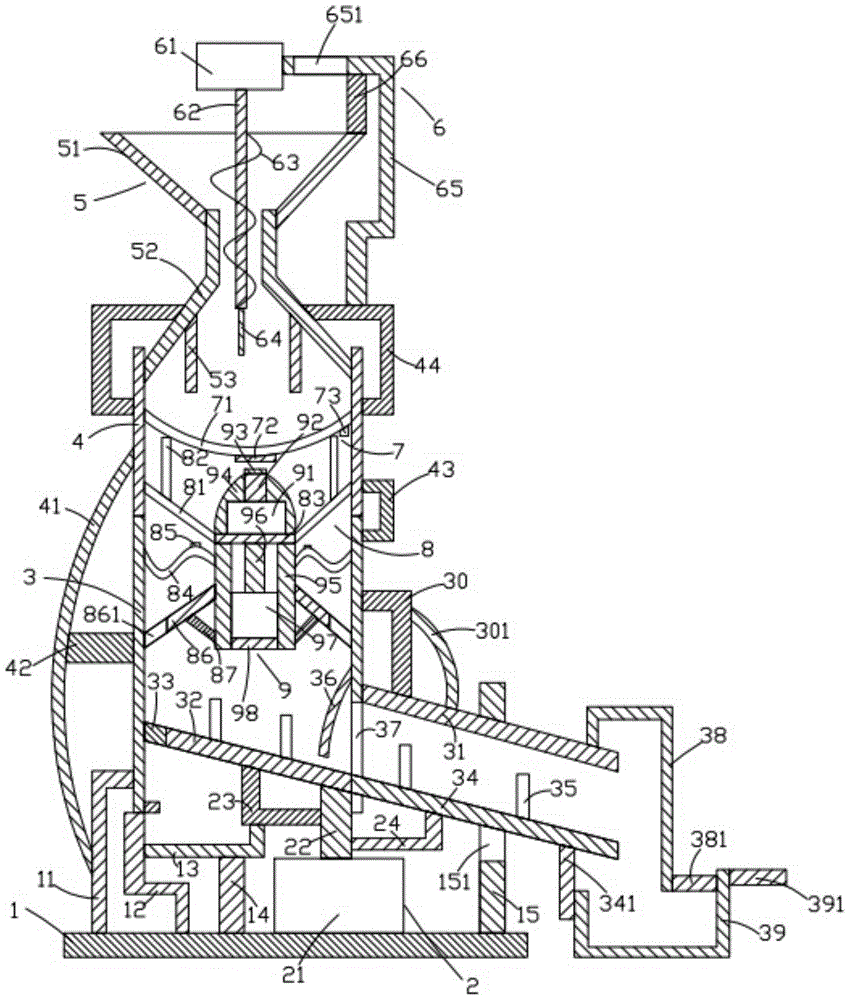

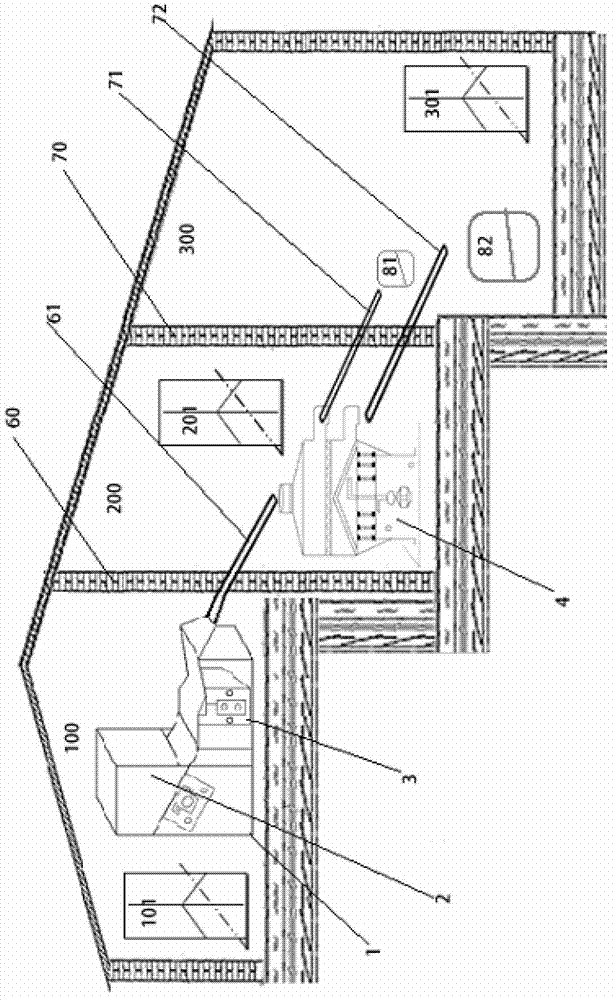

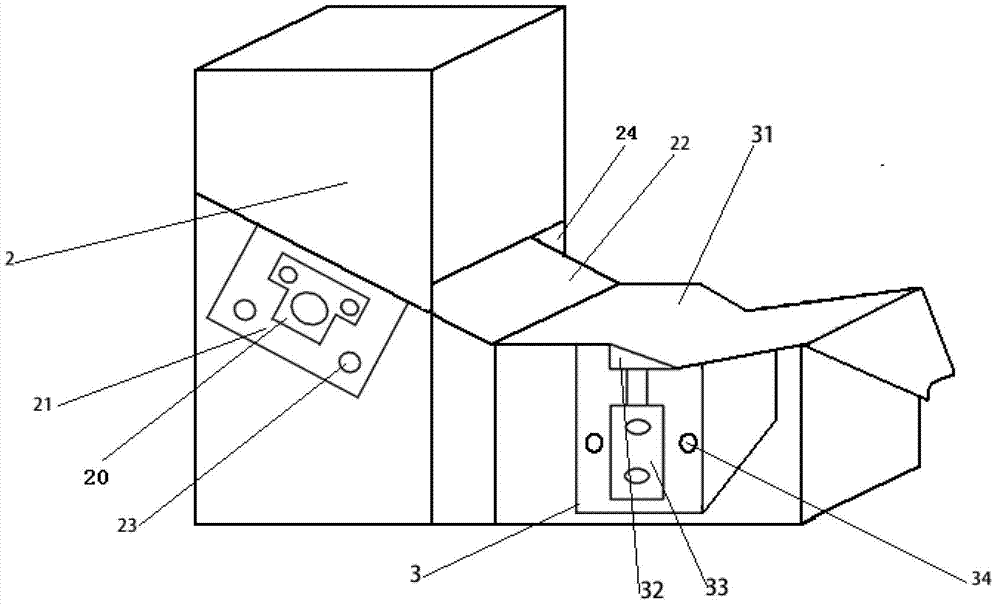

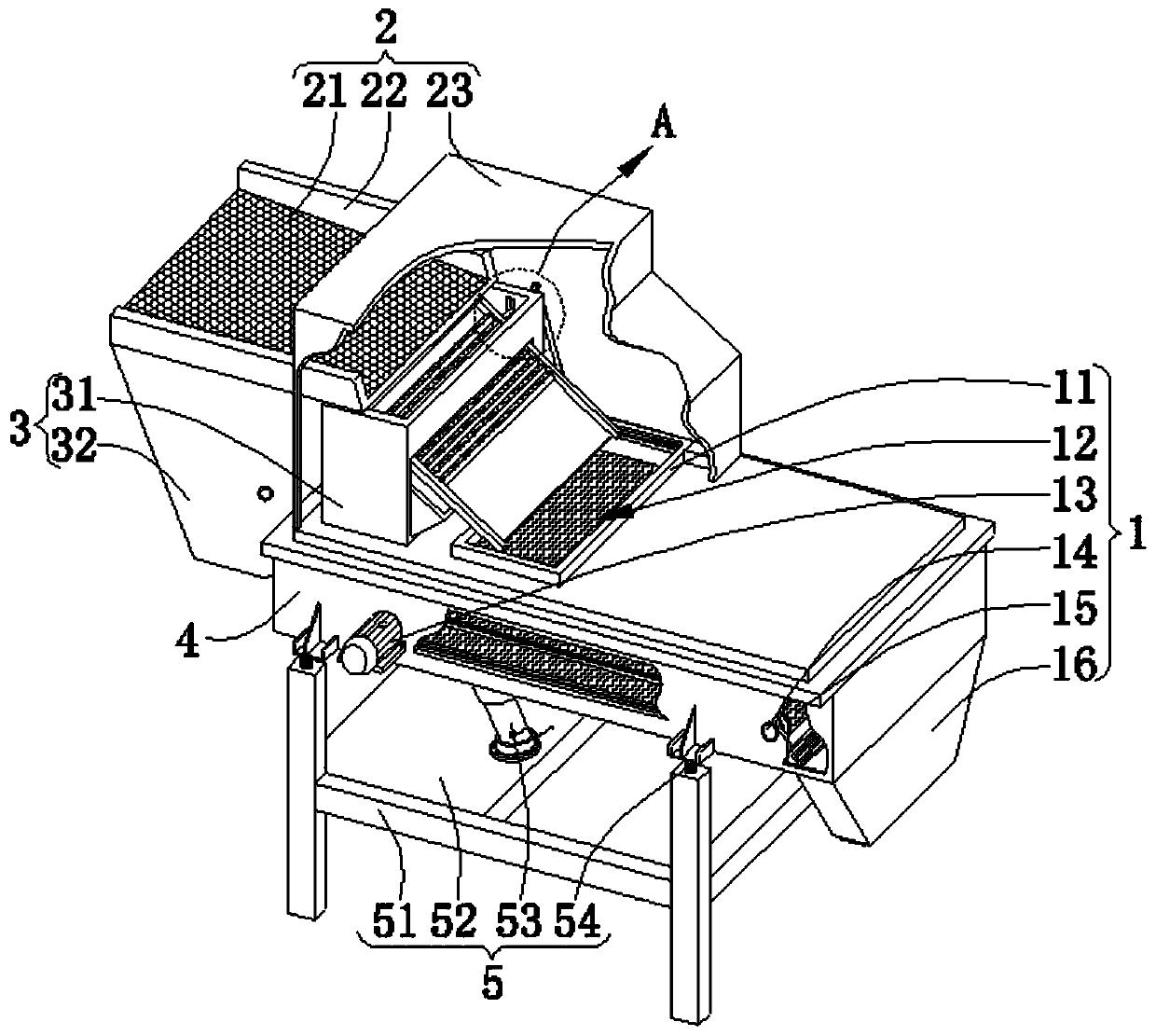

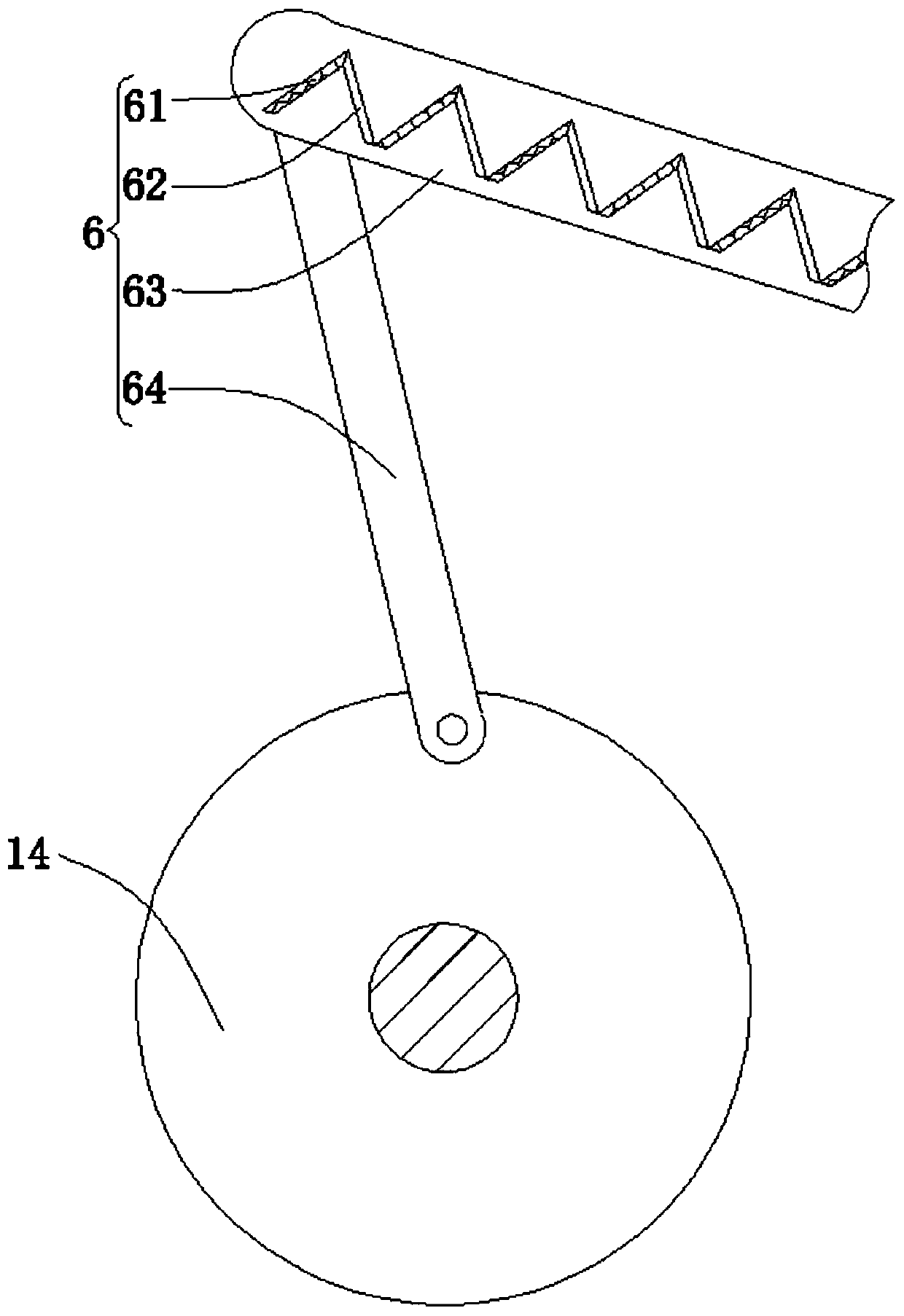

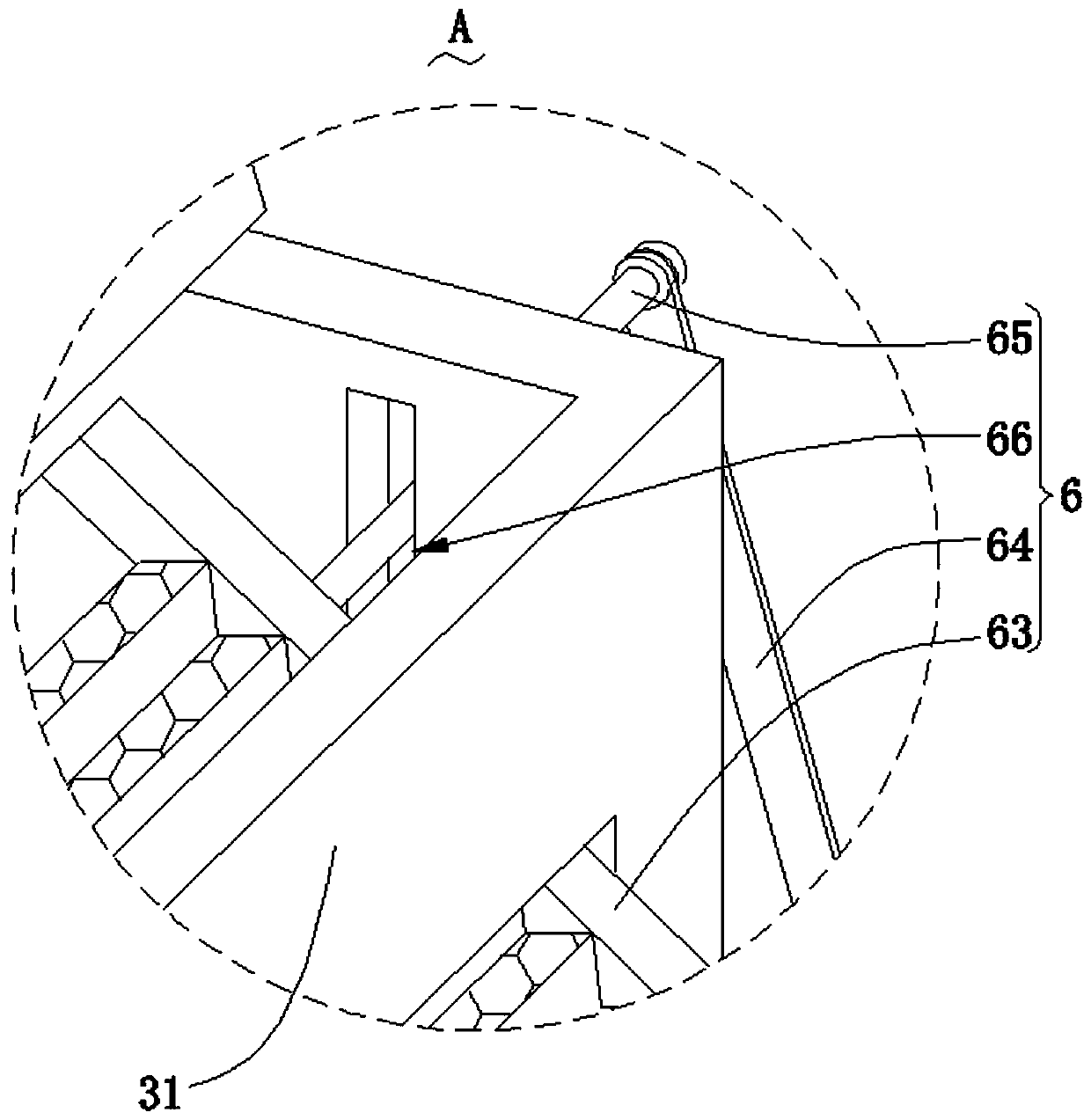

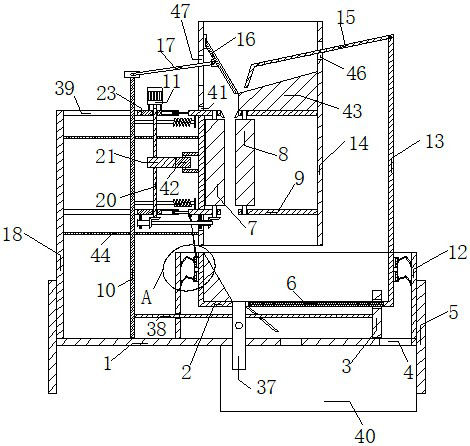

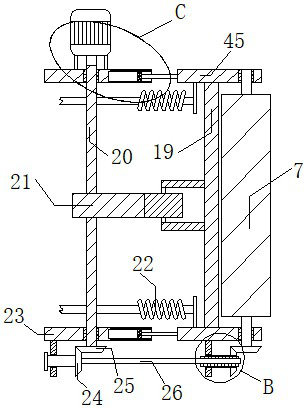

A powder vibrating screen for ore mining

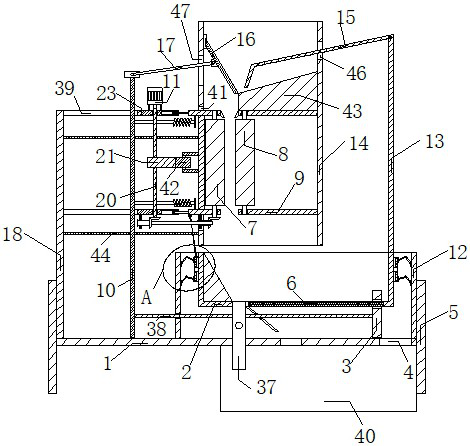

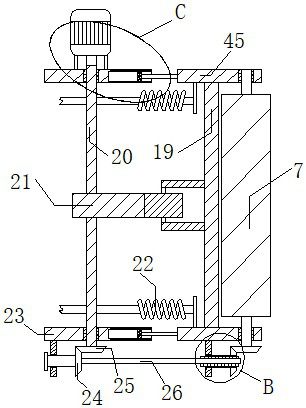

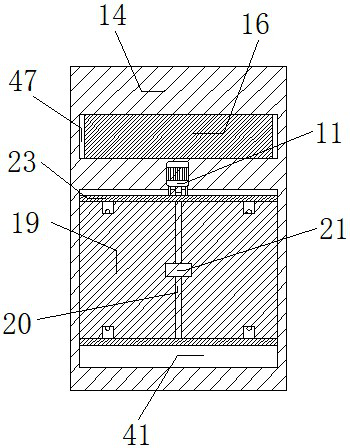

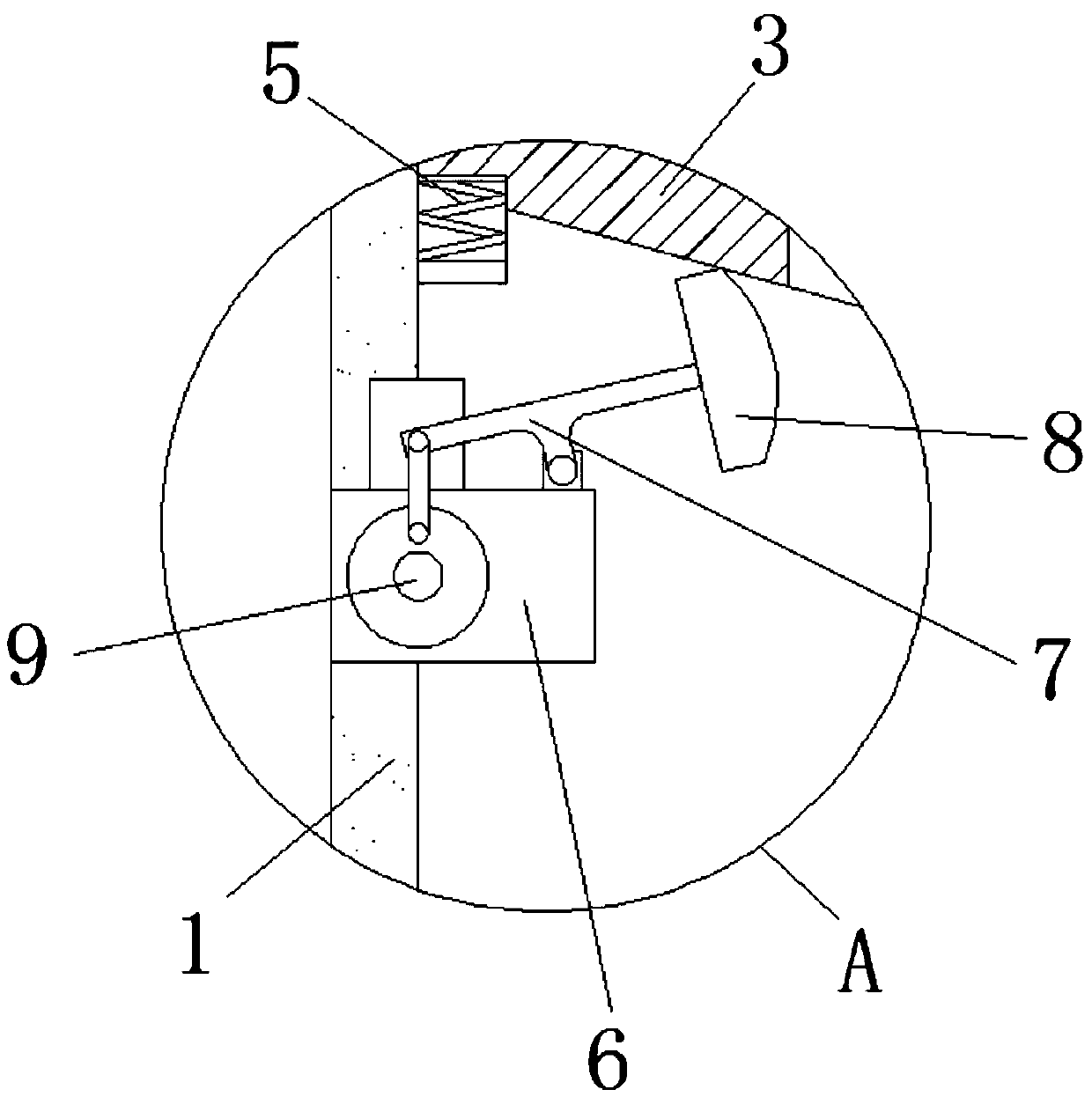

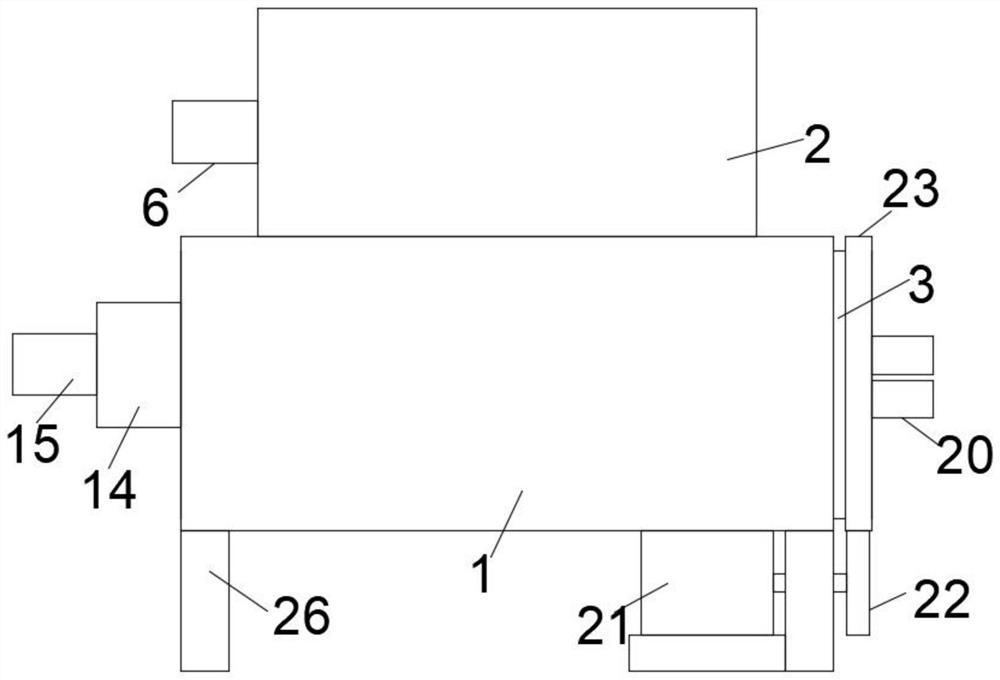

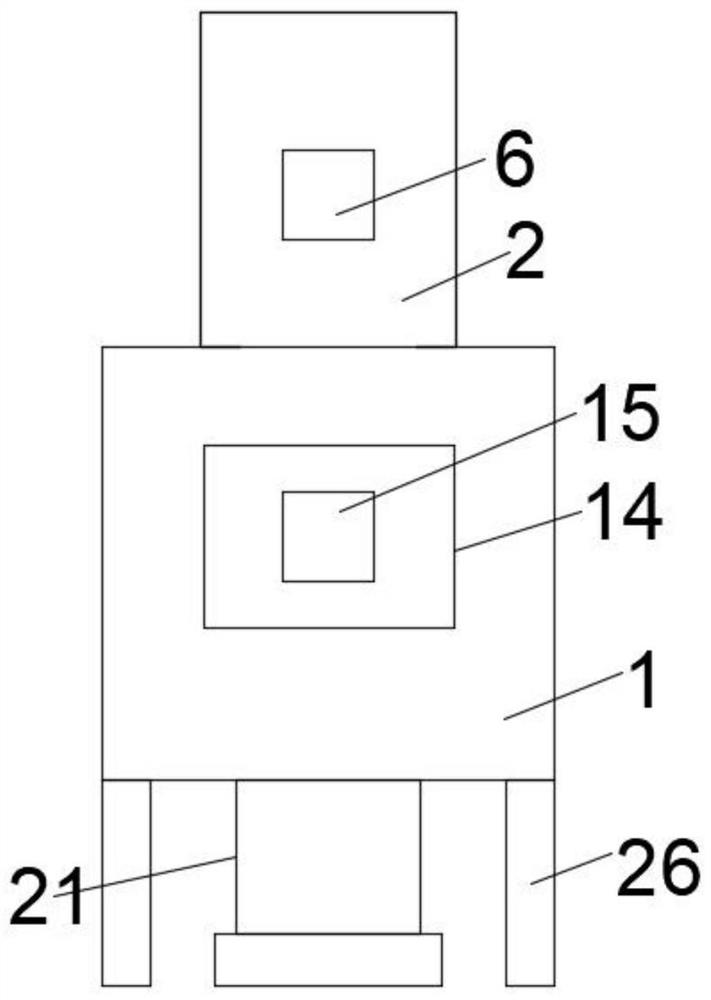

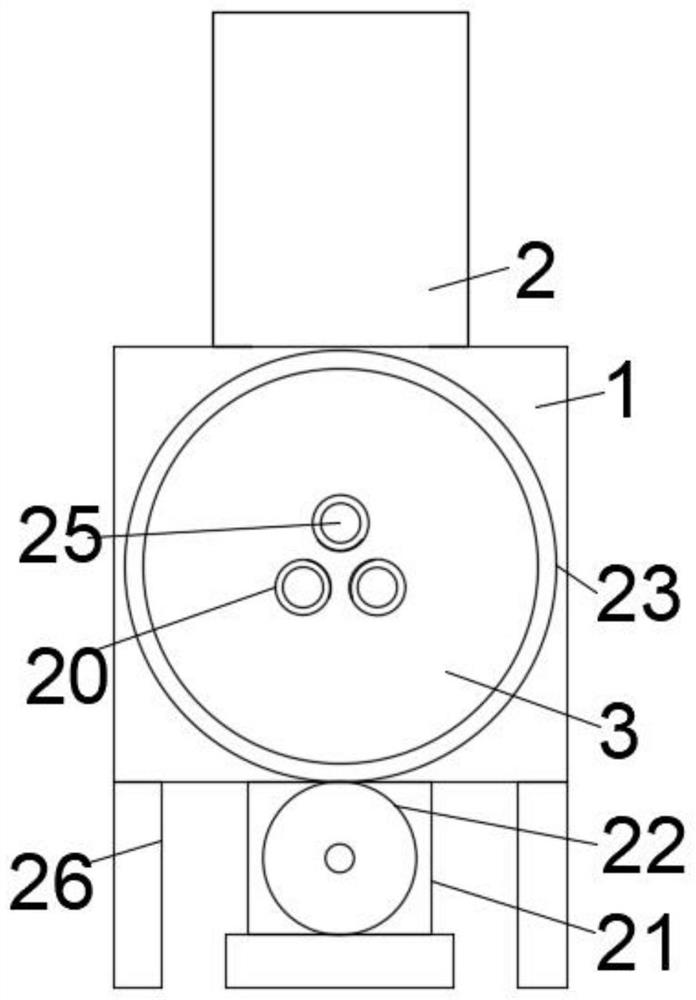

A powder vibrating screen for ore extraction, comprising a base (1), a cylinder device (2), a lower frame body (3), an upper frame body (4), a feeding device (5), a material pushing device (6), a mesh device (7), a screening device (8), and a pushing device (9); the base (1) being provided thereon with a first bracket (11), a second bracket (12), a third bracket (13), a first support pillar (14), and a second support pillar (15); the cylinder device (2) comprising a first cylinder (21), a first pushing rod (22), a fourth bracket (23), and a fifth bracket (24); the lower frame body (3) being provided thereon with a first support rod (30), a discharging frame (31), a first slant plate (32), a closing block (33), a second slant plate (34), a first filter plate (35), a first curved rod (36), a baffle (38), and a material receiving box (39); the upper frame body (4) being provided thereon with a second curved rod (41), a third cross rod (42), a first connection rod (43), and a first fixing frame (44); the feeding device (5) comprising a hopper (51), a material collection frame (52), and a second vertical rod (53); the material pushing device (6) comprising a first motor (61), a rotation shaft (62), a screw rod (63), a third vertical rod (64), a second fixing frame (65), and a third support pillar (66); and the mesh device (7) comprising a mesh (71), a first magnet (72), and a first vibrator (73). The frequency of toppling can be reduced, reducing the labor intensity of an operator.

Owner:TONGLING ZHONGDU MINING CONSTR

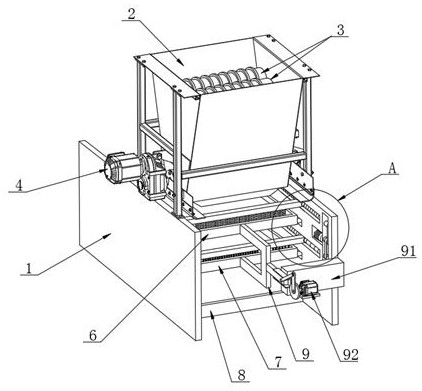

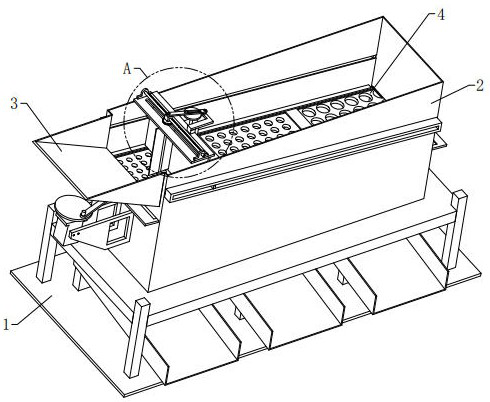

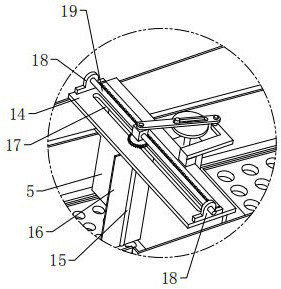

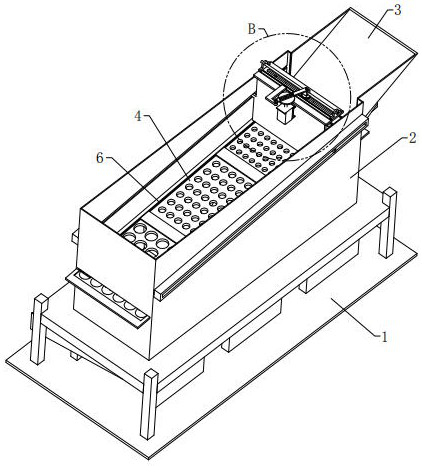

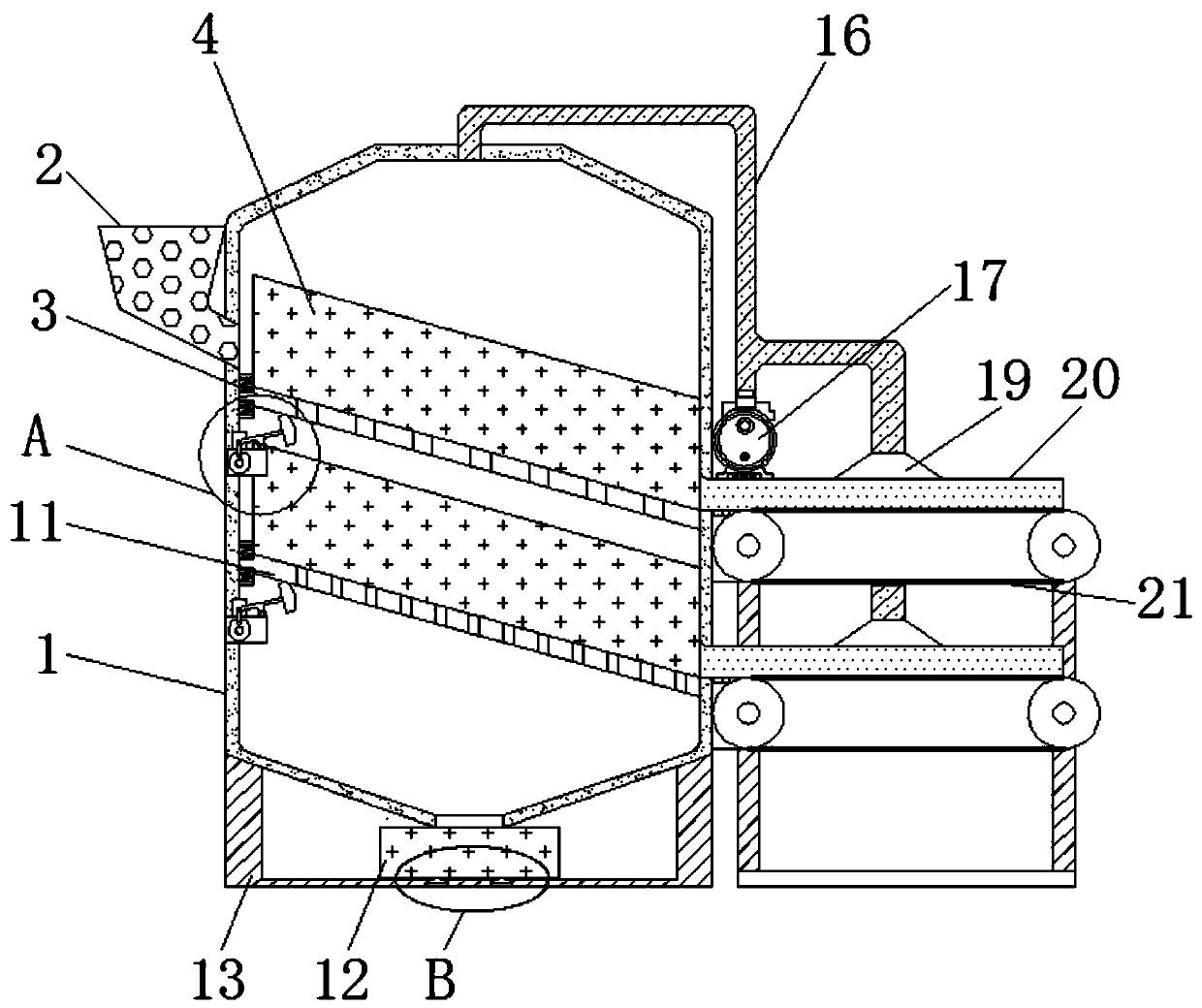

Chinese chestnut screening device

InactiveCN112191504ASieve evenlyImprove screening accuracySievingScreeningReciprocating motionEngineering

The invention relates to the technical field of Chinese chestnut processing, in particular to a Chinese chestnut screening device. The device comprises a machine frame, a screening box, and a screening mechanism, wherein the screening box is horizontally arranged on the machine frame, the top of the screening box is of an opened structure, one end of the top of the screening box is provided with afeeding slideway, the screening mechanism is arranged on the screening box and is used for screening Chinese chestnuts with different diameters; and the screening mechanism comprises a screening plate and a movable baffle, wherein the screening plate is inclined and is arranged at the upper end of the interior of the screening box in a reciprocating motion mode in the length direction of the screening box, the movable baffle is vertical and is located above the screening plate in a movable mode in the length direction of the screening plate, a preset distance is formed between the bottom of the movable baffle and the top of the screening plate, and preset distances are formed between the two sides of the movable baffle and the inner side of the screening box. According to the Chinese chestnut screening device, the Chinese chestnuts can be evenly shifted while screening, the Chinese chestnuts are screened through screens with different mesh diameters, and thus the screening precision rate is increased, and the production efficiency is improved.

Owner:李江勇

Discharging device for screening bright firework beads

Owner:浏阳市万盛烟花制造有限公司

Method for preparing expanded powder fireproof coating from perlite

The invention relates to a method for preparing an expanded powder fireproof coating from perlite. The method comprises a bottom plate, a support frame and a screening device, wherein the support frame is mounted in the middle of the upper end of the bottom plate, a section of the support frame is of a U-shaped structure, and the screening device is mounted in the support frame. The method can solve the problems that when existing equipment is used for screening powder raw materials, a screening effect is poor, screening is uneven, a screen cannot be effectively vibrated, the raw materials cannot make full contact with the screen, the screening efficiency of the raw materials is affected, and when the existing equipment is used for screening the powder raw materials, the screen usually cannot be effectively cleaned, so that large-particle impurities in the raw materials are likely to block meshes of the screen, and subsequent screening of the raw materials is not facilitated. And generally, the screen cannot be effectively cleaned, so that large-particle impurities in the raw materials are easy to block meshes of the screen, and subsequent screening of the raw materials is not facilitated.

Owner:武佳蒙

Sifter

ActiveUS20110005980A1Reduce the amount requiredIncrease the screening areaSievingGas current separationEngineeringMechanical engineering

A sifter comprising: a receiver having a supply chamber; a sieve assembly having a sieving chamber coupled to the supply chamber; a rotor having a rotating shaft laterally arranged to pass through the supply chamber and the sieving chamber; a drum having a circular cross-section and having a larger diameter than the diameter of the rotating shaft, the drum being extended in at least space of the sieving chamber and arranged coaxially with the sieve; a cylindrical sieve located inside the sieving chamber and arranged coaxially with the rotating shaft; a stirring rotor located in an inner area of the sieving chamber inside the sieve comprising a rotating blade attached to the rotating shaft; an extraction member; and an outlet for discharging powder passing through the sieve from the inner area to the outer area.

Owner:TSUKASA

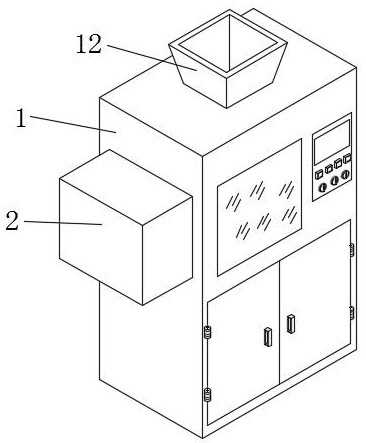

Feeding mechanism with pretreatment function for high-purity silicon production and using method thereof

ActiveCN112473779AAvoid cloggingImprove grinding efficiencyGrain treatmentsStructural engineeringMechanical engineering

The invention discloses a feeding mechanism with a pretreatment function for high-purity silicon production and a using method thereof. The feeding mechanism comprises a flat plate, a concentric-square-shaped frame is arranged above the flat plate, a U-shaped frame is movably connected into the concentric-square-shaped frame, straight plates are movably connected to the outer walls of the left side and the right side of the concentric-square-shaped frame, and the bottoms of the straight plates are fixedly connected with the top of the flat plate; and supporting plates are fixedly connected tothe left side and the right side of the flat plate correspondingly, a screen is installed at the position, close to the right side, of the bottom of the U-shaped frame, a discharging pipe is installedat the position, close to the left side, of the bottom of the U-shaped frame, and the bottom end of the discharging pipe penetrates through the top of the flat plate and extends to the position belowthe flat plate. According to the feeding mechanism, through mutual cooperation of all assemblies, a first grinding piece can rotate and move leftwards and rightwards, so that the grinding and pretreatment efficiency is effectively improved, meanwhile, a swing plate can be driven to swing leftwards and rightwards, the purpose of intermittent feeding is achieved, and blockage caused by a barrel canbe effectively prevented.

Owner:江苏泓顺硅基半导体科技有限公司

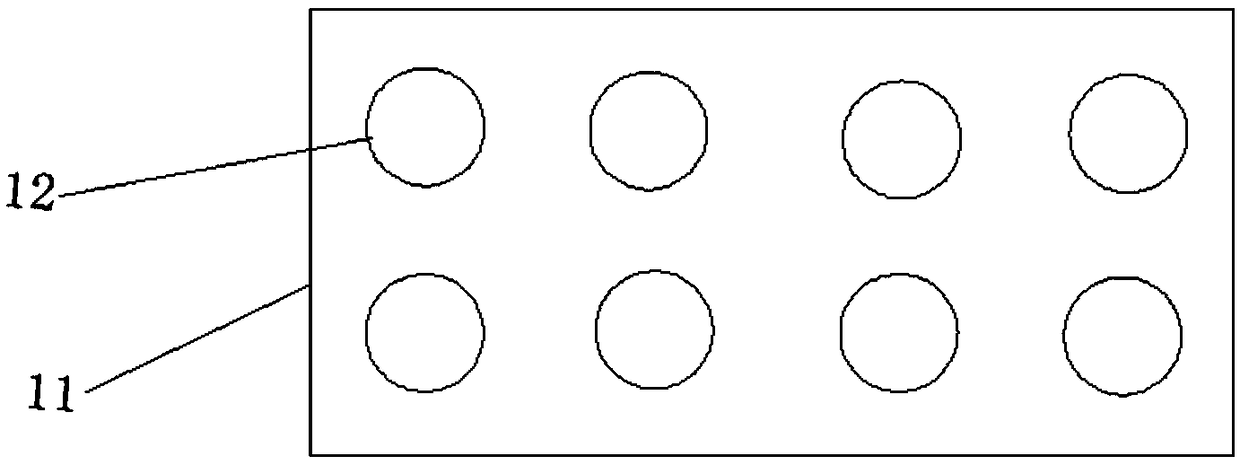

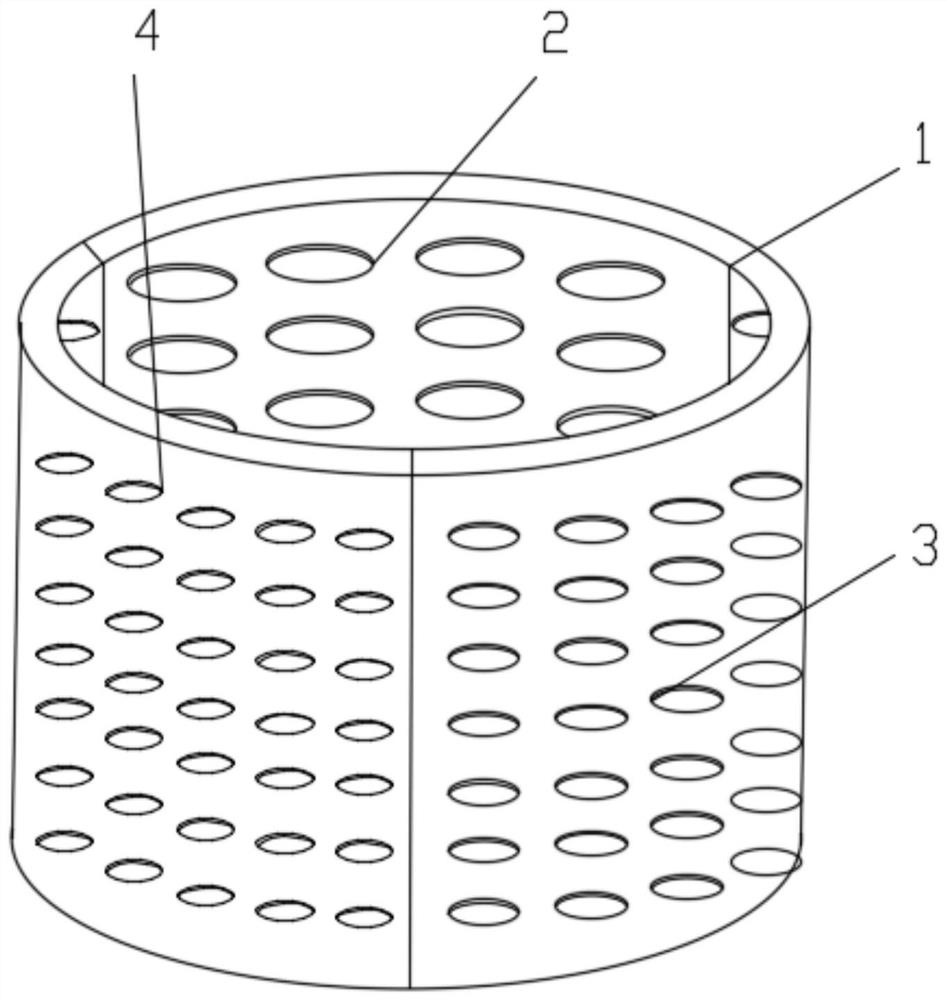

Metal screen cloth for pharmacy

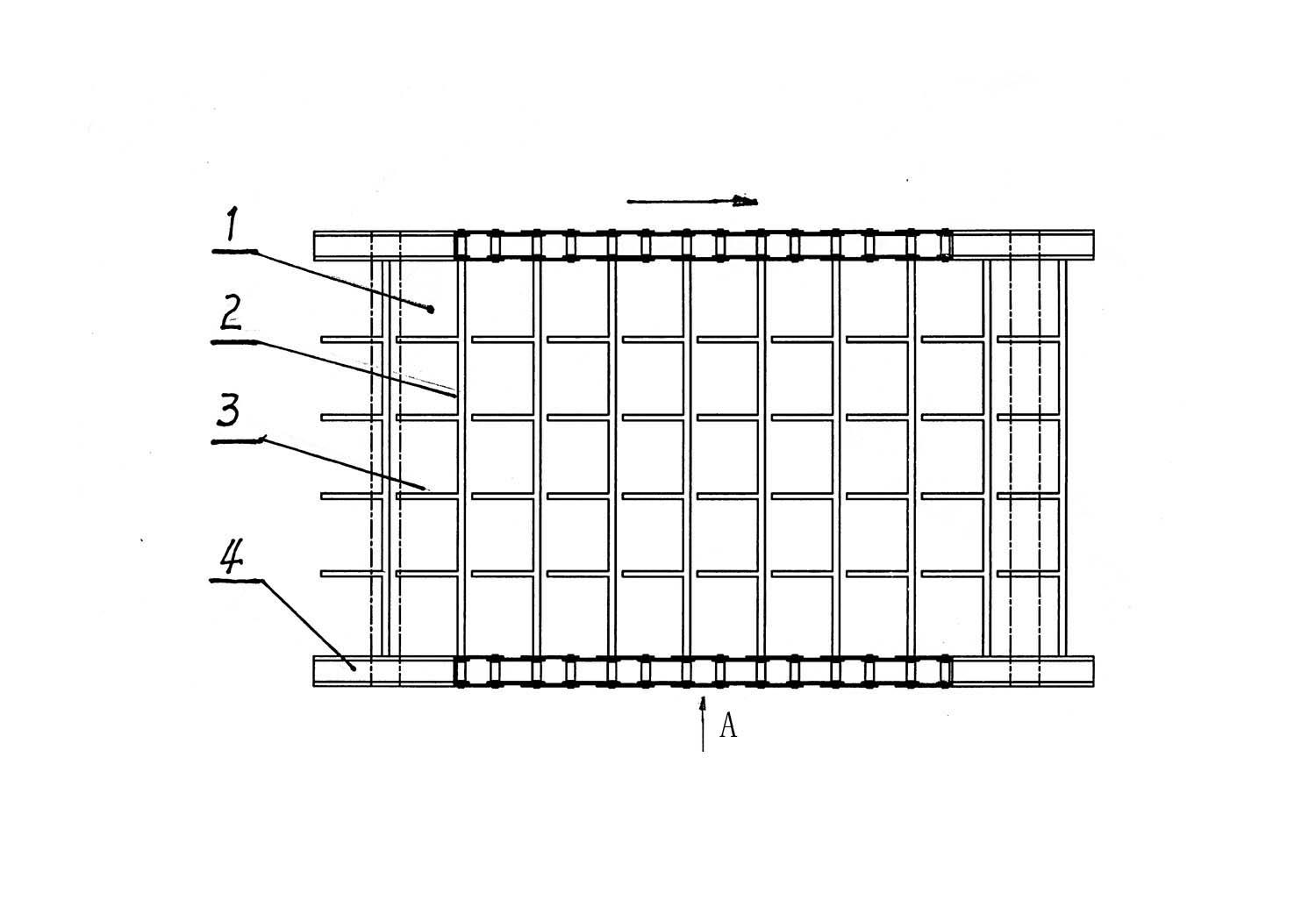

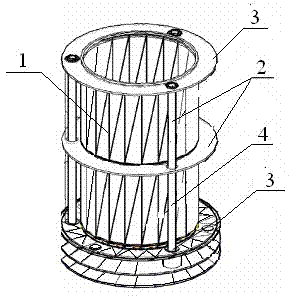

InactiveCN102825008AReasonable structural designEasy to useSievingScreeningBiomedical engineeringDrug granules

The invention discloses metal screen cloth for pharmacy, which comprises a screen cloth cylinder (1) and a screen cloth rack (2) for fixing the screen cloth cylinder (1), wherein the screen cloth rack (2) comprises an upper circular ring, a middle circular ring and a lower circular ring (3) and parallel vertical rods (4); the upper circular ring, the middle circular ring and the lower circular ring (3) are sleeved on the outer circumference of the screen cloth cylinder (1); and the parallel vertical rods (4) is used for connecting the three circular rings (3) together in parallel. The metal screen cloth for pharmacy provided by the invention has the advantages of rational structural design, convenience in use, firmness, durability, capabilities of uniformly sieving medicament particles, guaranteeing the quality of a medicament and increasing the working efficiency and wide application range.

Owner:WUJIANG WUHUA HARDWARE PROD

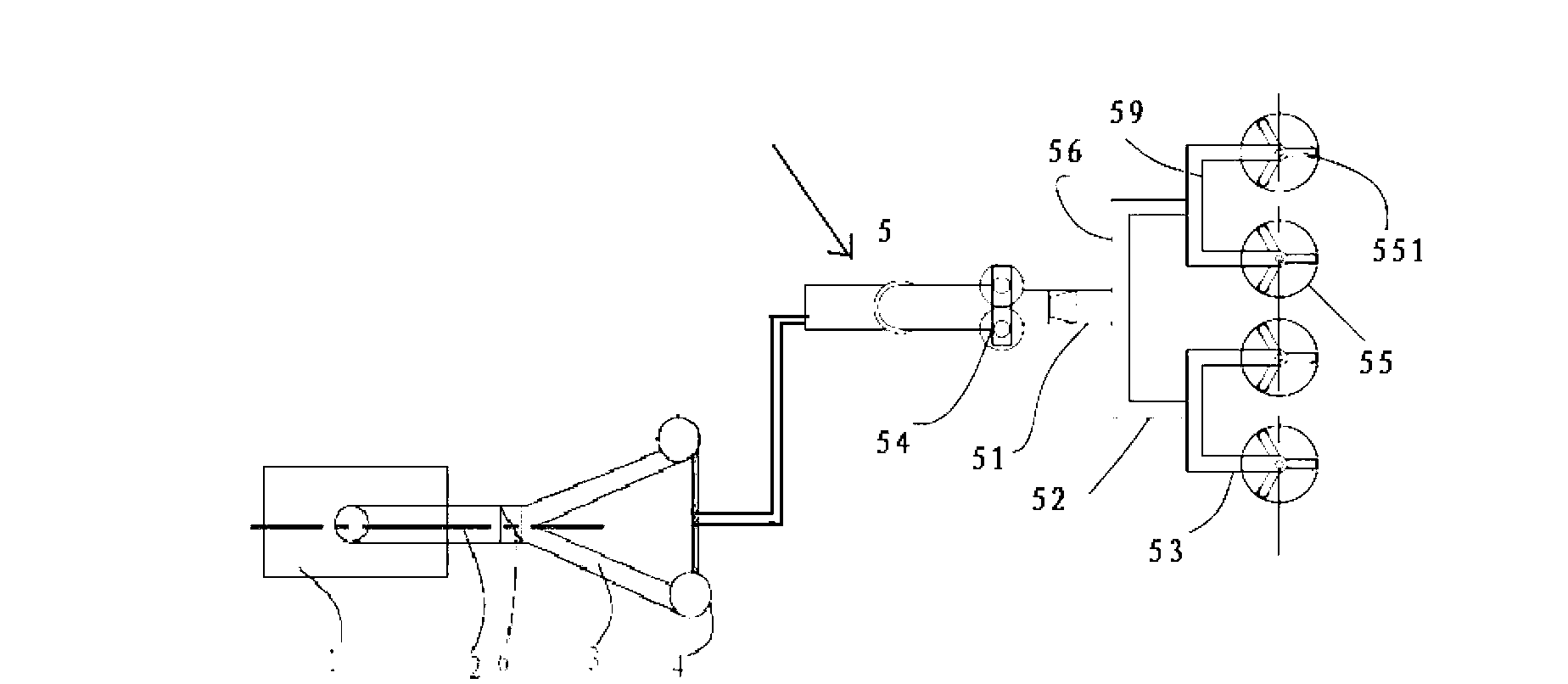

Pulverizing split-flow collecting device

InactiveCN103056012AEvenly distributedImprove collection effectVortex flow apparatusGrain treatmentsCyclonic separationEngineering

The invention relates to a separating collecting device, in particular to a pulverizing split-flow collecting device. The pulverizing split-flow collecting device comprises a freezing pulverizer, a discharge pipe, split-flow pipes and a rotary vibration sieve, wherein one end of the discharge pipe is connected with the freezing pulverizer, the other end of the discharge pipe is connected with one end of each split-flow pipe, the split-flow pipes are evenly arranged on two sides of the discharge pipe, the other end of each split-flow pipe is connected with the rotary vibration pipe, a ventilation door is arranged in the discharge pipe, a dust collecting device is arranged at the top of the rotary vibration sieve, the dust collecting device comprises a cyclone separation device and a first-level collecting pipe which is connected with the cyclone separation device, the first-level collecting pipe is connected with two second-level collecting pipes through a first split-flow pipe, the two second-level collecting pipes are respectively connected with two third-level collecting pipes through a second flow-split pipe, the third-level collecting pipes are connected with a dust removing device, the dust removing device comprises a dust removing pipe and dust removing covers which are connected with the dust removing pipe, and the dust removing covers are evenly distributed on the dust removing device. The pulverizing split-flow collecting device is capable of enabling solids to be evenly sieved, good in separating effect, good in collecting effect and high in safety.

Owner:SUZHOU AORAN COMMODITY

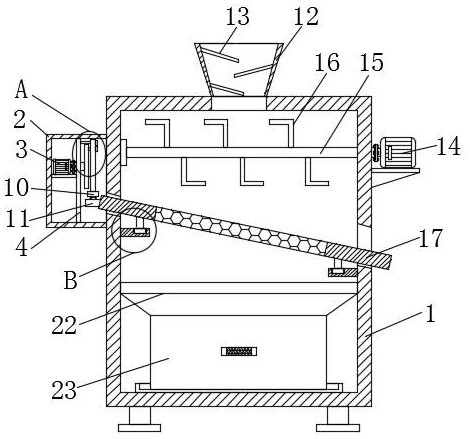

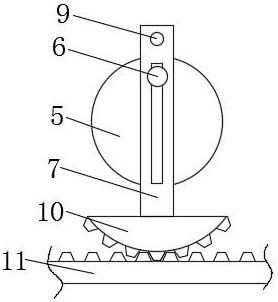

Rice screening device for rice production

PendingCN112354851AImprove screening efficiencyEvenly screenedSievingScreeningElectric machineGear wheel

Owner:寿县家豪米业有限公司

Aquatic feed particle powder screening device

The invention discloses an aquatic feed particle powder screening device which comprises a box body, a rotating shaft, a second screening plate, a dust collecting pipe and a cover plate. A feed inletis fixedly formed in the left side of the box body, baffle plates are arranged on the front and back sides of the upper end of a first screening plate, a fixed plate is mounted below a spring, the rotating shaft penetrates into the fixed plate, the second screening plate is located below the first screening plate, a collecting box is arranged below the second screening plate, a supporting seat isarranged below the collecting box, the dust collecting pipe is located at the upper end of the box body, a dust storage tank is mounted at the back end of a sucking pump, a dust collecting hood is mounted on the right side of the sucking pump, the cover plate is located at the lower end of the dust collecting hood, and a conveyor belt is mounted at the lower end of the cover plate. The aquatic feed particle powder screening device can screen particles and detritus of an aquatic feed uniformly, and can collect the dust, so that the powder is collected more cleanly.

Owner:XUZHOU KEXING TECH DEV CO LTD

Plastic particle screening device

PendingCN113733395AScreen thoroughlySieve evenlySievingScreeningStructural engineeringElectrical and Electronics engineering

The invention discloses a plastic particle screening device. The plastic particle screening device comprises a box body supported by supporting columns, a feeding box is arranged at the upper end of the box body, a segmented discharging device is arranged in the feeding box, a discharging baffle is arranged at the position, located at the lower end of the segmented discharging device, of the feeding box, a cylinder movably connected to the box body is arranged below the discharging baffle, the cylinder abuts against the lower end face of the discharging baffle, the interior of the cylinder is divided into a first screen part, a second screen part and a material leakage net part through partition plates at equal angles, a first transmission device is arranged at the lower end of the box body, a material conveying device opposite to the first screen part, the second screen part and the material leakage net part is arranged in the cylinder, and one end of the cylinder is provided with a discharge pipe opposite to the first screen part, the second screen part and the leakage net part. According to the plastic particle screening device, the cylinder is driven to rotate through the transmission device, so that the staying time of plastic particles on the first screen part, the second screen part and the material leaking net part is the same, the plastic particles can be uniformly screened, and then screening is more thorough.

Owner:霍山诚宇新材料科技有限公司

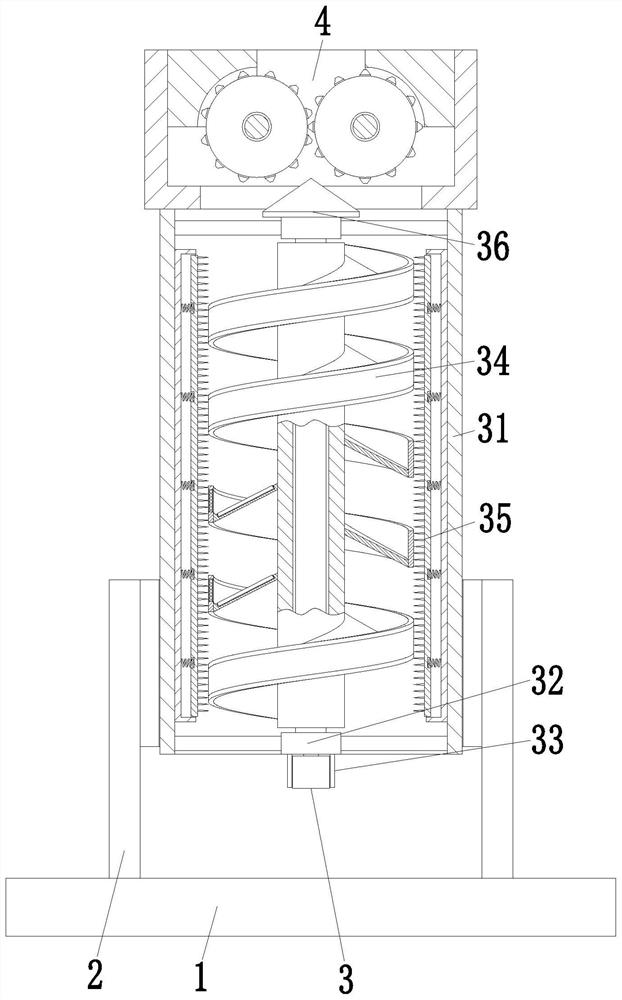

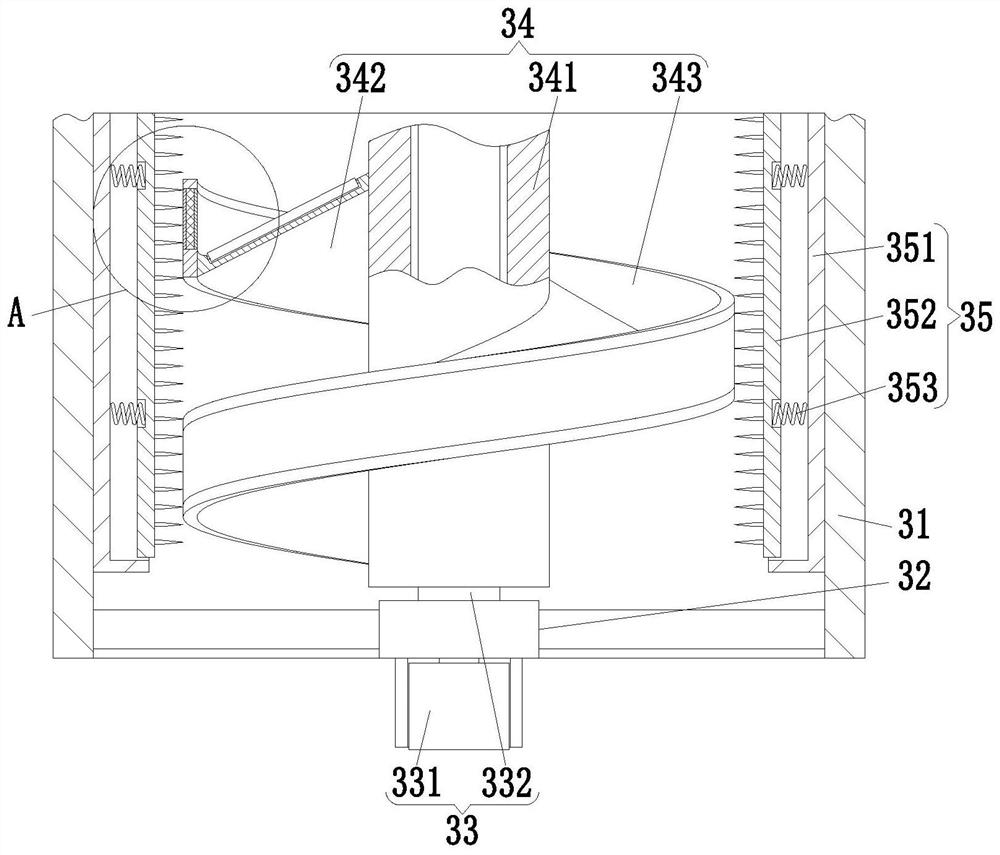

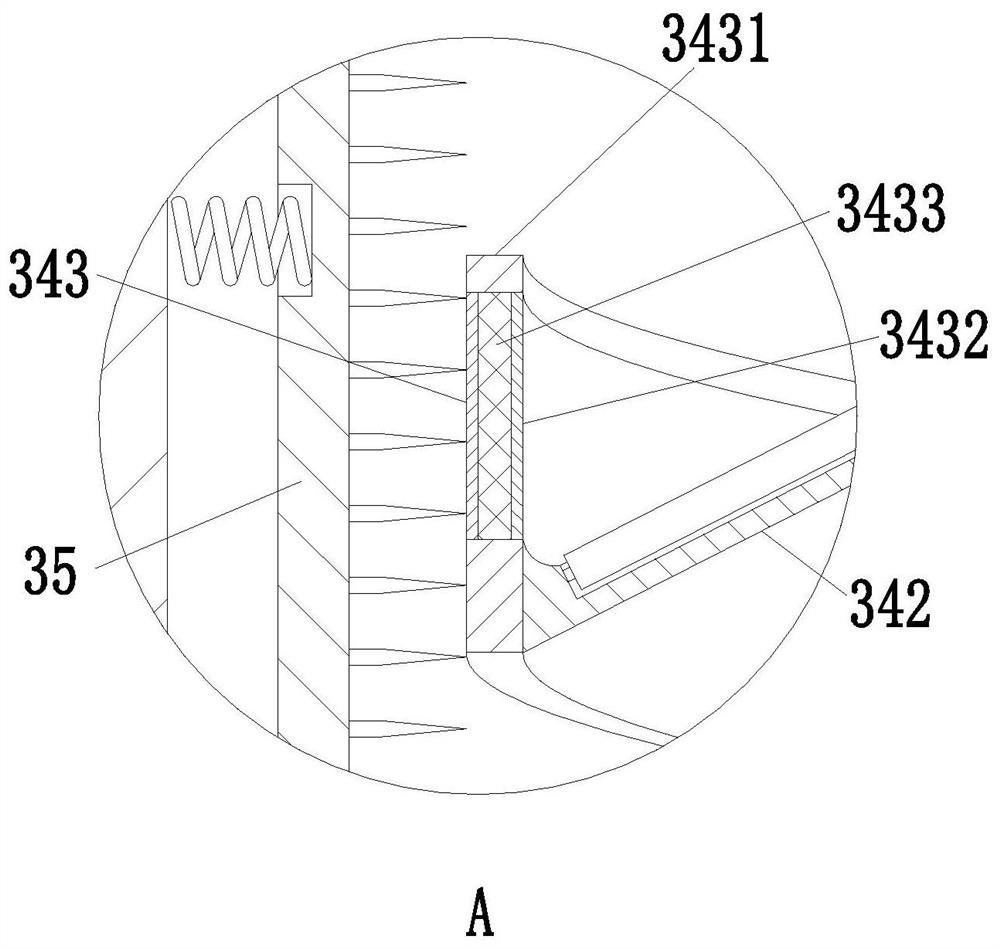

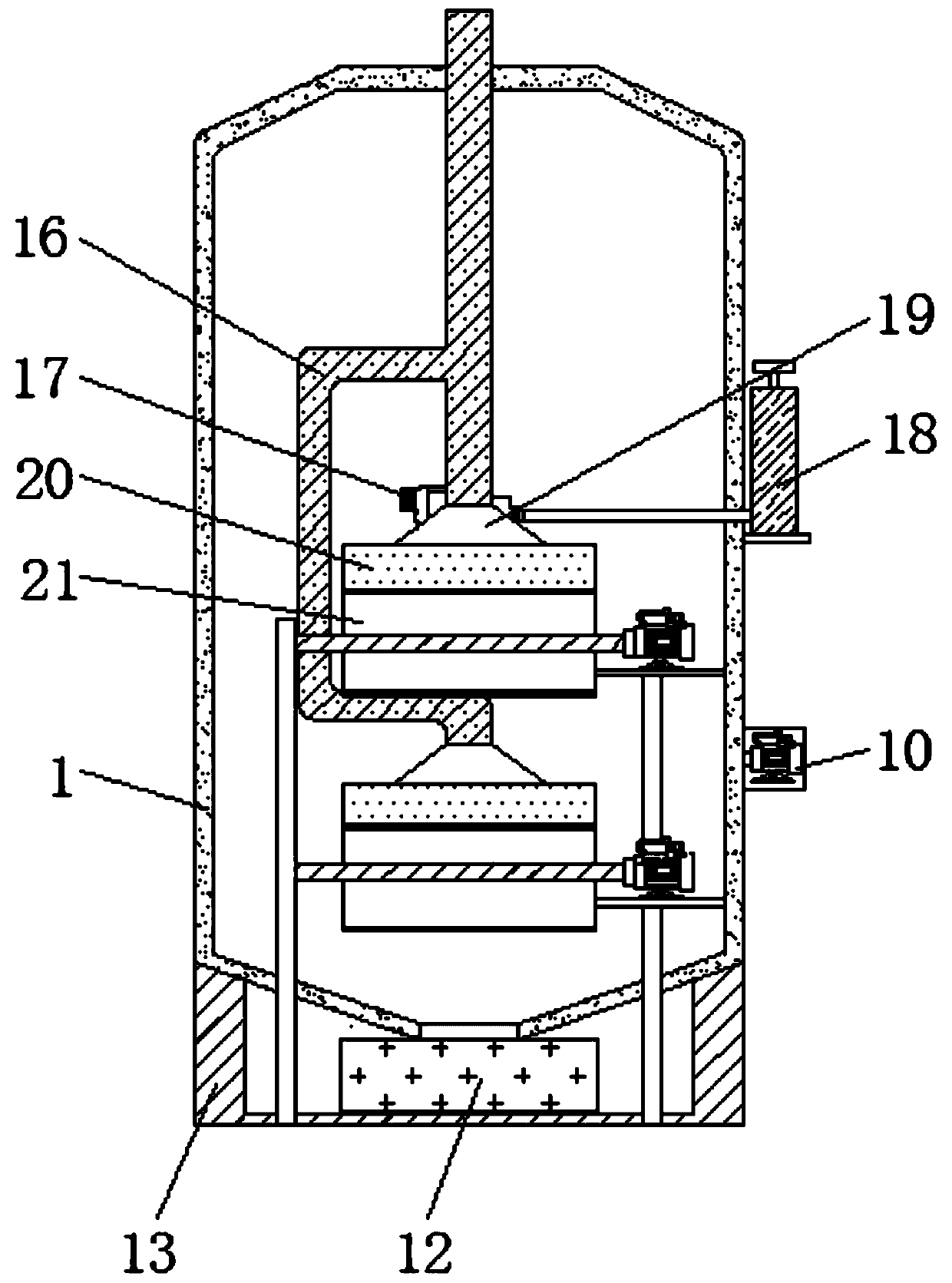

Spiral vibrating type classifying screen

InactiveCN106269473AReduce the chance of missingFine screening resultSievingScreeningDrive motorEngineering

The invention discloses a spiral vibrating type classifying screen. The spiral vibrating type classifying screen comprises a feeding hopper, a driving motor and a vibrating screen, and the vibrating screen is divided by a plurality of screen plates into a plurality of sub vibrating screens; a corresponding barrel is connected to the exterior of each sub vibrating screen, and one barrel, one screen plate, one sub vibrating screen and a corresponding center shaft form one screening compartment; and the hole diameters of screen holes of each screening compartments are the same, and the hole diameters of screen holes of the screening compartments are sequentially reduced from top to bottom. By means of the spiral vibrating type classifying screen, the spiral sub vibrating screens and the screen plates are adopted, screen holes are formed in the sub vibrating screens and the screen plates, and the sub vibrating screens and the screen plates are combined. The spiral sub vibrating screens conduct screening while conducting transporting, and screened materials are screened for the first time. When conveyed to the screen plates, the materials are screened for the second time, and the screened materials enter the next screening compartment. The sub vibrating screens and the screen plates both vibrate under the effects of the driving motor, double guarantees are achieved, the rate of leakage of wee materials is decreased, and the screening result is more exquisite.

Owner:CHENGDU DAHONGLI MACHINERY

A kind of multi-stage vibrating screening equipment for coal gangue separation

ActiveCN109746183BComprehensive screeningSieve evenlySievingScreeningSolid structureStructural engineering

Owner:ANHUI UNIV OF SCI & TECH

Screening machine set

Owner:SHANGHAI DONGMENG ROAD & BRIDGE MACHINERY

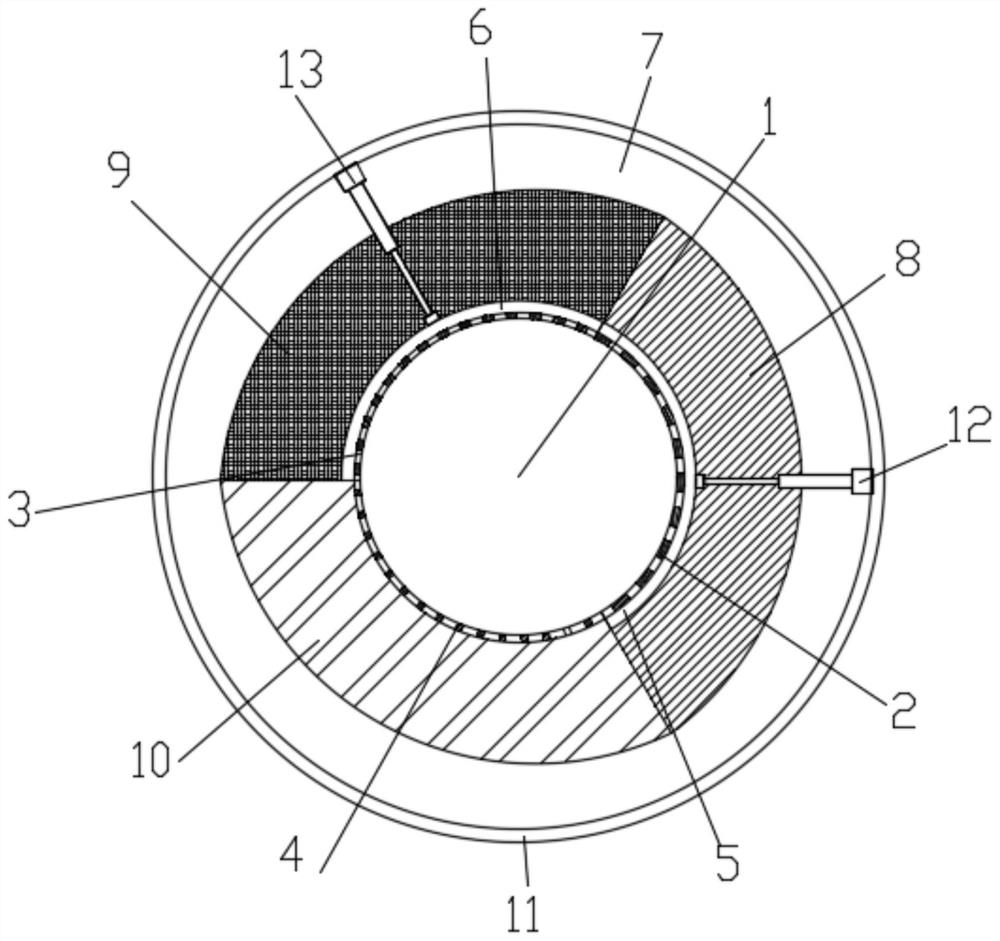

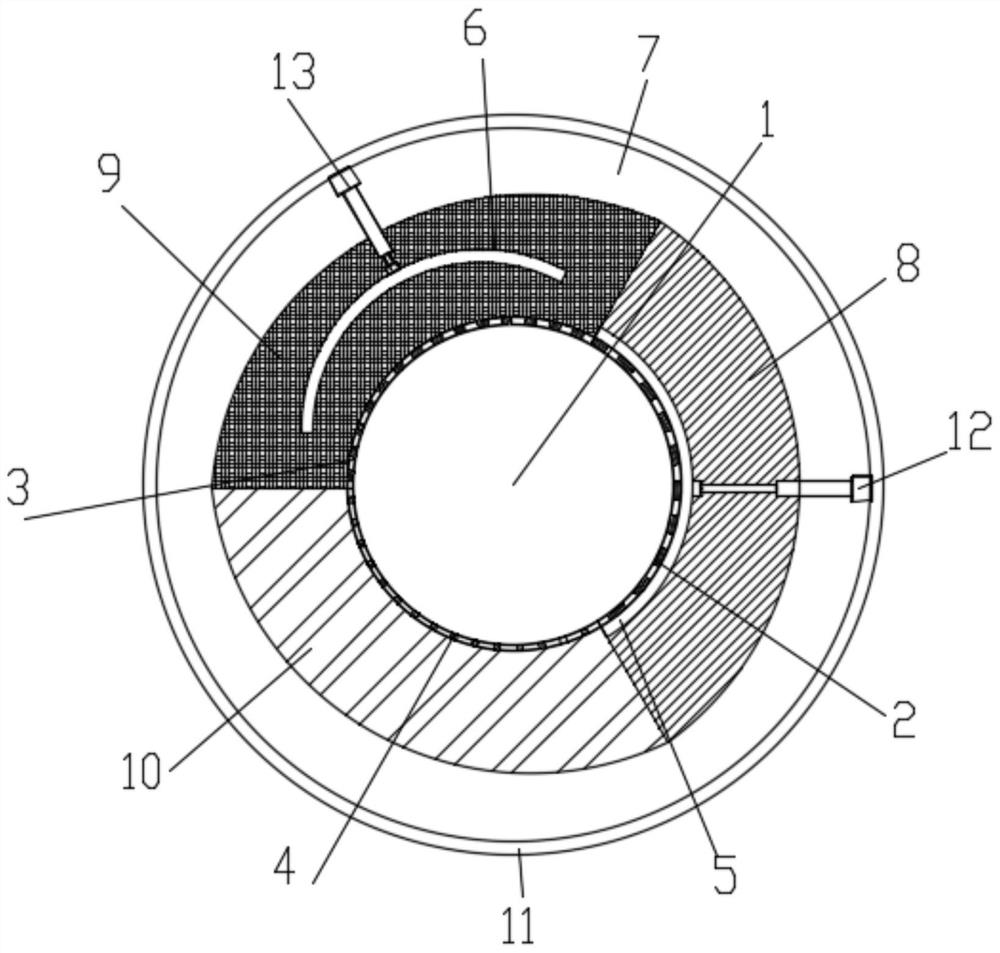

Hunan lotus seed screening equipment

InactiveCN113083655AImprove work efficiencySieve evenlySievingScreeningSocial benefitsAgricultural engineering

The invention provides Hunan lotus seed screening equipment. The equipment is characterized in that a screening barrel is divided into a first fan-shaped screen, a second fan-shaped screen and a third fan-shaped screen in the circumferential direction, the aperture of the first fan-shaped screen is larger than that of the second fan-shaped screen, the aperture of the second fan-shaped screen is larger than that of the third fan-shaped screen, a first shielding device is arranged at the first fan-shaped screen, the first shielding device selectively shields and exposes screen holes in the first fan-shaped screen, the second fan-shaped screen is provided with a second shielding device, and the second shielding device selectively shields and exposes screen holes in the second fan-shaped screen. In the specific operation practice, by controlling the opening sequence of the first shielding device and the second shielding device and by means of the centrifugal force principle, Hunan lotus seeds in the screening barrel can be screened according to three hole diameter specifications, the working efficiency is high, screening is uniform, good economic benefits and social benefits are achieved, and the screening equipment is suitable for application and popularization.

Owner:岳阳嘉联生态农业股份有限公司

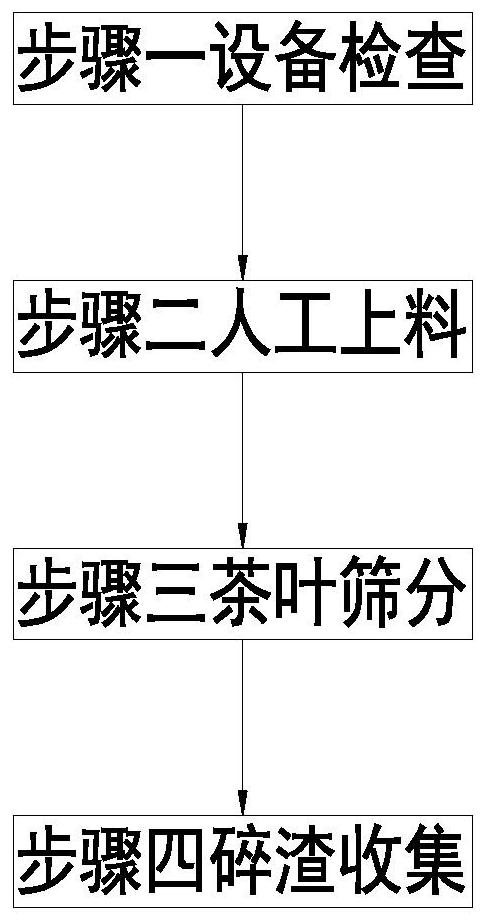

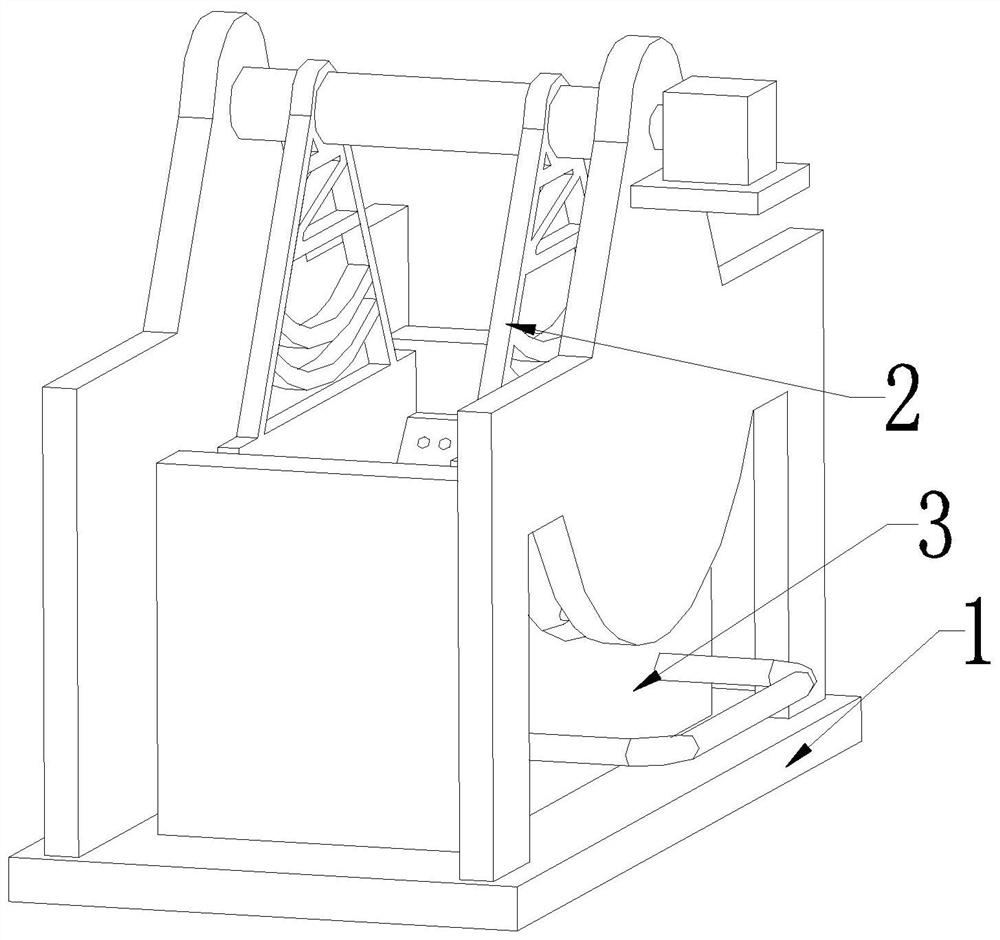

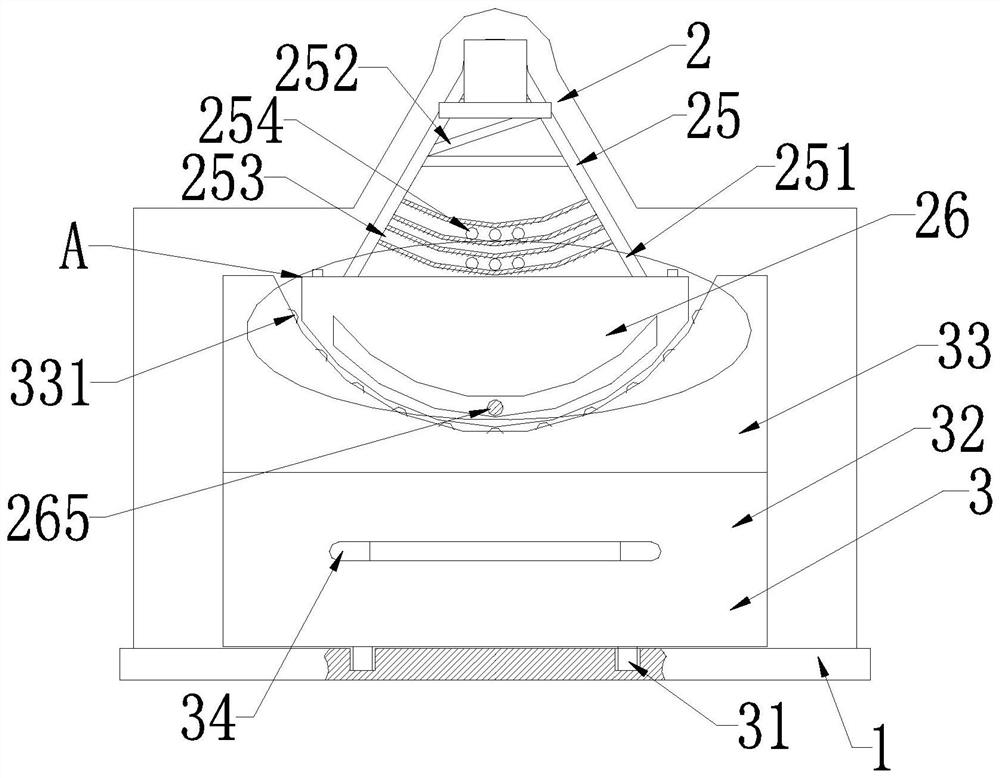

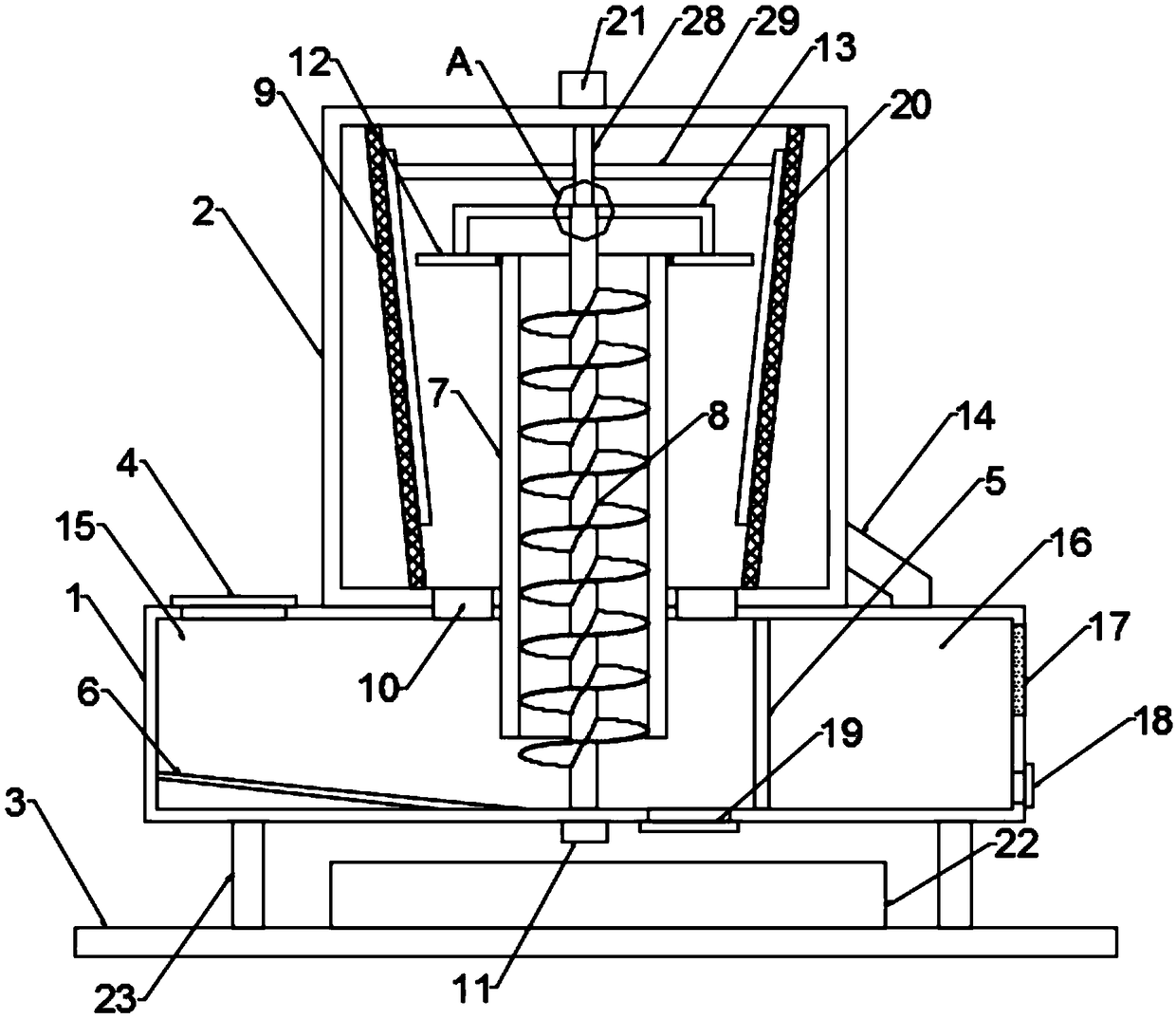

Tea making process

InactiveCN111889361AIncrease workloadSieve evenlySievingPre-extraction tea treatmentProcess engineeringTea leaf

The invention relates to a tea making process. The tea making process mainly comprises the following steps of equipment inspection, manual feeding, tea screening and broken residue collection. A tea screening device comprises a mounting frame, a screening suite and a collecting suite, and the screening suite and the collecting suite are sequentially arranged in the mounting frame from top to bottom. The tea making process can solve the following problems existing in the production process of existing tea that a, in the stir-frying process of the existing tea, the water of the tea needs to be stir-fried to be dry, so that the tea becomes dry and fragile, a large number of tea fragments are carried during bottling, and the quality is greatly influenced; and b, after the tea which is stir-fried to be dry is screened, the screened broken materials are often put into a collecting bag for unified storage, when a collecting belt is used for collecting, the phenomenon that the collecting bag is separated and leaked due to the fact that a bag opening is separated from a collecting container often occurs, then the phenomenon that the broken tea residues are scattered occurs, manual cleaningis needed, the workload of workers is greatly improved, and manpower is wasted.

Owner:仇芳

Agricultural bean grain reciprocating screening device

InactiveCN108906619AAvoid cloggingAvoid top loadingGas current separationScreening effectEngineering

The invention discloses an agricultural bean grain reciprocating screening device which comprises a feeding box and a screening barrel. A partition is arranged inside the feeding box and divides the inside of the feeding box into a feeding chamber positioned at the left end and a discharging chamber positioned at the right end, the screening barrel is provided with a backflow port communicated with the feeding chamber, the backflow port is positioned on the inner side of a screening net barrel, the side wall of the screening barrel is communicated with the discharging chamber through a guide pipe, a first discharging port is arranged on the side wall of the discharging chamber, a second discharging port is arranged on the side wall of the bottom of the feeding chamber, and a bottom baseplate is arranged on the lower side of the feeding box and connected with the feeding box through multiple damping devices. The device is simple in structure; a screw conveyor is uniform in bean grain lifting, thereby being uniform in screening, so that the circumstance that screening effect is bad due to simultaneous screening of many grains is avoided; repeated screening can be realized, so that screening effect is improved; feeding from the top end is avoided during feeding, so that labor is saved.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com