Tea making process

A production process and tea technology, which is applied in tea treatment before extraction, solid separation, filtration and sieving, etc. It can solve problems such as affecting sales, wasting manpower, and leakage of collection bags, so as to avoid secondary crushing, avoid industrial waste, and improve work efficiency. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

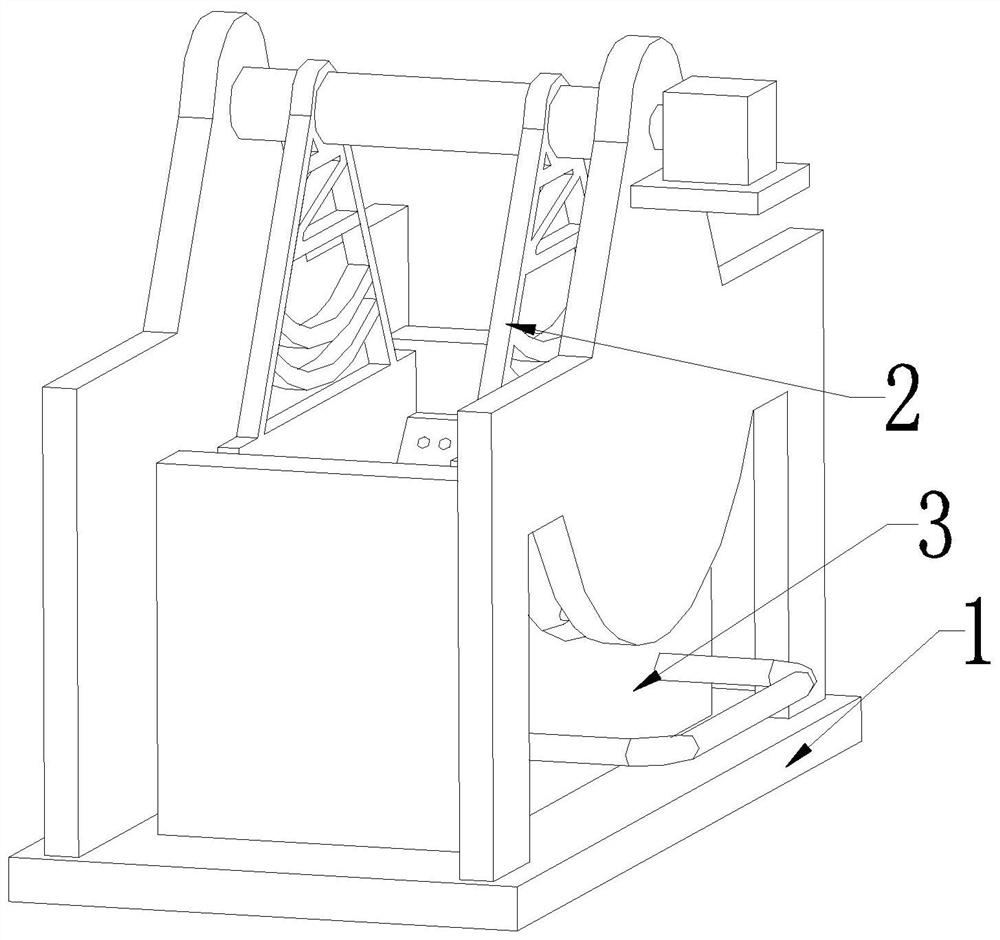

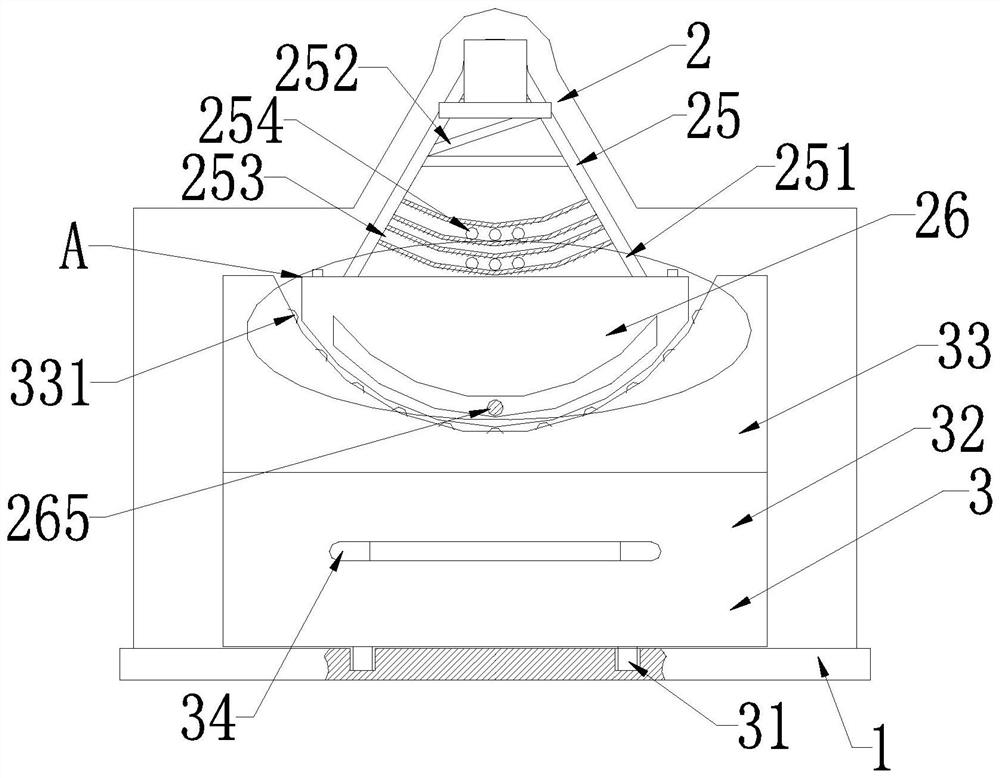

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

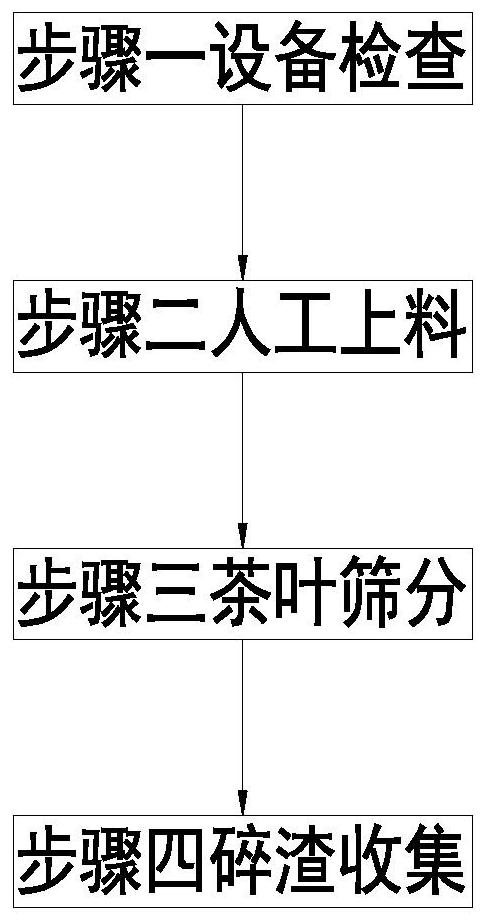

[0030] Such as Figure 1 to Figure 7 As shown, a tea making process mainly includes the following steps:

[0031] Step 1: Equipment inspection: Check the operation of the equipment before starting the tea screening device to screen the fried tea leaves;

[0032] Step 2: Manual feeding: manually place the roasted tea leaves on the holding plate 27, and install the holding plate 27 on the sieve rack 26, so as to achieve the purpose of manual feeding;

[0033] Step 3: Tea sieving: After completing the manual feeding operation of step 2, the No. 1 motor starts to work, and then the rotating block 23 is driven to move through the toggle block 22 on the rotating rod 21, thereby driving the sieve clamp to move through the connecting frame 25 , To screen the roast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com