Patents

Literature

153results about How to "Screen thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

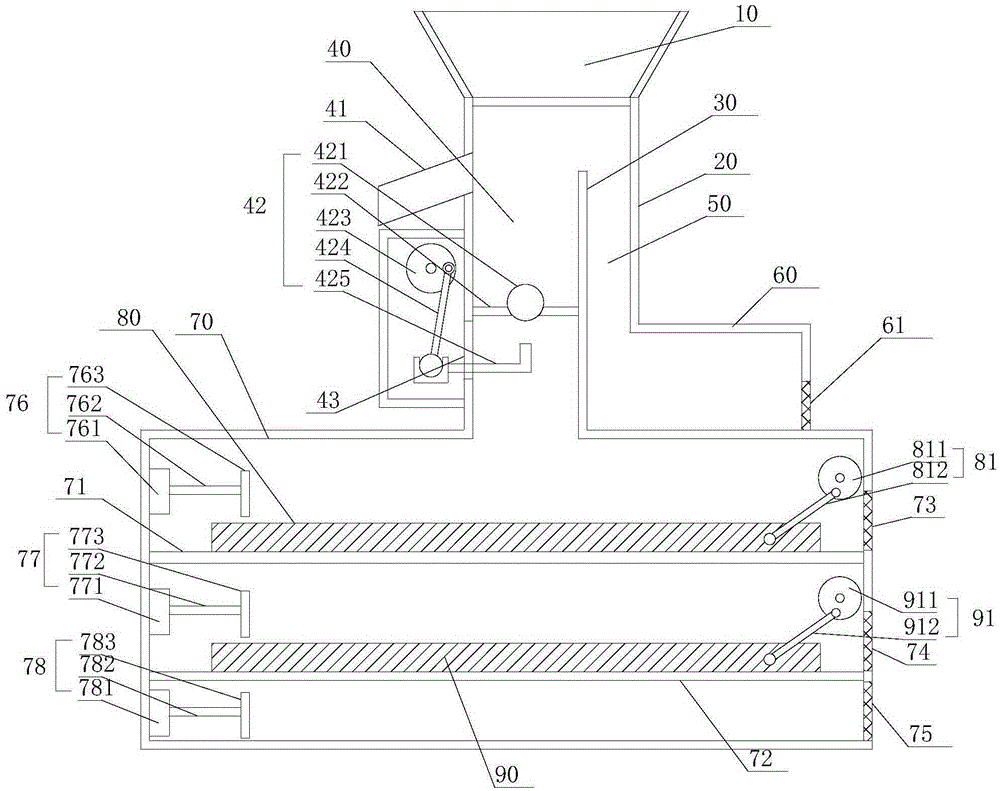

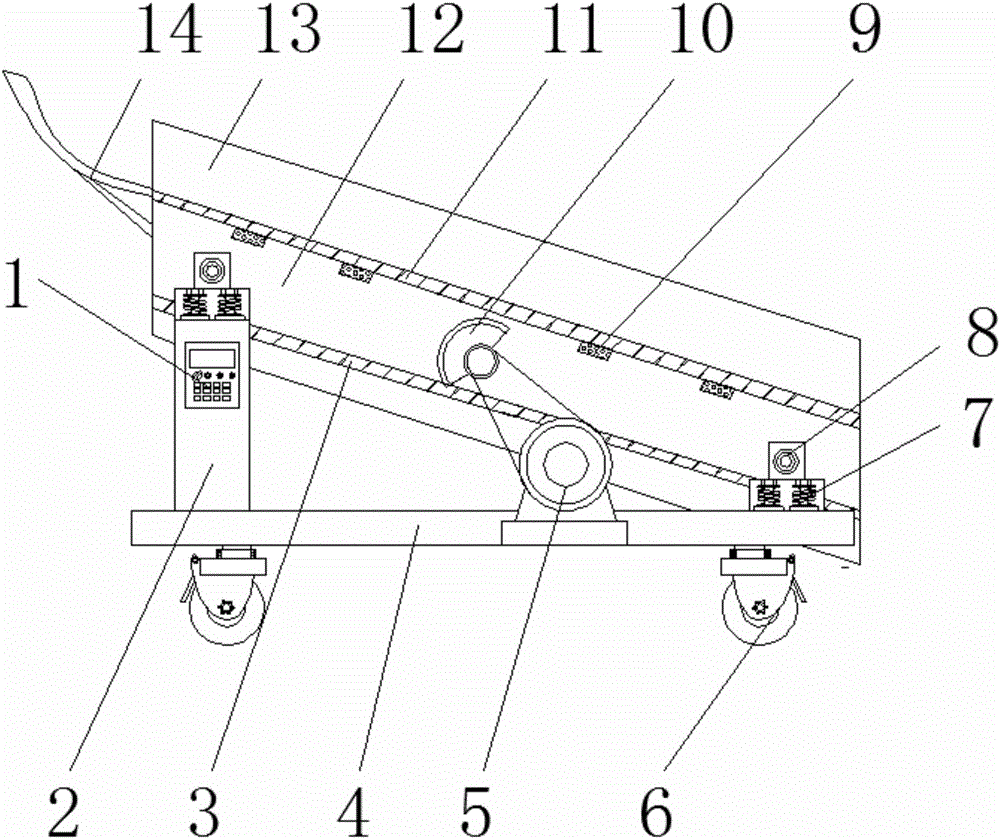

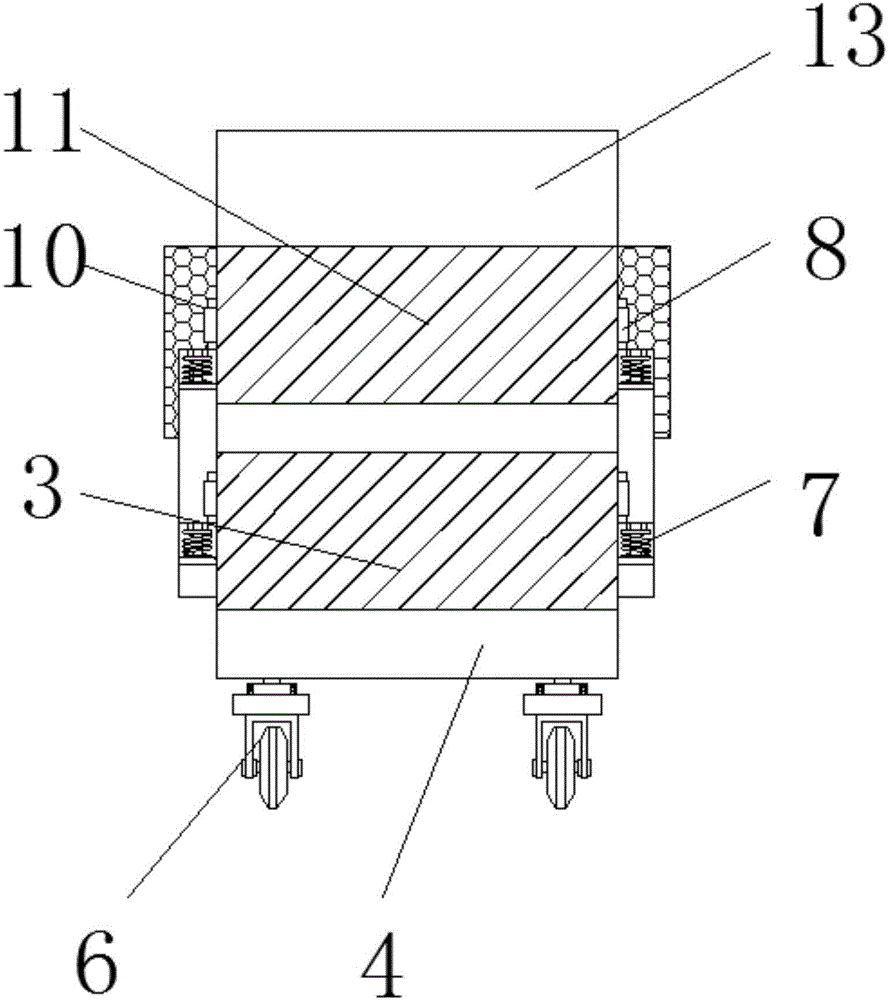

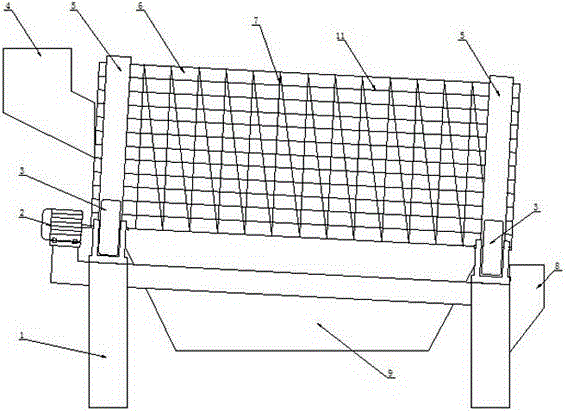

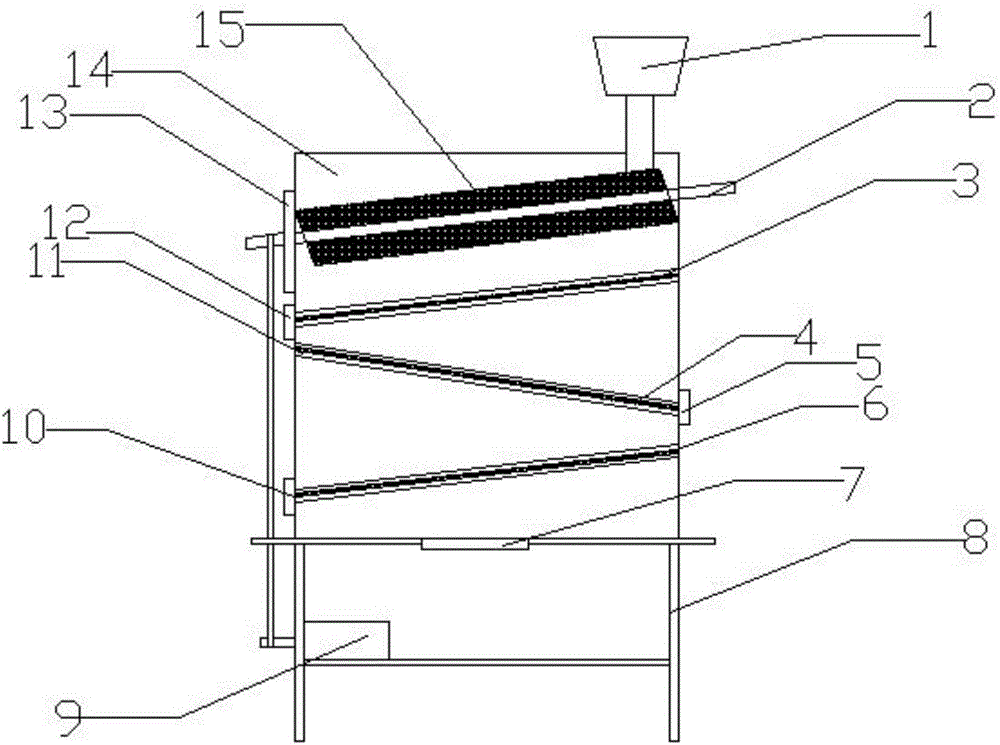

Three-machine-driving double-mass-body subresonance self-synchronizing probability constant thickness screen and parameter determining method

ActiveCN107252780AImprove efficiencyImprove screening efficiencySievingScreeningSingle stageEngineering

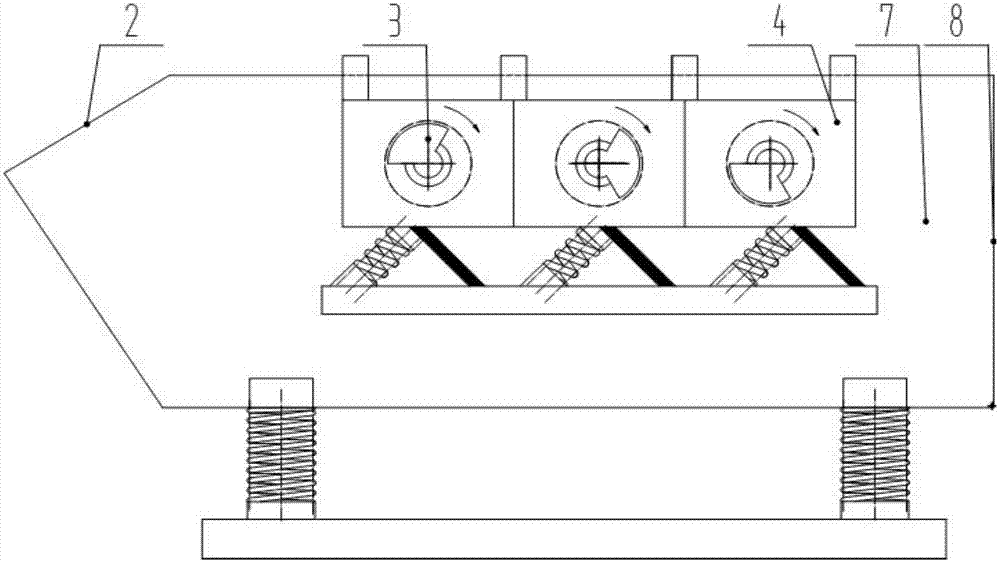

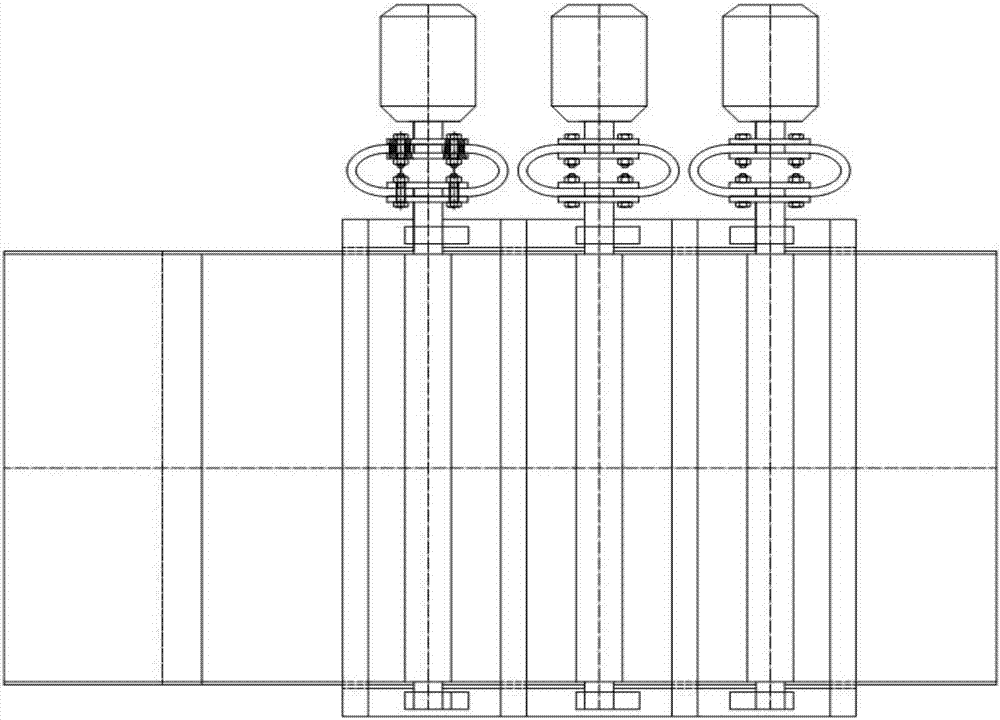

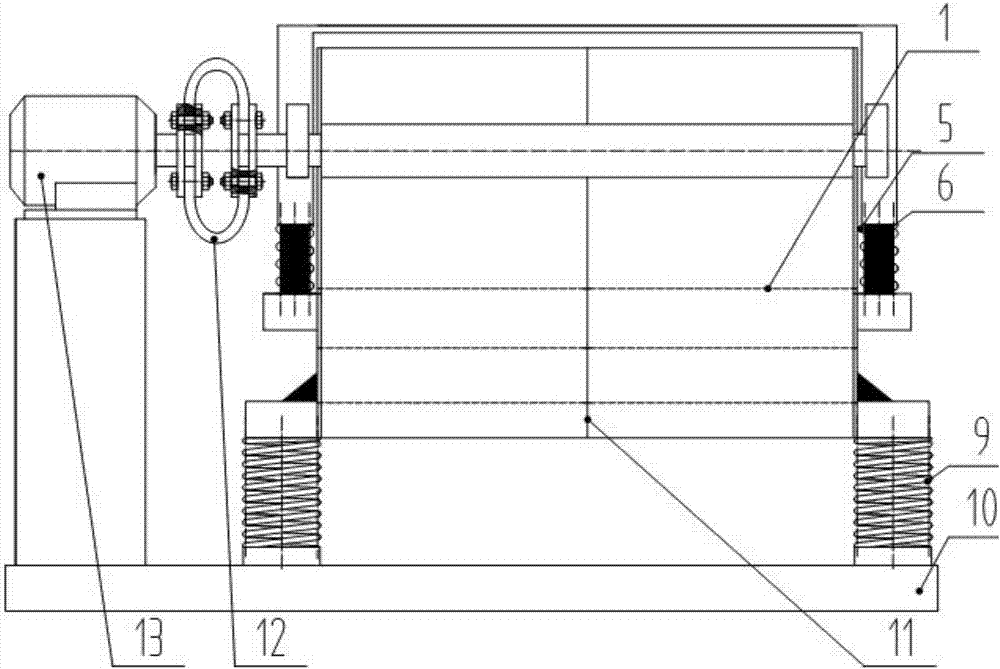

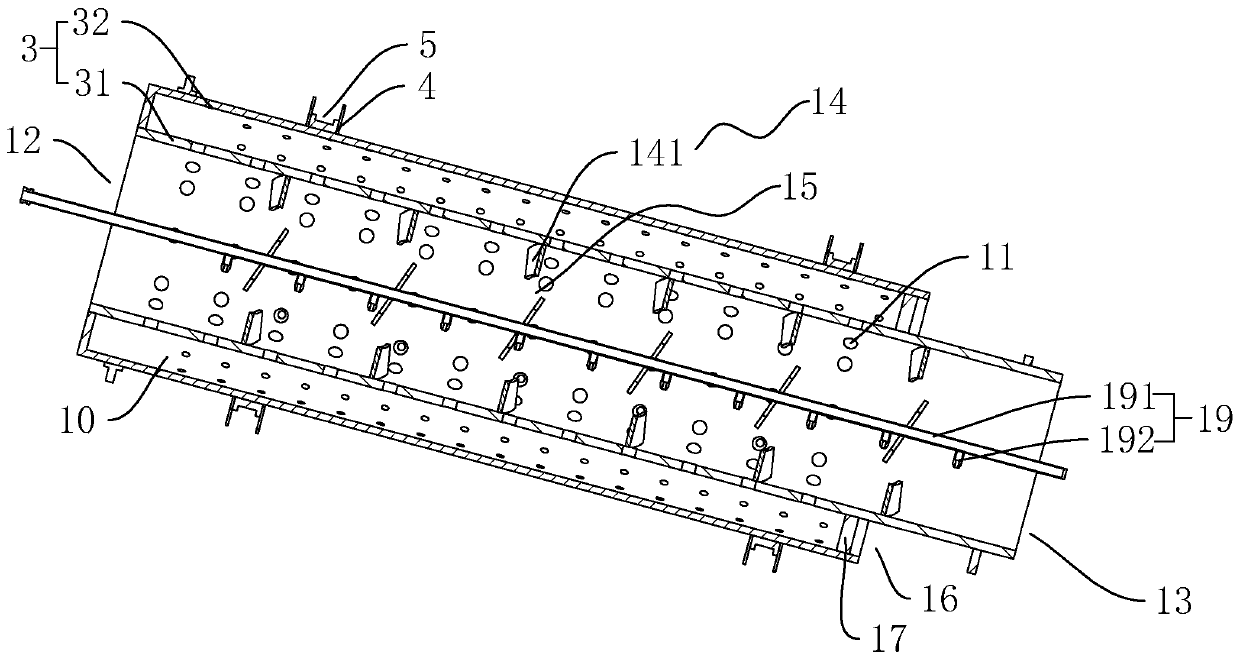

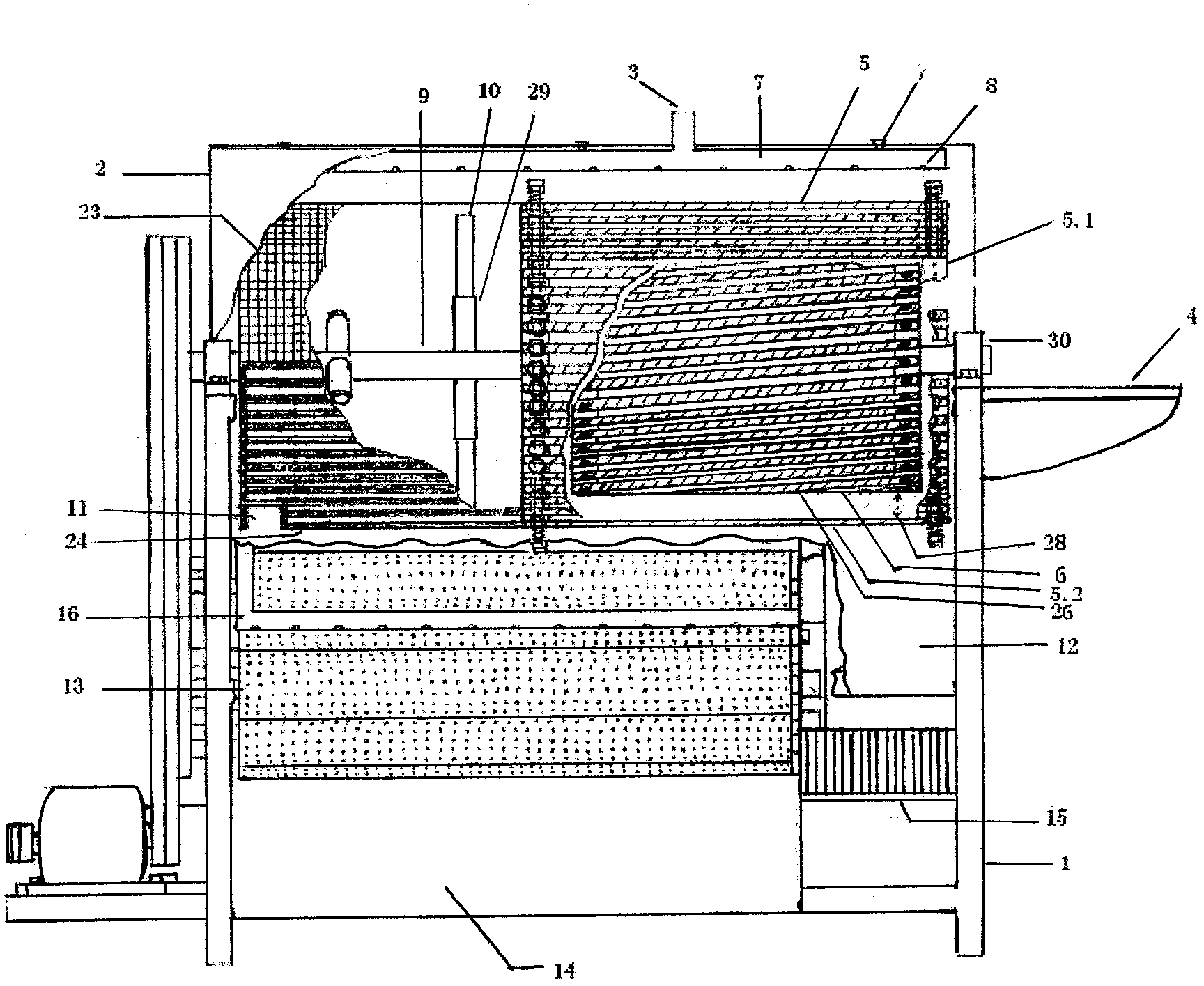

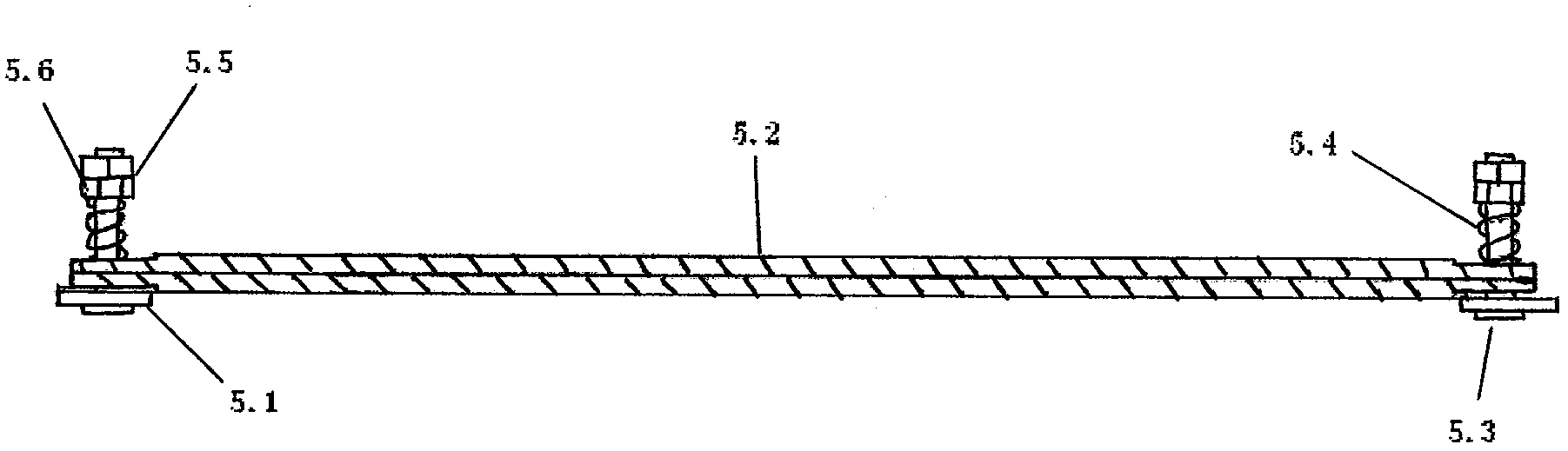

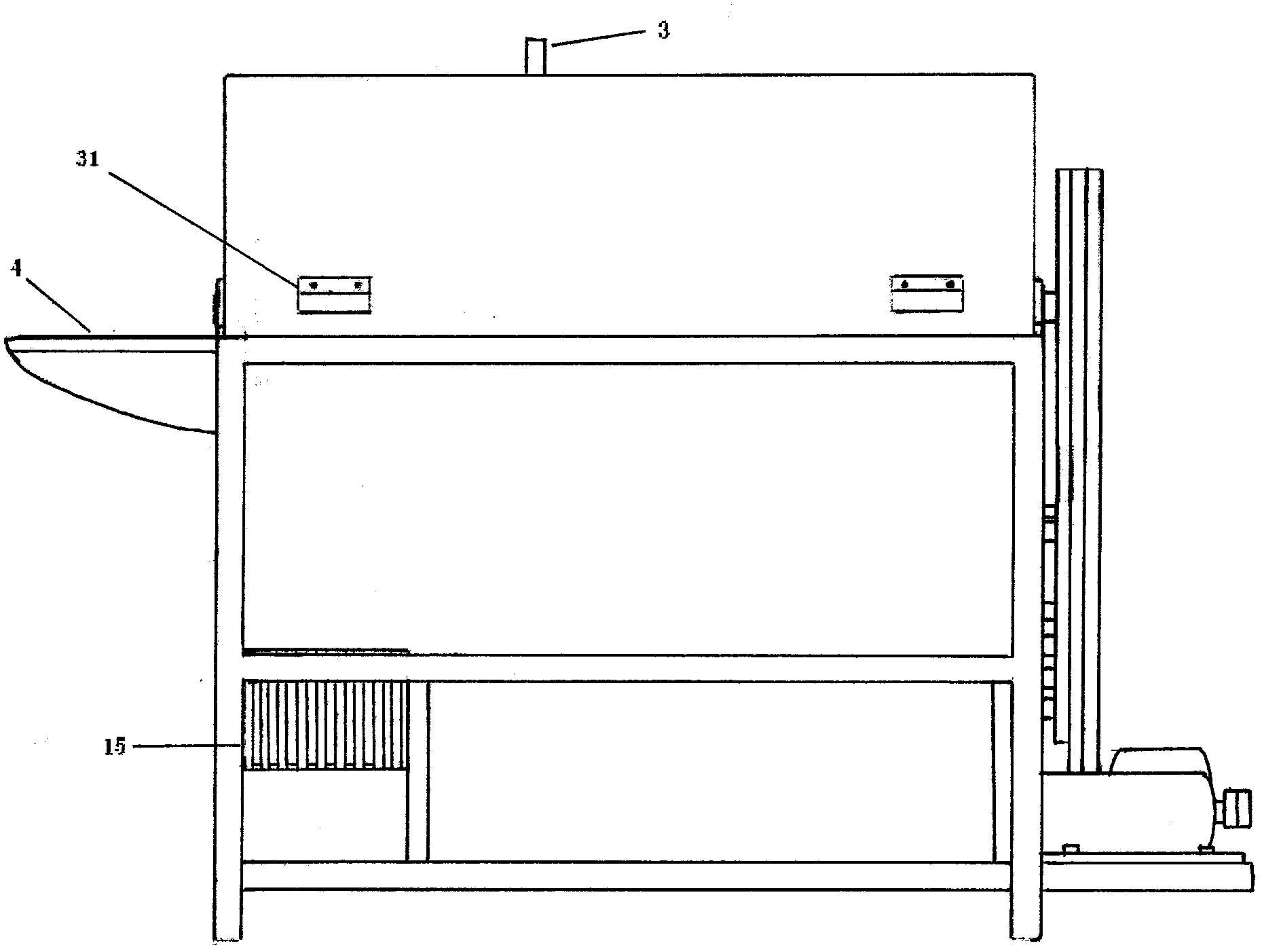

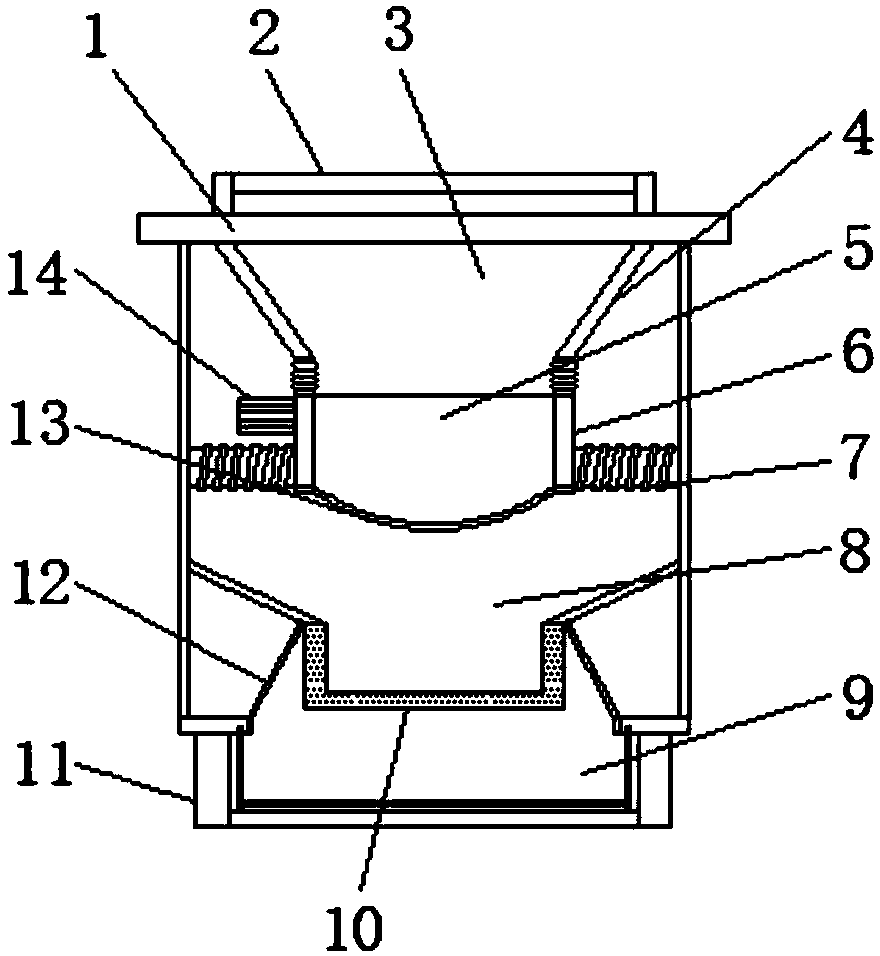

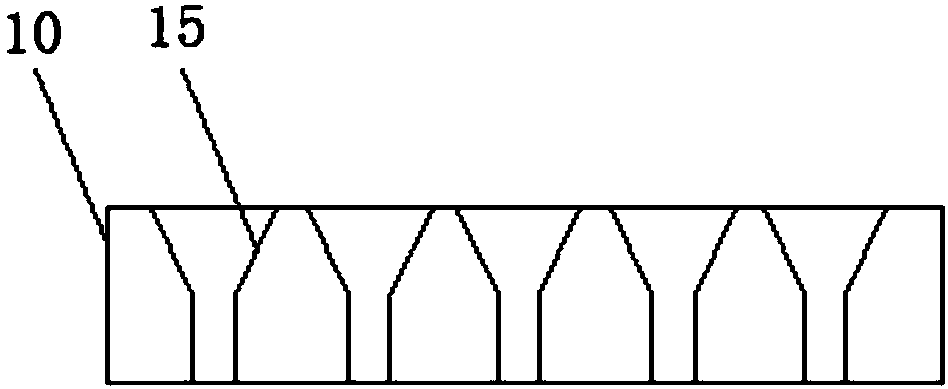

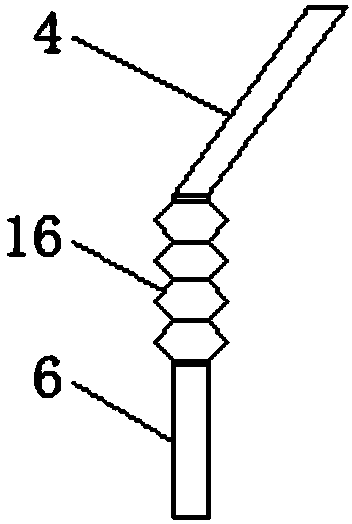

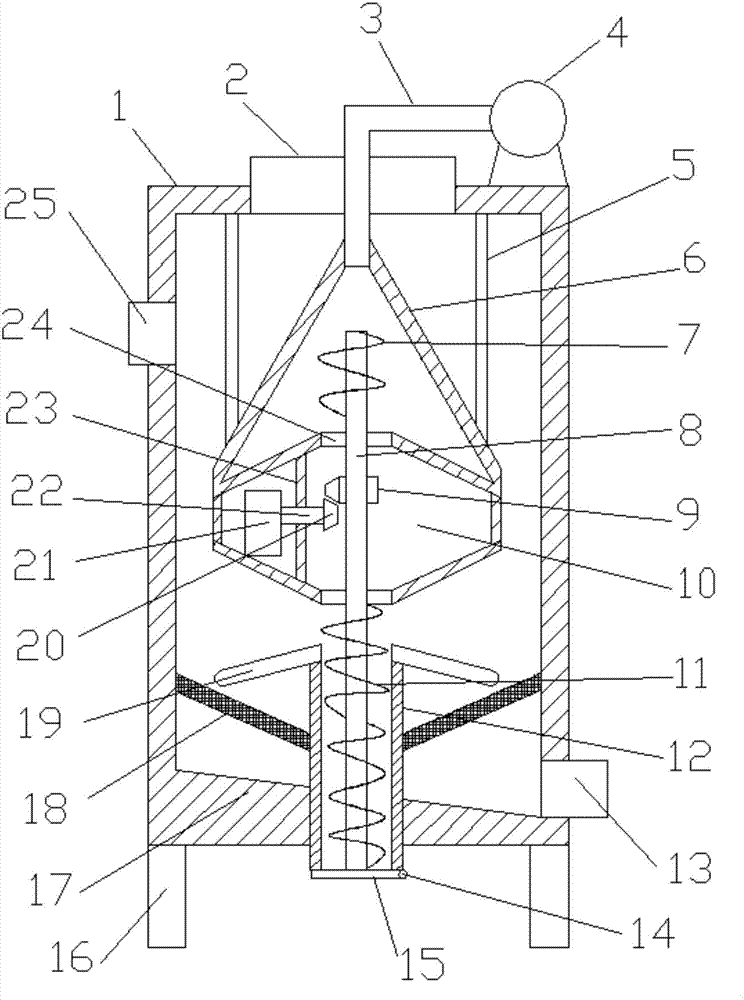

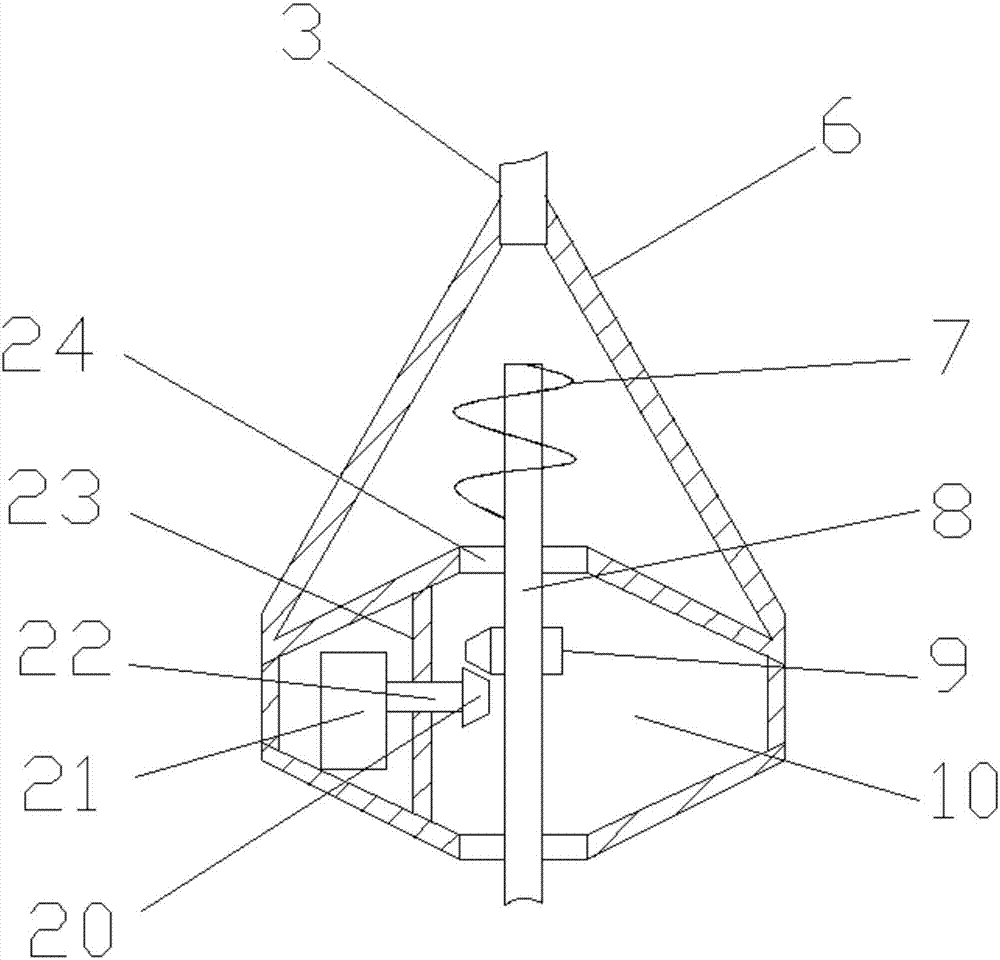

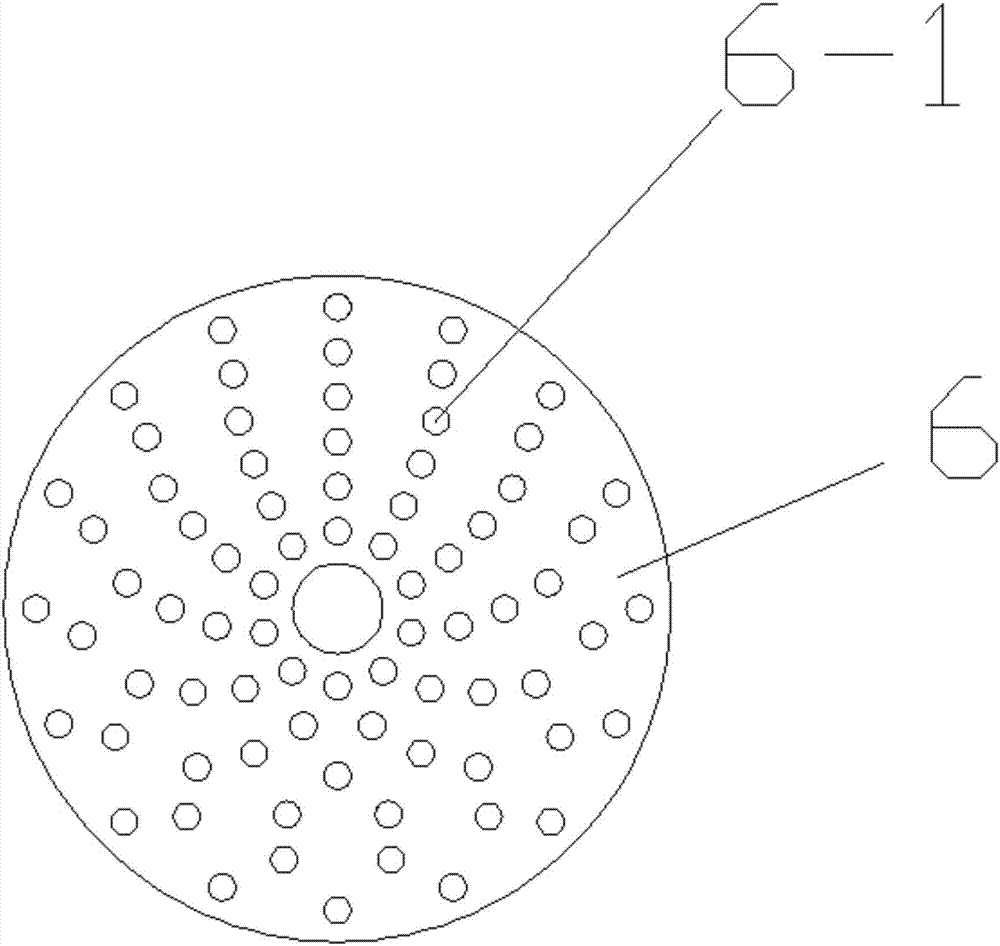

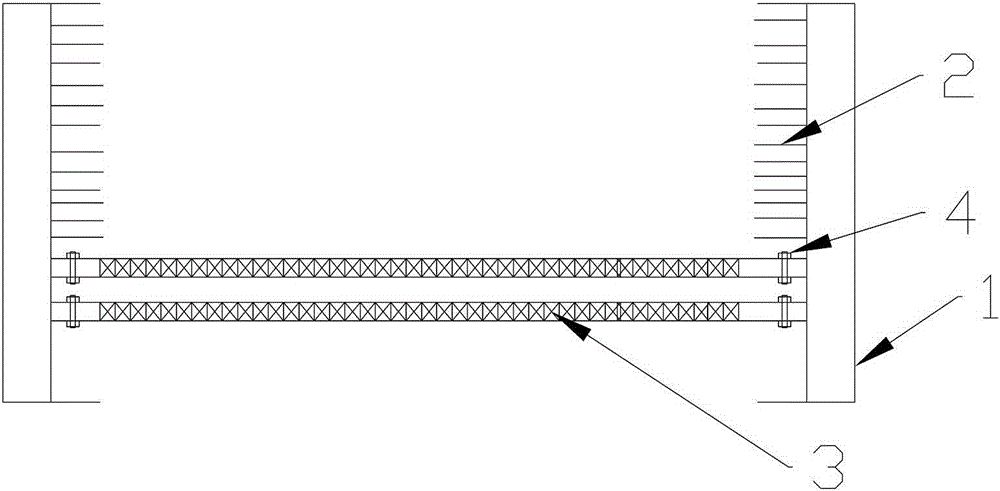

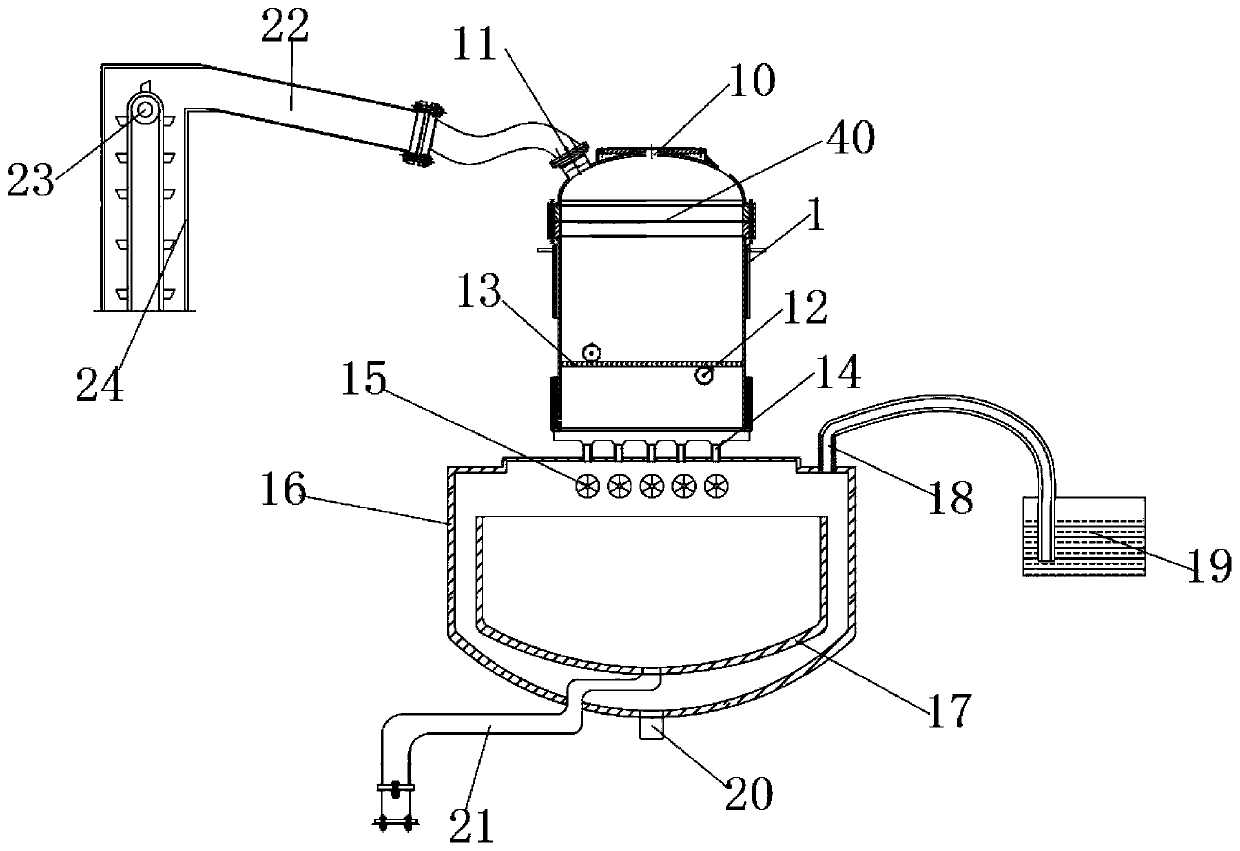

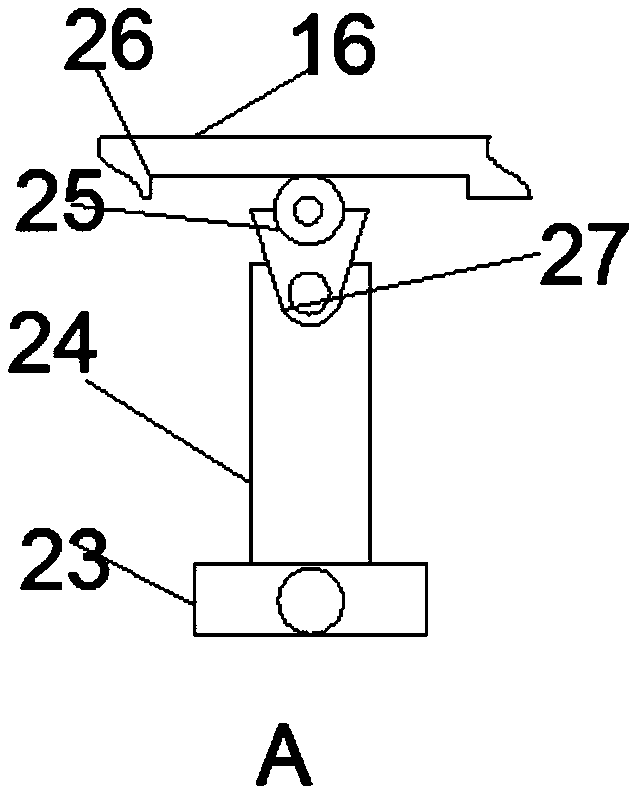

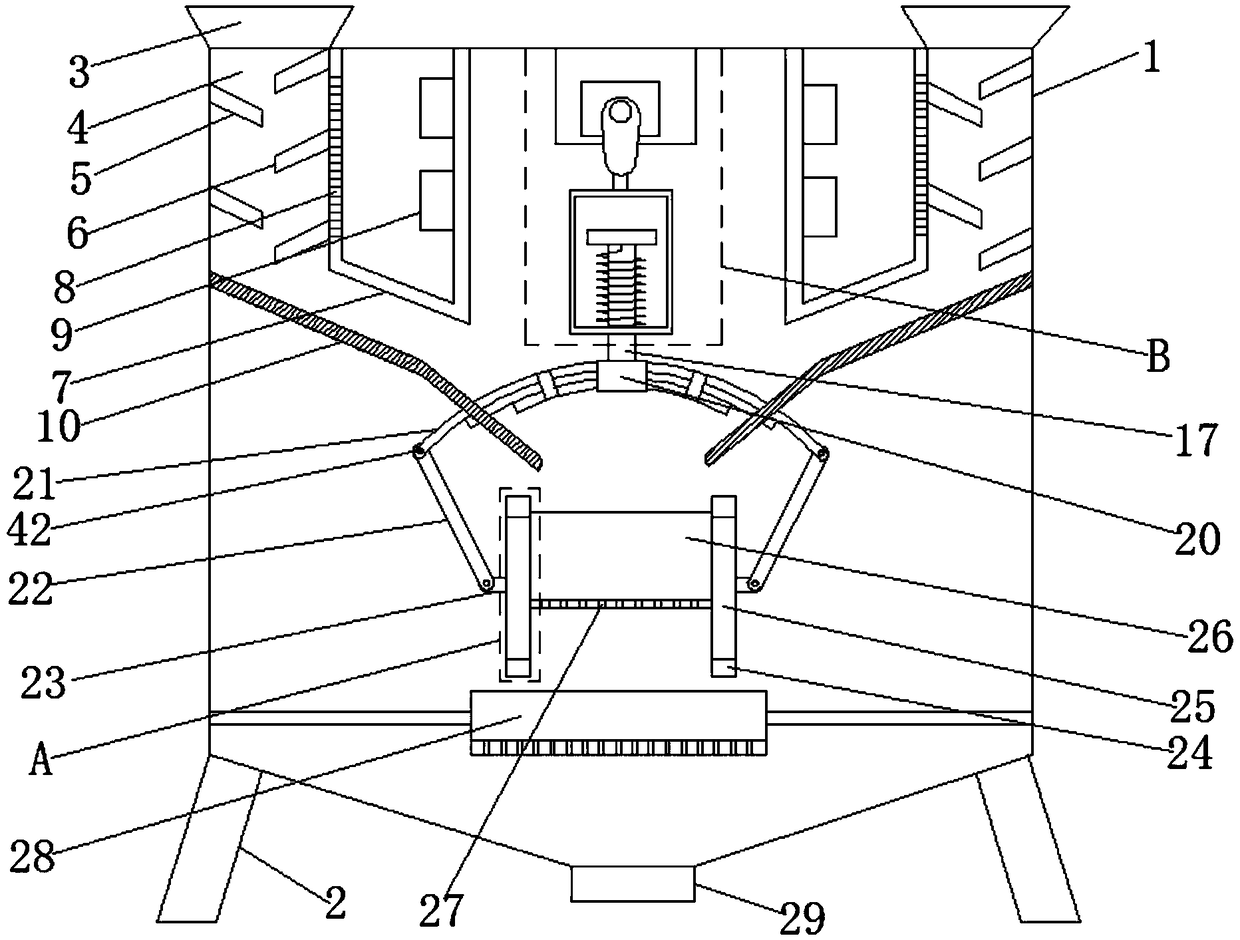

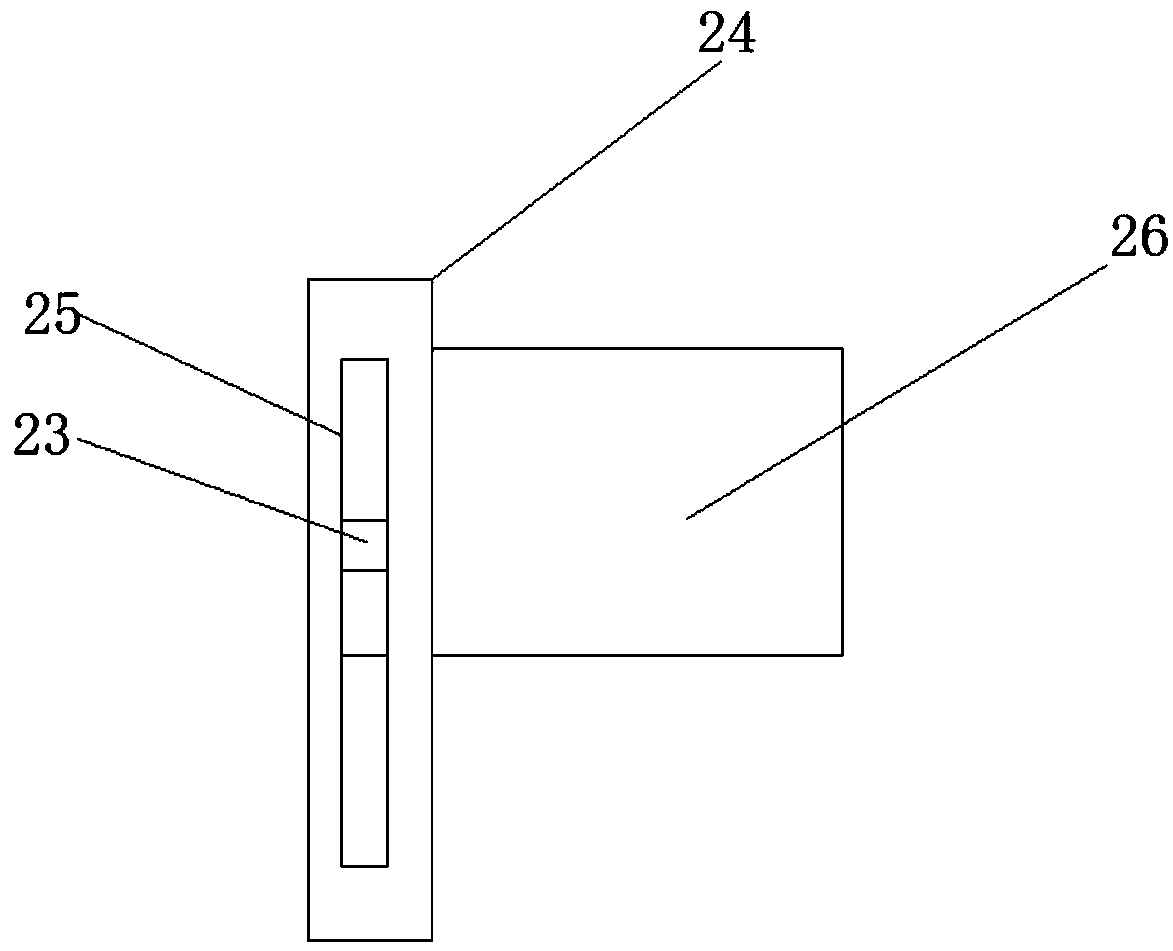

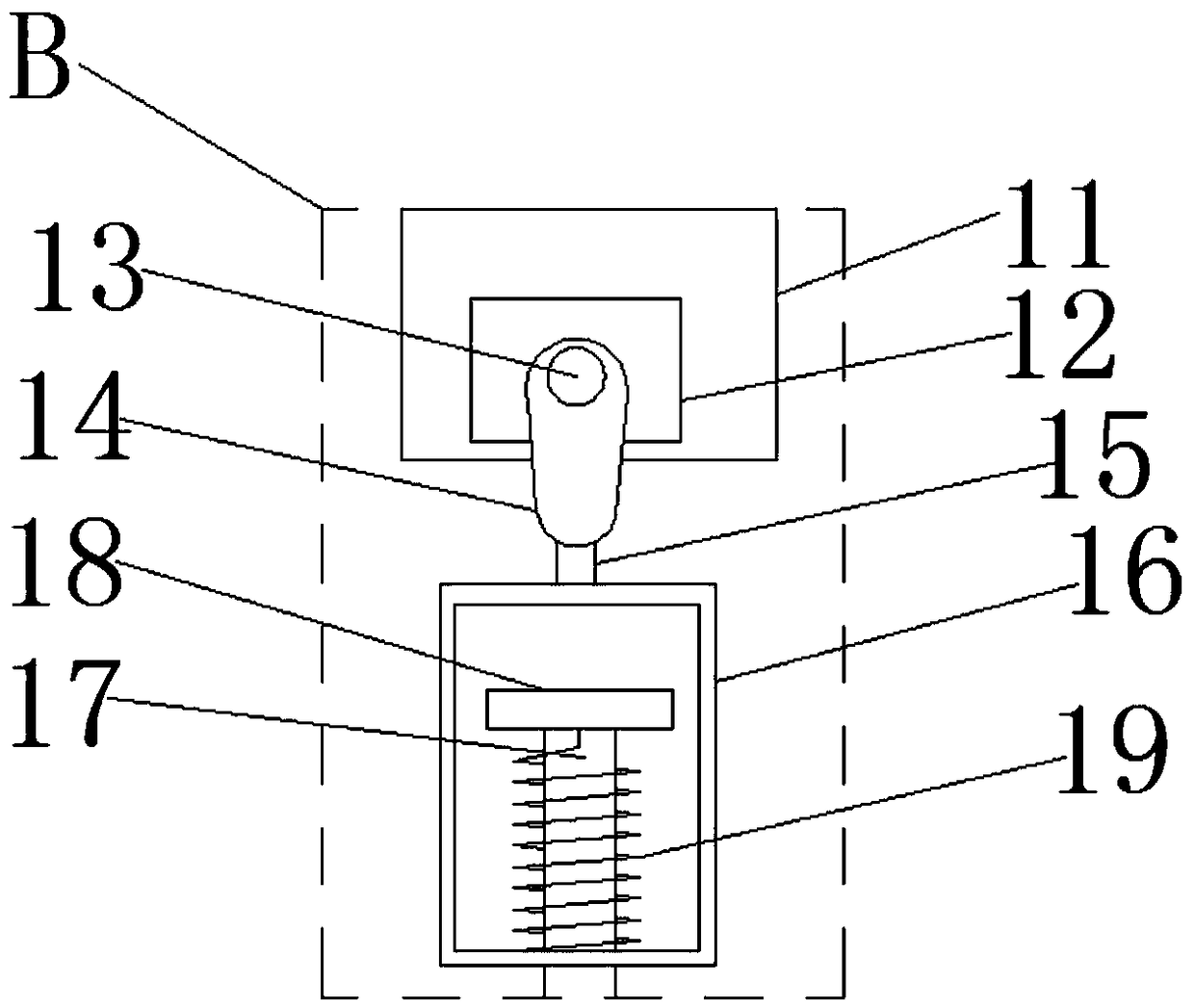

The invention discloses a three-machine-driving double-mass-body subresonance self-synchronizing probability constant thickness screen which is mainly applied to industrial and mining enterprises. Double mass bodies of the three-machine-driving double-mass-body subresonance self-synchronizing probability constant thickness screen are of a novel structure, one mass body drives the other mass body, so that a sensitive subresonance system is formed, and the overall mechanical performance is affected by variation of loading capacity. Compared with a single-mass-body system, a double-mass-body system can achieve the same effect by smaller power. Compared with a traditional single-stage system and a double-stage system, the driving frequency is improved, screening is more complete, and the working efficiency is further improved. Three different coupling vibration exciters have the same rotating direction, so that self-synchronous driving is achieved, and energy saving is achieved. Through application of a probability constant thickness screen theory, probability quick layering, screen blockage preventing and constant thickness high-efficiency screening of materials on a machine body are achieved, the screening efficiency and the yield are improved, and large-scale screening machines are achieved. Three-machine self-synchronizing driving is adopted to improve the uniform distribution of exciting force on a screening machine.

Owner:NORTHEASTERN UNIV

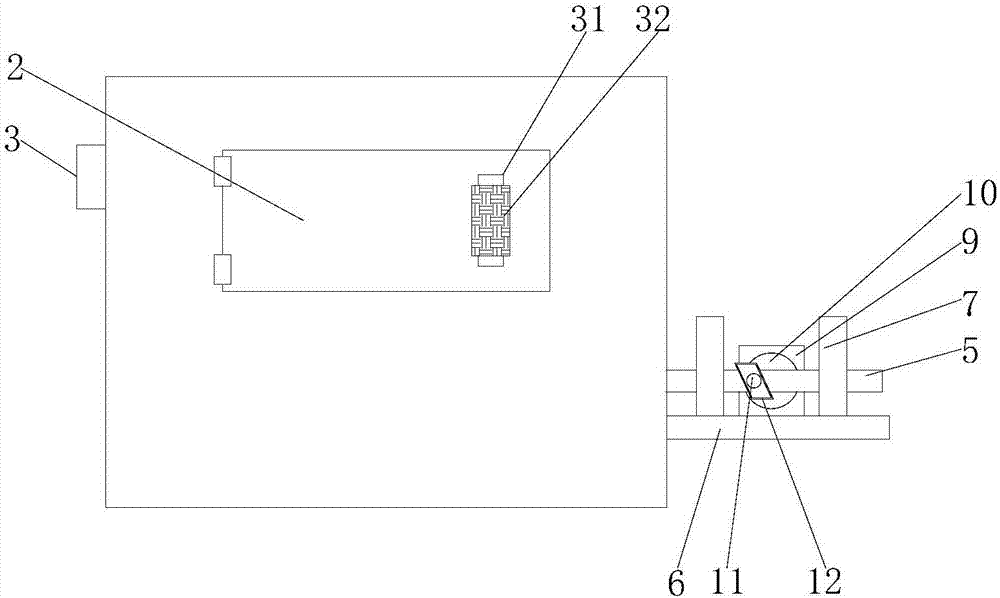

Raw material screening machine for novel material production

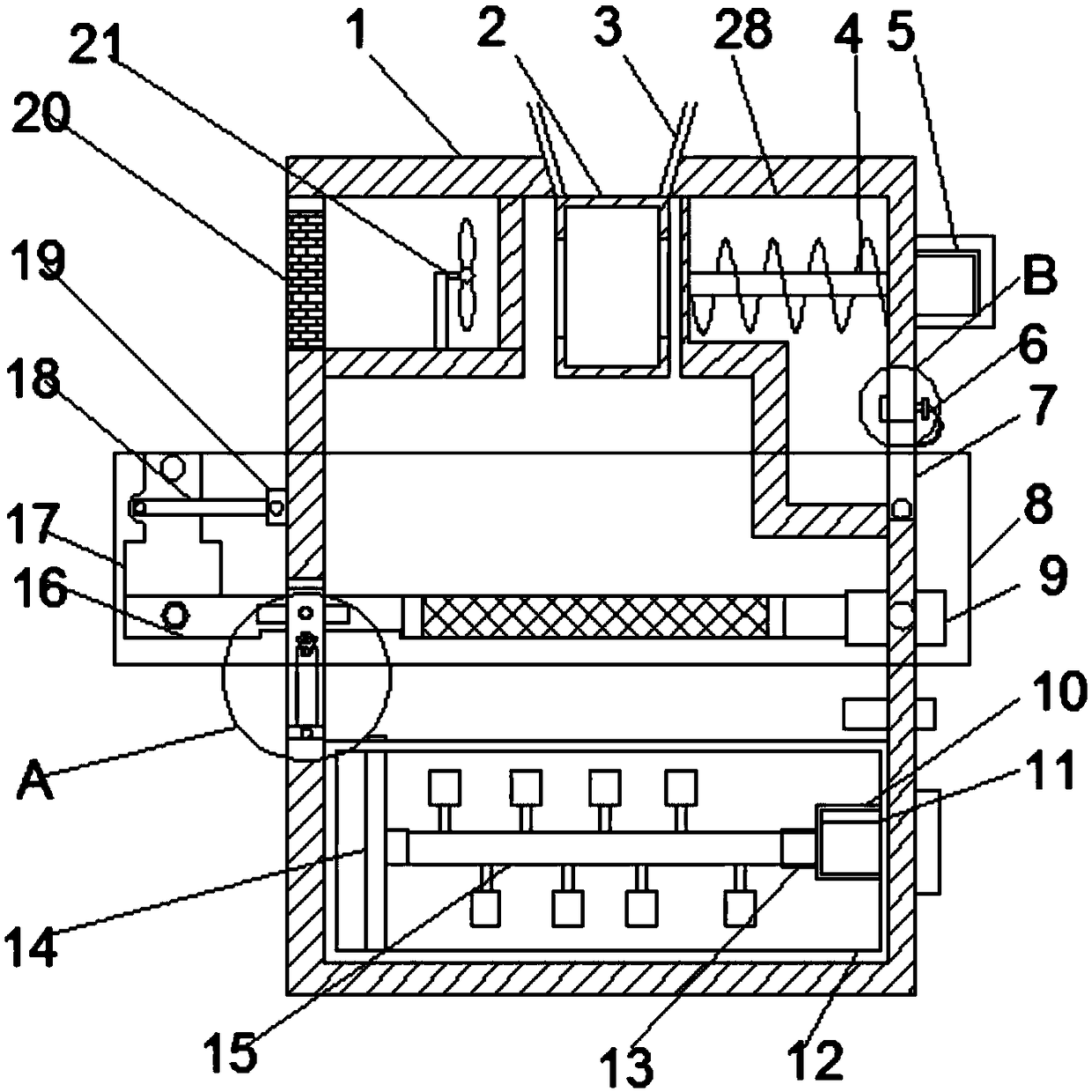

The invention discloses a raw material screening machine for novel material production. The raw material screening machine comprises a machine body. The positive surface of the machine body is movably connected with a movable door through a hinge; a controller is fixedly installed on the top of the left side of the machine body; a screening box is arranged inside the machine body; the right side of the screening box is fixedly connected with a shaking rod; the end, far from the screening box, of the shaking rod penetrate through the machine body and extends to the exterior of the machine body; the bottom of the right side of the machine body is fixedly connected with a fixed plate; the two sides of the top of the fixed plate both are fixedly connected with fixed columns; through holes are formed inside the fixed columns; the end, located outside the machine body, of the shaking rod penetrates through the through holes and extends to the right sides of the fixed columns; a first motor is fixedly installed on the top of the fixed plate and between the two fixed columns; the output end of the first motor is fixedly connected with a turntable; and the positive surface of the turntable is fixedly connected with a sliding block. Using is convenient, and screening of raw materials is thorough.

Owner:FOSHAN FEISHIDA NEW MATERIAL TECH CO LTD

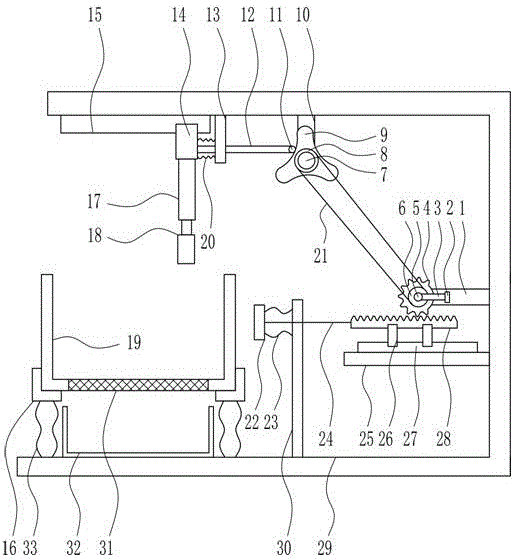

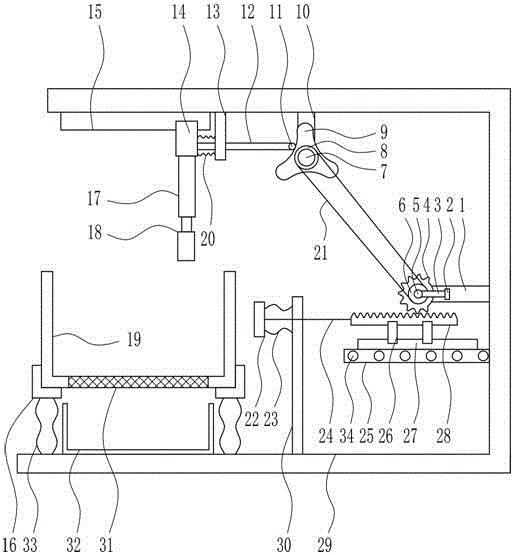

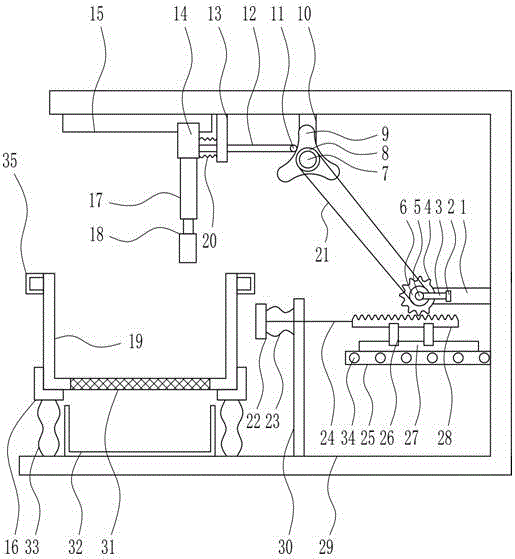

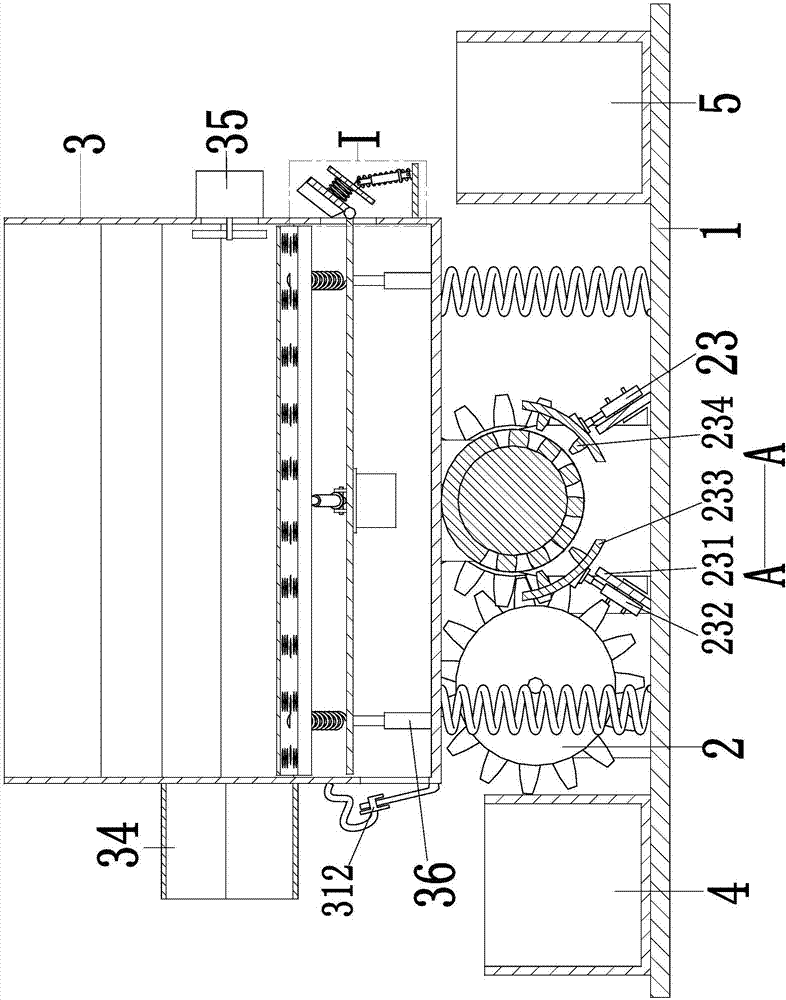

Powder screening device for lithium battery production technology

The invention relates to a powder screening device, particularly to a powder screening device for a lithium battery production technology, and provides the convenient-operation, thorough-screening and novel-structure powder screening device for the lithium battery production technology. The powder screening device for the lithium battery production technology comprises a first bearing seat, a grab handle, a connecting rod, a special shape gear, a first rotating shaft, a first belt pulley, a second rotating shaft, a second belt pulley, a disc cam, a second bearing seat, and the like, wherein third springs are in symmetrical hook connection with the left side of the bottom in a mounting rack; and fixed blocks are in hook connection with the top ends of the third springs. According to the powder screening device, the effects of convenient operation, thorough screening and novel structure are achieved, besides, the manufacturing cost is low, the structure is reasonable, the maintenance is easy, the utilization is convenient, the input of manpower and material resources is reduced, and the working efficiency is improved.

Owner:烟台北海电气有限公司

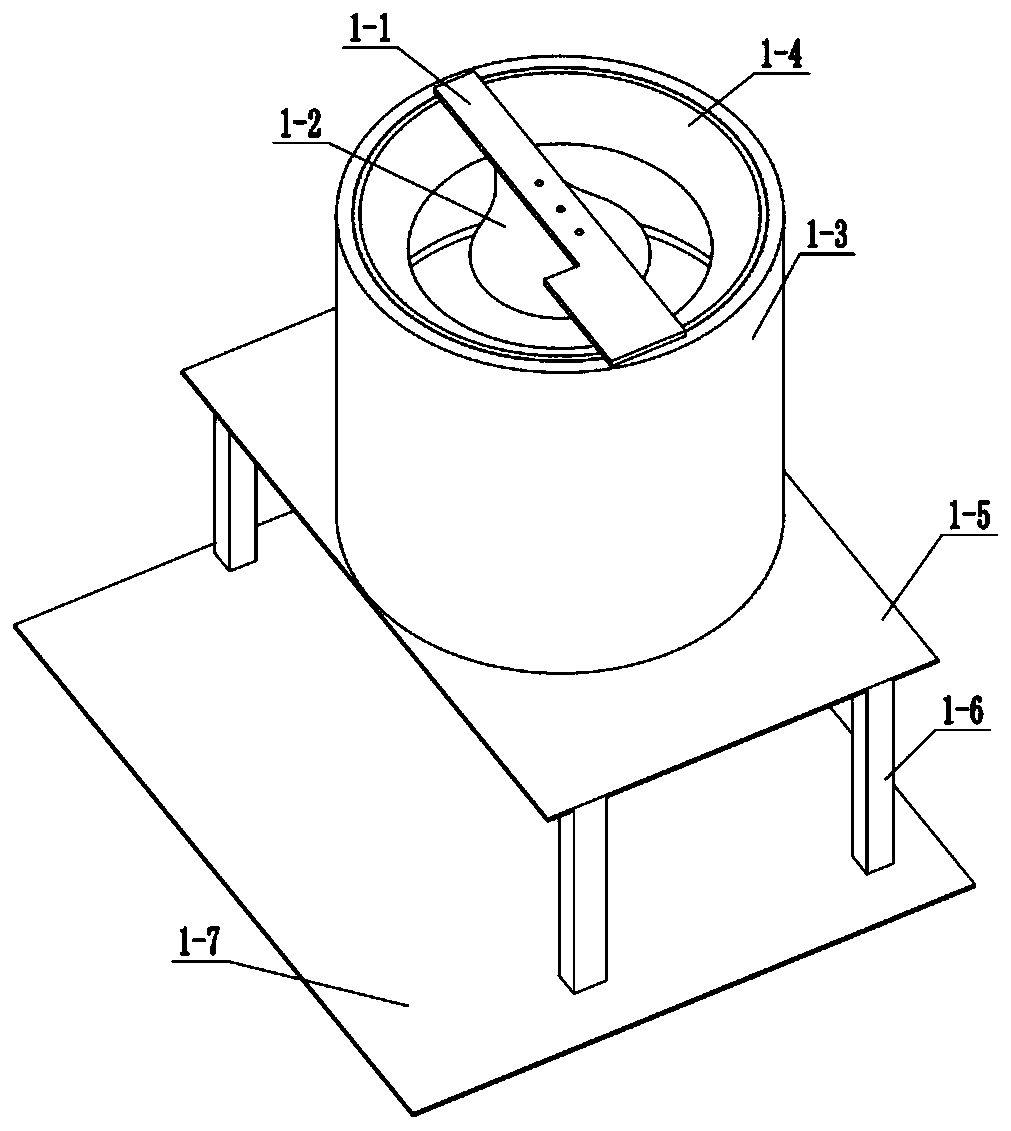

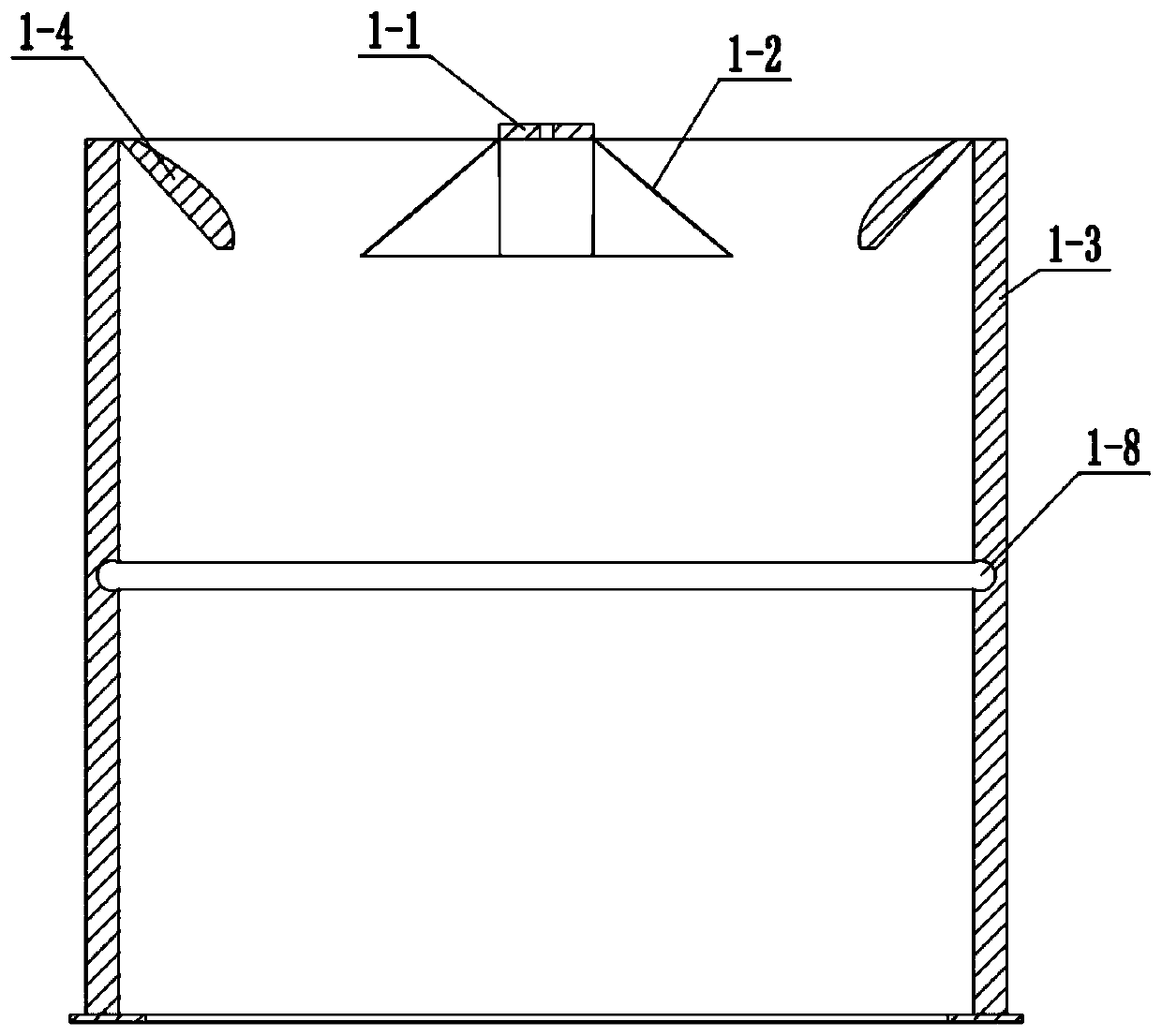

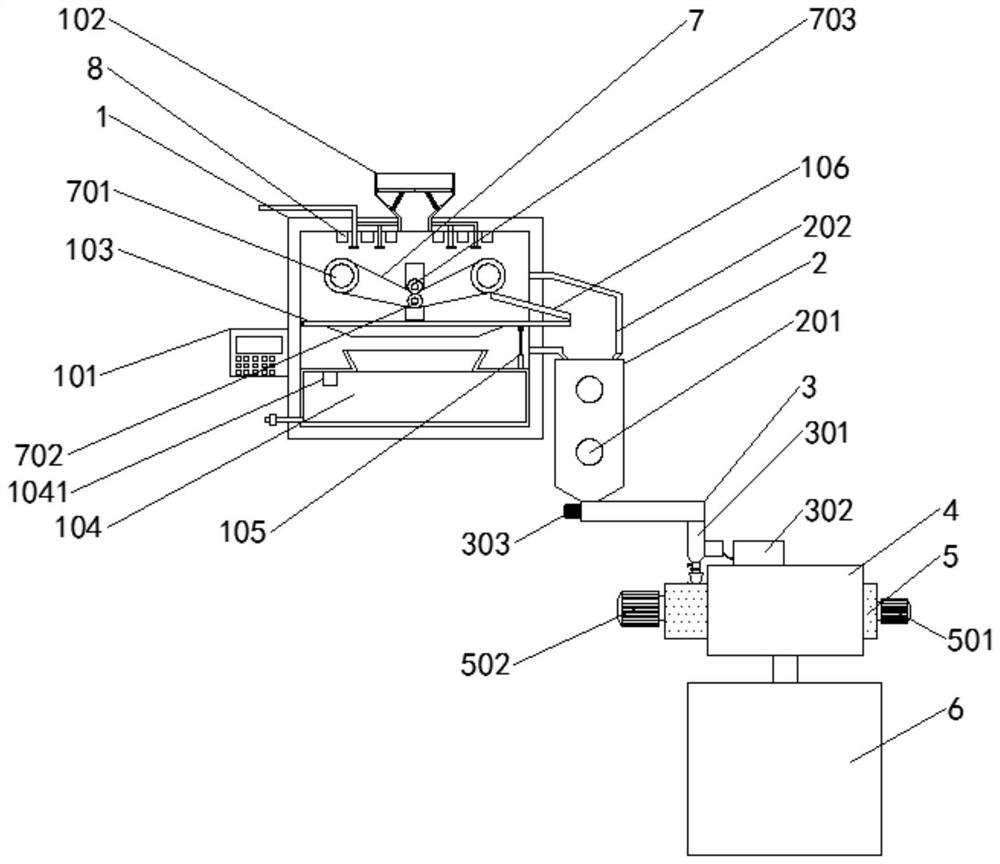

Circular building sand screening device

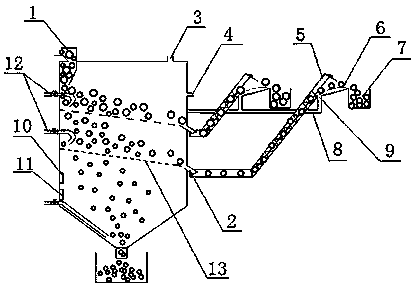

InactiveCN109127348AAchieve decentralizationImprove liquiditySievingScreeningScattering functionScreening effect

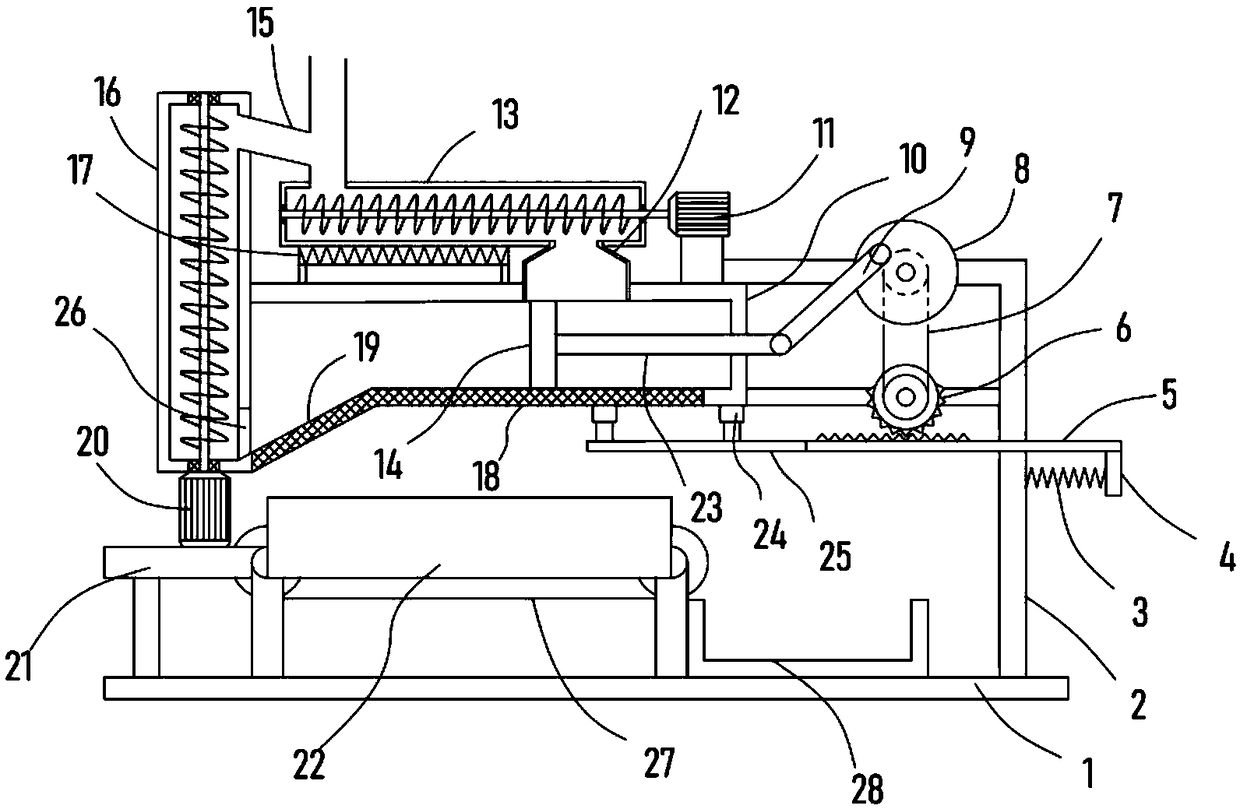

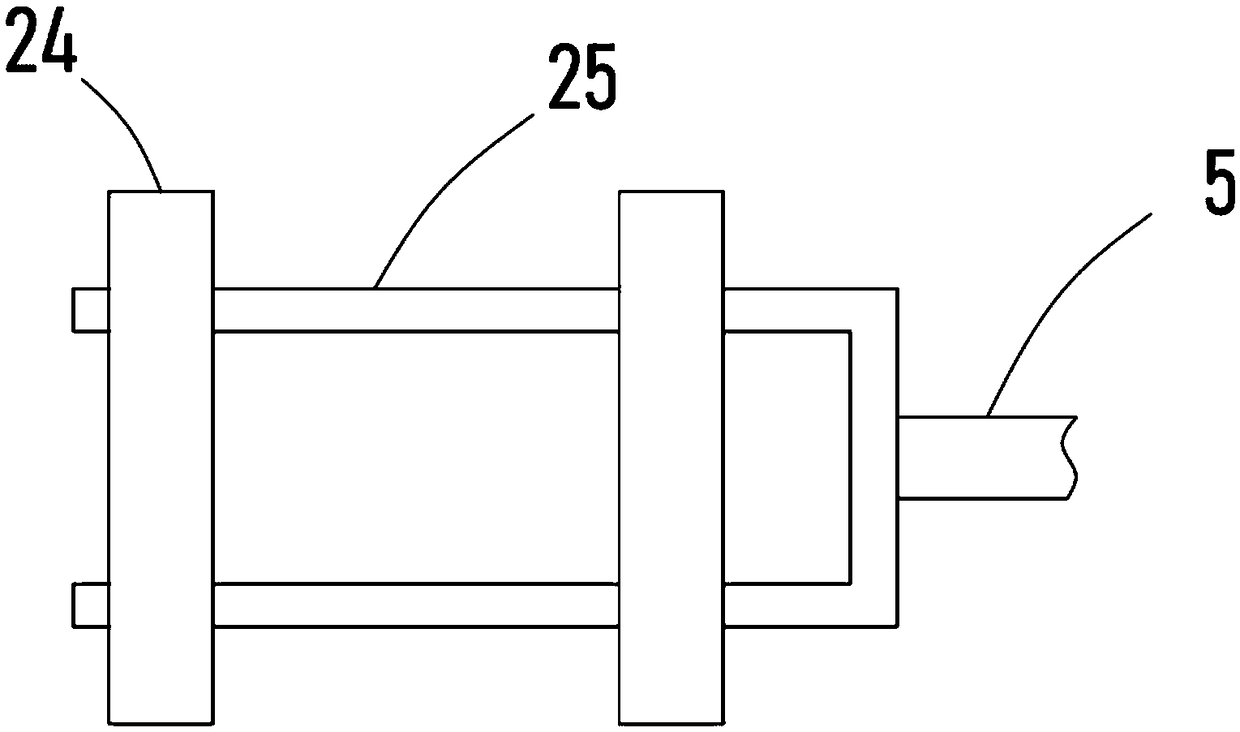

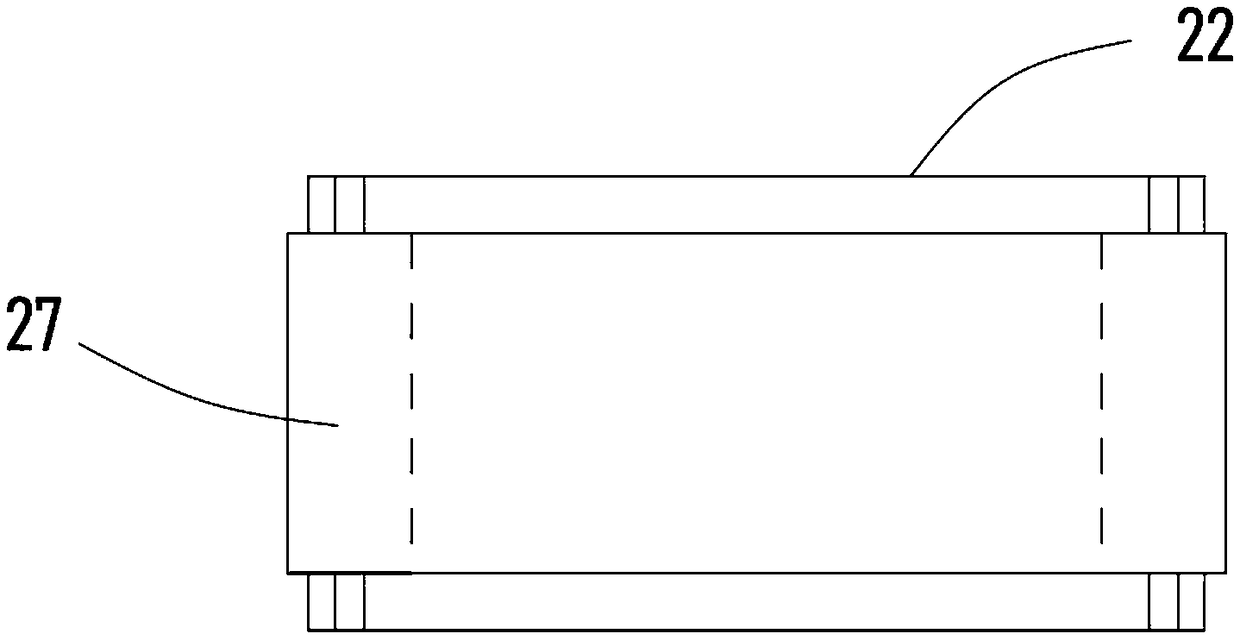

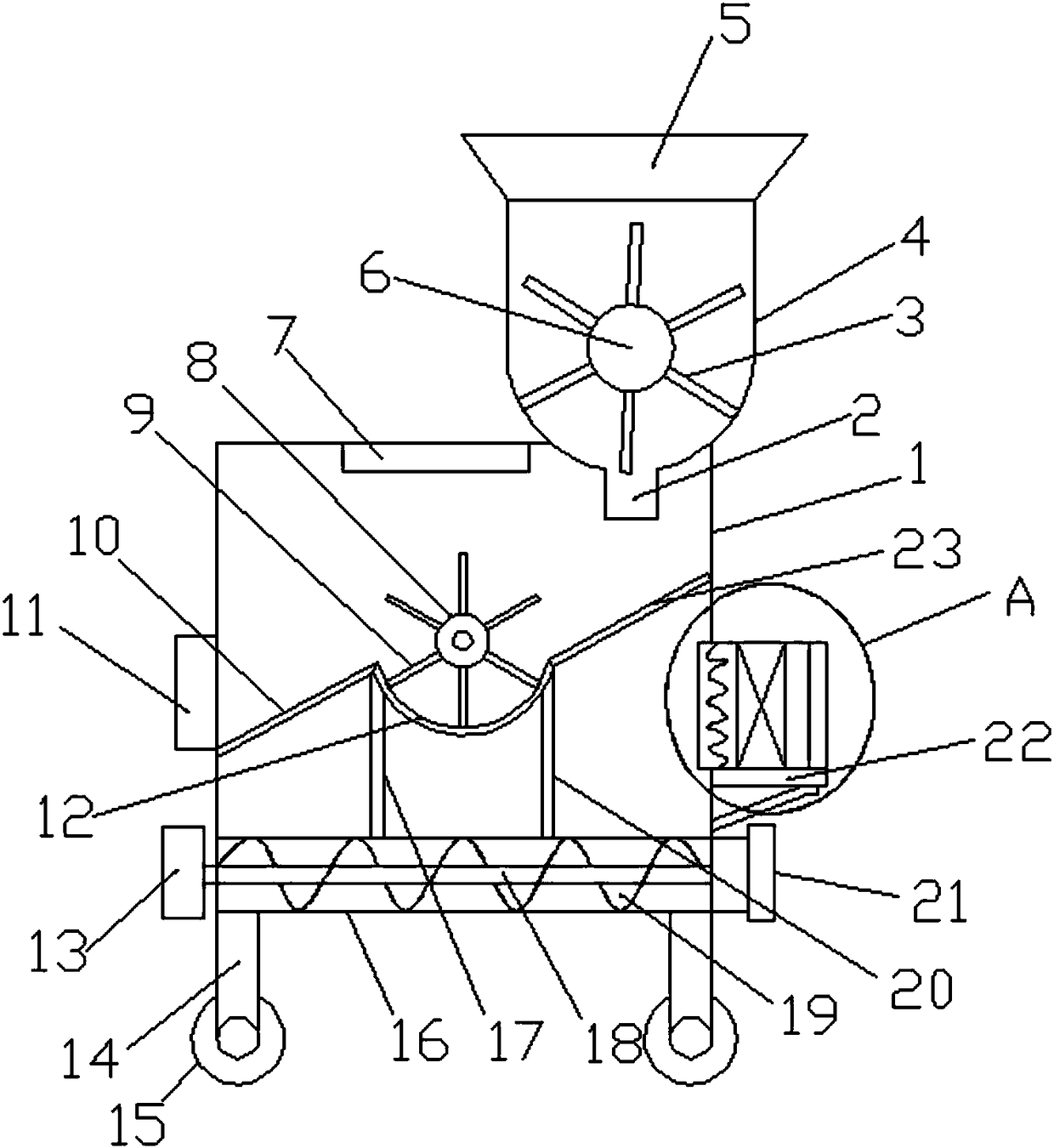

The invention discloses a circular building sand screening device, and relates to the technical field of building machines. The circular building sand screening device comprises a supporting bottom plate, and a transverse packing auger driven by a motor I is horizontally and fixedly mounted on the supporting frame. A dispersing barrel communicating with the transverse packing auger through a discharging pipe is arranged below the transverse packing auger. A conveying belt mounted on a supporting table is arranged below a horizontal screen, and a longitudinal packing auger driven by a motor IIis fixedly mounted on the supporting table. A lifting inlet communicating with the dispersing barrel is formed in the lower right side wall of the longitudinal packing auger, and a circulating pipe ismounted between the upper right side wall of the longitudinal packing auger and the transverse packing auger in a communicating manner. According to the circular building sand screening device, sandcan be screened through the horizontal screen and an inclined screen and passes. By means of conveying of the transverse packing auger and the longitudinal packing auger, on one hand, the scattering function on the sand is improved, the mobility of the sand during screening is improved, and the screening effect is improved; and on the other hand, repeated and circular screening of the sand can beachieved, screening can be more sufficient and thorough, and the screening quality of the sand is improved.

Owner:霸州市辉月网络技术有限公司

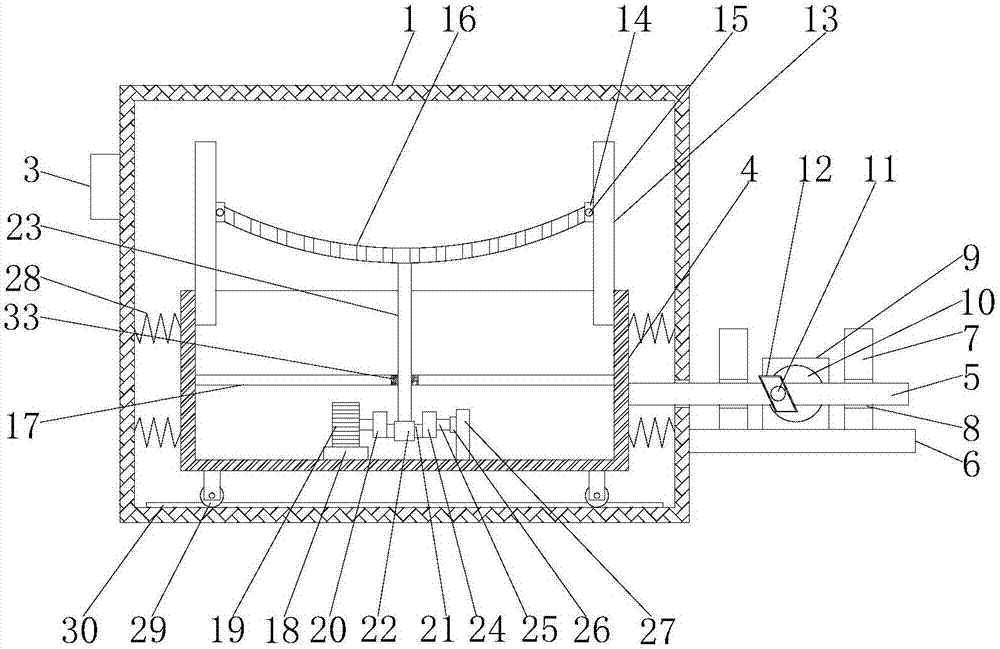

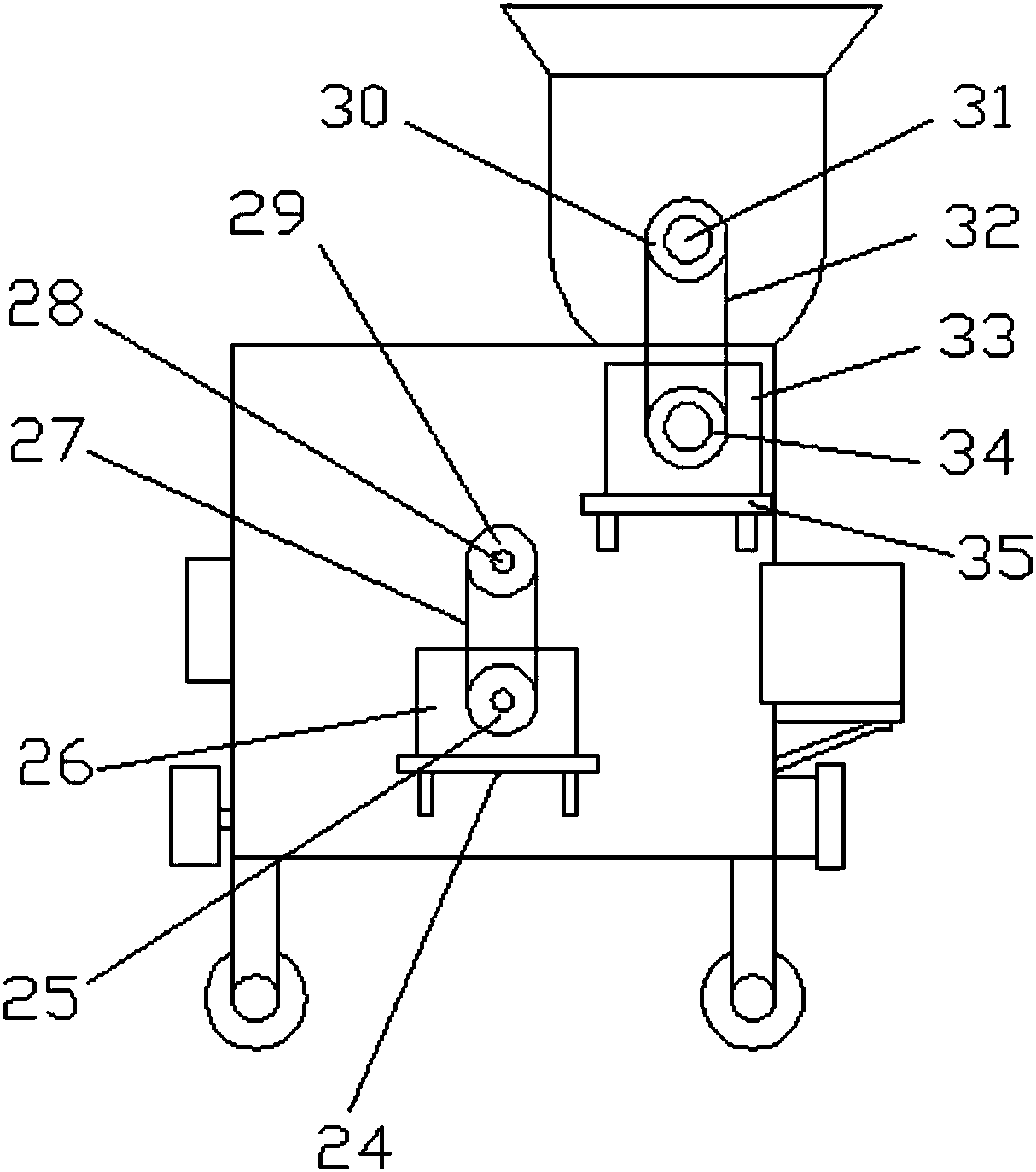

Efficient screening and impurity removing device for coal powder production

The invention discloses an efficient screening and impurity removing device for coal powder production. The device comprises a shell, wherein a feeding cylinder is arranged at the right end of the topof the shell, and a discharging pipe is arranged at the bottom end of the feeding cylinder. According to the efficient screening and impurity removing device for coal powder production, a dischargingroller rotates to realize quantitative feeding of pulverized coal into an arc-shaped screen, a scraping brush roller drives scraping plates to scrape and brush the pulverized coal in the arc-shaped screen, the scraping brush roller reversely rotates to scrape the pulverized coal in the arc-shaped screen into a flow guide screen for screening, the pulverized coal on the flow guide screen falls into the arc-shaped screen under the action of gravity, circulating screening is realized through the scraping brush roller, screening is more thorough, coarse material particles subjected to thorough screening are gathered in the arc-shaped screen, the scraping brush roller rotates in the forward direction to scrape the coarse material particles into a flow guide plate, and the coarse material particles are discharged from a coarse material outlet through the flow guide plate, so that efficient screening and impurity removal of the pulverized coal are realized; and in addition, a fan and an electric heating wire in an air pipe are electrified to work, and then hot air is generated to quickly dry the pulverized coal on the flow guide screen and the arc-shaped screen.

Owner:王兴民

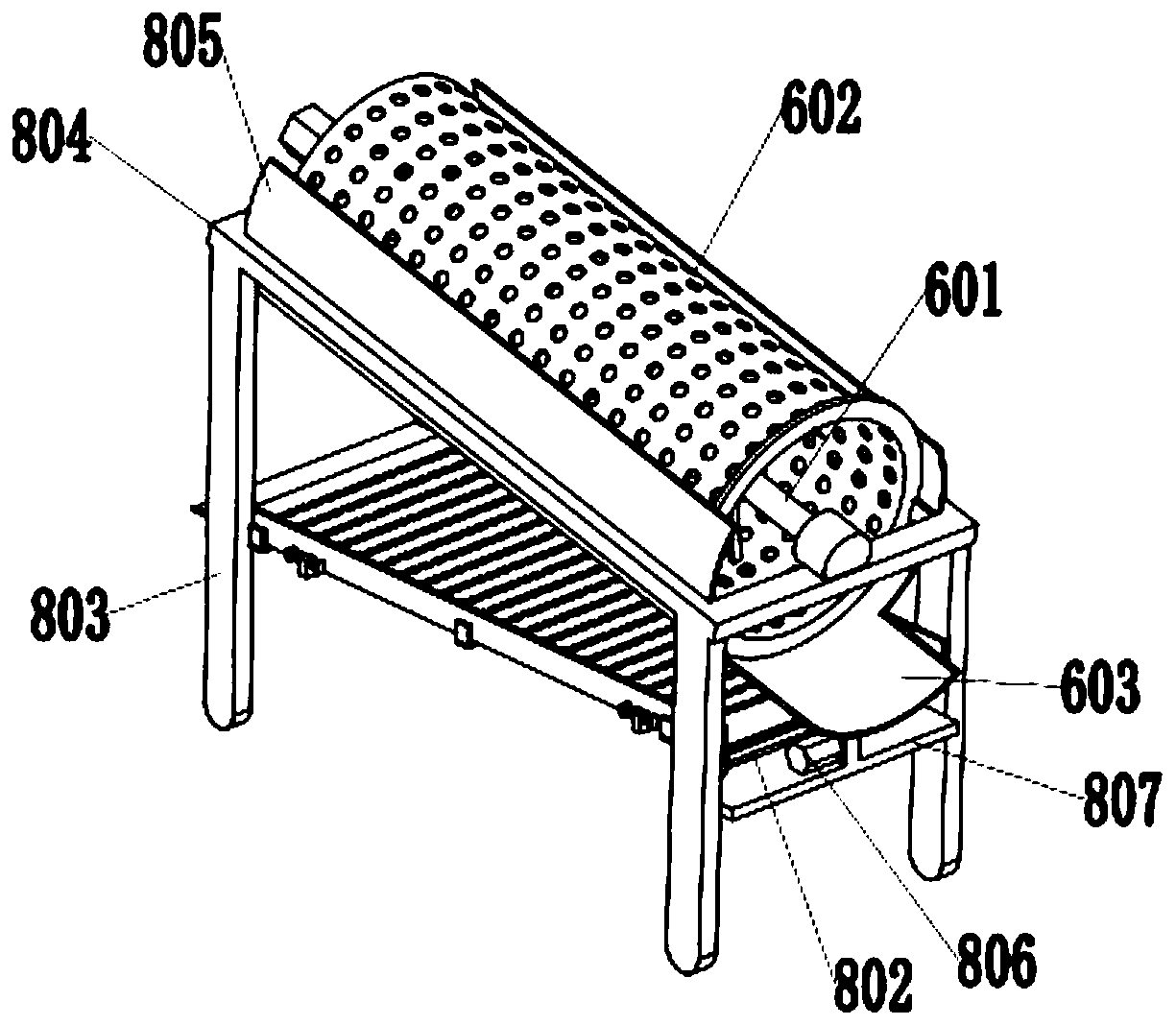

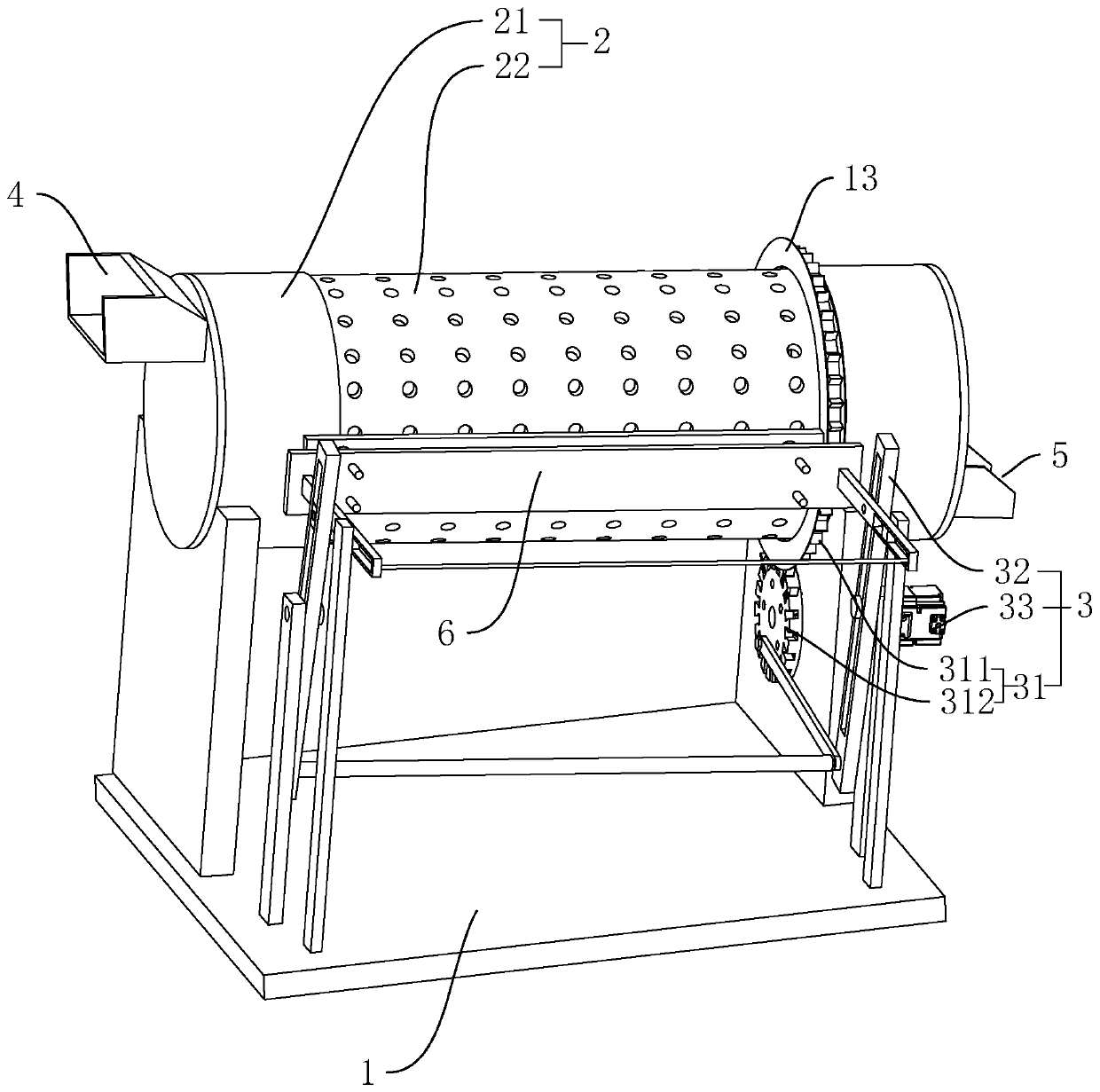

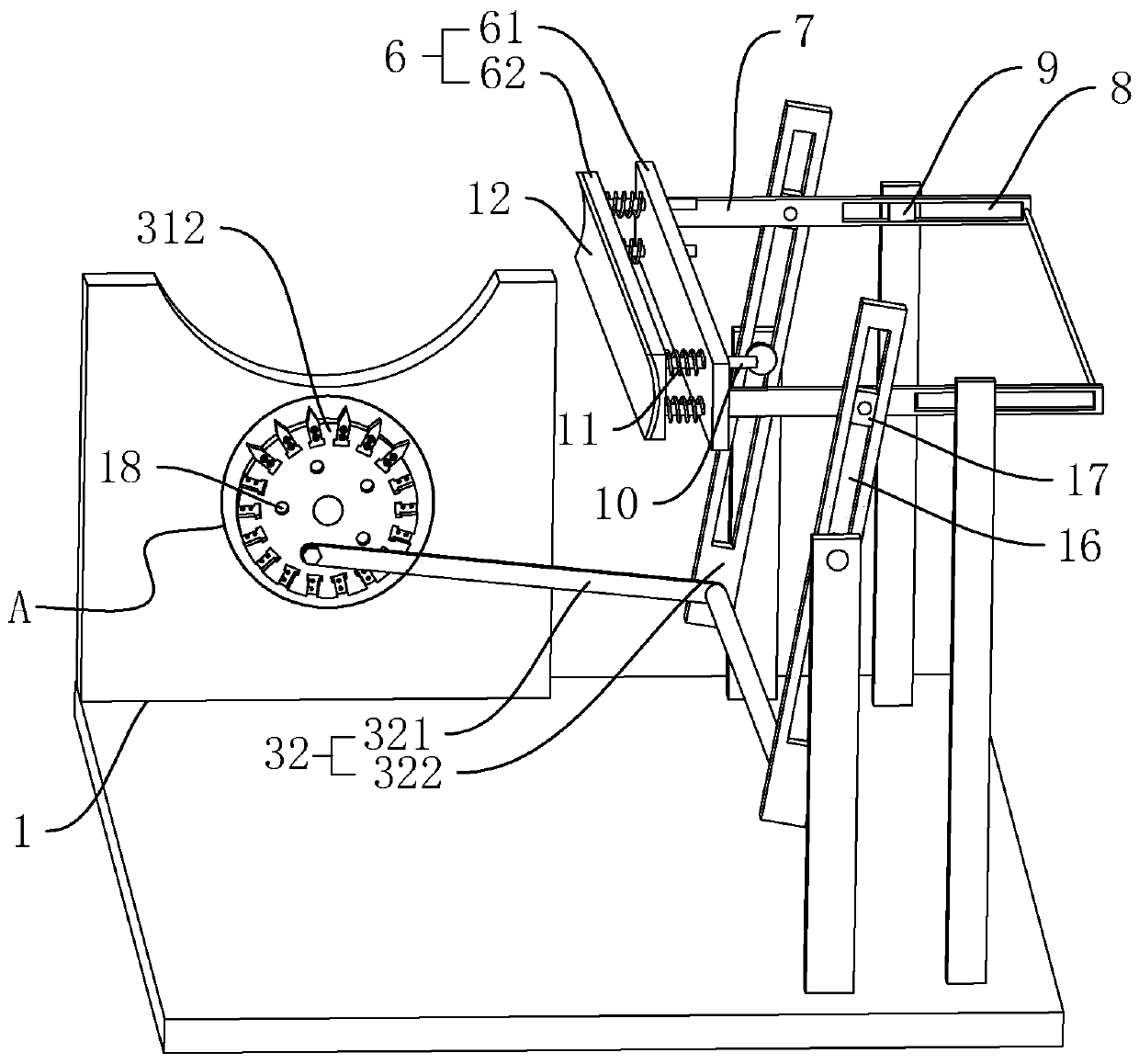

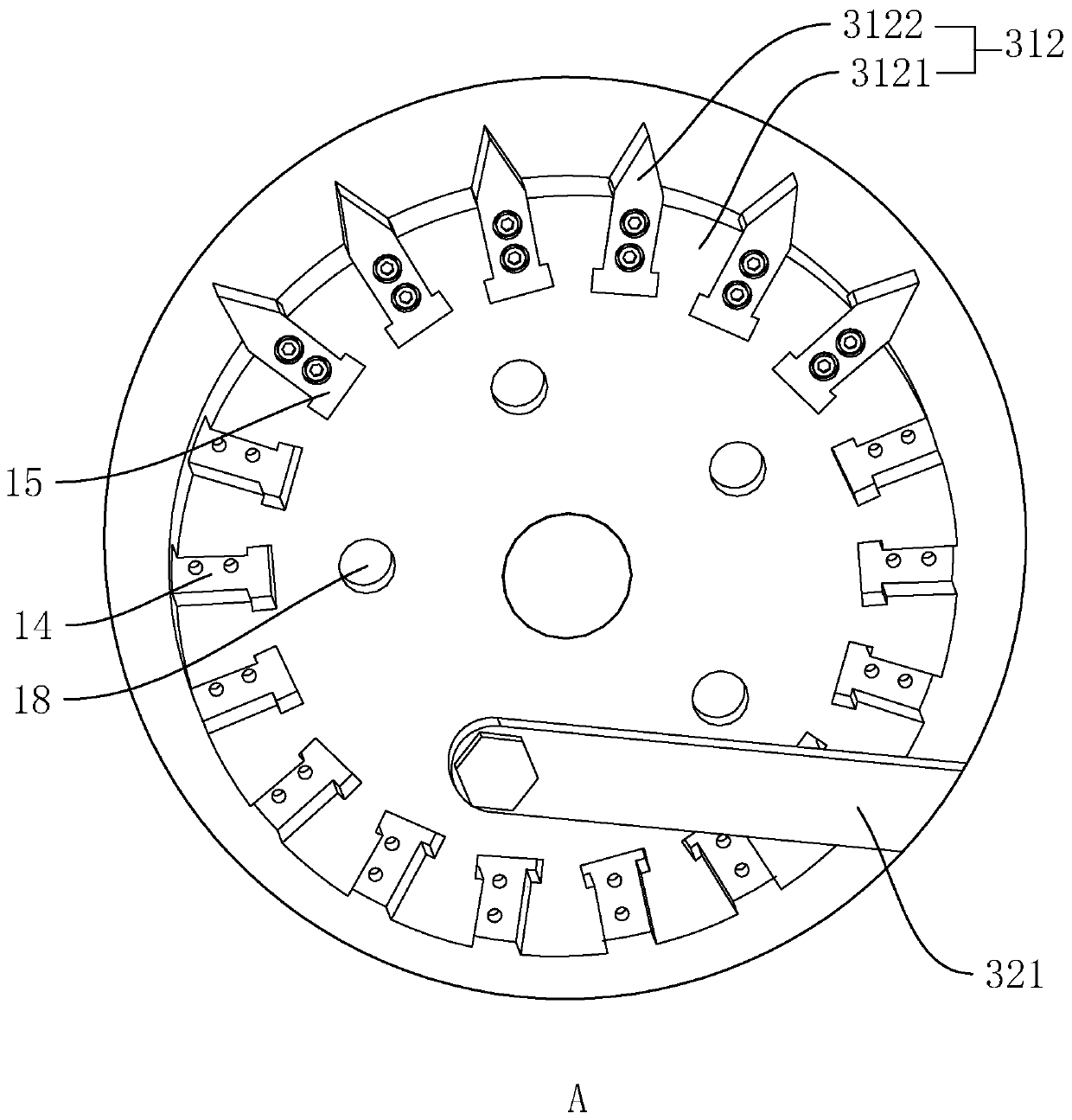

Ore washer

The invention discloses an ore washer, and relates to the technical field of limestone crushing. According to key points of the technical scheme, the ore washer comprises a rack and a mounting cavityformed in the rack; a screen drum is rotationally connected into the mounting cavity, and a driving motor is further arranged on the rack; the rotating axis of the screen drum is set obliquely downwards, the screen drum comprises an inner drum body and an outer drum body coaxially fixed to the outer side of the inner drum body, and a containing cavity is formed between the inner drum body and theouter drum body; screen holes are formed in the inner drum body and the outer drum body in the circumferential direction correspondingly, and the diameter of the screen holes in the inner drum body islarger than the diameter of the screen holes in the outer drum body; the two axial ends of the inner drum body are provided with a feeding inlet and a coarse material outlet correspondingly, and a fine material outlet is further formed in the end, away from the feeding inlet, of the outer drum body; a first washing assembly is further arranged on the rack; and the lower end of the mounting cavityfurther communicates with a waste liquid outlet. Through combination of rotation of the screen drum and spraying of the first washing assembly, ore material grading operation is completed while an ore material is washed, and thus the ore material is directly guided out in grades after being washed.

Owner:安徽友邦新材料有限公司

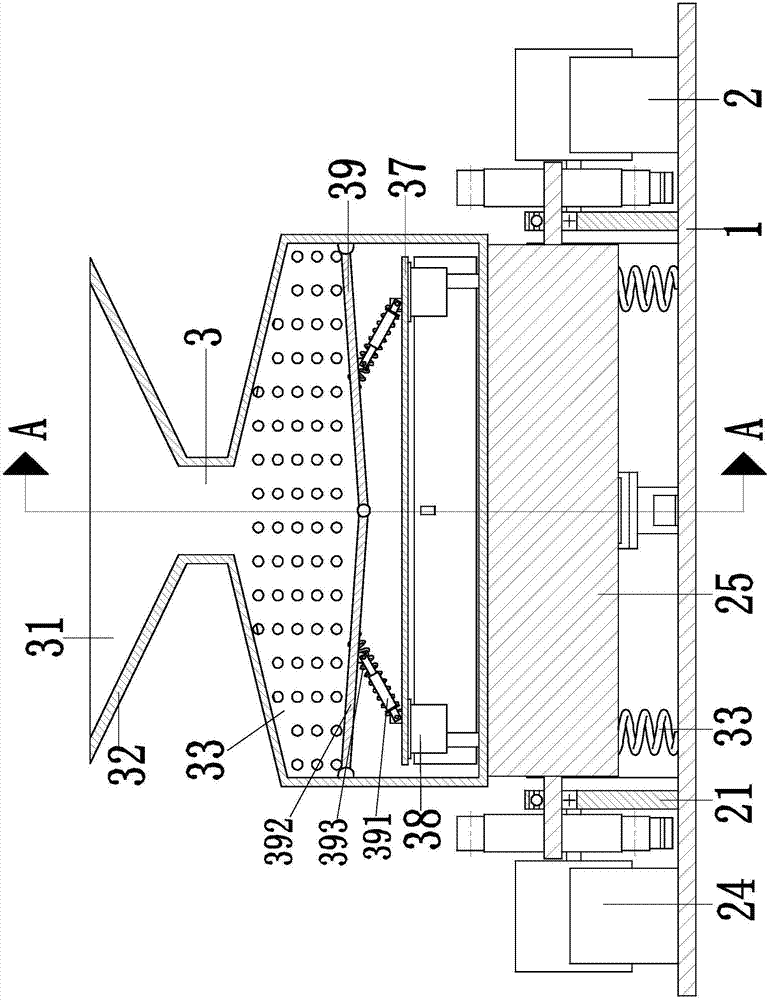

Blade-free rubbing peeling integrated machine for peeling and cleaning thin shell green peel walnuts

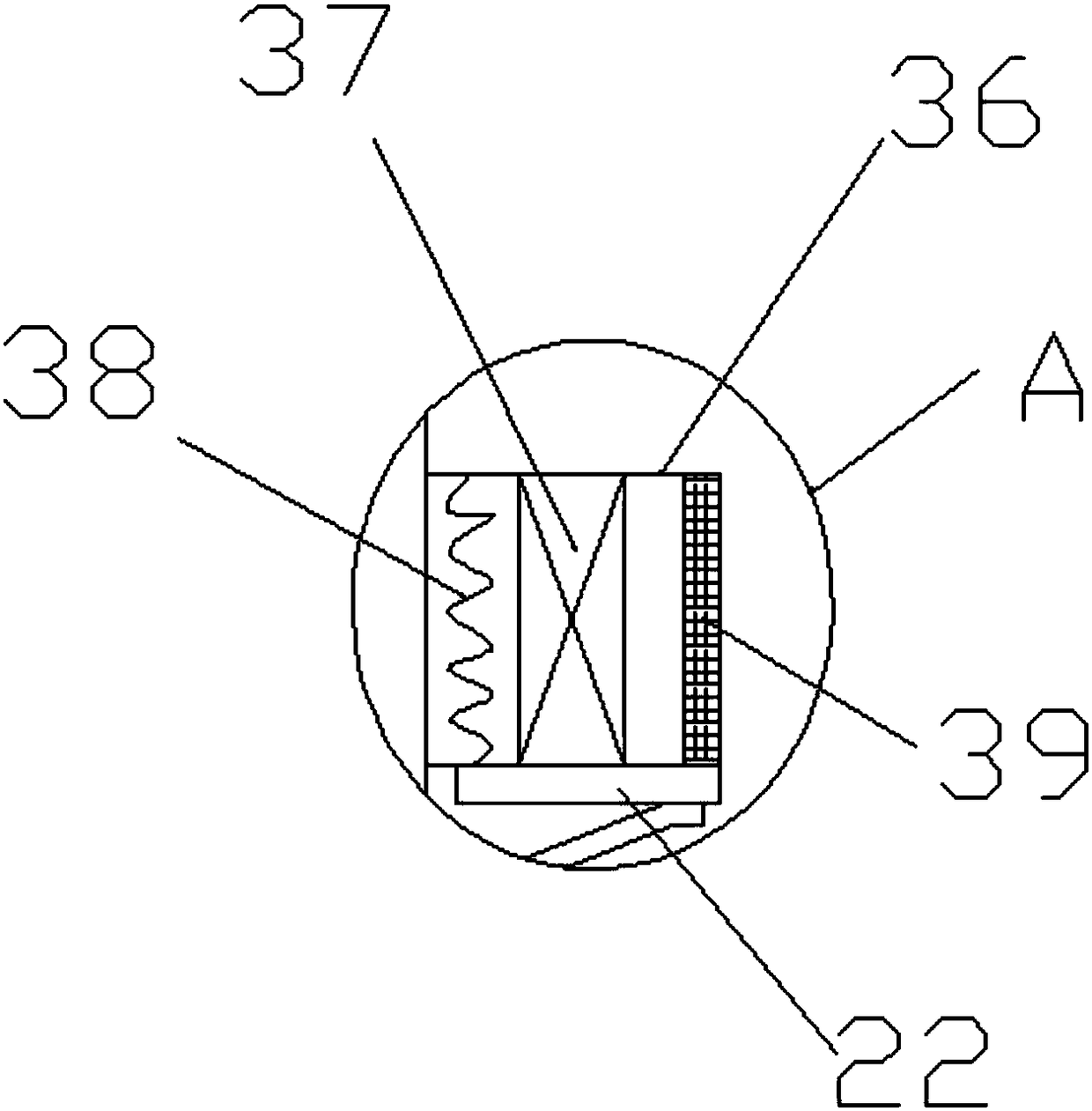

InactiveCN103040077AReduce the rate of cracked and rotten fruitThe process flow is reasonably extendedHuskingHullingProduction rateWalnut Nut

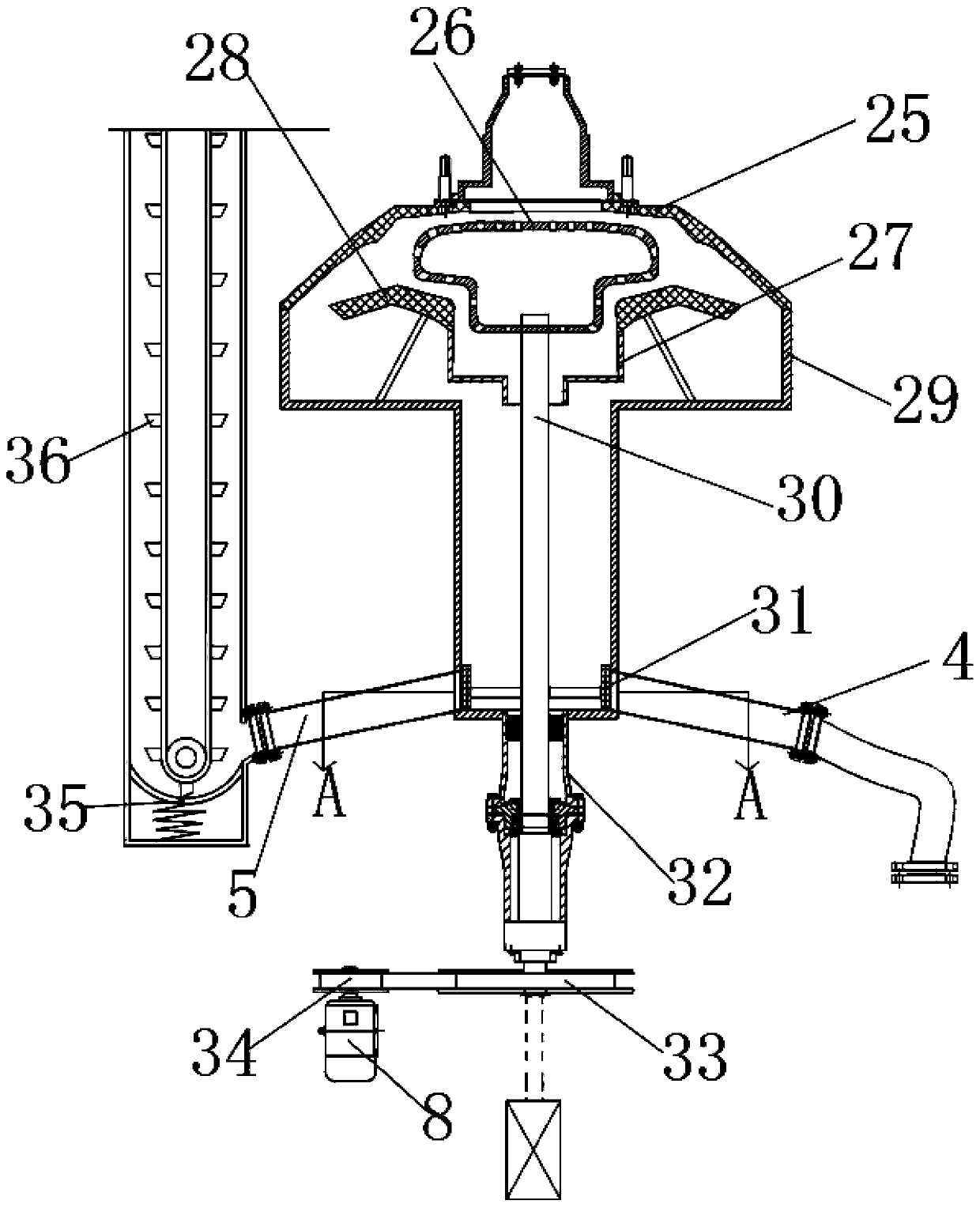

The invention relates to a walnut handling device, particularly to a blade-free rubbing peeling integrated machine for peeling and cleaning thin shell green peel walnuts to solve the problems of high nut breaking rate, low peeling rate, low producing efficiency and incomplete cleaning in the existing device. The blade-free rubbing peeling integrated machine comprises a machine frame, a machine cover, a peeling mechanism, a cleaning mechanism and a transmission mechanism. The peeling mechanism includes elastic peeling stators, screening stators, an upper water spraying pipe, a stirring rubber bar and peeling rotors arranged on a spindle. The cleaning mechanism includes a brush roll assembly and a lower water spraying pipe. The transmission mechanism includes a motor, a reducer, a big pulley arranged at one end of the spindle, a small pulley arranged at one end of the brush roll assembly and V-belts. The rotten fruit rate is greatly reduced, the peeling rate is increased and cleaning effect is good due to the fact that a blade-free rubbing peeling process, rubber bar stirring screening and a lengthened design of arranging the peeling mechanism and cleaning mechanism high and low are utilized. The mechanization of peeling and cleaning operations of thin shell green peel walnuts which are of a new superior variety and capable of increasing production continuously in recent years is achieved.

Owner:尹雄虎

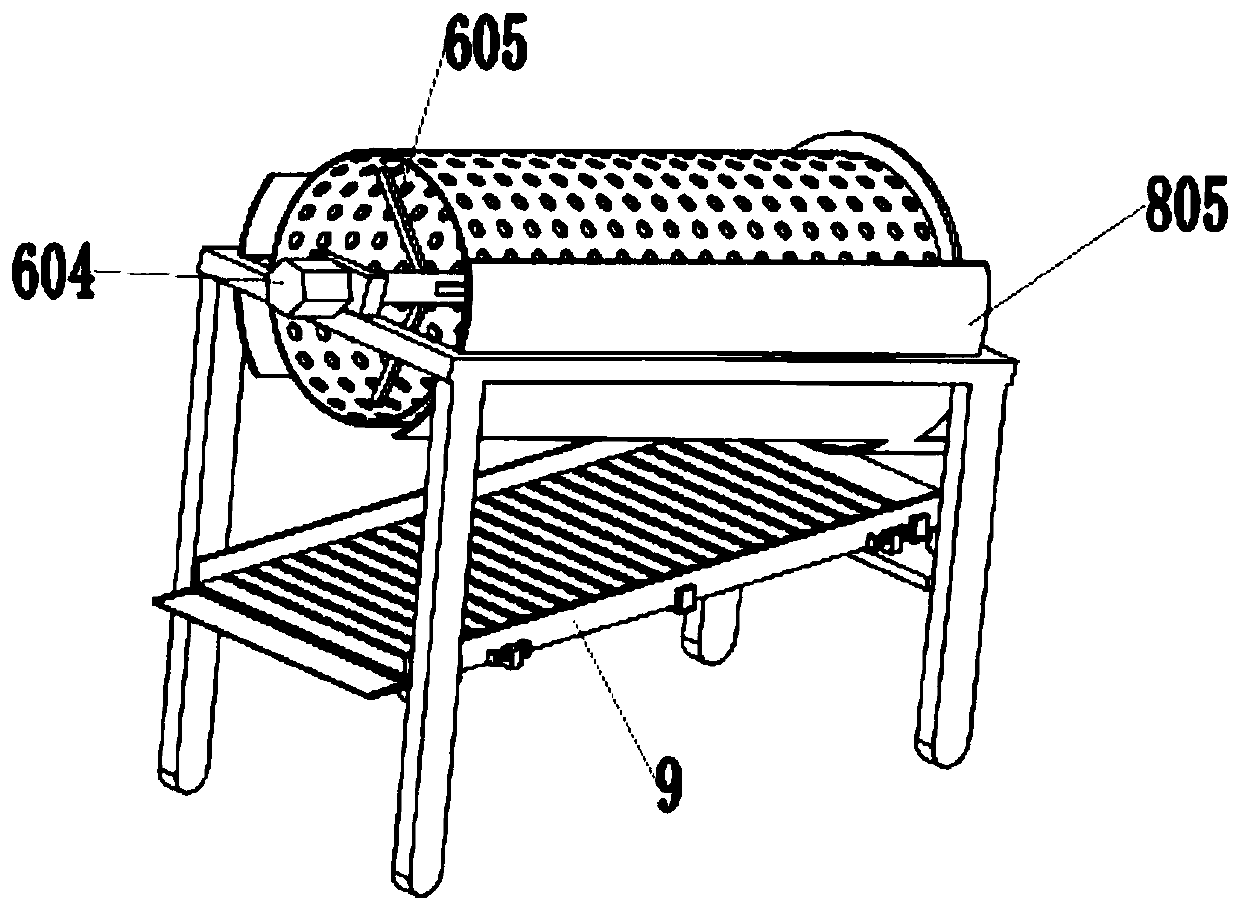

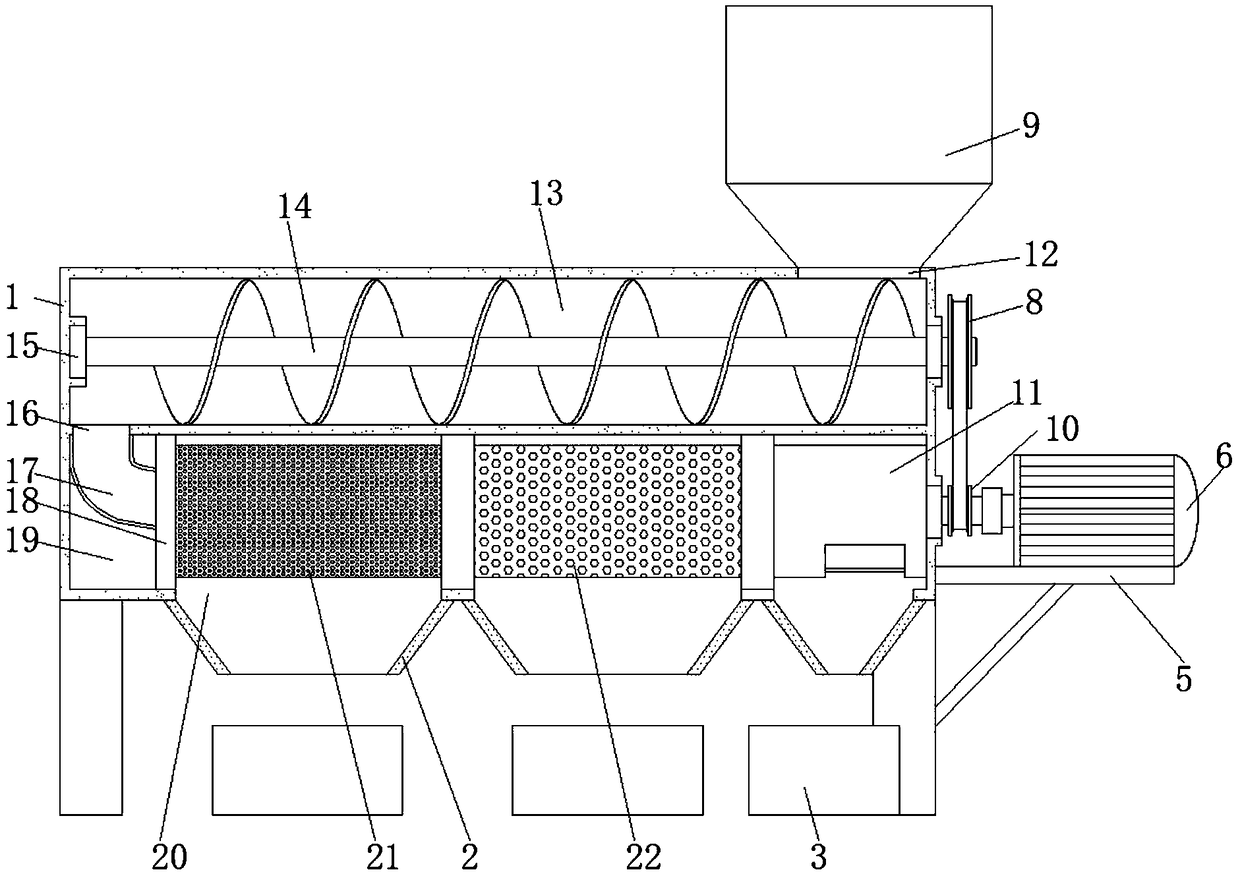

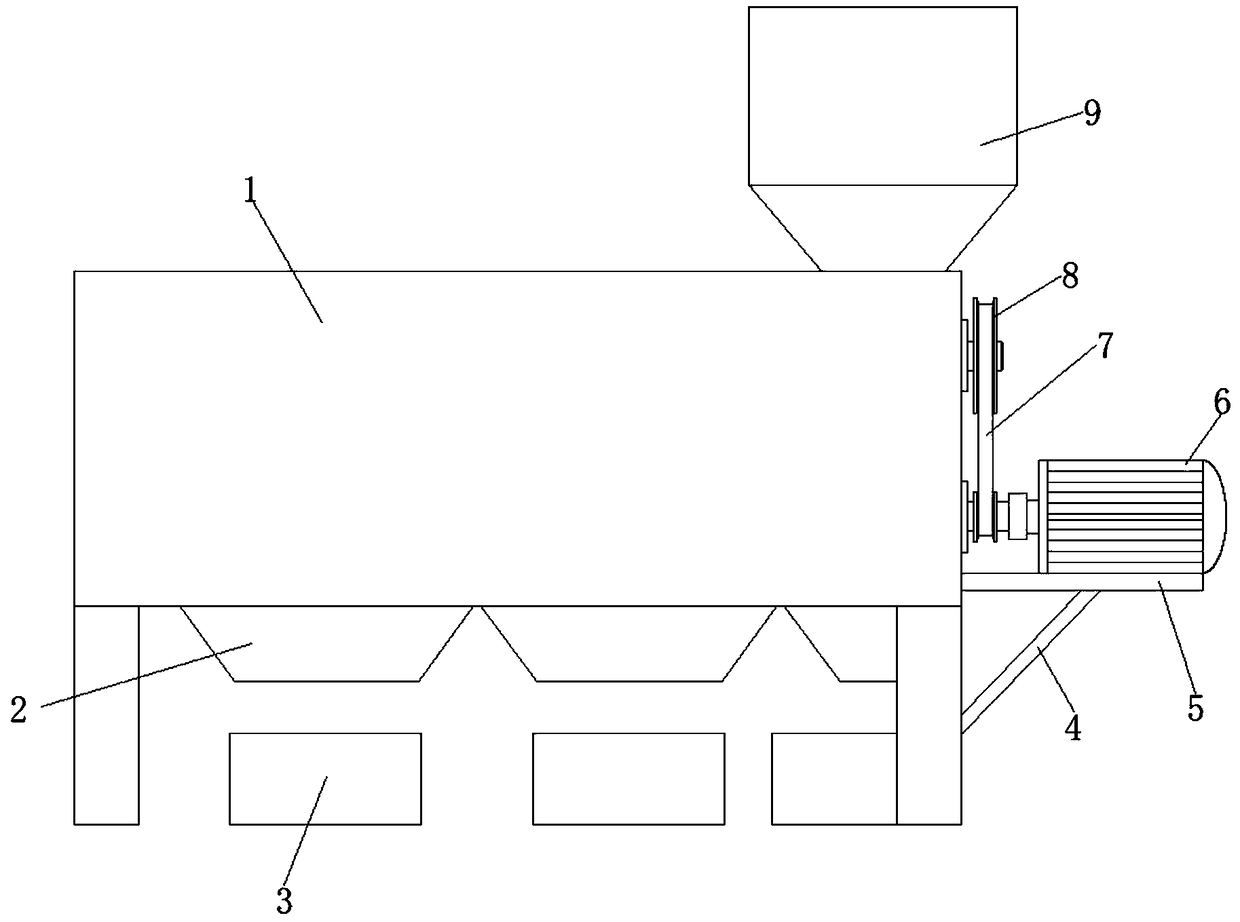

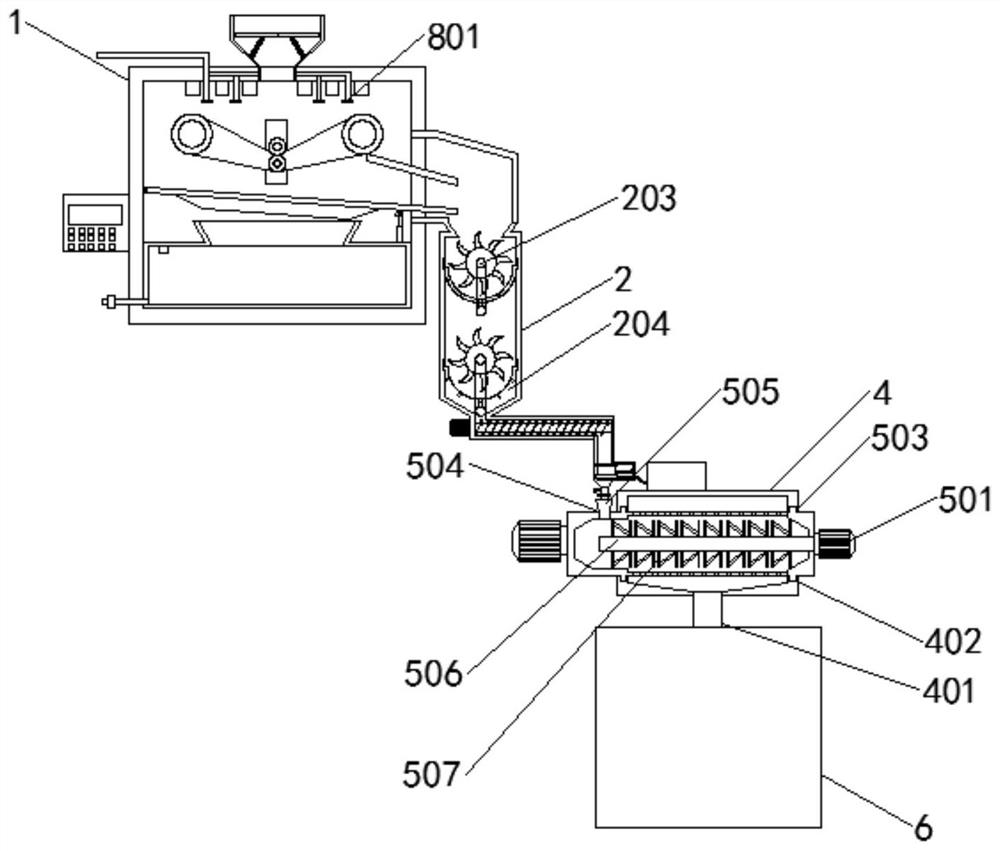

River sand screening device for construction

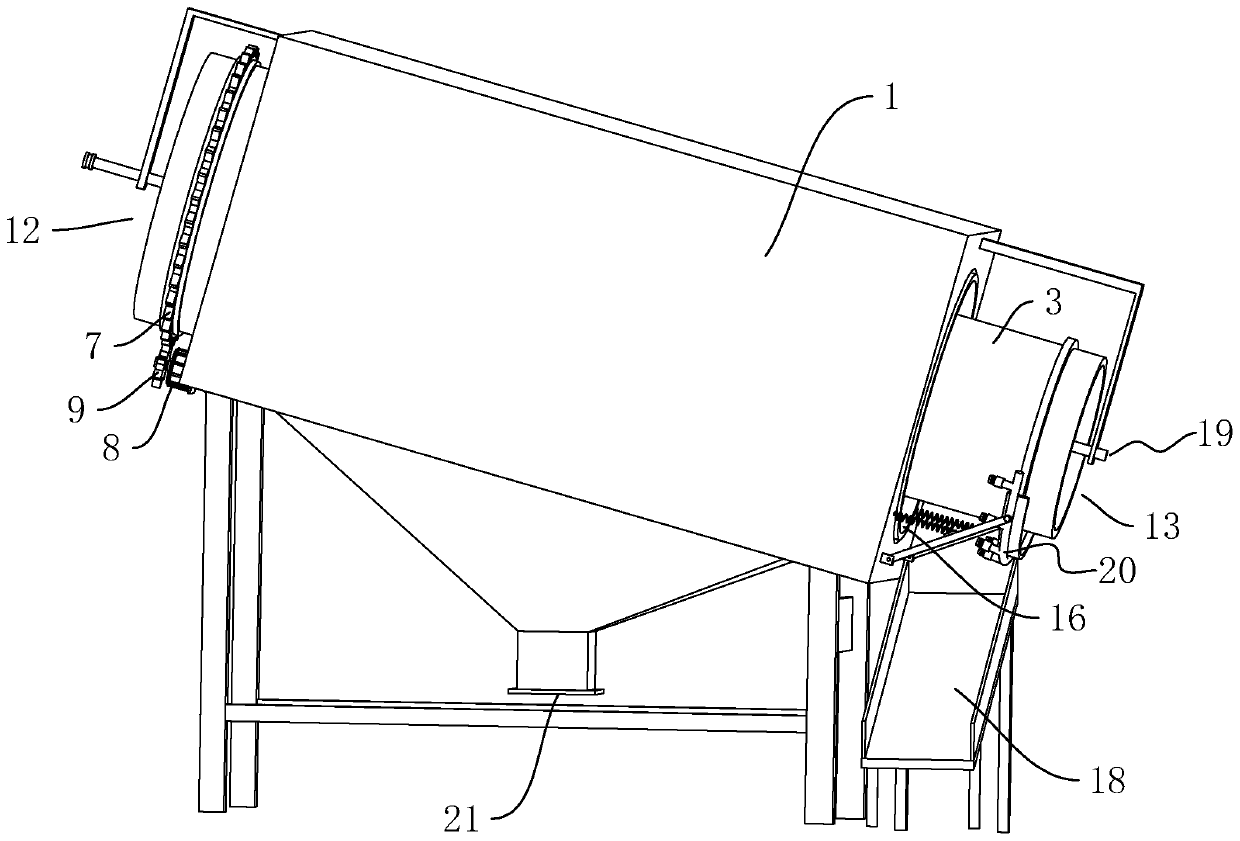

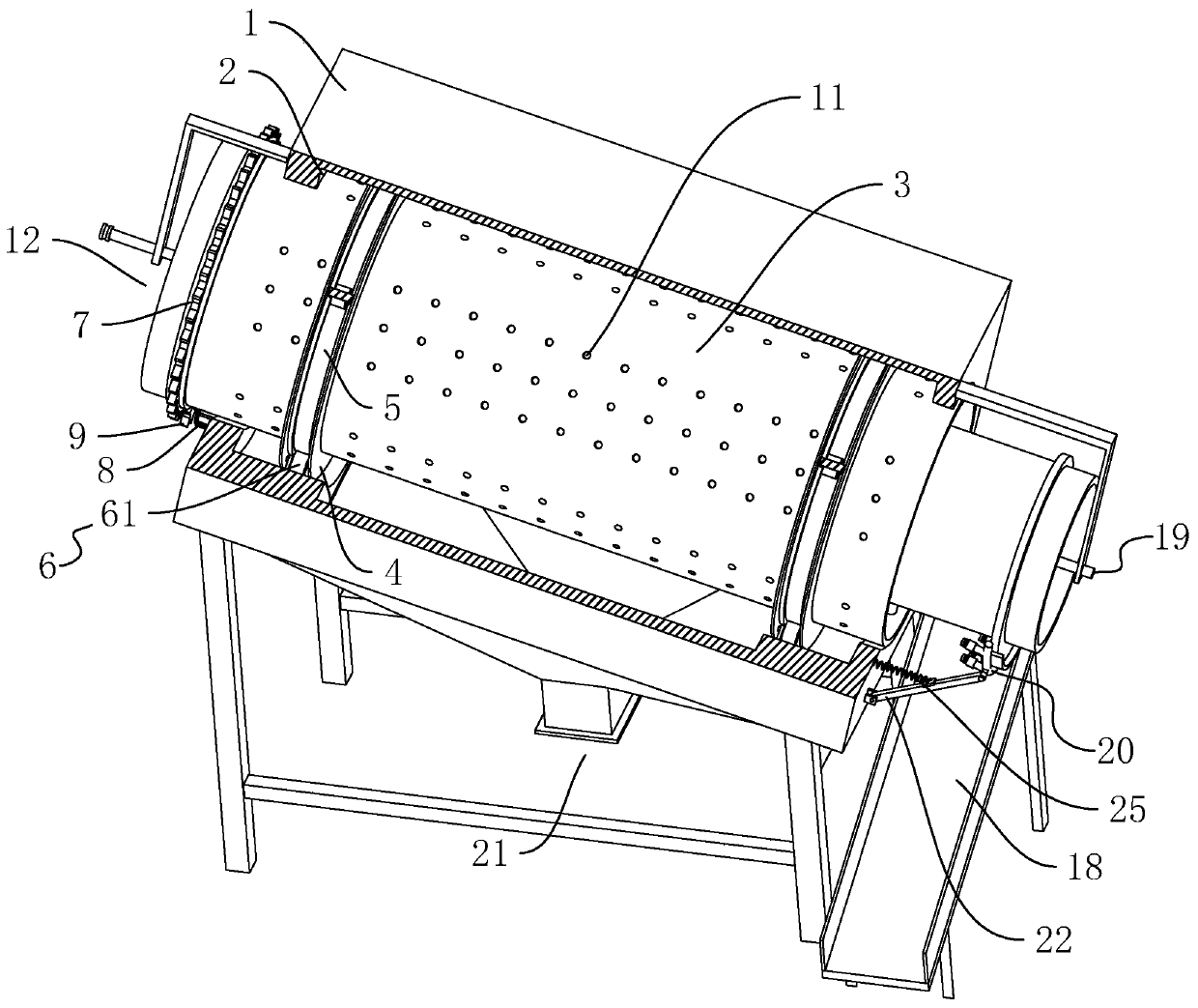

ActiveCN111054631ASmooth slidingIncrease profitSievingSand dryingEnvironmental engineeringSand filter

The invention discloses a river sand screening device for construction. The sand screening device comprises a sand feeding hopper, a drying cylinder, a primary screening device and a secondary sand screening device, the drying cylinder is mounted at the upper end of a bracket; the drying cylinder is of a double-layer hollow structure, a heating block is arranged between the outer cylinder wall andthe inner cylinder wall of the drying cylinder; one end of the drying cylinder is connected with a sand inlet hopper; the other end of the drying cylinder is communicated with the primary screening device; the primary screening device is a sand screening barrel; the sand screening barrel is installed on a supporting frame, first screening holes are formed in the side wall of the sand screening barrel, the second-stage sand screening device comprises a swing frame and a sand filtering plate, a sand screening plate is fixed to the upper end of a swing frame, second screening holes are formed inthe sand screening plate, the swing frame is connected with the supporting frame and located below the sand screening barrel, and the sand screening plate and the sand screening barrel are opposite in inclination direction. The problem that wet sands with small particles are mutually adhered is solved, the working efficiency is improved, the screening effect is improved, the utilization rate of the sand is increased, waste is avoided, and the construction cost is reduced.

Owner:济南工程职业技术学院

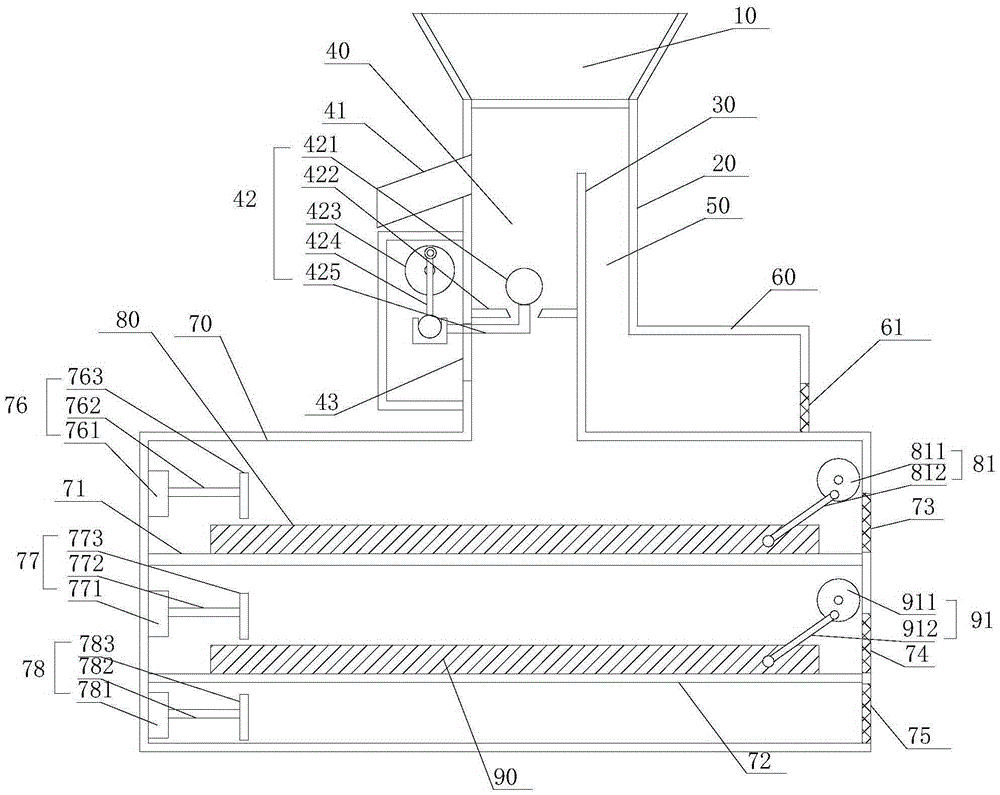

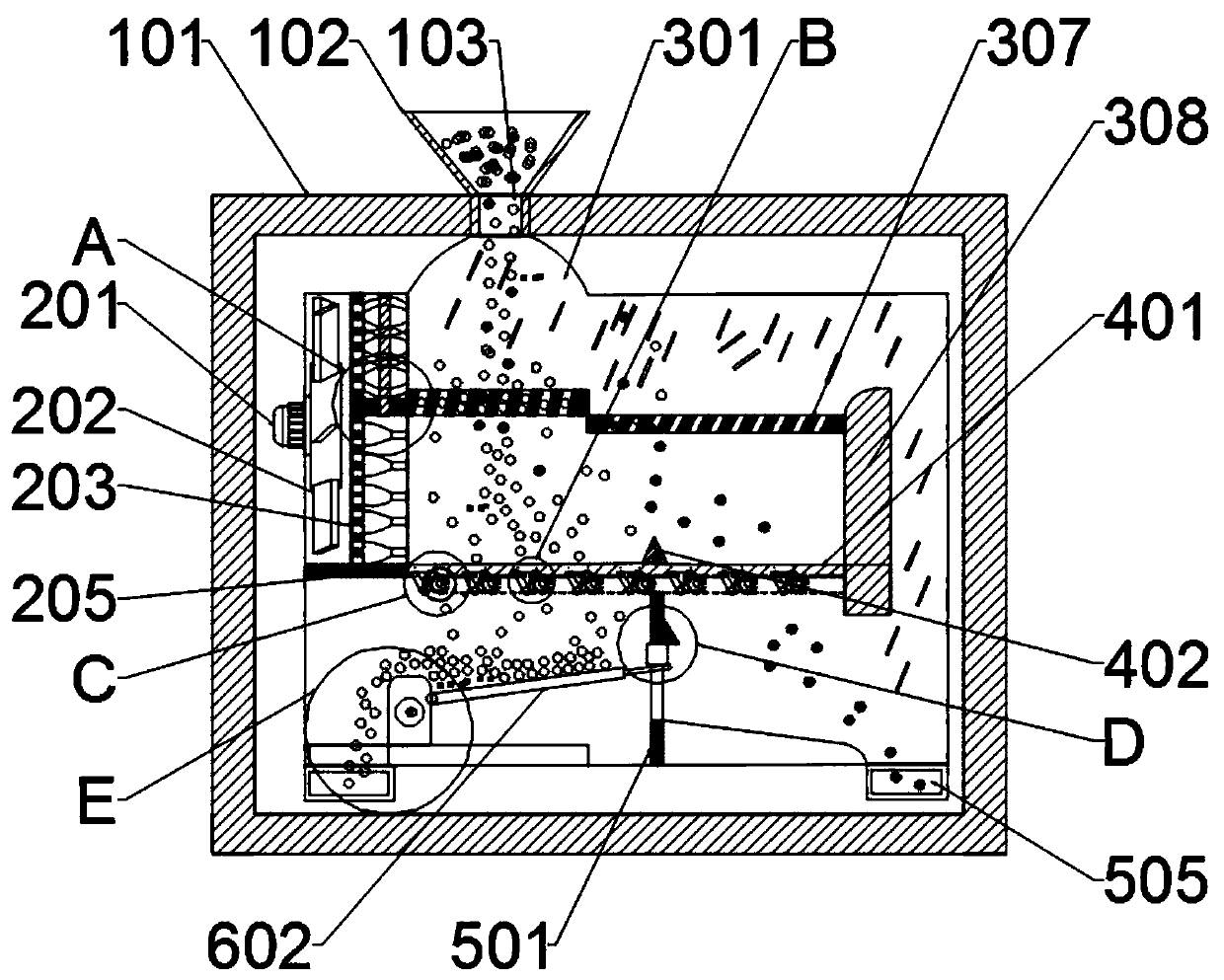

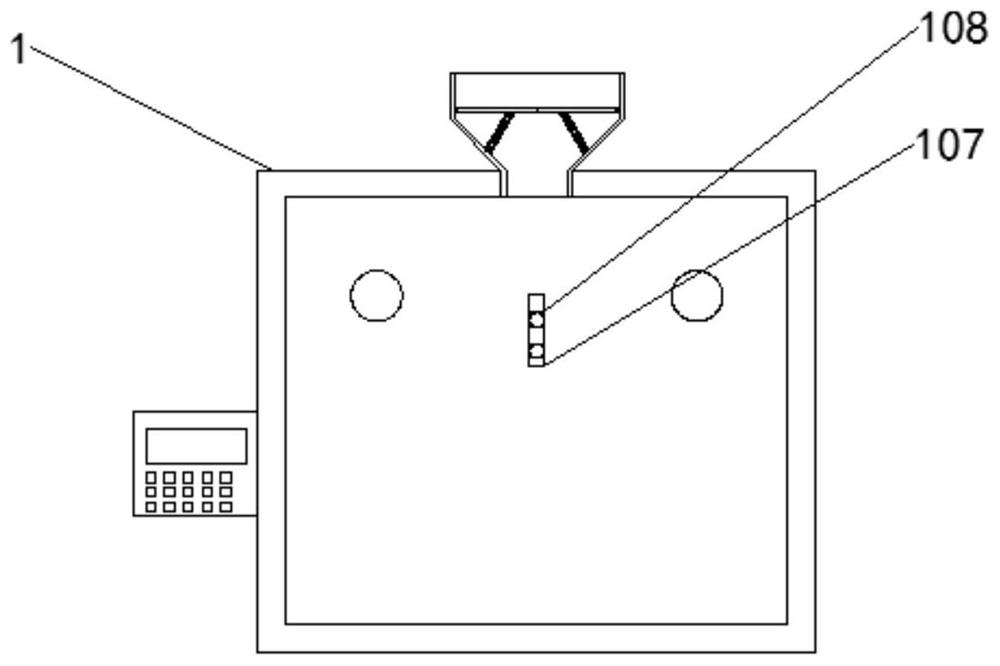

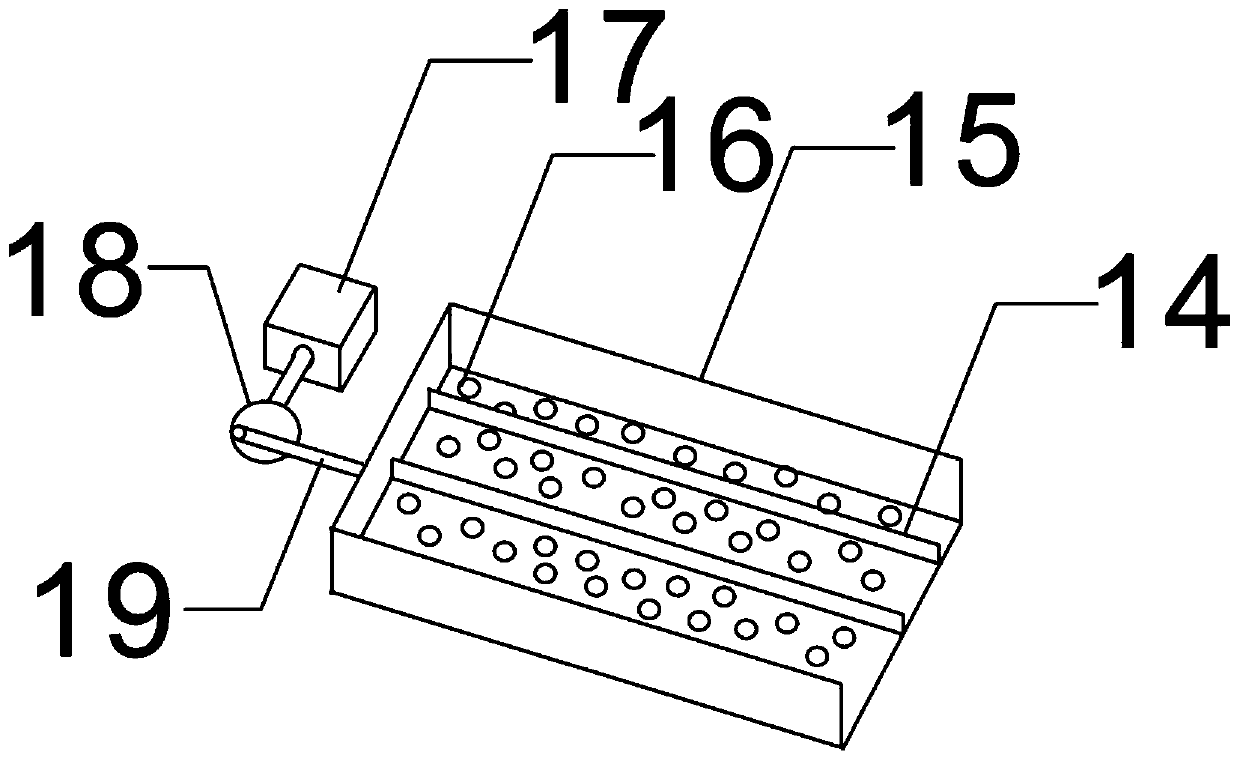

Full-automatic niblet screening device

ActiveCN105409476AReduce labor processImprove work efficiencyThreshersEngineeringUltimate tensile strength

The invention provides a full-automatic niblet screening device. The full-automatic niblet screening device comprises a feeding device and a screening device, wherein the feeding device comprises a feeding hopper and a feeding tube; a flow distributing plate is arranged in the feeding tube; the inside of the feeding tube is divided into a material flowing channel and an impurity flowing channel by the flow distributing plate; a quantitative feeding device is arranged in the material flowing channel and comprises a quantitative feeding plate and a piston type jacking device; the quantitative feeding plate is mounted on the inner wall of the material flowing channel; a quantitative feeding opening is formed in the quantitative feeding plate; a movable ball is arranged at the quantitative feeding opening; the piston type jacking device is movably mounted on the inner wall of the material flowing channel and is used for jacking up the movable ball in an intermittent manner; and an air feeding tube is arranged at the inlet end, close to the material flowing channel, of the side wall of the feeding tube; and the screening device comprises a screening box as well as a first screening unit and a second screening unit which are arranged in the screening box. The full-automatic niblet screening device is simple in structure and thorough in screening, can completely separate niblets from stalks, can separate the niblets with different plumpness degrees, and is low in labor intensity and high in work efficiency.

Owner:全椒县汊河农机服务专业合作社

Multi-level corn kernel screening device

The invention provides a multi-level corn kernel screening device which comprises a base, a feeding hopper, a first piston type jacking device, a second piston type jacking device, a first drive mechanism and a screening box. The discharging end of the feeding hopper is provided with a first opening and a second opening. The first opening is provided with a first movable ball. The first piston type jacking device is movably arranged on the screening box to be used for jacking the first movable ball in an intermittent manner. The first piston type jacking device moves in the vertical direction. The second opening is provided with a second movable ball. The second piston type jacking device is movably arranged on the screening box to be used for jacking the second movable ball in an intermittent manner. The second piston type jacking device moves in the vertical direction. A first rotary disc, a first screen plate, a second screen plate and a third screen plate are horizontally arranged in the screening box. The multi-level corn kernel screening device is simple in structure and thorough in screening, the screening process is conducted in a fully-sealed box body, no dust is generated, corn kernels with different satiation degrees can be separated, and labor intensity is low.

Owner:全椒县汊河农机服务专业合作社

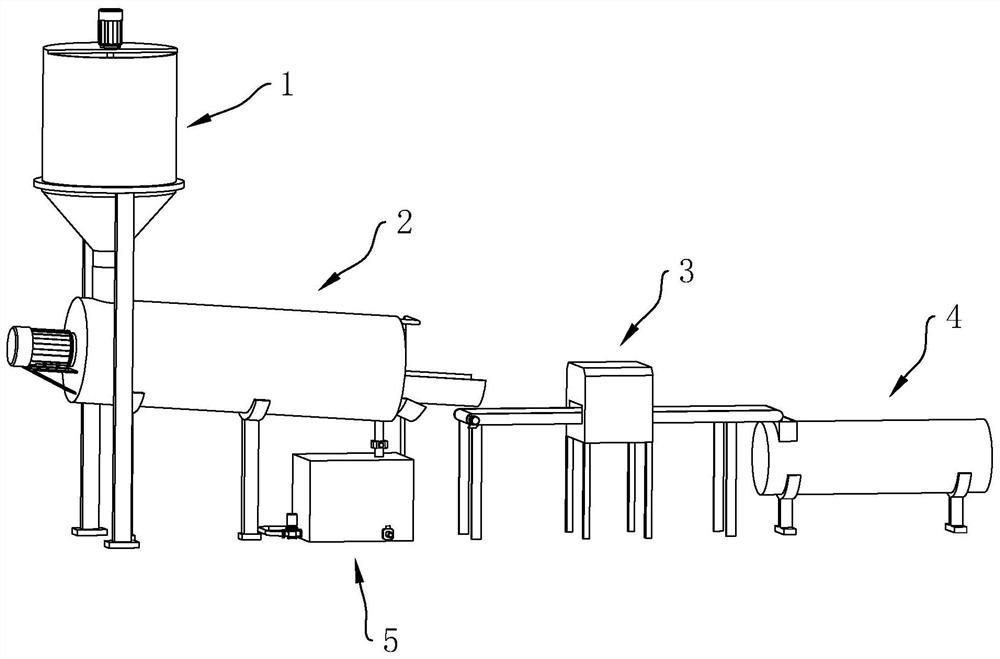

Concrete excess material recycling treatment system

The invention relates to a concrete excess material recycling treatment system which comprises an excess material collecting device, a sand-stone separating device, a drying device, a ball milling device and a slurry treatment device, and the excess material collecting device is arranged on the upper portion of the sand-stone separating device and used for collecting concrete excess materials. Theslurry treatment device is arranged below the sand-stone separating device and used for treating separated slurry, the drying device is connected to one side of the sand-stone separating device and used for drying separated stones, and the ball milling device is connected to one side of the drying device and used for carrying out surface ball milling treatment on the dried stones. The stones aredried and then subjected to ball-milling treatment, so that adhered substances on the surface are removed, and accordingly the quality of separated aggregates is improved. The concrete excess materialrecycling treatment system has the effect of improving the quality of the aggregates separated from the concrete excess materials.

Owner:汉中尧柏磊金节能环保建材有限公司

Screening device for casting sand

InactiveCN109014032AScreen thoroughlyAvoid accumulationMould handling/dressing devicesScreening effectScreening method

The invention discloses a screening device for casting sand. The screening device includes a machine shell, supporting legs are arranged at the four corners of the bottom face of the machine shell, asupporting plate is horizontally welded to the bottom of the right side face of the machine shell, a driving motor is mounted on the upper surface of the supporting plate, and an inner cavity of the machine shell is separated by a separating plate into a conveying cavity located at the top of the inner cavity of the machine shell and a screening cavity located at the bottom of the inner cavity ofthe machine shell; and a feeding opening is formed in the top of the right end of the conveying cavity. According to the screening device for casting sand, the driving motor is used to drive a screentube to rotate to screen the sand, compared with a traditional vibration screening method, a rolling screen can flip the sand, the accumulation of the sand is prevented, the sand can also be preventedfrom clogging a screening hole, so that the sand can be screened more thoroughly; and before the sand enters the screen tube, a feeding screw rod is used for feeding, the sand can be made to enter the screen tube at the uniform speed, the fact that the sand is accumulated in the screen tube due to more sand entering the screen tube once is prevented, and the screening effect is improved.

Owner:ANHUI SIYUAN SANQING INTELLIGENT MFG CO LTD

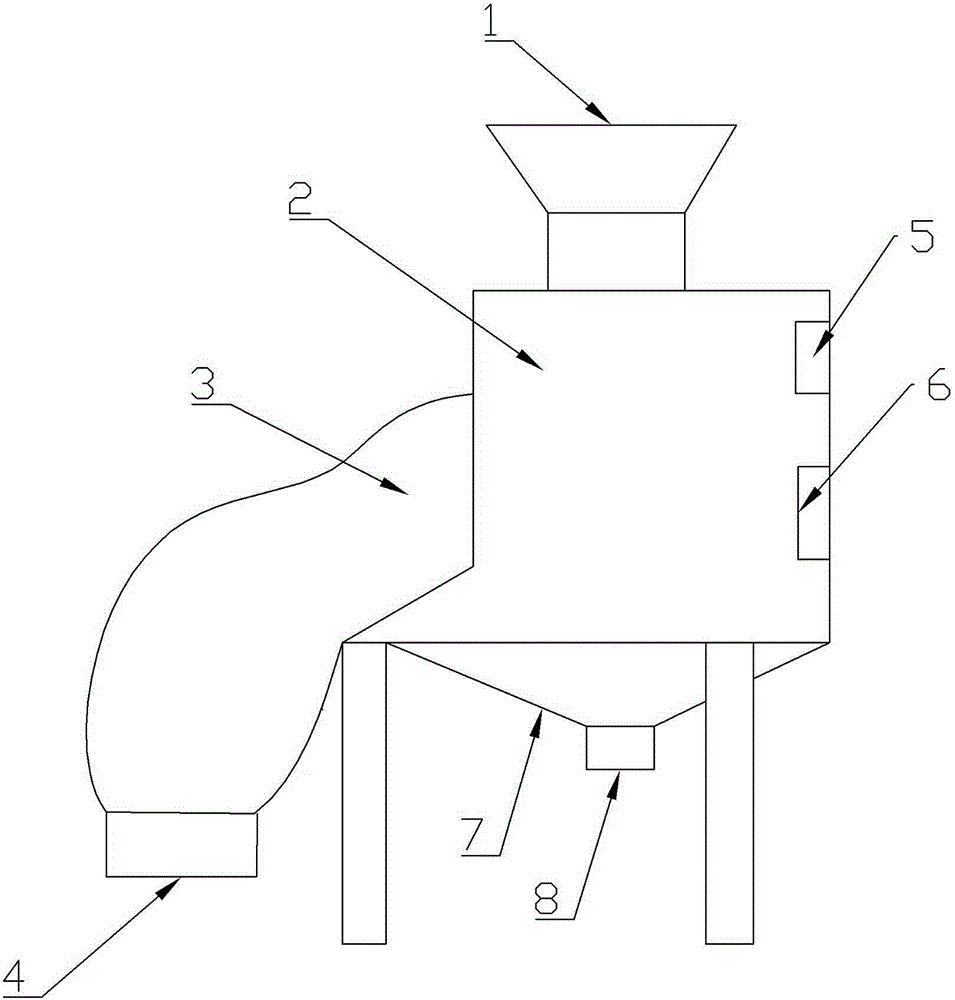

Forage grass crushing equipment

ActiveCN110433928AReduce the degree of shreddingScreen thoroughlySievingFeeding-stuffLow speedScreening effect

The invention relates to the field of feeds, in particular to forage grass crushing equipment. The problems that because the feed crushing is beneficial to the digestion and absorption of livestock and the granularity of the feed for feeding different livestock is different, the crushing degree cannot be controlled in traditional forage grass crushing equipment, the crushed forage grass with different lengths cannot be classified, and the screening effect is not good are solved. The equipment aims to solve the above problems. The equipment has two different crushing effects. During low-speed rotation. A motor rotating speed 1:1 is conveyed to a rotary drum, rotary drum cutting knives rotate, forage grass is cut, and the crushing degree of the forage grass is low; during high-speed rotation, a transmission system is accelerated to run, spring cutters on a rotating column are thrown out under strong centrifugal force; the number of the cutters is increased; meanwhile, the crushing degreeof the forage grass is low; the crushed forage grass is classified by a sieve plate, so that the long section and the short section can be collected; and the sieve plate can vibrate up and down, so that the feed is completely screened, and the situation that the feed is leaked occurs is avoided.

Owner:常德嘉粮机电科技有限公司

Environment-friendly shaking type sand sieving equipment for constructional engineering

InactiveCN107755252ANo cloggingReduce cloggingSievingScreeningElectric machineryArchitectural engineering

The invention discloses an environment-friendly vibrating sand screening equipment for construction engineering, which comprises a sand screening equipment body. There are feeding bins, primary screening bins and secondary screening bins. The inner sides of the feeding bins are symmetrically provided with deflectors, and springs are fixed below the vibrating motor and on the outer walls of the support plates. In the present invention, the environment-friendly vibrating sand screening equipment for construction, firstly, due to the setting of the primary screening chamber and the secondary screening chamber, the sand used for construction can be screened twice, so that the screening is more thorough. The sand is finer. Secondly, due to the setting of the vibration motor, rubber belt and spring, the arc-shaped filter screen can be driven to shake by the vibration motor during the screening operation, so that the arc-shaped filter screen will not be blocked.

Owner:成都尚智恒达科技有限公司

Efficient grain drying and screening device

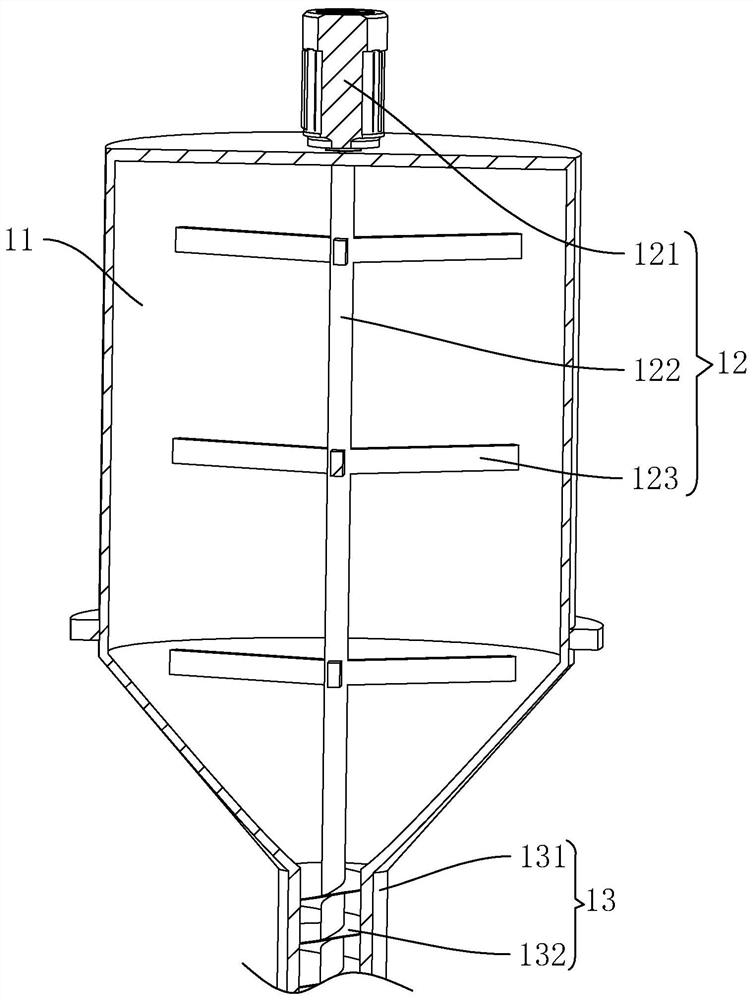

InactiveCN107576184AImprove drying efficiencyEvenly heatedSievingScreeningFixed bearingAgricultural engineering

The invention discloses an efficient grain drying and screening device which comprises a shell. Supporting legs are arranged at the bottom of the shell in a bilateral symmetry mode, and a feeing portis formed in the top of the shell; a flow guiding cone is arranged at the inner top end of the shell and is of a cone-shaped shell structure, and ventilating holes are uniformly formed in the side surface of the flow guiding cone; a draught fan is arranged on the right side of the top end of the shell and penetrates through the middle of the feeding port through an air pipe and communicates with the top end of the flow guiding cone; a machine cabin is arranged at the bottom end of the flow guiding cone, and a vertical rotary shaft vertically penetrates through the middle of the machine cabin;and the upper side and the lower side of the vertical rotary shaft are sleeved with fixing bearings arranged at the top and the bottom of the machine cabin. According to the efficient grain drying andscreening device provided by the invention, the structure is novel, structural arrangement is compact and reasonable, a drying mechanism is ingeniously arranged, grain heating is uniform, and the drying efficiency is high; and additionally, a screening mechanism is ingeniously arranged, secondary screening is achieved, and screening is more thorough.

Owner:迟一

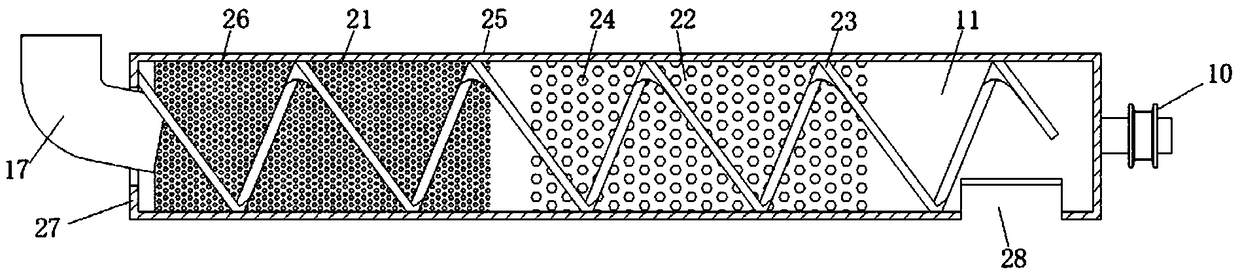

Screen for rice sieving machine

The invention relates to the technical field of rice sieving equipment, in particular to a screen for a rice sieving machine. The rice sieving machine comprises a screen frame and two screens, wherein limiting plates are symmetrically arranged at the two sides of the screen frame; multiple limiting plates are vertically and uniformly distributed on the screen frame; the distances between all the limiting plates at the same side are equal to the thicknesses of the screens; the limiting plates are provided with connecting holes; locking bolts are arranged in the connecting holes; the screens are provided with through holes corresponding to the connecting holes, and are connected with the limiting plates through the locking bolts; and all the screens are connected to the adjacent limiting plates. Compared with a traditional screen, the equipment only needs one type of screen to combine different types of screen holes to satisfy actual demands, so that the cost is saved for users, the installation trouble is reduced, and the screen is practical.

Owner:CHONGQING ZHIRUIDE TECH

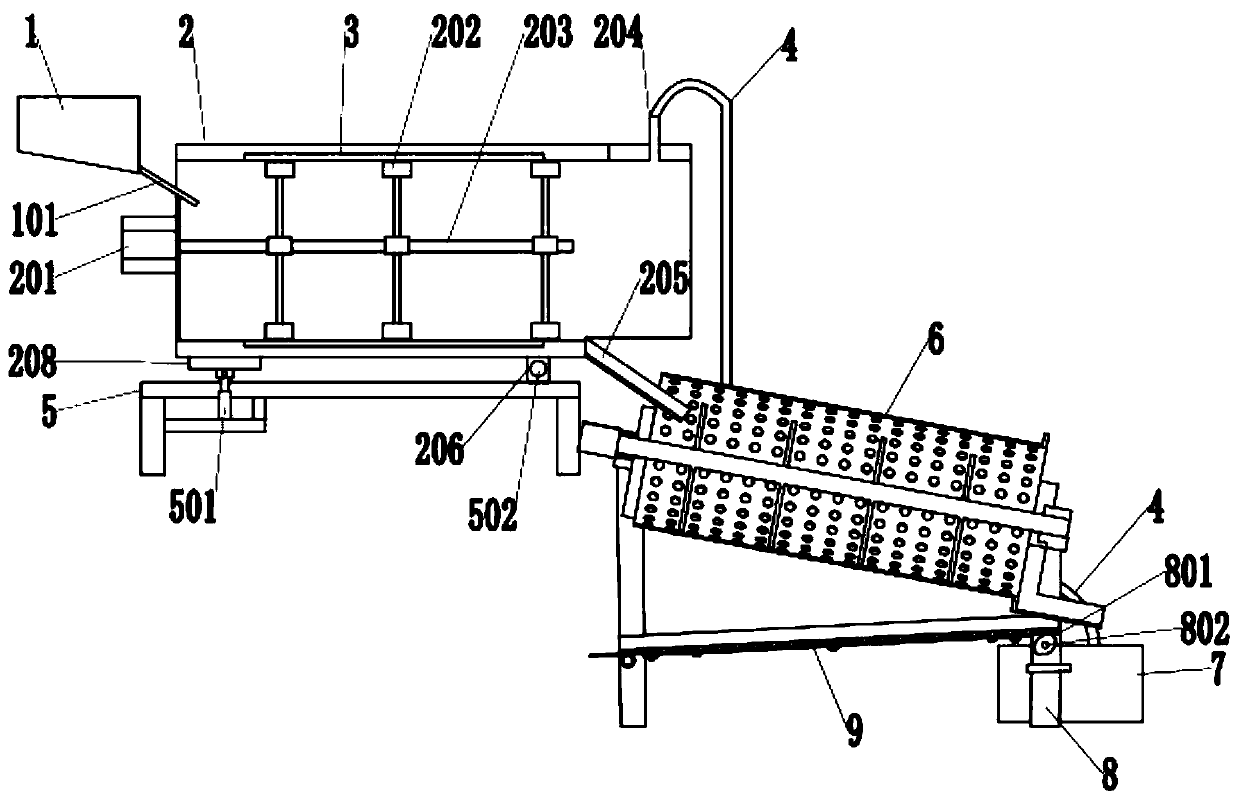

Through-flow air screen cleaning and screening device for screening corns

ActiveCN111389728AAvoid wastingAvoid direct hitsSievingGas current separationAgricultural scienceHigh density

The invention discloses a through-flow air screen cleaning and screening device for screening corns, and belongs to the technical field of agricultural machinery. The through-flow air screen cleaningand screening device for screening the corns comprises a feeding component, a power component and a lightweight excluding and screening component; the feeding component is positioned on the outermostside of the device; the power component is arranged on one side in the feeding component; and the lightweight excluding and screening component is arranged on one side of the power component. The through-flow air screen cleaning and screening device for screening the corns is scientific and reasonable, and safe and convenient to use; lightweight impurities, such as corn whisker and corn leaves, doped in the corns are separated from the corns by utilizing crisscross air staggered up and down; and then hollow bad corns mixed in high-quality corns are screened out by purging by utilizing transverse high-speed air; high-density substances, such as stone, doped in the corns are effectively intercepted by utilizing a vibrating effect; and finally, the inclination direction of a corn material guide plate is controlled by utilizing an electromagnet. The effect of switching matched operations of screening and waste material unloading is achieved, so that a waste material cannot remain in the device.

Owner:滨州鸾飞数控机械有限责任公司

Spiral tower-type screening machine

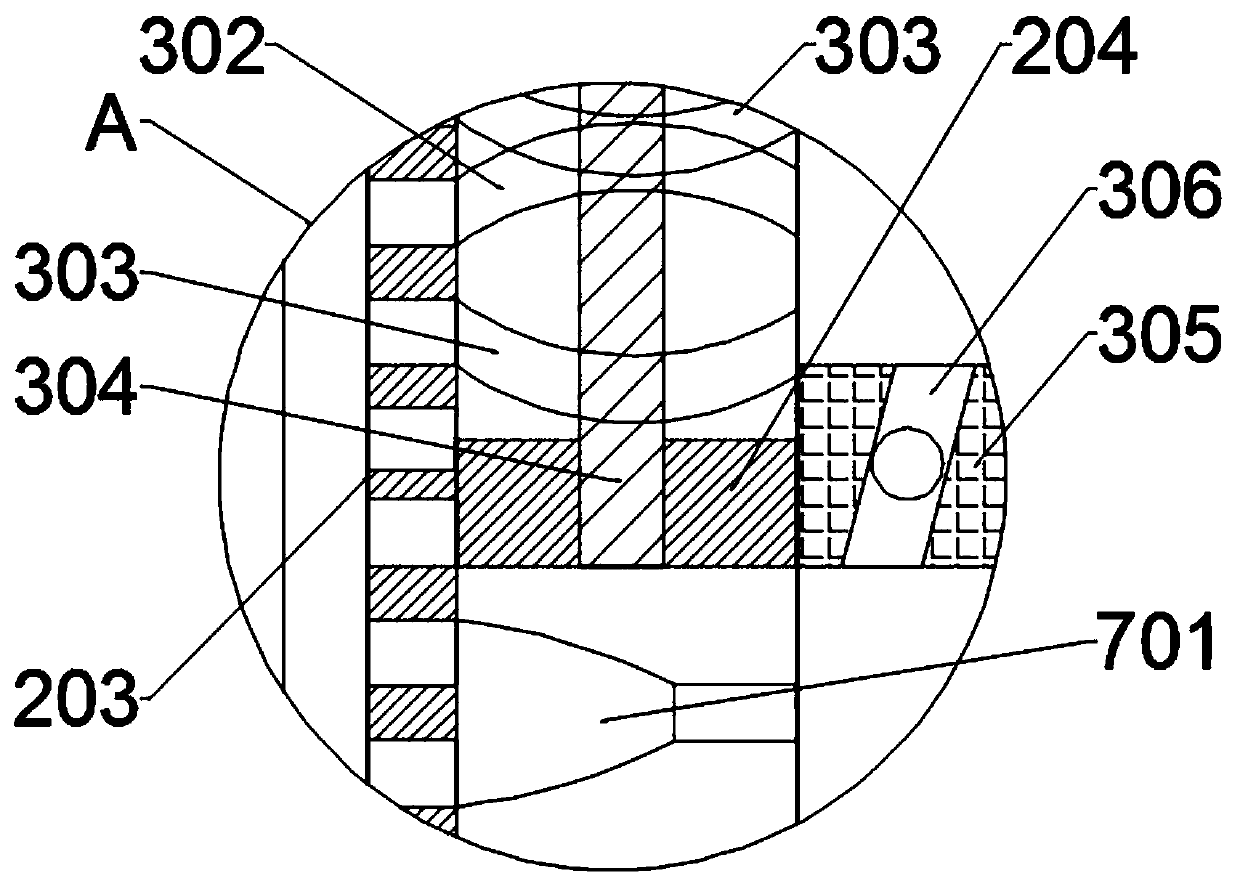

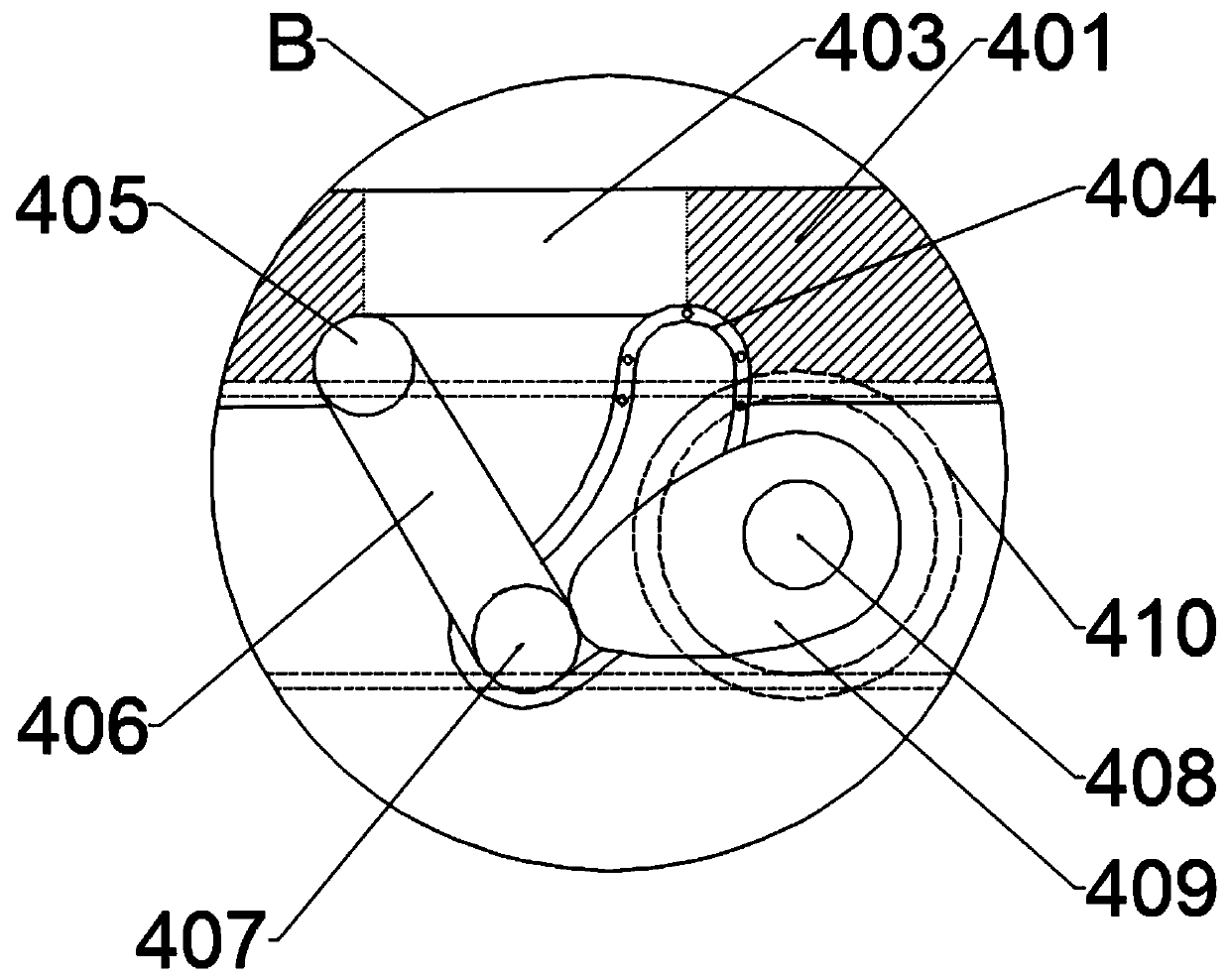

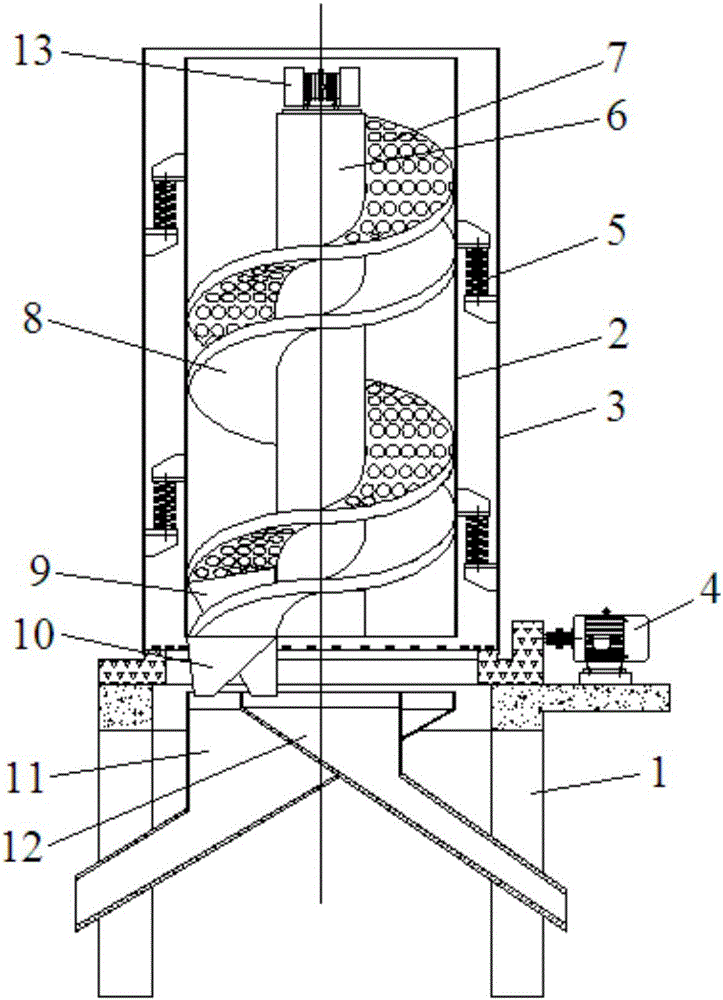

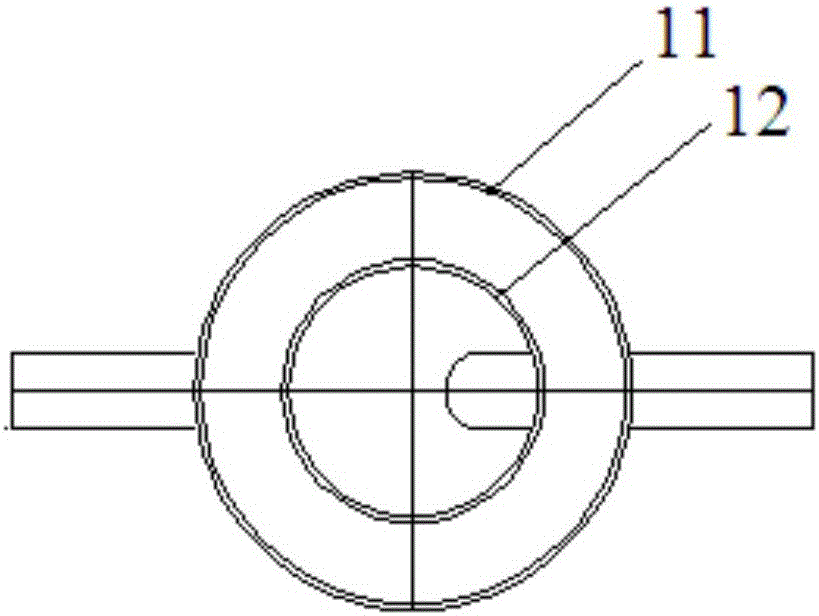

InactiveCN106040569ALarge amount of sieveScreen thoroughlySievingScreeningTowerMechanical engineering

The invention discloses a spiral tower-type screening machine which comprises a bracket, an inner screen body and an outer screen body. The outer screen body is rotationally mounted on the bracket. A driving mechanism for driving the outer screen body to rotate on the bracket is arranged on the bracket. A plurality of elastic damping devices are respectively connected between the inner screen body and the outer screen body. A column body is arranged in the inner screen body. One or more spiral screen stencils are fixedly connected between the inner screen body and the column body. Guide chutes are respectively and fixedly connected to the bottom ends of the spiral screen stencils. A fine aggregate bin and one or more coarse aggregate bins are respectively mounted on the bracket. The coarse aggregate bins are correspondingly matched with the guide chutes in the bottom ends of the spiral screen stencils. A vibration device is mounted on the inner screen body or the column body. The spiral tower-type screening machine is simple and concise in structure, material screening is thorough and clear, the screening quantity is large, wear of the screen stencils is little, energy consumption is low, noise is small, the phenomenon that the materials block screen holes is prevented, the noise and dust sealing effect is good, the cost is reduced, the environment is improved, time and labor are saved in mounting and processing, maintaining is simple, and the working efficiency is improved.

Owner:盛金平

Medical waste disposal device

InactiveCN111998348AEasy to controlEasy to operateLavatory sanitoryMedical waste disposalRefuse DisposalsMechanical engineering

The invention discloses a medical waste disposal device. A crushing shaft is arranged in a rotating screen net, the outer sidewall of the crushing shaft is fixedly connected with a plurality of equally distributed crushing knives, a plurality of uniformly distributed screen holes are formed in the middle of the outer sidewall of the rotating screen net in a penetrating manner, and the screen holesare located in a fixed cylinder. The left side of a conveying cavity is fixedly connected with a conveying motor. The top end of the inside of a disposal box is fixedly connected with a plurality ofevenly distributed ultraviolet disinfection lamps, disinfectant spray heads are arranged between every two adjacent ultraviolet disinfection lamps, a filter belt is arranged below the multiple ultraviolet disinfection lamps, the fitter belt is in a V shape, the waste comes in from the disposal box and falls on the filter belt, the filter belt rotates to make the waste be turned over on the filterbelt constantly, the ultraviolet disinfection lamps are turned on, the disinfectant spray heads are opened, the disposal and disinfection of the turnover waste are further facilitated, when the wasteis turned over, the liquid waste flows to the lower side through the filter belt, and thus the effect of separating the liquid waste from solid waste is realized.

Owner:刘贵芳

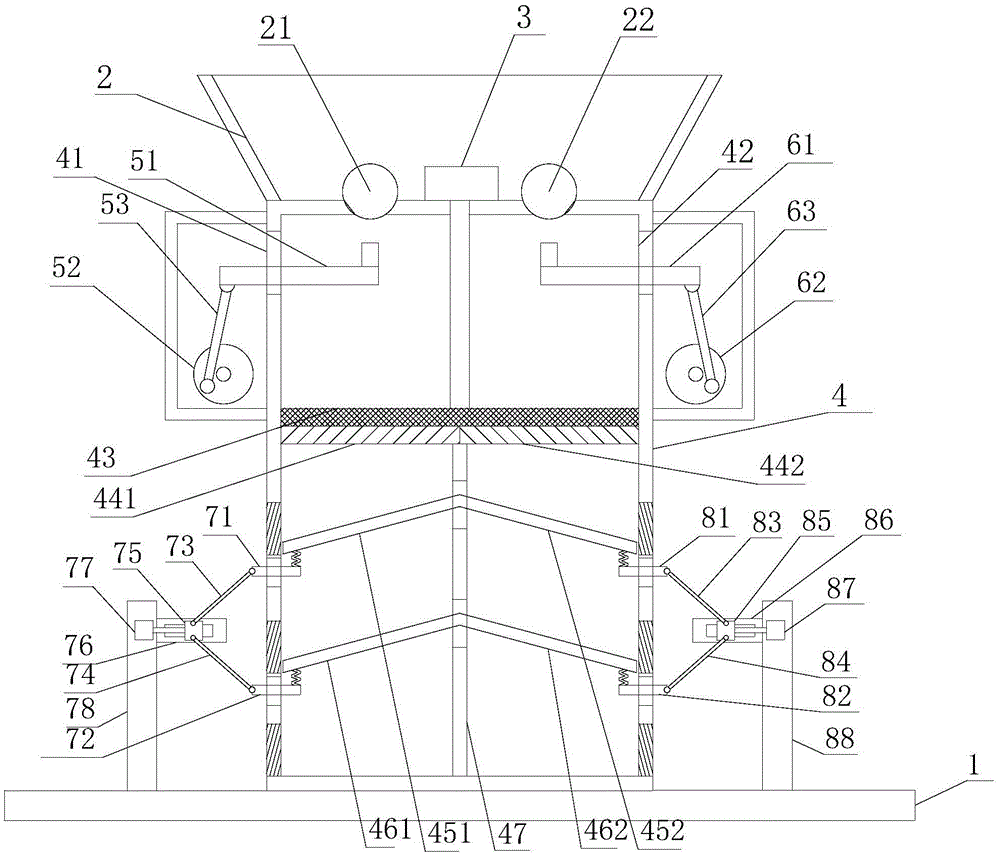

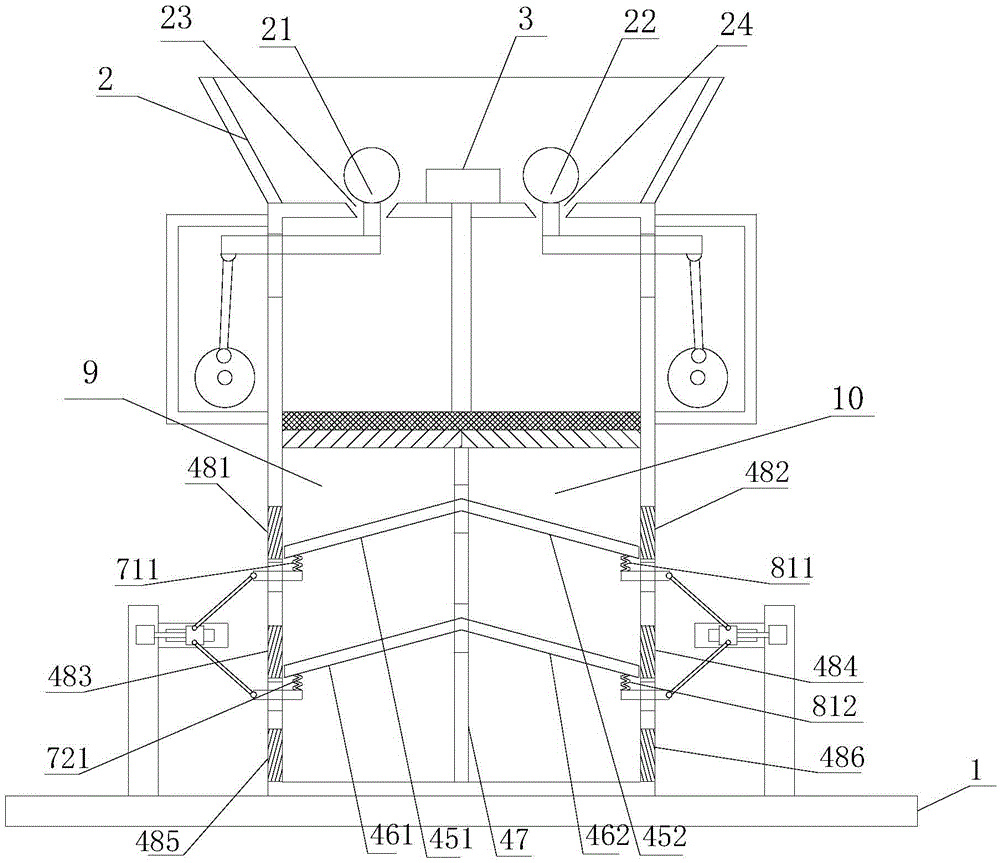

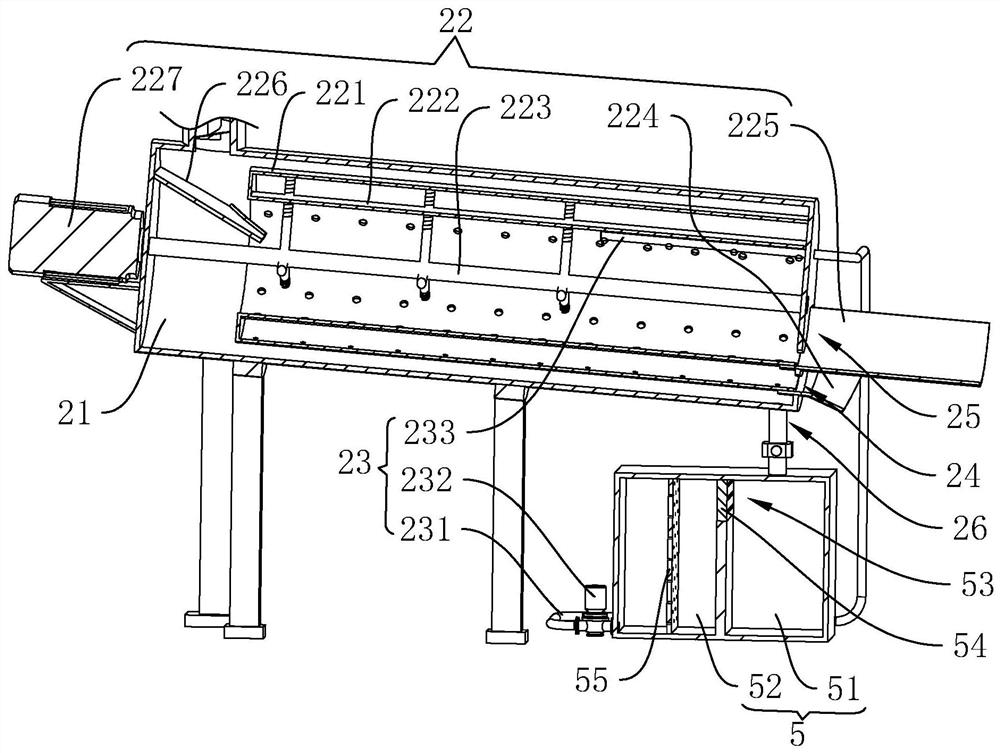

Multi-particle-size-section soil continuous washing and sieving all-in-one machine

InactiveCN108746173ASpeed up the repair processImprove decontamination abilitySievingScreeningWater leakEngineering

The invention discloses a multi-particle-size-section soil continuous washing and sieving all-in-one machine. The all-in-one machine comprises a shell, wherein at least three washing chambers are arranged in the shell from the top to the bottom; every two adjacent washing chambers communicate with each other through one layer of sieve net obliquely placed; each washing chamber is provided with a gas guide-in pipe used for guiding in compressed air and a material outlet connected with a material collector arranged outside the shell; a screw elevator for lifting materials into the material collector and a filter net for filtering the materials are sequentially arranged between the material outlet and the corresponding material collector; a backflow pipe is arranged at the outer part of the shell, and the pipe body of the backflow pipe is provided with a plurality of water leaking openings; liquid in the screw elevator flows back into the washing chamber through the water leaking openingcorrespondingly connected with the screw elevator; the top of the shell is provided with a material inlet and a washing solution inlet; and the top washing chamber is provided with a water level overflow opening. By adopting a wet sieving process, sieving and washing can be simultaneously carried out on soil, and more than three particle size sections of soil can be obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

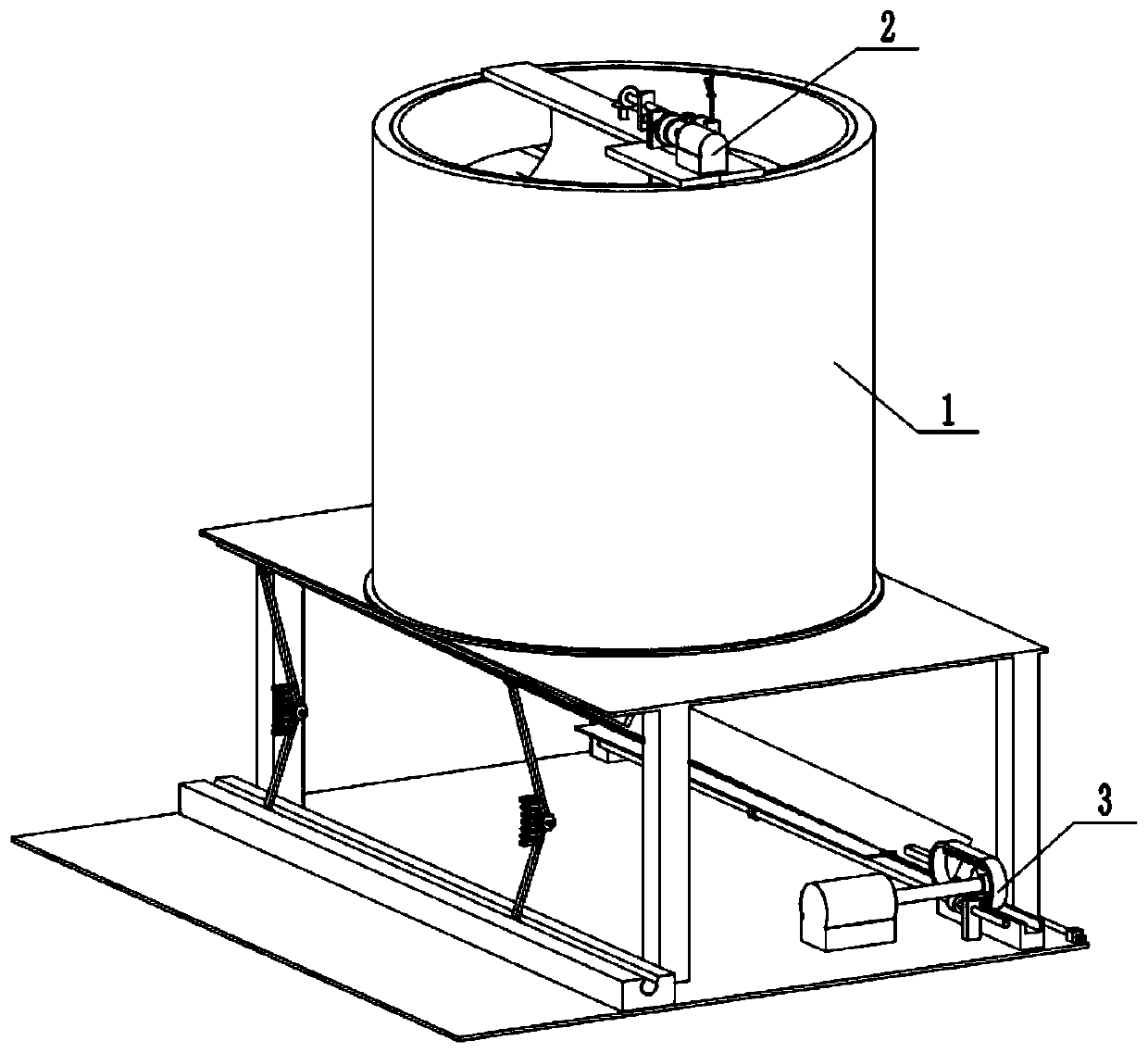

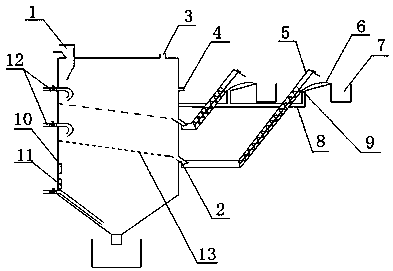

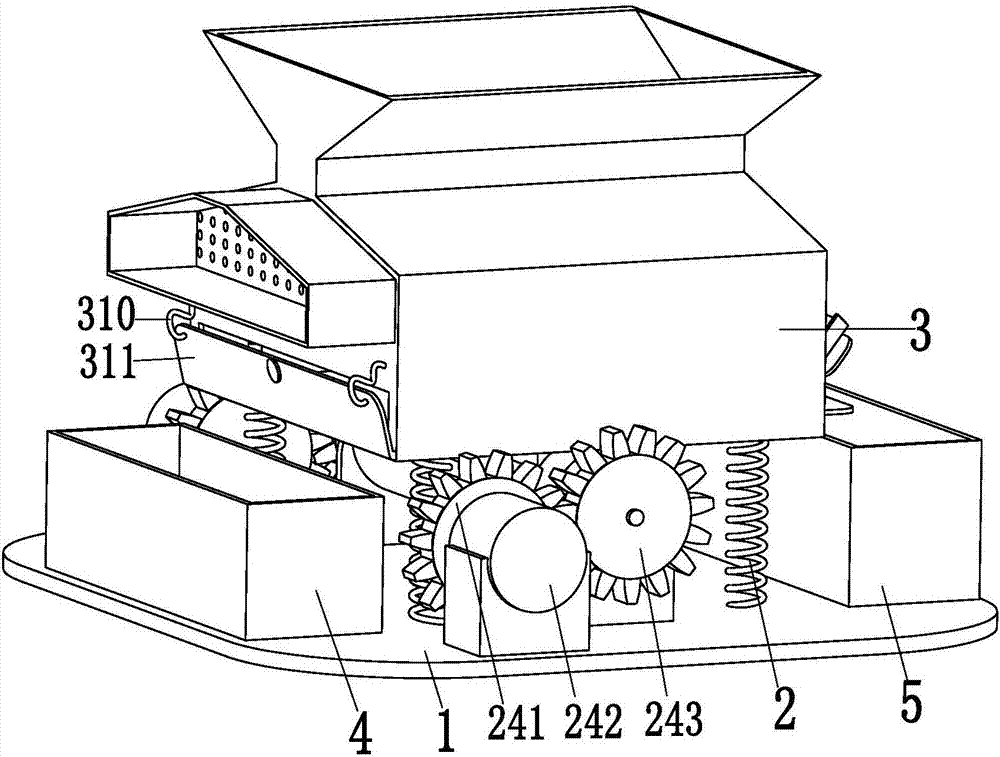

Automatic screening, processing and production equipment for rice

InactiveCN107185832ARealize the function of automatic screeningReduce labor intensitySievingGas current separationBiochemical engineeringUltimate tensile strength

The invention relates to automatic screening, processing and production equipment for rice. The automatic screening, processing and production equipment comprises a bottom plate, wherein a rotating device is mounted on the bottom plate; a screening device is mounted on the rotating device; a first collection box is mounted at the front end of the bottom plate; a second collection box is mounted at the rear end of the bottom plate; the second collection box collects rice particles, which meet the requirement after being screened; and the rotating device is matched with the screening device to complete an automatic rice screening process. The automatic screening, processing and production equipment can solve the problems that as workers are required to screen the rice with a screening tool to separate impurities from the rice and to classify and collect the screened rice during processing based on an existing small-sized workshop, the rice cannot be thoroughly screened by the workers, the labor intensity is high and the working efficiency is low can be solved, and an automatic rice screening function can be realized.

Owner:安庆米锐智能科技有限公司

Practical cereal screener capable of improving screening strength

InactiveCN106824528AEasy to moveEasy to installSievingScreeningAgricultural engineeringControl switch

The invention discloses a practical grain screening machine capable of increasing the screening force, which comprises a horizontal beam, a vibrating motor, a vibrator and a material inlet. The bottom of the horizontal beam is provided with universal wheels, and the top of the horizontal beam A support column is provided, and a control switch is provided on the front surface of the support column close to the upper position of the horizontal beam, and a screen box is provided above the support column. After the universal wheel is used in the present invention, when the machine is finished, it will It is better to move the machine, which facilitates the movement and placement of the machine. After using the electromagnet, when the agricultural products are screened and filtered, the scrap iron impurities can be adsorbed in it, saving the need for subsequent production. Some unnecessary troubles in the processing process, after using two vibrators, you can change the selection intensity of the screening machine at will, making the screening more thorough.

Owner:WEIFANG MODERN ENVIRONMENTAL TECH

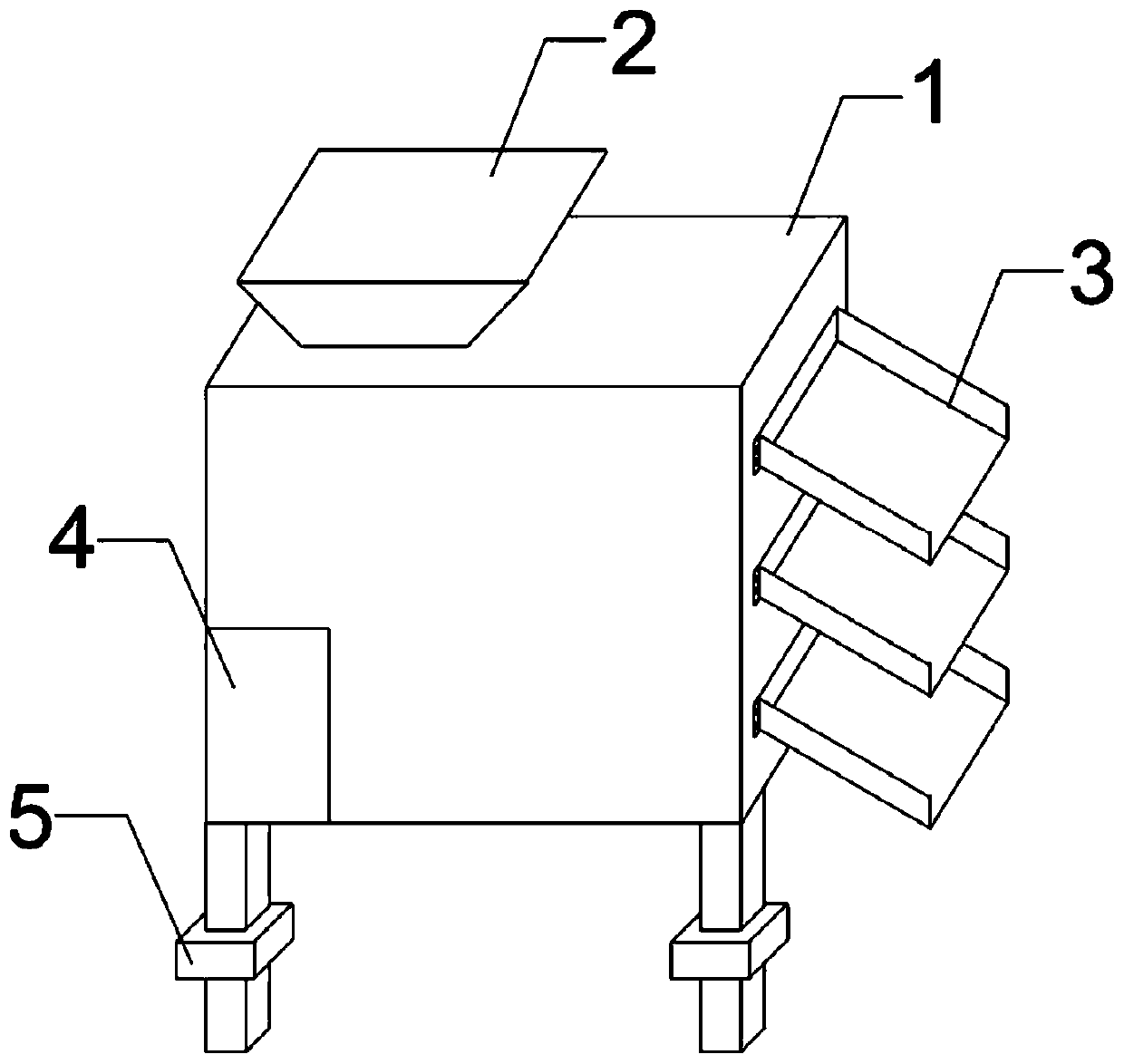

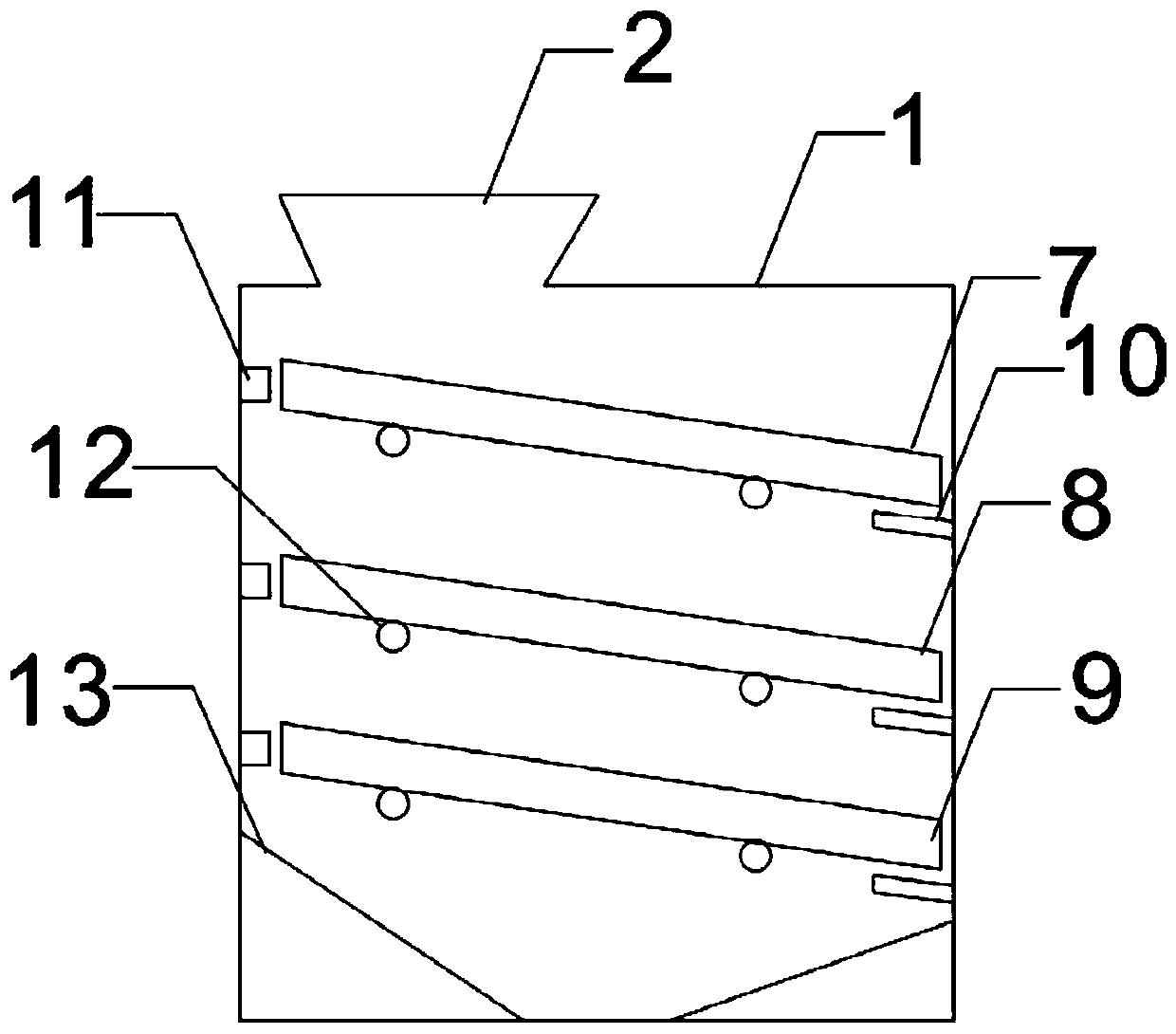

Automatic screening device for aggregate of cementing dam building material

InactiveCN110882906AImprove work efficiencyReduce manufacturing costSievingNon-rotating vibration suppressionArchitectural engineeringElectric machinery

The invention discloses an automatic screening device for aggregate of a cementing dam building material. The automatic screening device comprises a housing, a feeding hopper, a feeding groove and a supporting frame, wherein the feeding hopper is arranged on one side of the upper part of the housing; the feeding groove is formed in the housing; the supporting frame is arranged below the housing; acontrol device is further arranged on the housing; a plurality of screening plates are arranged in the housing; mounting bases are arranged on the portions, on one sides of the upper ends of the screening plates, of the housing; motors are arranged on the mounting bases; the output ends of the motors are in transmission connection with rotating discs; rotating shafts are arranged below the screening plates; the motors can drive the screening plates to move back and forth on the rotating shafts through transmission rods; a discharging opening is formed in the lower end of the housing; and second connecting plates are obliquely arranged on the two sides of the discharging opening. According to the automatic screening device, the aggregate can be automatically screened in a multi-stage manner at a time, the aggregate screening work efficiency is greatly improved, and the production cost is reduced; and damage of vibration to the device can be relieved, and the problems that aggregate screening is incomplete, vibration damage is caused, the service life is shortened, the work efficiency is low, and the production cost is high are effectively solved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Vibrating screen

The invention discloses a vibrating screen, and relates to the field of mining engineering. According to the technical scheme, the vibrating screen comprises a base and a screening device, wherein thescreening device is arranged on the base; the screening device is obliquely arranged downwards in the length direction of the base, the screening device comprises two mounting cylinders which are correspondingly and fixedly connected to the base and a screen cylinder which is rotationally connected between the two mounting cylinders, a feeding opening is formed in the mounting cylinder located atthe upper part, and a discharging opening is formed in the mounting cylinder at the lower part; a knocking part is further arranged on the base, and the knocking part is slidably connected to the base; and a driving device is further arranged on the base, and the driving device comprises an intermittent transmission assembly used for driving a screen cylinder to intermittently rotate, a knockingtransmission assembly used for driving the knocking part to move for knocking and a driving motor arranged on the base. When the driving device drives the screen cylinder to intermittently rotate, thescreen cylinder can be knocked by the driving device at a rotation gap of the screen cylinder, so that screening of materials through the screen cylinder is more thorough, and therefore the screeningeffect of the materials is better.

Owner:安徽友邦矿业有限公司

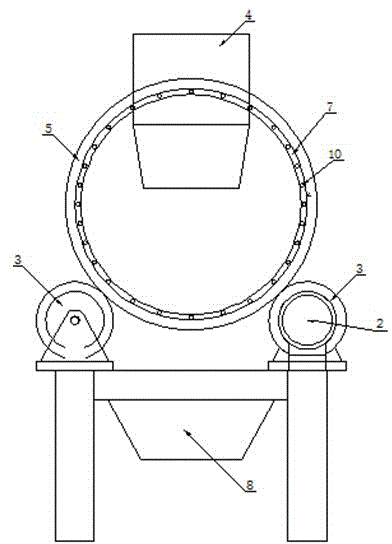

Rotary screen capable of rotating forwards and backwards and provided with spiral screening rings

InactiveCN105312219AScreen thoroughlyImprove screening efficiencySievingScreeningScreening effectAerospace engineering

The invention provides a rotary screen capable of rotating forwards and backwards and provided with spiral screening rings, and belongs to the field of screening equipment. The defects that according to an existing rotary screen, screening efficiency is low, the screening effect is poor, and a screen net is prone to be blocked are overcome. The rotary screen is composed of a rack, a motor, four rolling wheels and a screen body, wherein the motor, the four rolling wheels and the screen body are installed on the rack, the left of the rack is higher than the right of the rack, the motor is connected with one rolling wheel, the screen body comprises two rollers, weft-direction screening strips parallel with the screen body in direction and the spiral warp-direction screening rings with screening holes in ring bodies, one roller is borne on every two rolling wheels, and the weft-direction screening strips penetrate through the screening holes in the warp-direction screening rings to form the screen. In this way, screening efficiency is improved, the screening effect is optimized, and a screen net is prevented from being blocked.

Owner:XINJIANG JINYUXIN NEW MATERIAL CO LTD

Highly-throwing rice sieving machine

InactiveCN105214945AAchieve the purpose of screeningScreen thoroughlyGas current separationAgricultural engineeringMechanical equipment

The invention belongs to the technical field of agricultural mechanical equipment, and specifically discloses a highly-throwing rice sieving machine. The highly-throwing rice sieving machine comprises a highly-throwing frame, wherein a charge port is formed in the top end of the highly-throwing frame, a discharge port is formed in the bottom end of the highly-throwing frame, an opening used for discharging vacant shells is formed in one sidewall of the highly-throwing frame, a vertical slide way is formed in a sidewall opposite to the opening, of the highly-throwing frame, a fan is installed on the slide way, and the fan is slidably connected with the highly-throwing frame; and the distance between the top end and the bottom end of the highly-throwing frame is 1-3m. Compared with the traditional fan sieving, the equipment is capable of throwing and dispersing rice, capable of greatly achieving a sieving purpose by matching with a position design for a fan, thorough in sieving, capable of sieving according to the proportions of impurities contained in rice to meet different sieving needs, and high in practicability.

Owner:CHONGQING ZHIRUIDE TECH

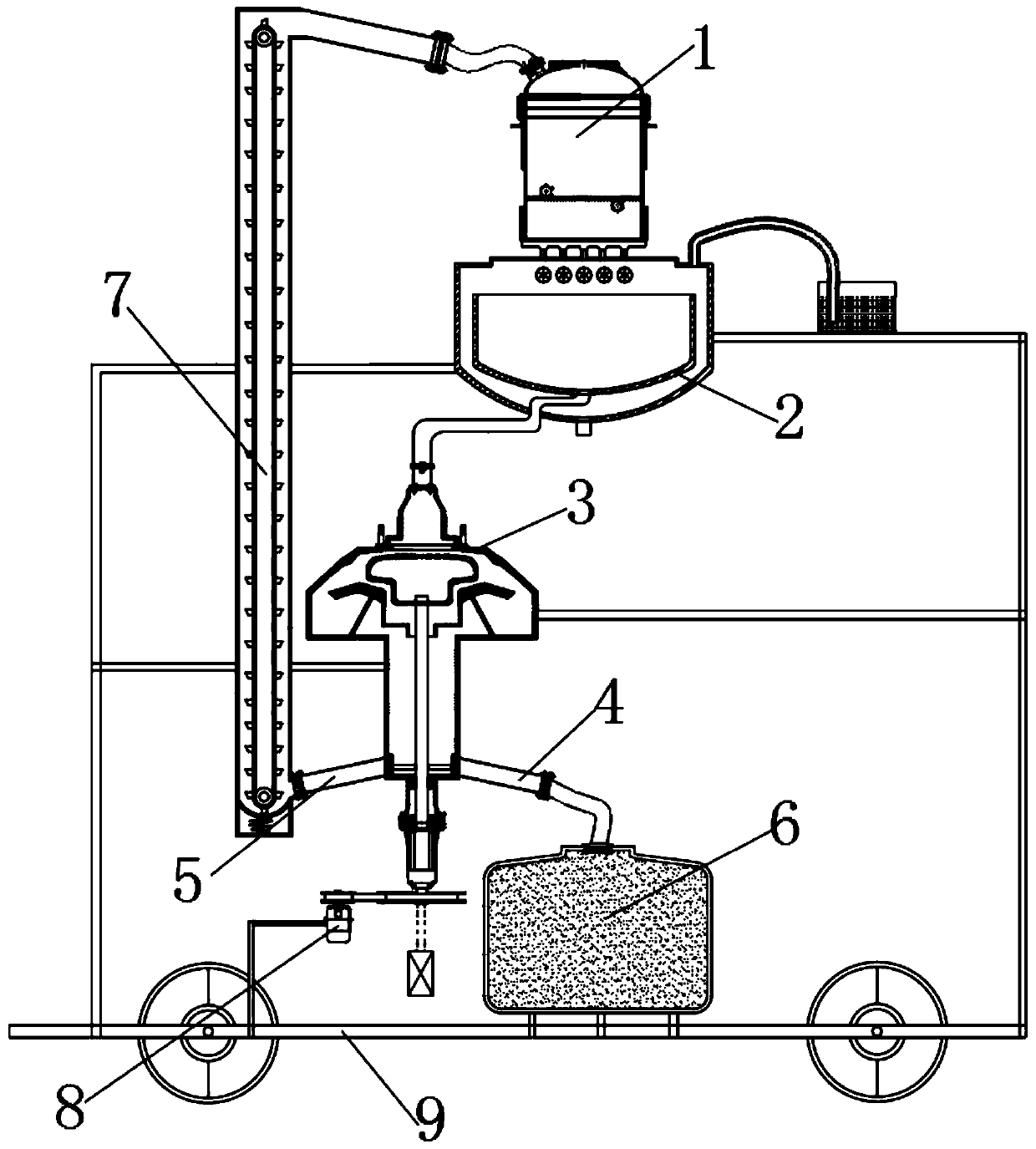

Grain screening and drying device

InactiveCN110340017AAffect healthGood sealingSievingGas current separationMechanical engineeringMesh grid

The invention discloses a grain screening and drying device. The grain screening and drying device comprises a drying assembly, a screening assembly and a lifting device; the screening assembly is used for screening grains and separately placing and temporarily storing the grains; the drying assembly is used for drying the screened grains; the dried grains enter a storage bin or are lifted to thescreening assembly by the lifting device for secondary treatment; and the drying assembly, the screening assembly and the lifting device are all arranged on a machine base. The grain screening and drying device has the good sealing property, so that dust in rice is prevented from polluting a surrounding environment and affecting the health of workers. According to the grain screening and drying device, five shunting pipes are arranged below a feeding bin to separately treat and screen rice, and are matched with three buffer grids and screens, so that the rice is capable of being screened morethoroughly; the drying assembly of the grain screening and drying device is internally provided with a shunting mechanism, so that the drying is more sufficient; and the grain screening and drying device is provided with a switching device, in other words, the direction of the grains is controlled through a plug, so that the grain screening and drying device is free and flexible.

Owner:ANHUI SCI & TECH UNIV

Rapeseed oil processing and screening equipment

ActiveCN108993901AScreening efficiency is efficient and sufficientTo achieve the screening effectGas current separationFatty-oils/fats productionOil processingRapeseed

The invention discloses rapeseed oil processing and screening equipment. The rapeseed oil processing and screening equipment comprises a box body and a filtering device. A feeding inlet is formed in the intermediate position of the upper end of the box body, and a passage tube is connected to the lower end of the feeding inlet. Air inlets are formed in the left and right sides of the passage tube,and the upper end of the right side of the passage tube is connected with a buckle through a drawstring. A blowing chamber is formed in the left end of the left side air inlet, and a fan is arrangedin the blowing chamber. An air vent is inlayed in the left side of the box body, and the filtering device is arranged directly below the passage tube. When a user uses the rapeseed oil processing andscreening equipment, in order to ensure that oil is cleaner when the rapeseed oil is processed, a cleaning function is added on the basis of screening, so that rapeseed can be thoroughly cleaned, andan agitator can be disassembled through an internal thread of a moving plate; and after cleaning, standing is performed for a period of time, the surface floating objects are removed and water is drained. The rapeseed oil processing and screening equipment is more thorough in screening.

Owner:安庆市望马楼生态农业发展有限公司

Niblet classifying and screening device

ActiveCN109013333ASimple structureNo manual operationSievingGas current separationEngineeringMechanical engineering

The invention discloses a niblet classifying and screening device. The niblet classifying and screening device comprises a shell; multiple brackets are arranged at the lower end of the shell; feed hoppers are arranged on two sides of the upper end of the shell; feed ports are formed in the lower ends of the feed hoppers and positioned in the shell; first guide plates are arranged on one sides in the feed ports; second guide plates are arranged on the other sides in the feed ports; impurity collecting chambers are arranged on the sides, far from the first guide plates, of the second guide plates; multiple through holes are uniformly formed in one sides of the impurity collecting chambers; multiple air sucking machines are arranged on the other sides of the impurity collecting chambers; guide plates are arranged under the impurity collecting chambers and positioned on the side walls in the shell; and a first fixed plate is arranged at the upper end in the shell and positioned between theimpurity collecting chambers. The niblet classifying and screening device has the following beneficial effects: the screening process is performed in a totally closed box without generating dust; niblet can be totally separated from grain stalks; and meanwhile, the niblet with different fullness degrees can be classified and screened, so that the labor intensity is low, and the working efficiencyis high.

Owner:青岛穗禾集成房屋有限公司

Multi-stage circular screening machine for tea

The invention discloses a multi-stage circular screening machine for tea. The multi-stage circular screening machine for tea comprises a base. A shell is arranged on the base. A cylindrical mesh screen which inclines leftwards is arranged in the shell. A rotary shaft is arranged in the cylindrical mesh screen. A first-stage mesh screen which inclines leftwards is arranged below the cylindrical mesh screen. A second-stage mesh screen which inclines rightwards is arranged below the first-stage mesh screen. A third-stage mesh screen which inclines leftwards is arranged below the second-stage mesh screen. Vibrators are arranged around the first-stage mesh screen, around the second-stage mesh screen and around the third-stage mesh screen correspondingly. According to the multi-stage circular screening machine for tea, the cylindrical mesh screen is arranged and driven by the rotary shaft to rotate accordingly, tea turns in the cylindrical mesh screen, broken tea can be screened to the space below, and the broken tea is screened by the first-stage mesh screen, the second-stage mesh screen and the third-stage mesh screen layer by layer so as to be graded; and the vibrators are arranged around the first-stage mesh screen, around the second-stage mesh screen and around the third-stage mesh screen correspondingly and drive the mesh screens to vibrate, and thus tea can be screened completely.

Owner:HEFEI DEJIE ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com