Spiral tower-type screening machine

A screening machine and tower-type technology, which is applied in the direction of filtration, solid separation, grille, etc., can solve the problems of difficult control of environmental pollution, small processing capacity of a single unit, complex system, etc., and achieve thorough screening, simple structure, and simplified The effect of system settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

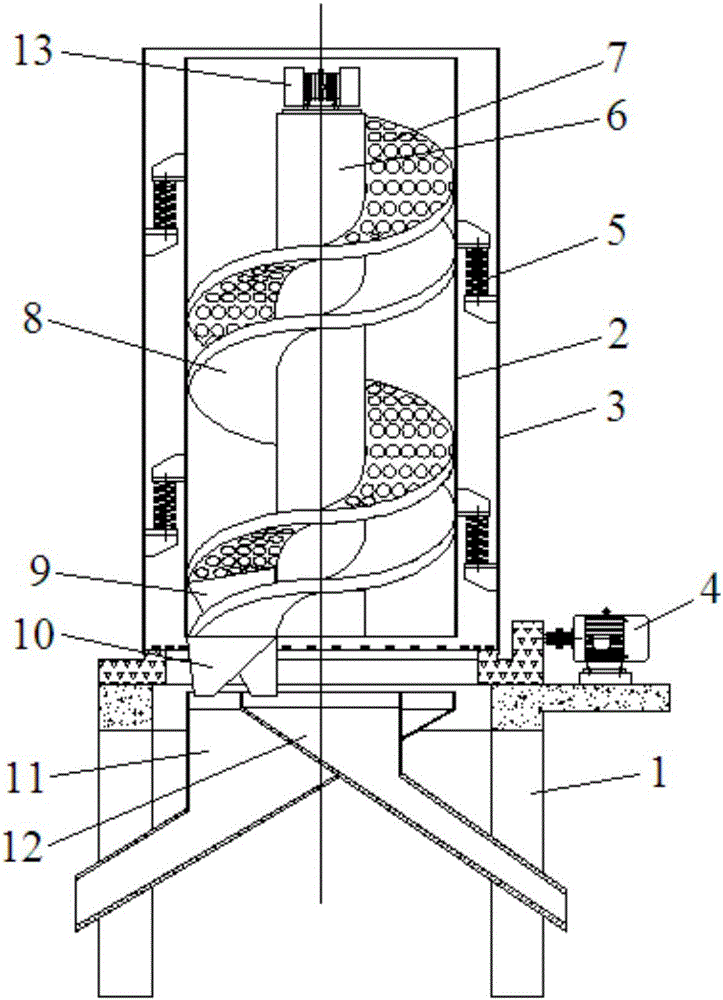

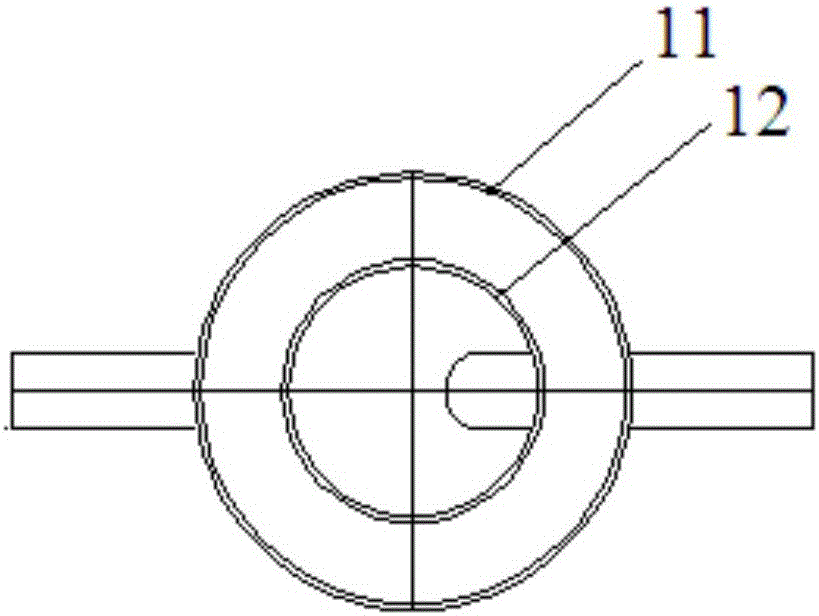

[0018] see figure 1 , 2 , a spiral tower screening machine, including a support 1, inner and outer sieve bodies 2, 3, the outer sieve body 3 is rotatably mounted on the support 1, and the drive for driving the outer sieve body 3 to rotate on it is installed on the support 1 Mechanism 4, a plurality of elastic damping devices 5 are respectively connected between the inner and outer sieve bodies 2 and 3, a cylinder 6 is arranged inside the inner sieve body 2, and a layer of Spiral screen 7 and spiral slide 8, spiral slide 8 is positioned at the bottom of one deck spiral screen 7, and the bottom of one deck spiral screen 7 is fixedly connected with guide groove 9, spiral The bottom of the chute 8 is fixedly connected with a chute 10, and the support 1 is respectively equipped with a fine material hopper 11 matched with the chute 10 and a coarse material hopper 12 matched with the guide chute 9; A vibrating device 13 is installed on the sieve body 2 or the cylinder body 6 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com