Forage grass crushing equipment

A technology of crushing equipment and crushing motor, applied in feed, solid separation, sieve and other directions, can solve problems such as poor screening effect, inability to classify forage grass, and inability to control the degree of crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

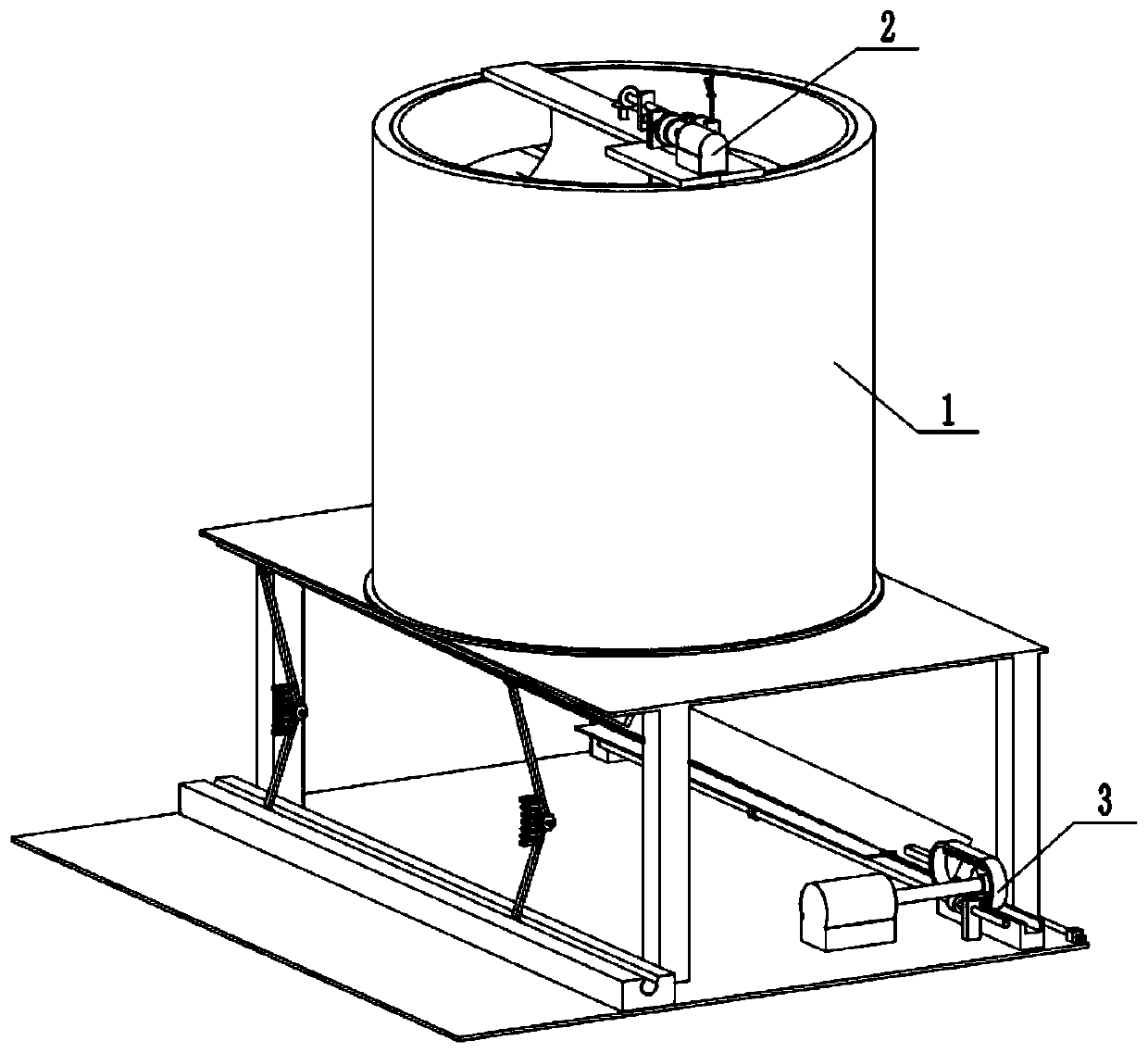

[0032] Combine below Figure 1-18 Explaining this embodiment, a forage crushing equipment includes a support assembly 1, a crushing assembly 2, and a sieving assembly 3. The crushing assembly 2 is connected to the support assembly 1, and the sieving assembly 3 and the support assembly 1 phase connection.

specific Embodiment approach 2

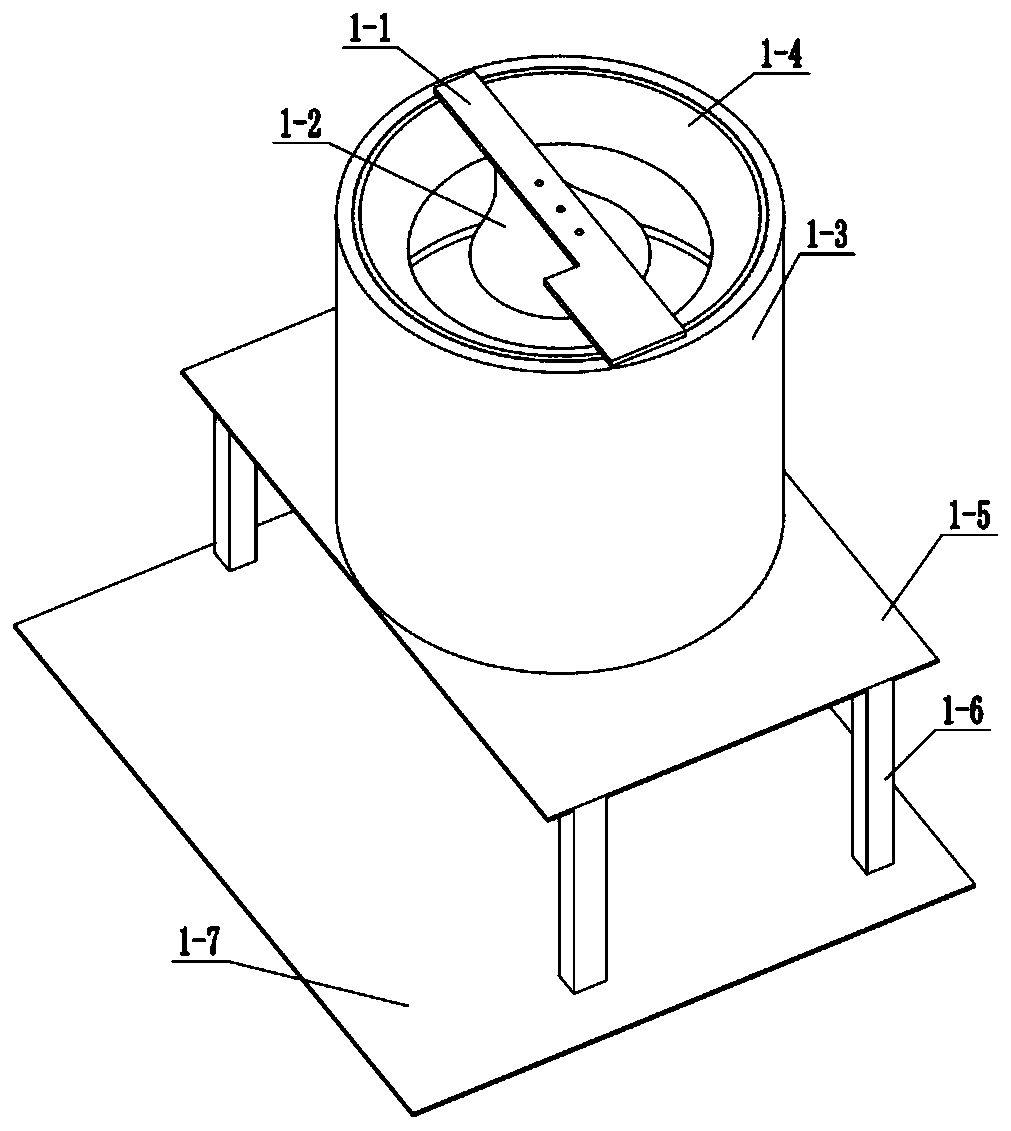

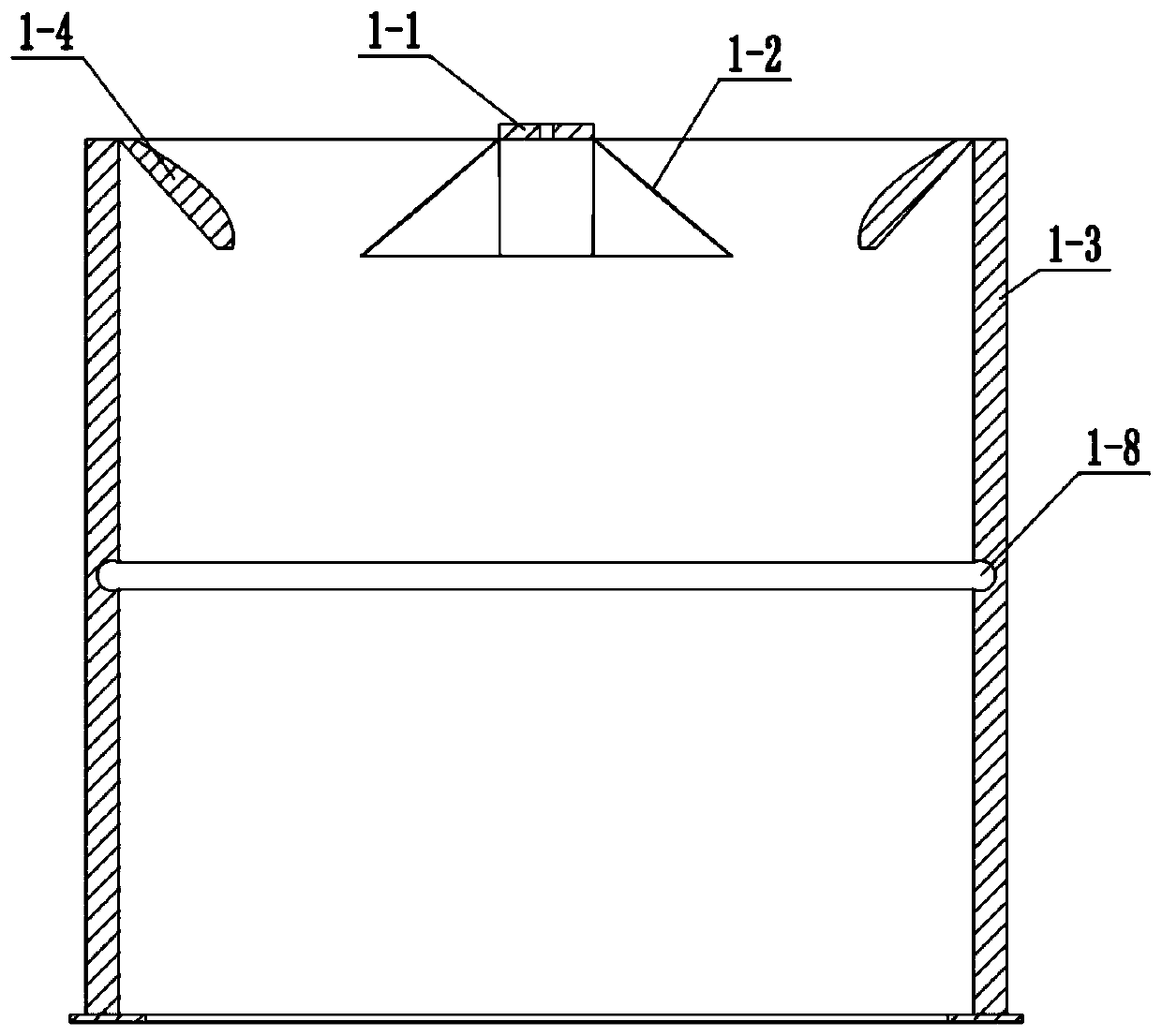

[0034] Combine below Figure 1-18 This embodiment will be described. This embodiment will further explain the first embodiment. The bracket assembly 1 includes a crushing power bracket 1-1, a crushing transmission shield 1-2, a crushing housing 1-3, and a cutting swash plate 1- 4. Crushing bottom plate 1-5, crushing bottom plate legs 1-6, screening bottom plate 1-7, crushing slide rail 1-8 and crushing outlet 1-9, crushing power support 1-1 and crushing shell 1-3 The crushing transmission shield 1-2 is connected to the crushing power support 1-1, the cutting inclined plate 1-4 is connected to the crushing shell 1-3, and the crushing shell 1-3 is connected to the crushing bottom plate 1-5. The discharge port 1-9 is located on the crushing bottom plate 1-5. The crushing bottom plate 1-5 is connected with the four crushing bottom legs 1-6, and the four crushing bottom legs 1-6 are all connected to the screening bottom plate 1-7. Connected, the crushing slide rails 1-8 are located...

specific Embodiment approach 3

[0036] Combine below Figure 1-18 This embodiment will be described. This embodiment will further explain the first embodiment. The crushing assembly 2 includes a crushing motor 2-1, a crushing motor shaft 2-2, a gear I2-3, a gear II2-4, and a gear II shaft 2. -5. Bevel gear Ⅰ 2-6, bevel gear Ⅱ 2-7, sun gear shaft 2-8, sun gear 2-9, planet gear 2-10, planet gear shaft 2-11, gear housing 2-12, gear housing connection Frame 2-13, drum 2-14, sliding column 2-15, drum cutter 2-16, operating rod 2-17, spring 2-18, pressure plate 2-19, pressure plate chute 2-20, pressure plate rotation Cylinder 2-21, pressure plate shaft 2-22, shaft sleeve 2-23, chute I 2-24, pressure lever 2-25, gear lever 2-26, operating lever shaft 2-27, spring limit column 2- 28. Gear plate 2-29, gear shift sleeve 2-30, gear shift slide 2-31, slide bar bracket 2-32, gear Ⅲ 2-33, gear Ⅳ 2-34, slide groove Ⅱ 2-35, gear one 2 -36, gear two 2-37, rotating column 2-38, rotating column slot 2-39, spring cutter slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com