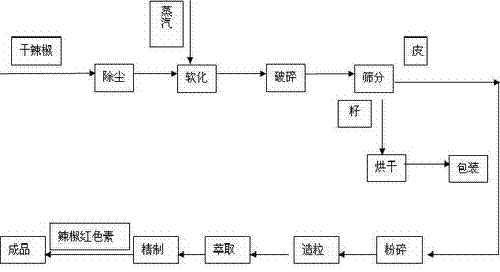

Method for separating pepper seeds from pepper skin of dry red peppers

A technology for chili peel and dried chili, which is applied in application, food preparation, food science and other directions, can solve the problems of increased seed red rind content, decreased dry chili powder yield, reduced pigment yield, etc., and achieves improved powder yield and separation. Good, the effect of reducing the degree of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A method for separating capsicum seeds and capsicum skin of dried chili is to soften the dry capsicum with water content less than 20% by humidifying, and then separate the capsicum seeds and capsicum skin after crushing. % dry peppers are steam sprayed and humidified. After steam spraying and humidifying, the moisture content of the peppers is between 25-27% and the pepper skins are sprayed and humidified evenly, and then the peppers with a moisture content between 25-27% are sprayed The chilli peppers evenly sprayed and humidified are immediately crushed, and the pepper seeds and pepper skins are separated after crushing. The steam spray humidification of the present invention is that the steam is directly fed into the closed material bin equipped with dried peppers, and the steam spray humidification is carried out on the raw materials, and the pressure of the steam is 0.5-0.6Mpa.

[0012] A kind of humidifying and softening device has been developed during the concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com