Concrete excess material recycling treatment system

A technology of recycling and concrete, which is applied in grain processing, filtration circuit, sieving, etc. It can solve the problems affecting the quality of aggregates and concrete, and achieve the effect of improving separation quality, facilitating separation and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached Figure 1-3 The application is described in further detail.

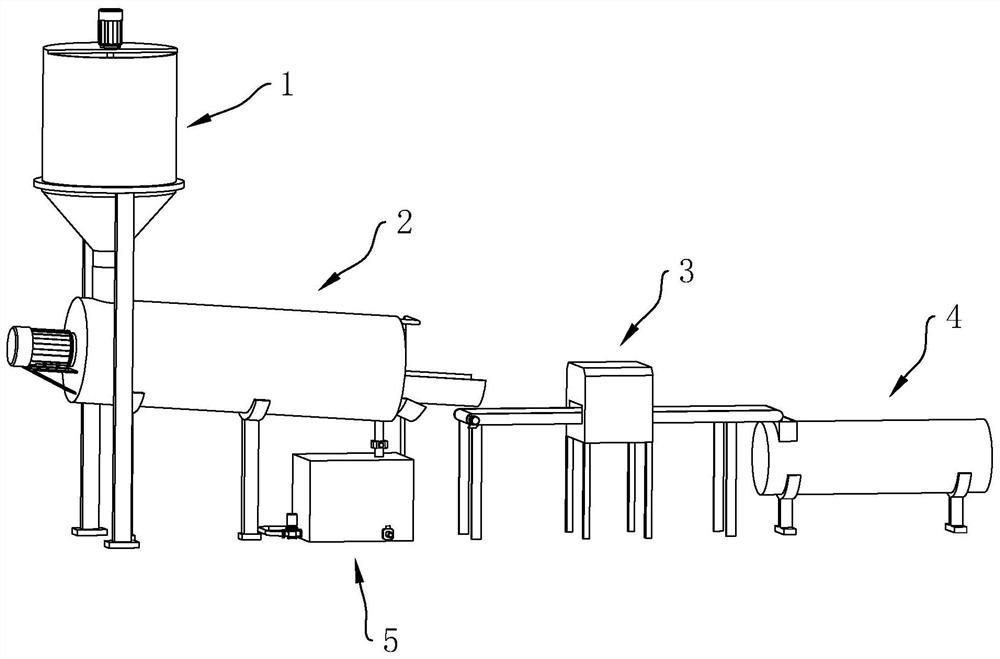

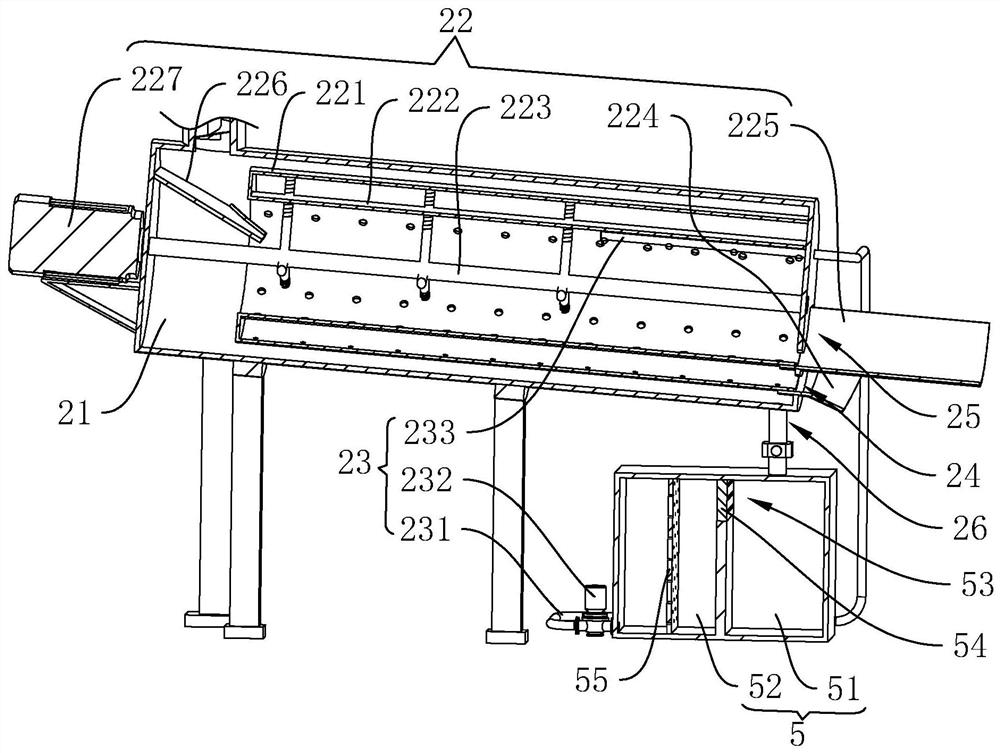

[0032] The embodiment of the present application discloses a system for recovering and processing residual concrete. refer to figure 1 , The recovery processing system includes a surplus material collection device 1 , a sand and gravel separation device 2 , a drying device 3 , a ball milling device 4 and a slurry processing device 5 .

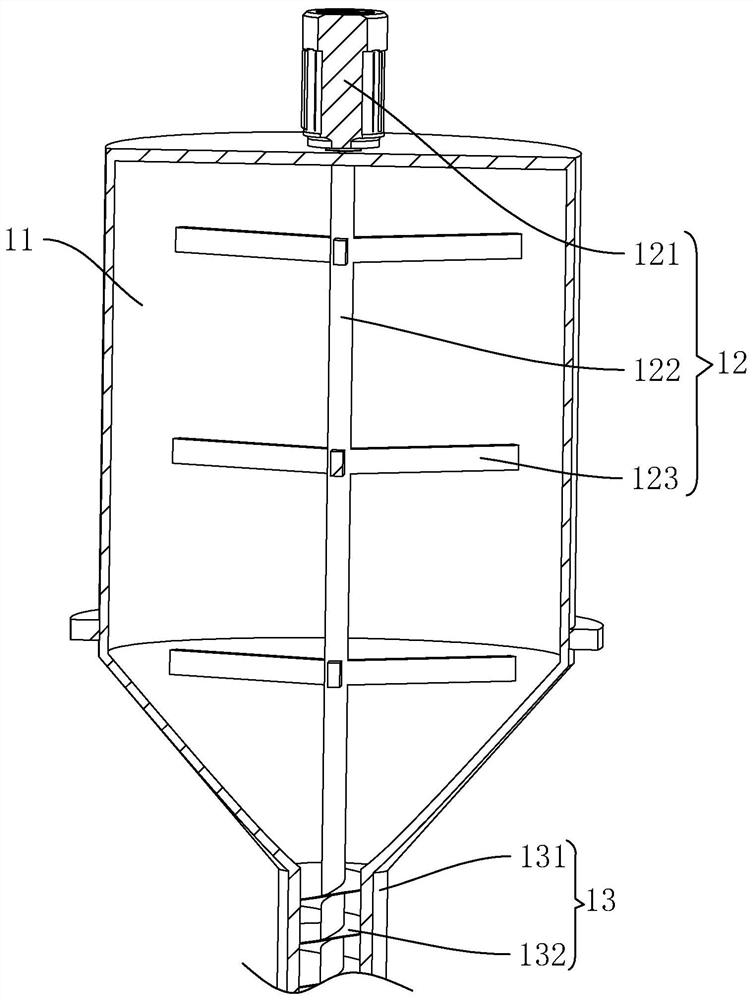

[0033] refer to figure 1 and figure 2Referring to the residual material collection device 1 is fixedly installed above the sand and gravel separation device 2 for collecting concrete residual material. The residual material collection device 1 includes a hopper 11 , a stirring component 12 and a feeding component 13 . The stirring assembly 12 includes a first motor 121, a stirring shaft 122 and a stirring blade 123, the stirring shaft 122 is vertically rotatably connected in the hopper 11, the top of the hopper 11 is provided with an opening, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com