Screen for rice sieving machine

A technology of screening machine and screen, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of large manpower consumption, inconvenience for users, and large influence of human factors, so as to save costs and reduce installation troubles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

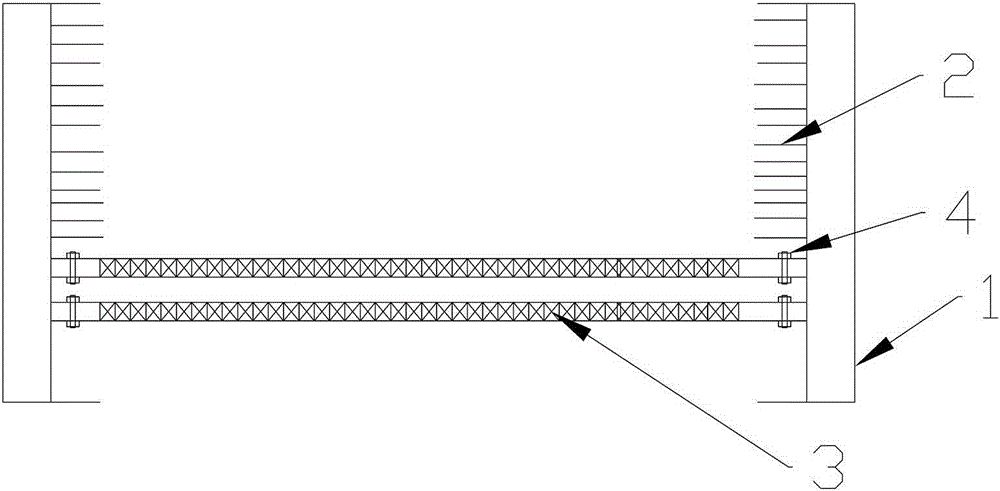

[0013] The reference signs in the accompanying drawings of the specification include: screen frame 1 , limiting plate 2 , screen 3 , and locking bolt 4 .

[0014] The embodiment is basically as attached figure 1 As shown: including 3 screen frames 1 and two screen screens 3, the left and right sides of the 3 screen frames 1 are provided with mutually symmetrical limiting plates 2, and the limiting plates 2 on each side are vertically evenly distributed on the On the frame 1 of the screen 3, the distance between the limit plates 2 on the same side is the same as the thickness of the screen 3, and each limit plate 2 is provided with a connection hole, and a locking bolt 4 is installed on the connection hole, and the edge of the screen 3 A through hole of the same size corresponding to the connection hole is provided on the top, and the screen 3 and the limiting plate 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com