Patents

Literature

37results about How to "Meet screening needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

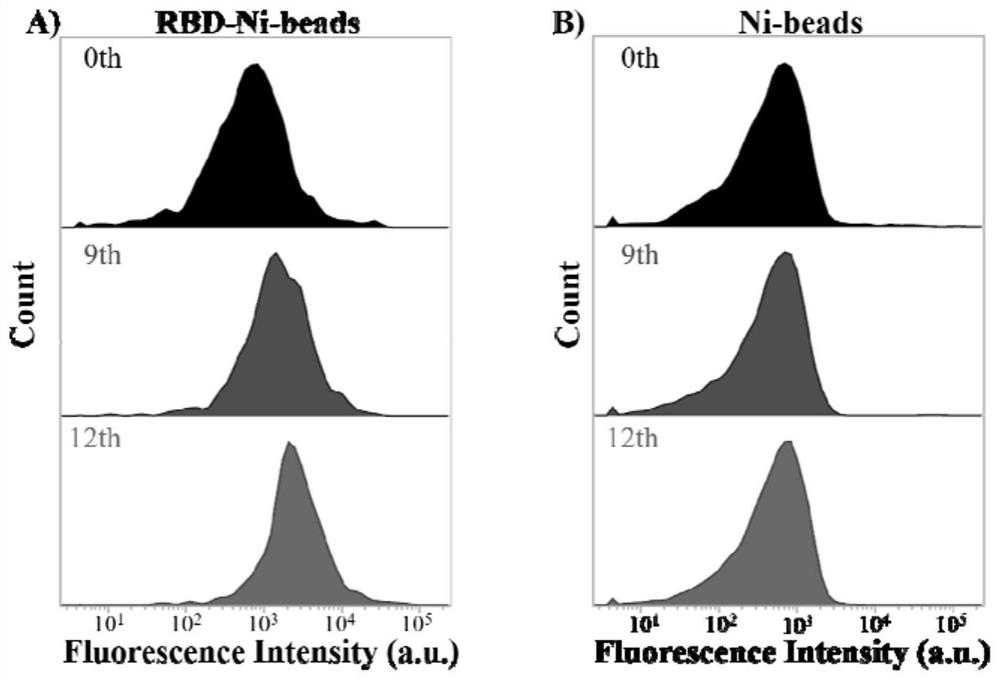

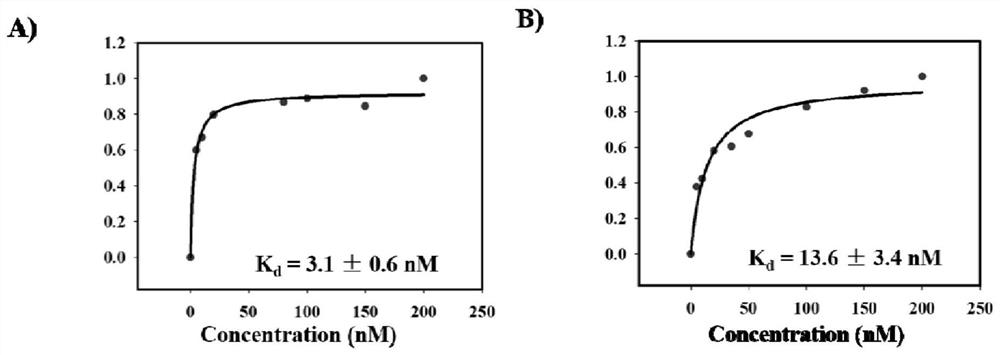

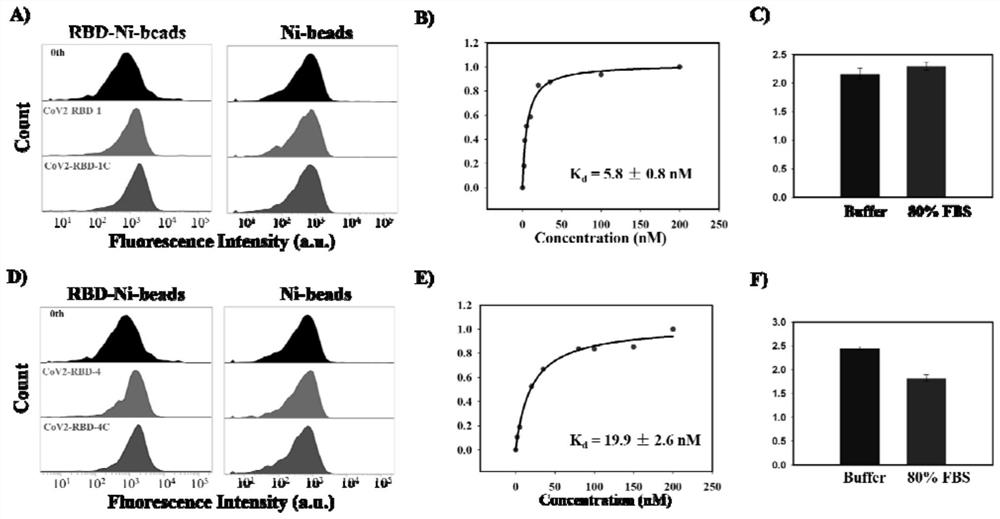

Nucleic acid aptamer of SARS-CoV-2 S protein or RBD protein and application of nucleic acid aptamer

ActiveCN111849994AReduce aggregationFast detection methodOrganic active ingredientsBiological material analysisAptamerDisease

The invention discloses a nucleic acid aptamer of SARS-CoV-2 S protein or RBD protein. The nucleic acid aptamer comprises nucleotide sequences as shown in SEQ ID NO: 1 to SEQ ID NO: 8. The aptamer provided by the invention can be used for providing rapid and accurate detection of SARS-CoV-2 S protein or RBD protein; meanwhile, the aptamer and angiotensin converting enzyme (ACE2) have a competitiveeffect, and the combination of SARS-CoV-2 S protein or RBD protein and ACE2 is efficiently blocked, so that the virus infection of cells is inhibited, and the aptamer can be used as a medicine for preventing and treating SARS-CoV-2 related diseases and becomes an antiviral potential medicine. The screening requirements of various application scenes such as families and communities are met, unnecessary patient aggregation is reduced, and an existing diagnosis and treatment system is supplemented.

Owner:XIAMEN UNIV

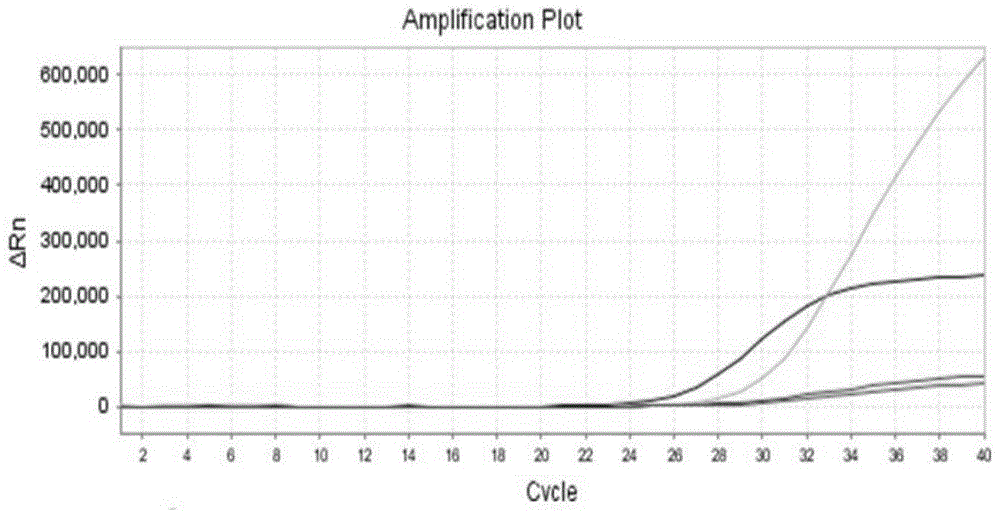

Kit and method for detecting aminoglycoside drug-induced deafness-sensitive gene

ActiveCN102925562ALong operating timeEasy to operateMicrobiological testing/measurementFluorescent pcrAminoglycoside Drugs

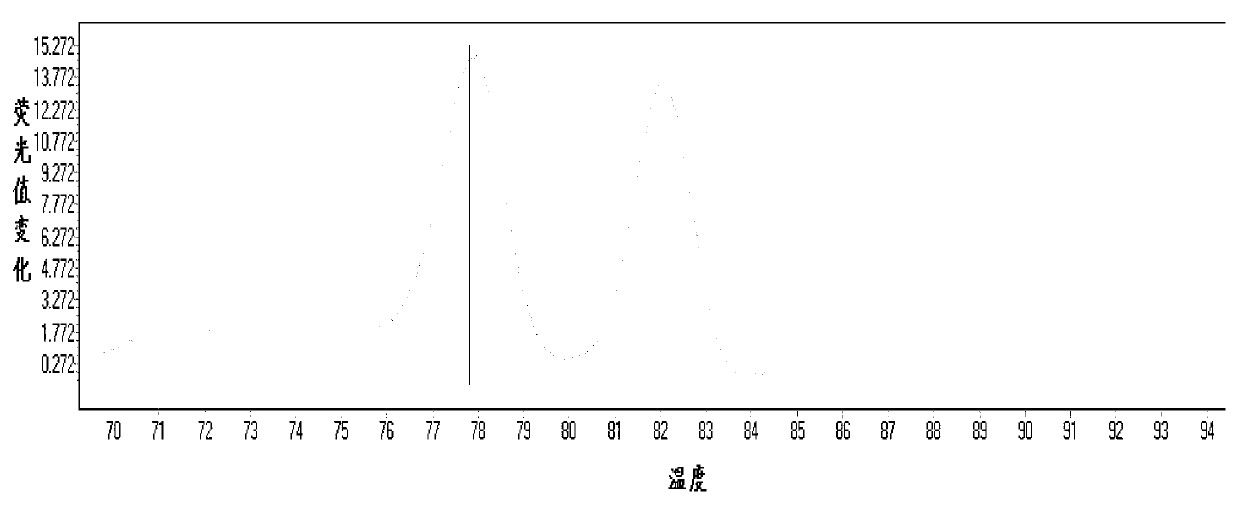

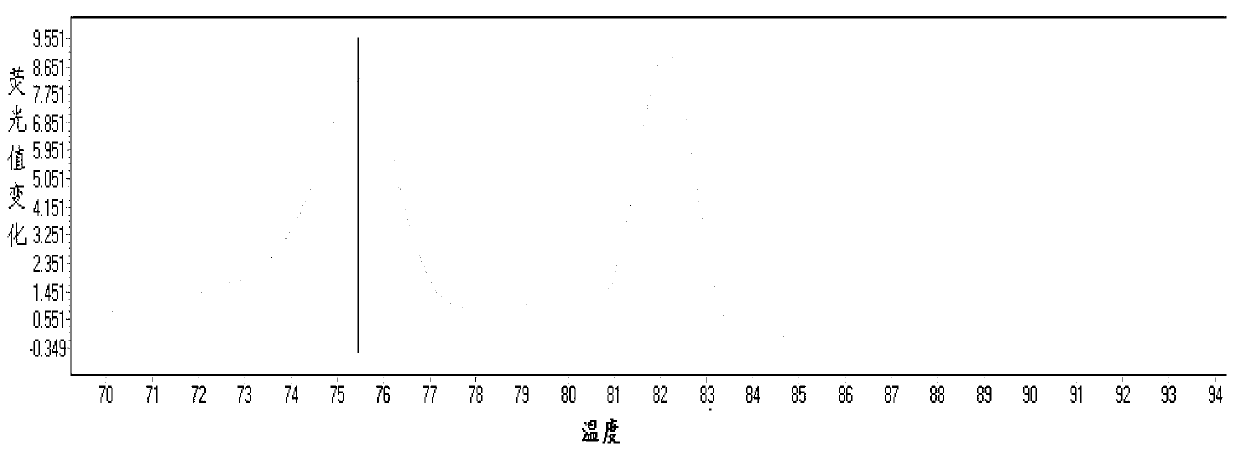

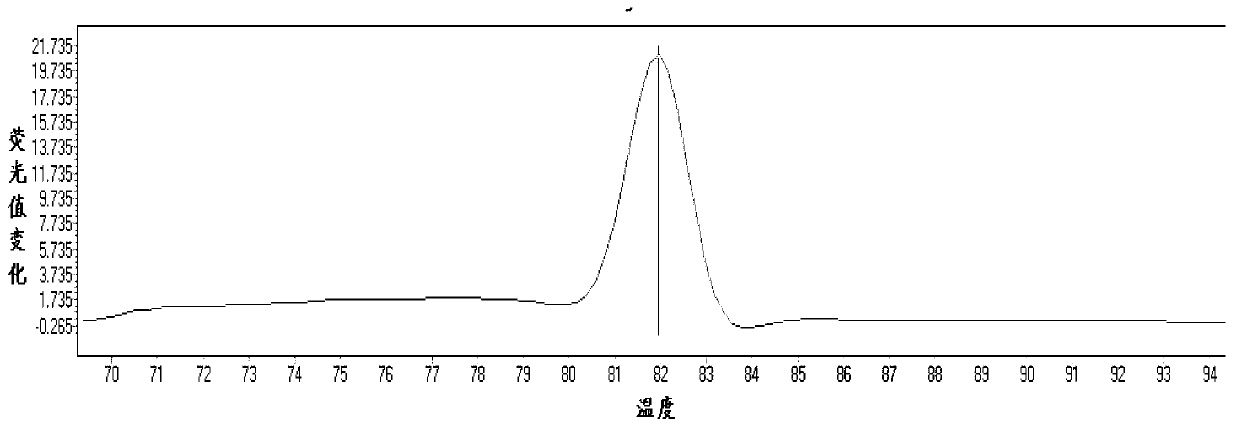

The invention relates to the field of gene detection, and particularly relates to a kit and method for detecting an aminoglycoside drug-induced deafness-sensitive gene through a fluorescent PCR (polymerase chain reaction)-melting curve method. The technical scheme of the invention provides a kit for detecting an aminoglycoside drug-induced deafness-sensitive gene. The kit comprises a PCR solution, a negative quality control sample and a positive quality control sample, wherein the PCR solution comprises primers, a PCR Buffer, a dNTP (deoxyribonucleotide triphosphate) mixed solution, saturated fluorescent dyes, a Taq enzyme and a UNG enzyme. In the invention, the specific PCR primers are designed according to SNP (single nucleotide polymorphism) sites of the aminoglycoside drug-induced deafness-sensitive gene, two aminoglycoside drug-induced deafness-sensitive sites can be detected in one PCR, the operation can be finished in one tube, and the detection is quick, accurate and wide in range.

Owner:亚能生物技术(深圳)有限公司

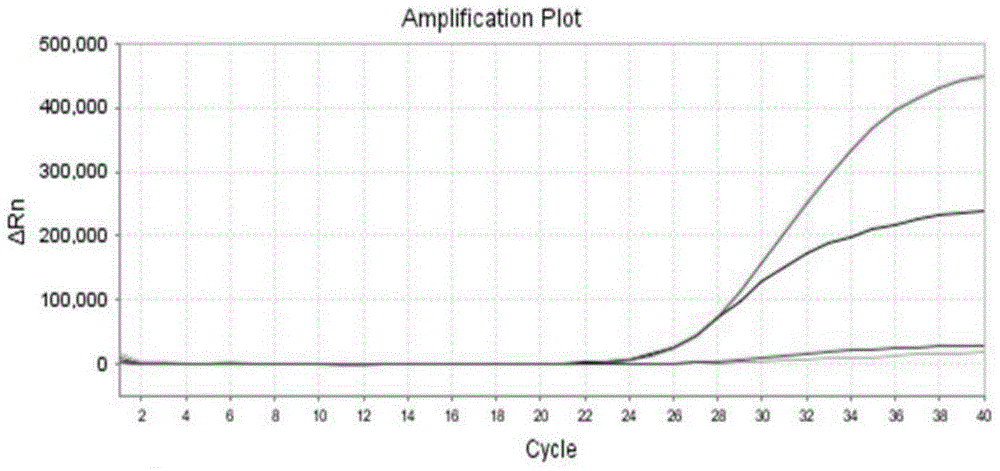

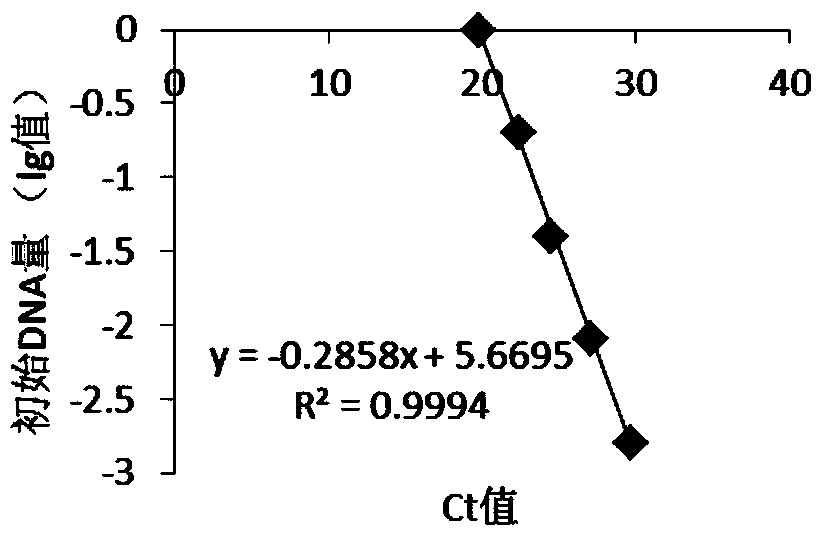

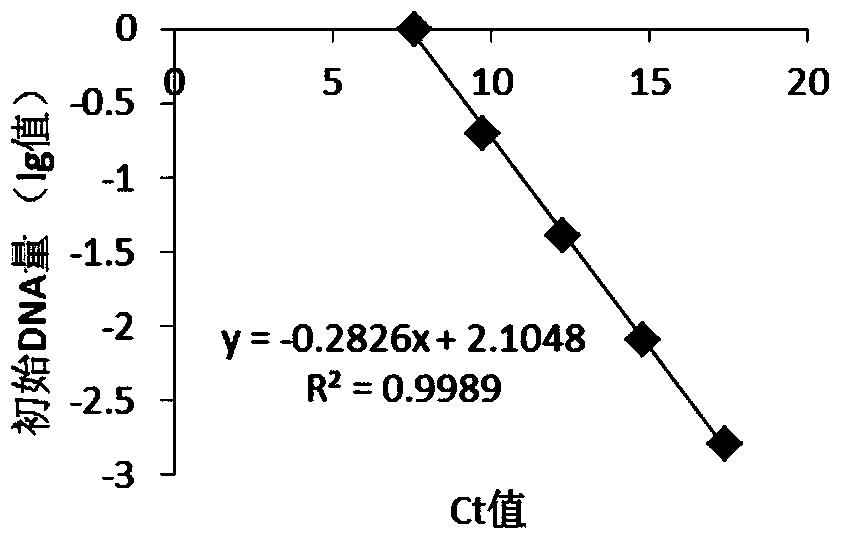

Method for detecting exogenous gene copy number in transgenic tobacco

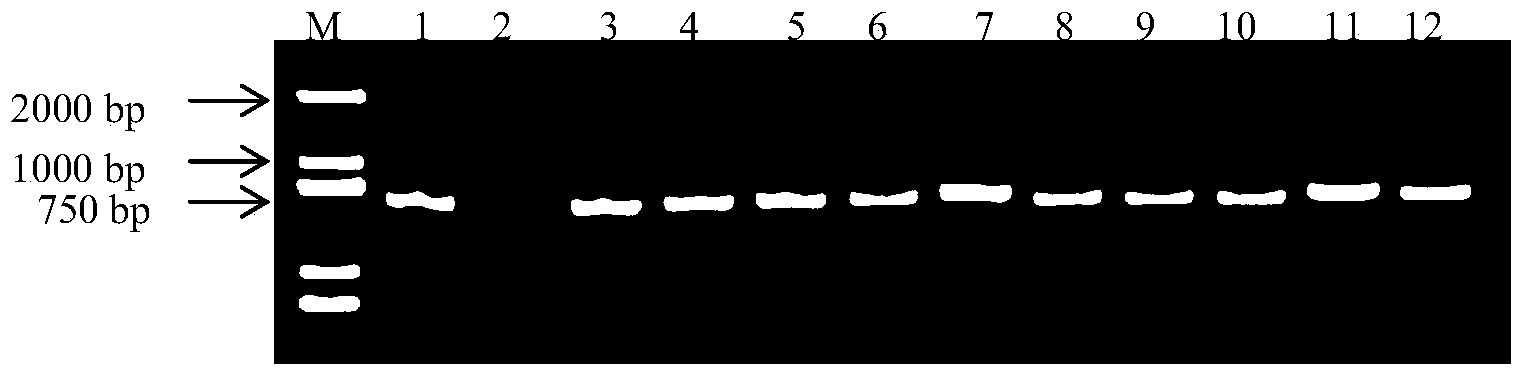

InactiveCN104032007AMeet screening needsMicrobiological testing/measurementDNA/RNA fragmentationReference genesRibonucleotide reductase

The invention discloses a method for detecting an exogenous gene copy number in transgenic tobacco. A real-time fluorescent quantitation PCR technology is utilized to simply, rapidly and accurately detect the exogenous gene copy number in transgenic tobacco. The invention discloses a pair of primers consisting of DNA molecules shown in (1) and (2), namely (1) a DNA molecule shown in SEQ ID No.3; and (2) a DNA molecule shown in SEQ ID No.4. A single-copy endogenous gene ribonucleotide reductase gene (RNR2) of the tobacco is selected as a reference gene, and the exogenous gene copy number in transgenic tobacco is detected through a SYBR GreenI real-time fluorescent quantitation PCR technology. The method disclosed by the invention provides a new thought for copy number analysis of the transgenic tobacco, and the screening requirement for excellent transformation plants in genetic engineering is met.

Owner:GUANGXI VETERINARY RES INST

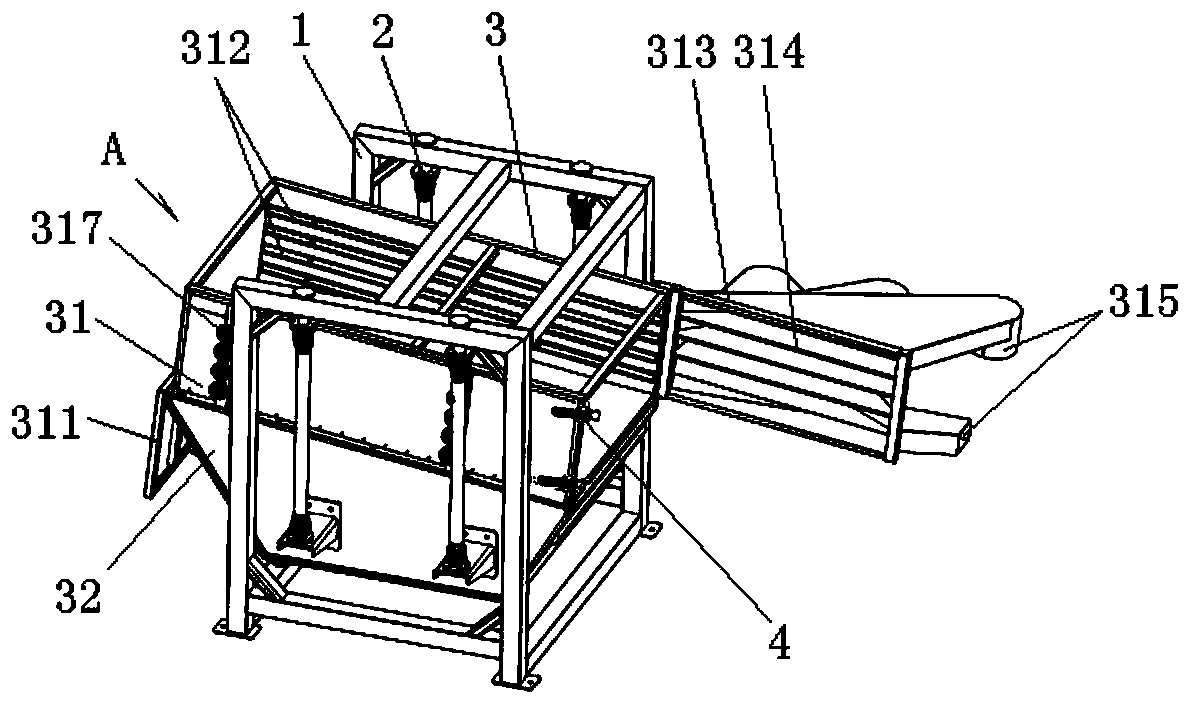

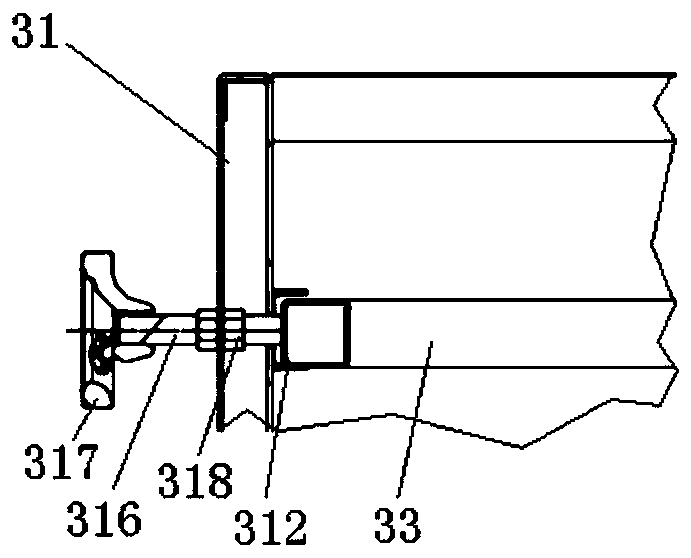

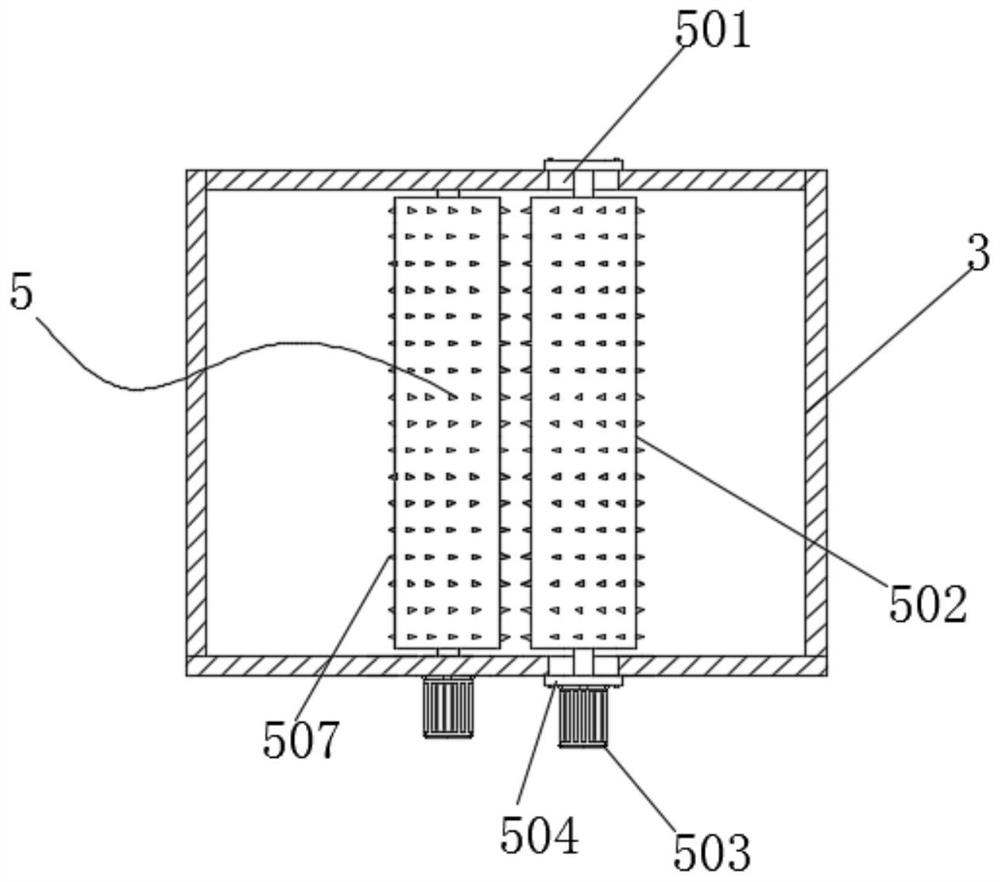

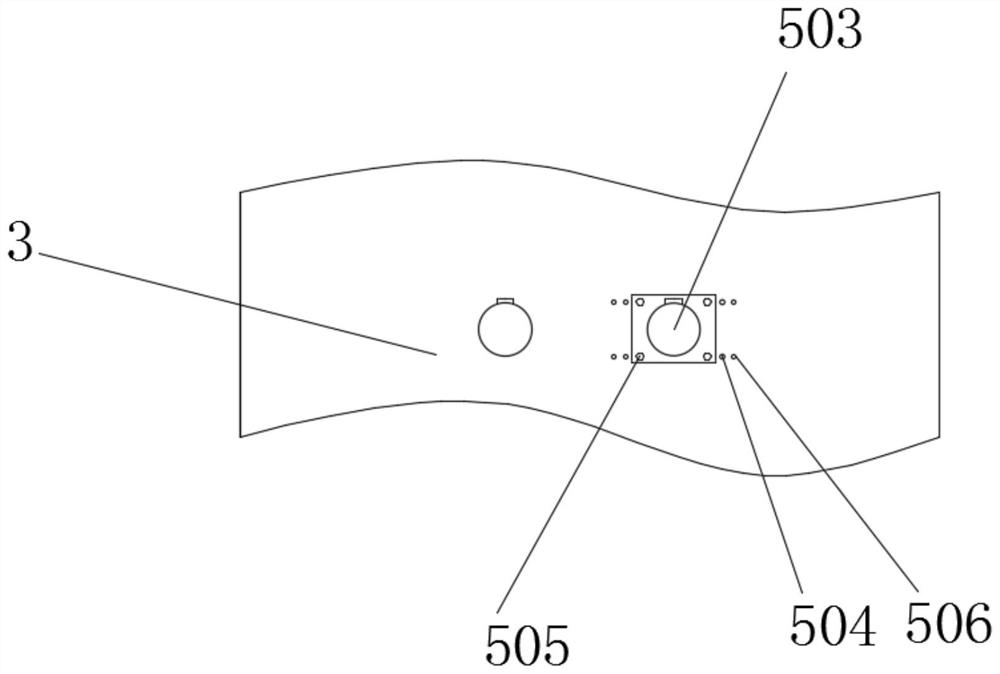

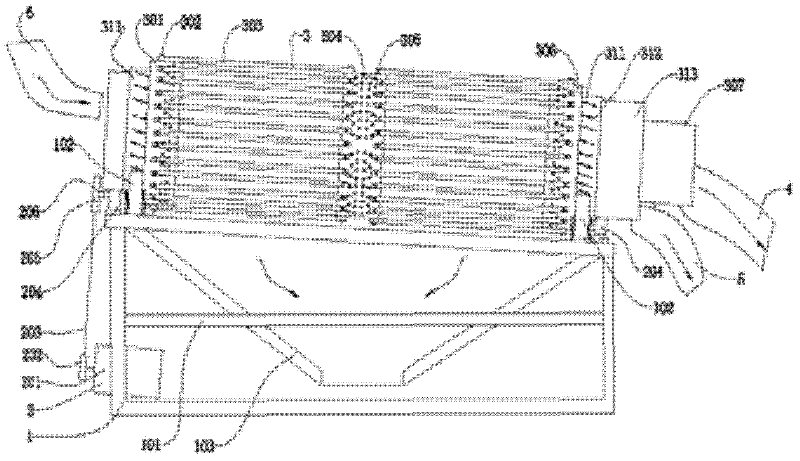

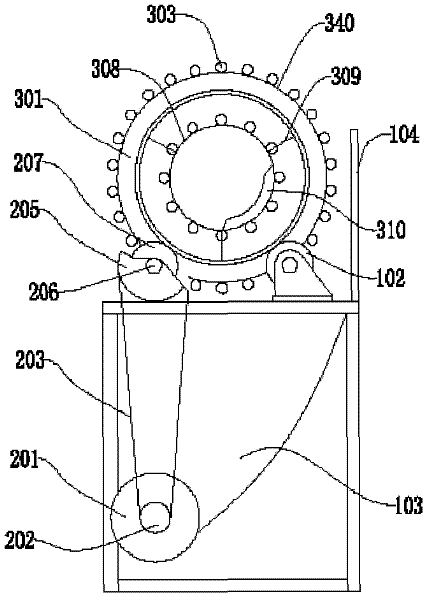

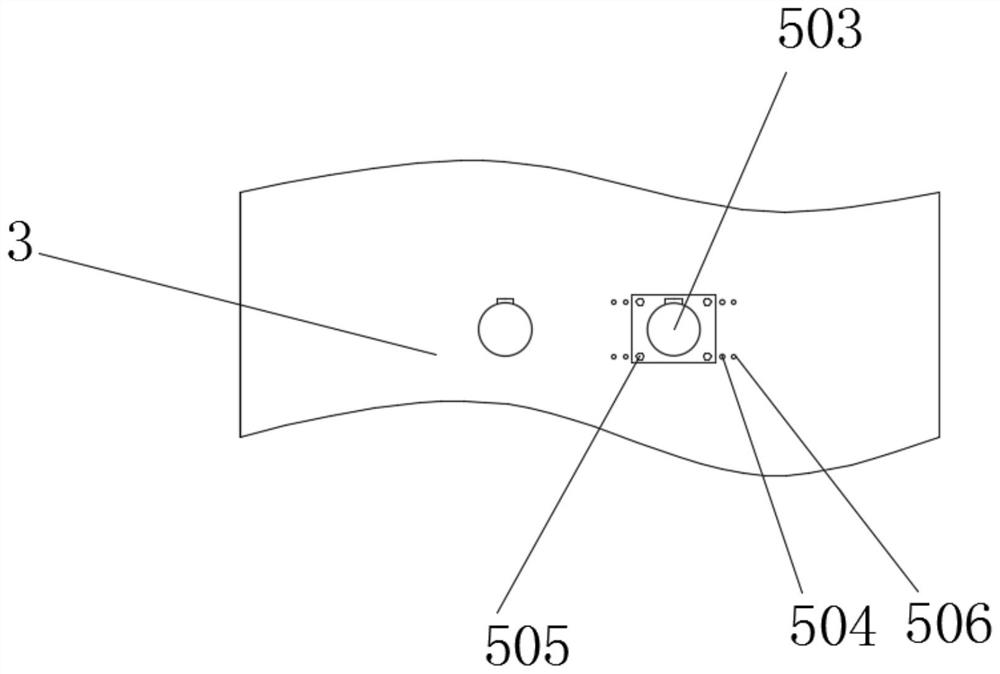

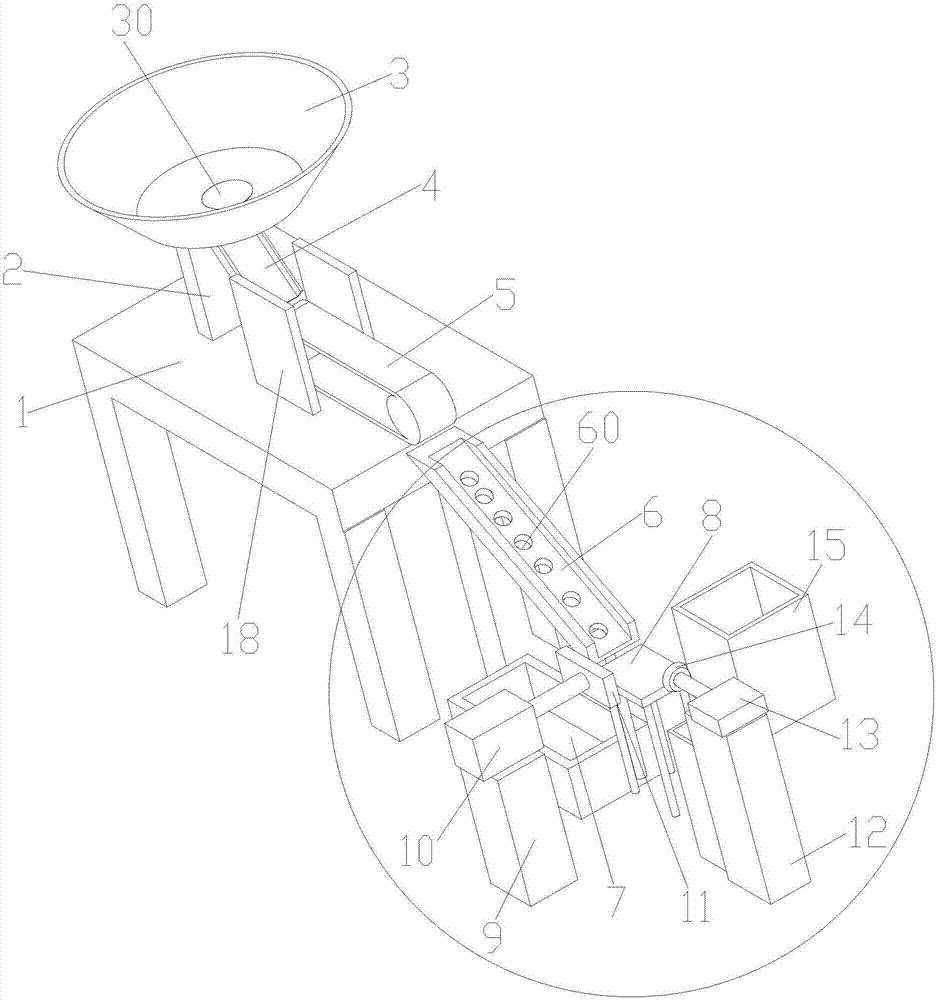

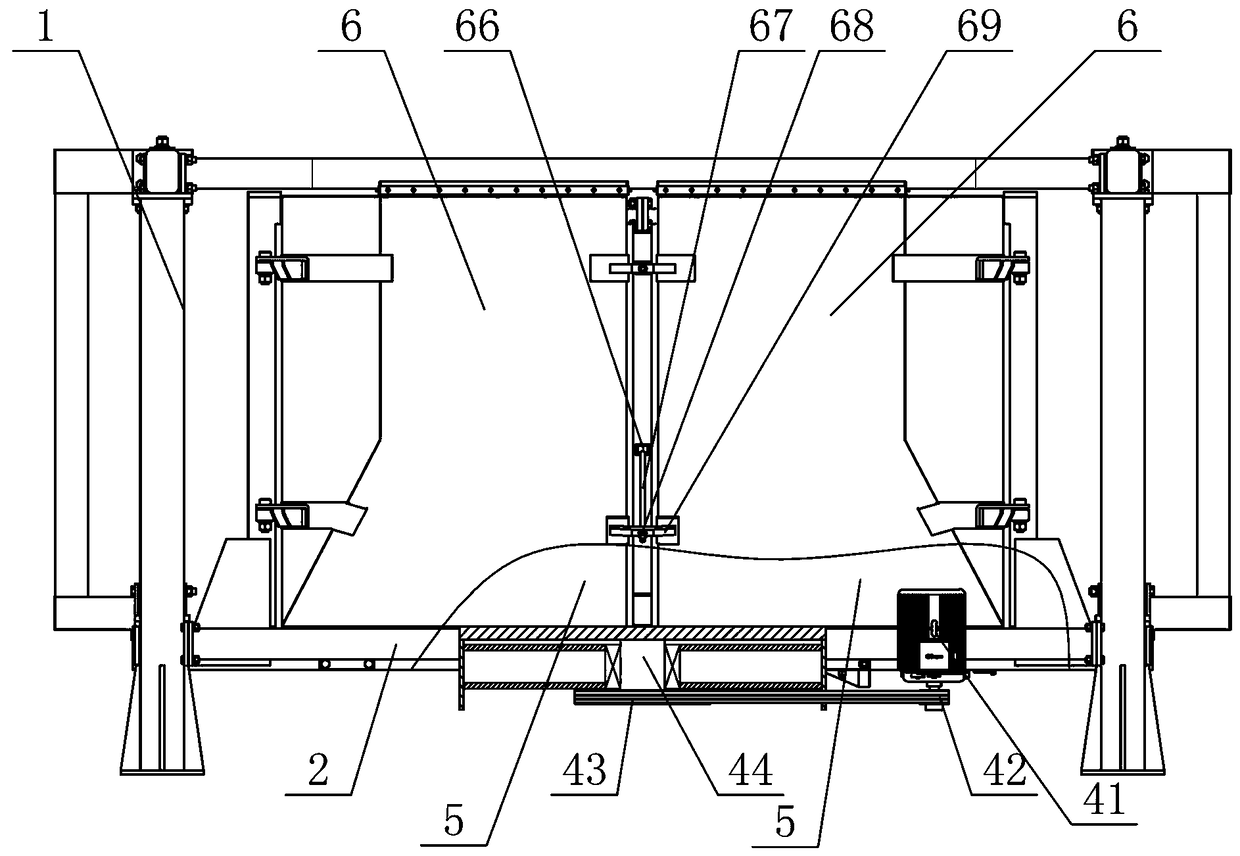

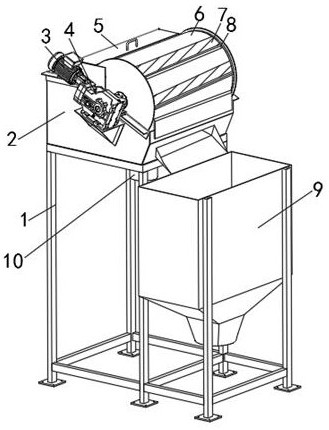

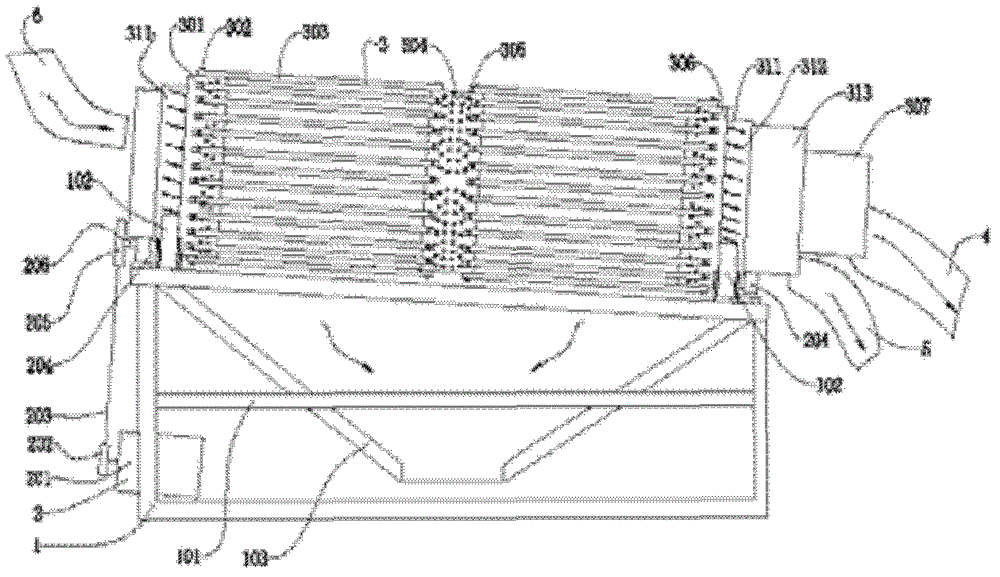

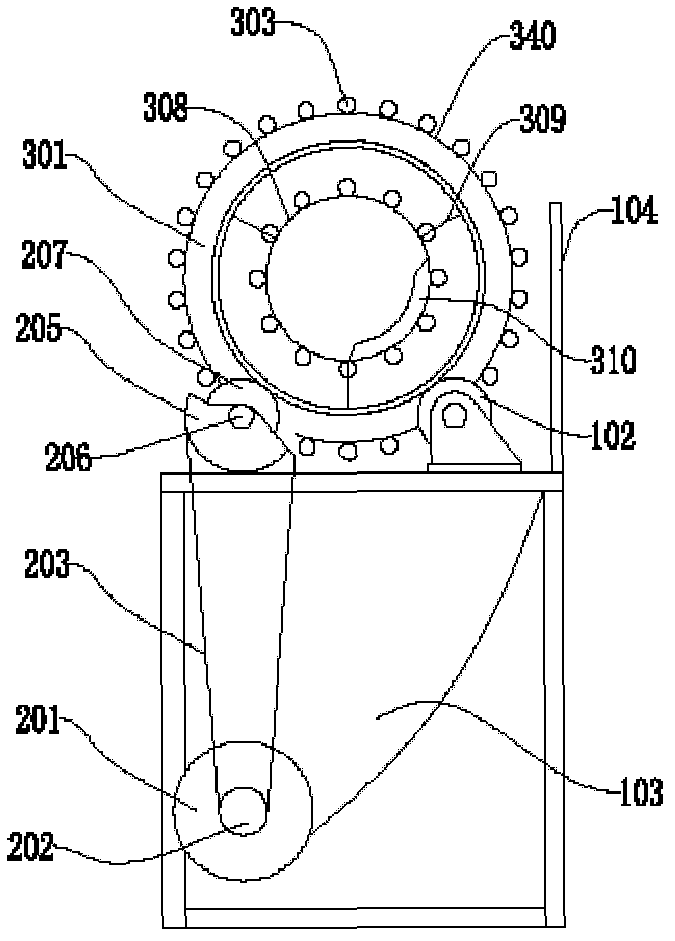

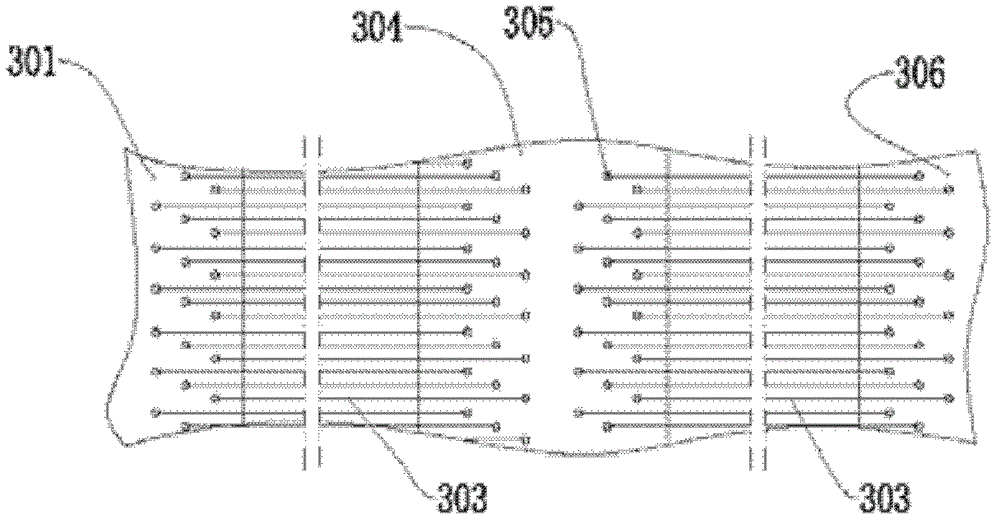

Multi-stage screening machine for aquatic products

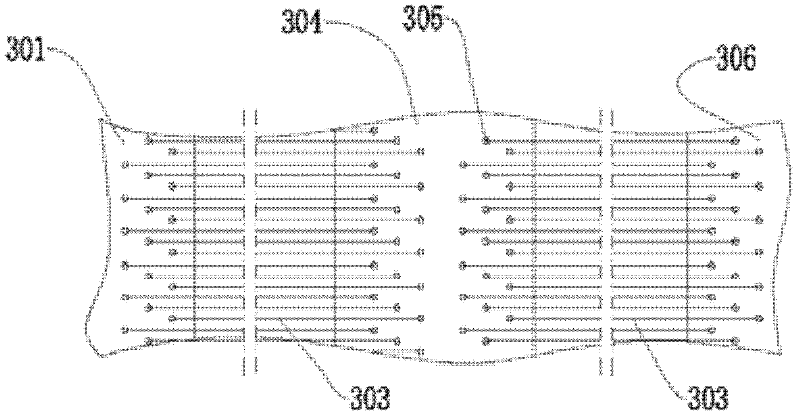

The invention relates to a multi-stage screening machine for aquatic products. The machine comprises a frame (1), a power transmission device (2) and a rolling cage barrel (3), wherein the rolling cage barrel (3) comprises a plurality of cylindrical rollers which are sleeved with one another; each layer of roller comprises a front barrel ring (301), a rear barrel ring (306), more than one middle barrel ring (304), and a grid (303) for connecting the front barrel ring (301), the rear barrel ring (306) and the more than one middle barrel ring (304); the peripheries of the front barrel ring (301), the rear barrel ring (306) and the more than one middle barrel ring (304) are provided with a plurality of staggered adjusting holes (305); and the two ends of the grid (303) are selectively connected with two corresponding adjusting holes (305) in each group of adjusting holes (305) to form different intervals, so that the requirement of screening various aquatic products is met.

Owner:顺祥食品有限公司

Bacterial strain capable of realizing high yield of L-alanine

InactiveCN106047740AIncrease productionImprove stabilityBacteriaMicroorganism based processesEscherichia coliSerial passage

The invention provides a bacterial strain capable of realizing high yield of L-alanine, belonging to the field of bioengineering technology. The bacterial strain capable of realizing high yield of L-alanine is named as Escherichia coli (EcQLS1) with an accession number of CGMCC No. 1764. The Escherichia coli (EcQLS1) strain is obtained through a combination of normal-temperature normal-pressure plasma mutation and high-flux screening, can greatly improve the yield of L-alanine and has good stability, wherein the yield of L-alanine has no obvious change after serial passage of the strain for five generations. Results of shake-flask experiments show that the yield of L-alanine reaches 120 g / L. The bacterial strain provided by the invention totally meets industrial mutation and screening demands on an L-alanine strain, is applicable to industrial fermentation production and has significant economic value.

Owner:QILU UNIV OF TECH +1

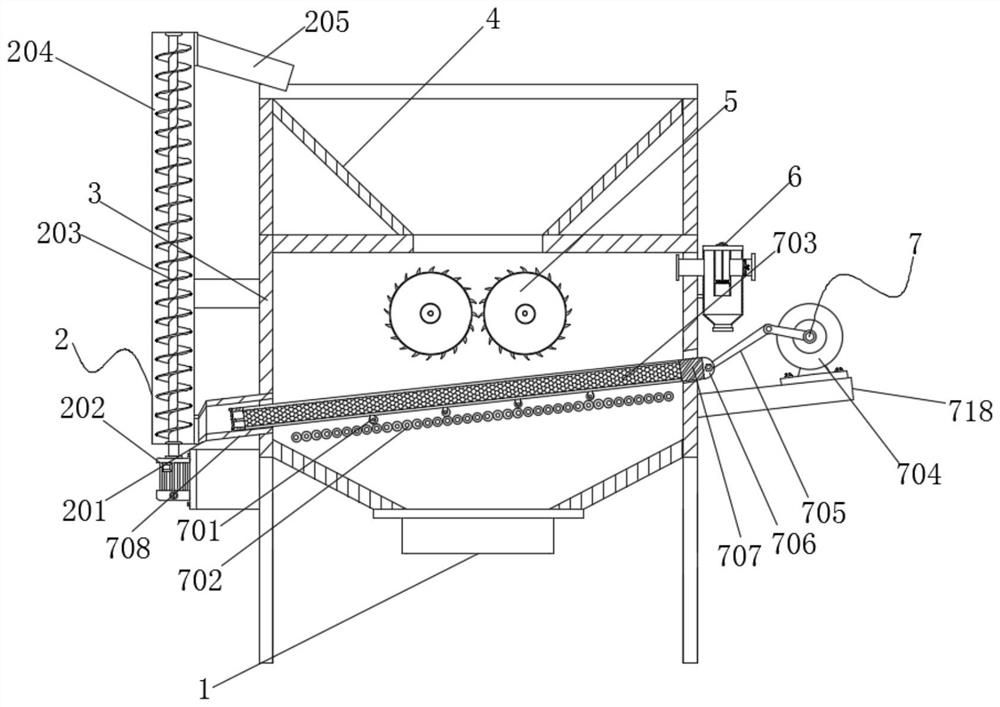

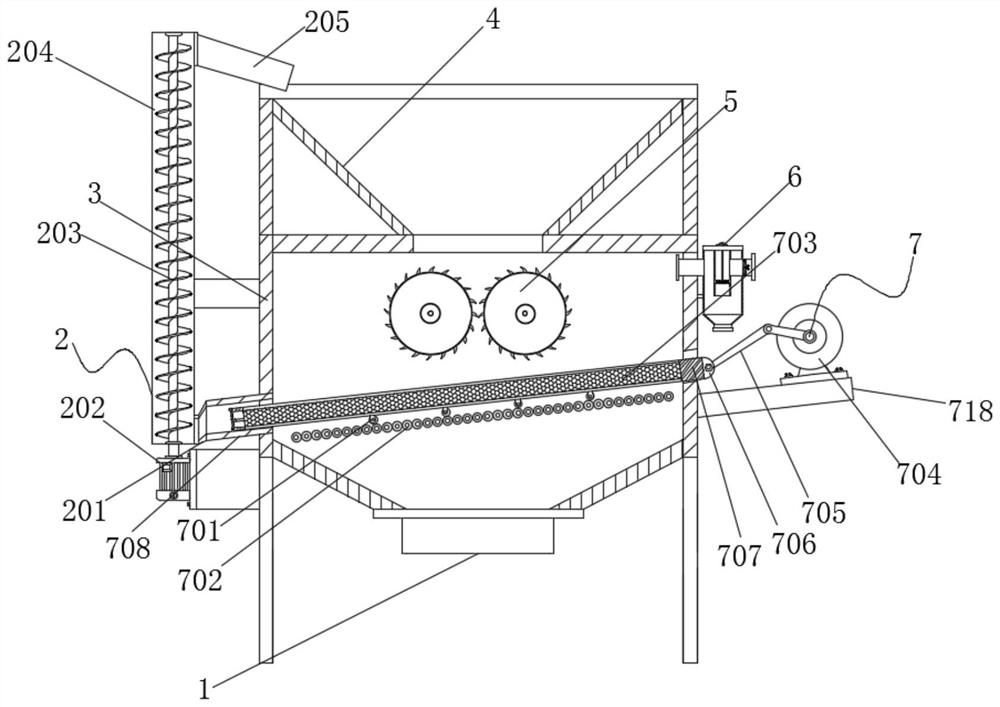

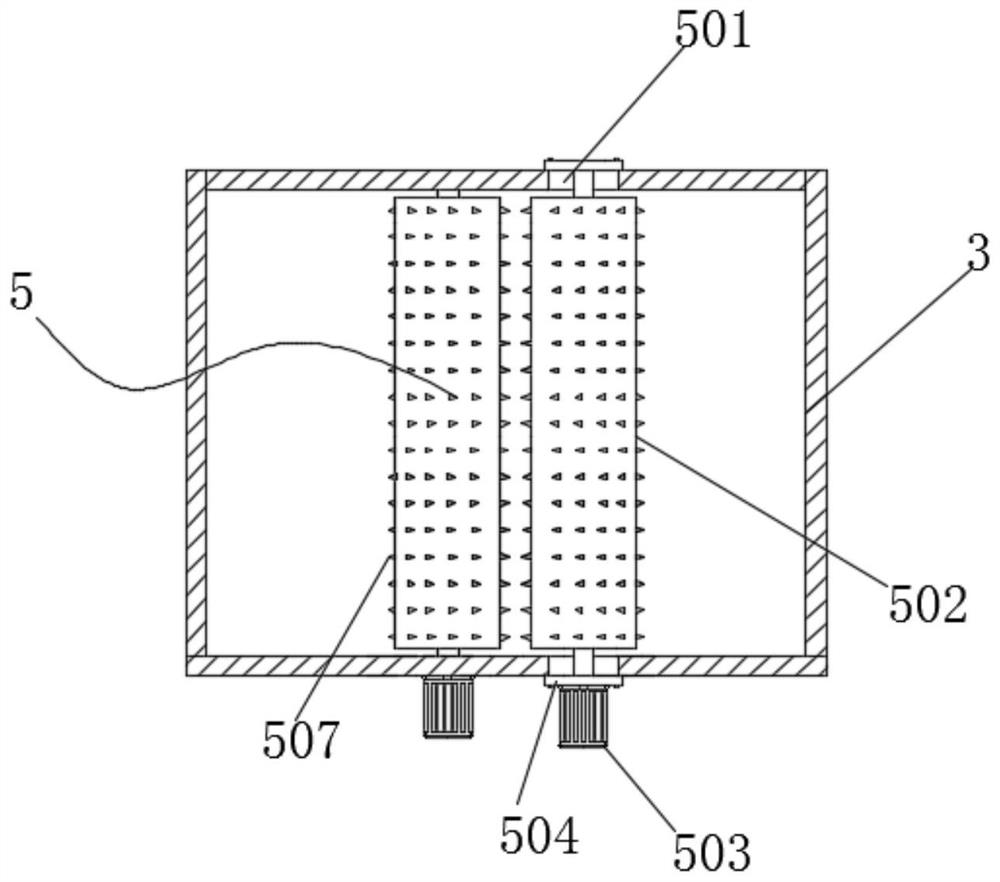

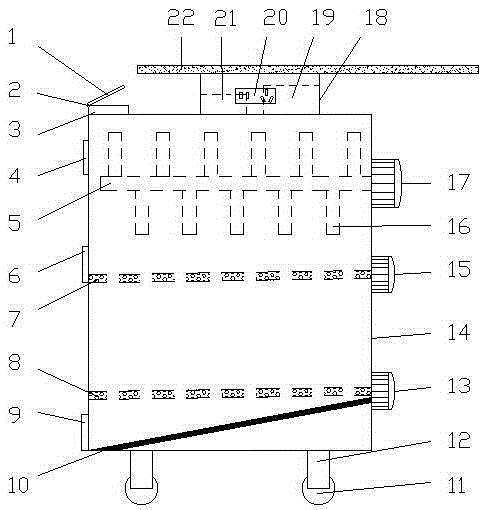

Screening type crushing device for food processing

InactiveCN113477312AImprove applicabilityEasy to operateSievingDispersed particle filtrationCrankStructural engineering

The invention discloses a screening type crushing device for food processing, and belongs to the technical field of crushing devices. The screening type crushing device for food processing comprises a crushing box body and a screening mechanism, wherein a charging hopper is arranged at the upper end of the crushing box body, a discharging hopper is arranged at the lower end of the crushing box body, and an air purifying mechanism is arranged at one side of the crushing box body; and a crushing mechanism is arranged in the crushing box body, and the screening mechanism is arranged below the crushing mechanism. According to the invention, screening is carried out through a screening net, a third motor is used for driving a crank rocker to rotate so as to drive a sliding frame plate to slide and vibrate back and forth in a reciprocating mode, raw materials on the screening net are screened, and in the reciprocating sliding process, rolling wheels at the lower end of the sliding frame plate roll on a roller shaft; and the sliding frame plate jolts and vibrates up and down when moving back and forth in a reciprocating mode, the materials on the screening net fall down faster, and the screening net vibrates up and down in the vertical direction while moving horizontally, so that efficient screening and a good screening effect are achieved.

Owner:田金举

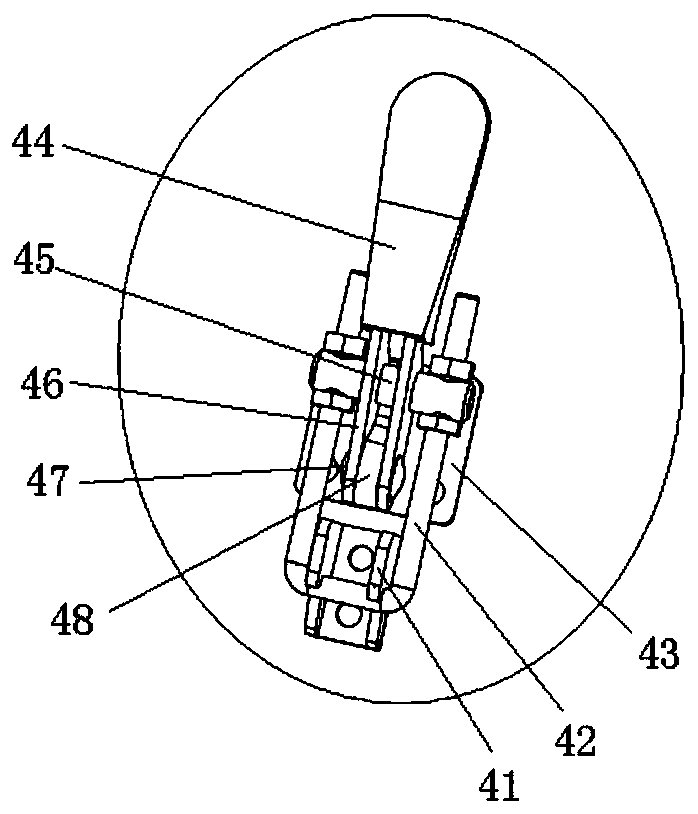

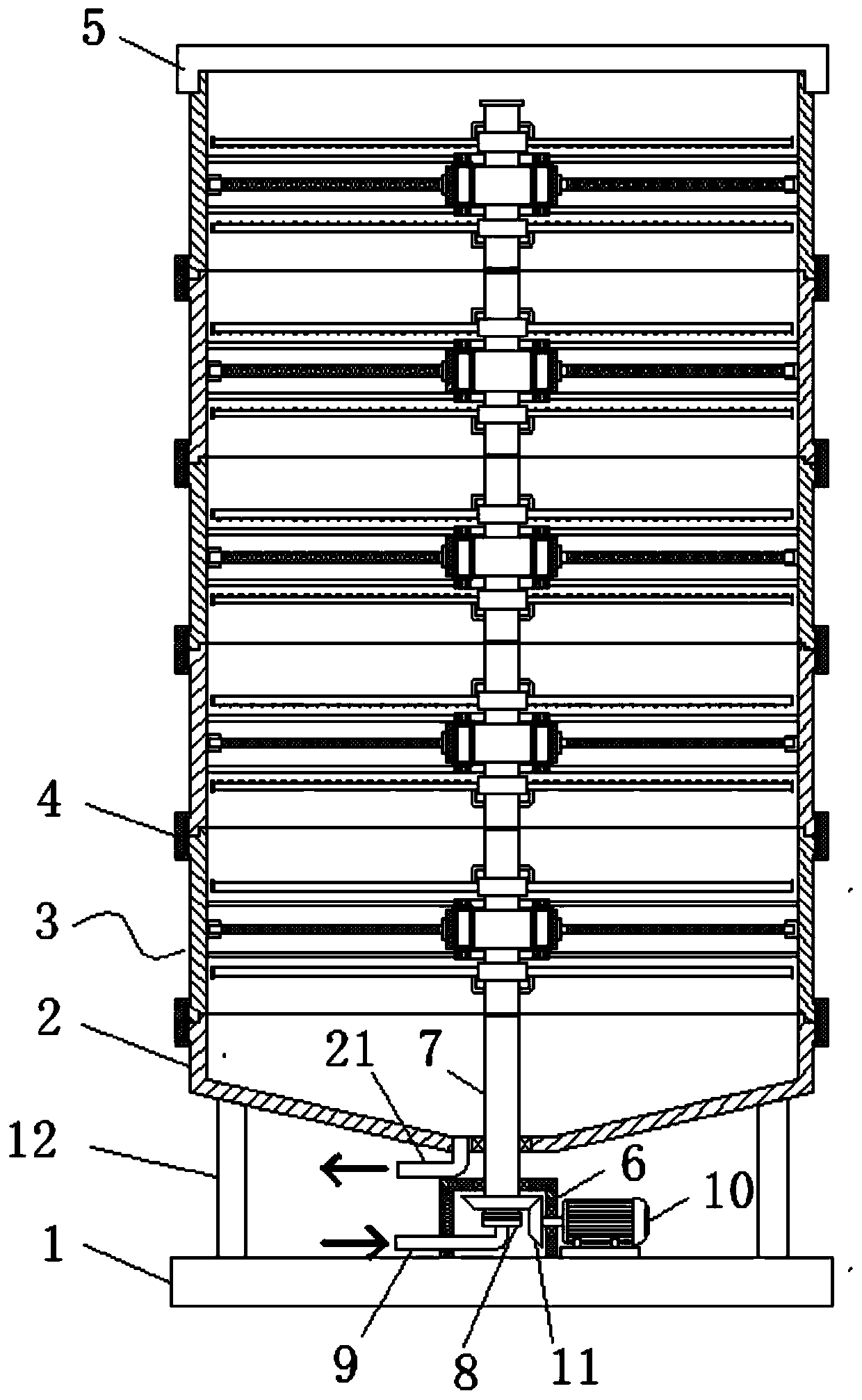

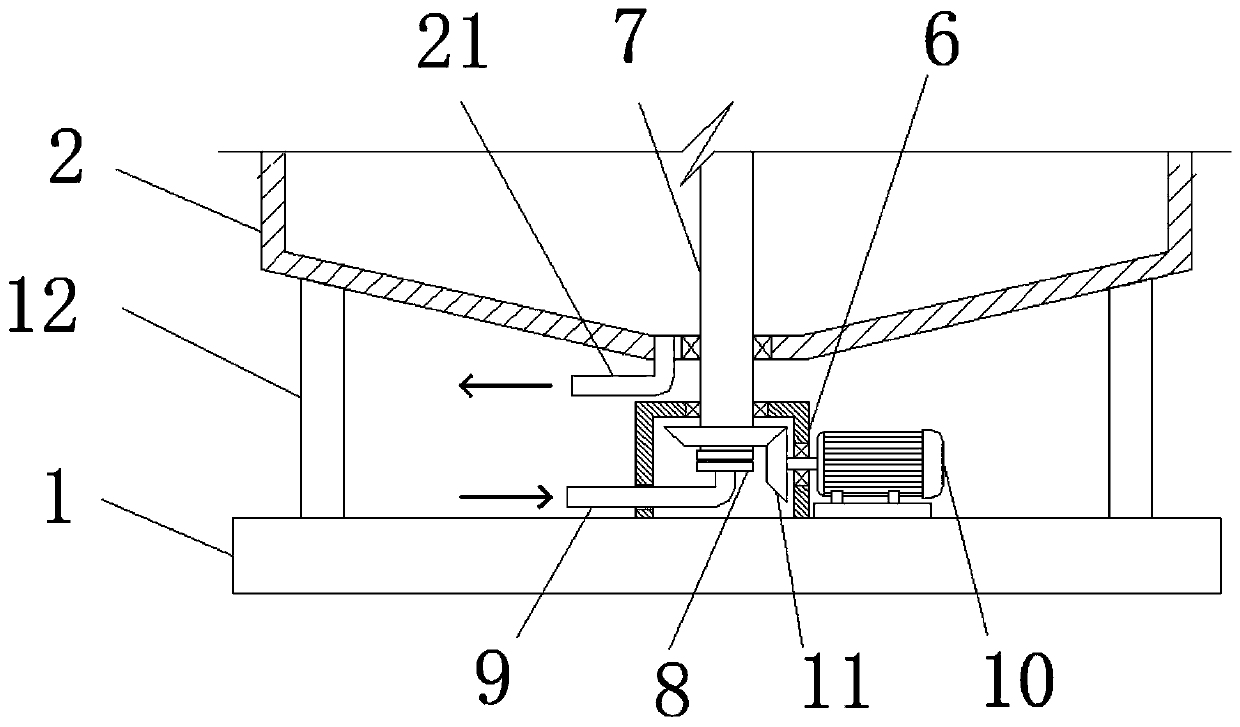

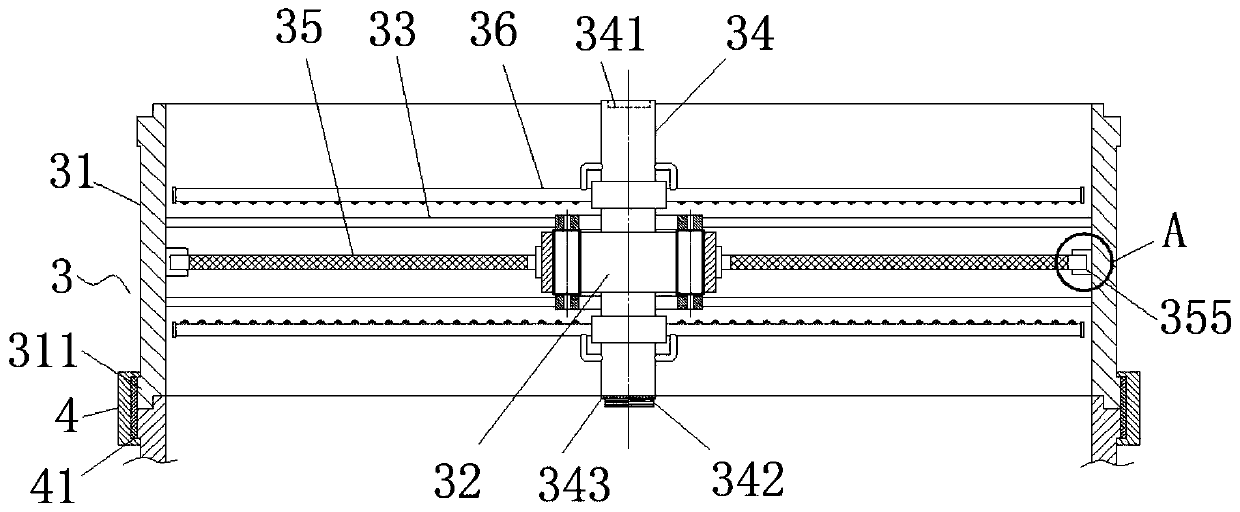

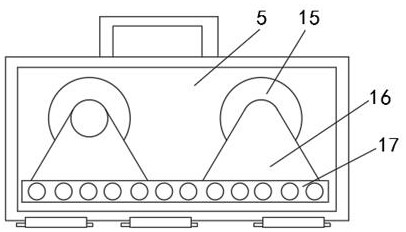

Automatic screening device for sample particles

The invention relates to an automatic screening device for sample particles. The automatic screening device comprises a sample inlet, an automatic screening mechanism, an automatic overturning mechanism, a screening mesh, a synchronous belt, bearings, a coupling, driving motors, a sample outlet and other parts. According to the automatic screening device, the whole system adopts an integrated design scheme, the sample feeding, screening, overturning and sample discharging stations are designed in a communicating manner from top to bottom, and the vibratory screening process is achieved by adopting a rotary reciprocating vibration method; the automatic screening device can be cleaned through high-pressure airflow and water flow, thereby ensuring that the cleaning process is convenient, no residue of the sample particles is left, and the cross contamination of samples is avoided; the driving motors can be adopted for linearly regulating the amplitude and the frequency of screening actions, thereby meeting the screening requirements of the samples of various types; the replacement of a screening mesh mechanism is convenient, different screening meshes can be replaced as required, andthen the screening, with different mesh numbers, of the sample particles can be completed; and meanwhile, the whole system adopts a modular design concept and can be conveniently combined with other devices for use, and the own superposition of a plurality of automatic screening devices can also be allowed, thereby meeting the technical requirements for the multi-layer and stage-by-stage screeningof the samples according to the mesh numbers.

Owner:合肥中科方舟机器人技术有限公司

Camellia oil seed sorting machine

InactiveCN105414016AMeet screening needsIncrease productivitySievingScreeningAgricultural engineeringLeather belt

The invention discloses a camellia oil seed sorting machine which comprises a shell and a first vibrating screen. A rotating shaft is arranged at the upper end of an inner cavity of the shell. Smashing blades are arranged on the outer surface of the rotating shaft. The rotating shaft is connected with a smashing motor through a belt. The smashing motor is arranged at the upper end of the right side of the outer surface of the shell. The first vibrating screen is arranged at the middle end of the inner cavity of the shell and connected with a first vibrating motor through a belt. The first vibrating motor is arranged at the middle end of the right side of the outer surface of the shell. A second vibrating screen is arranged at the lower end of the inner cavity of the shell and connected with a second vibrating motor through a belt. The second vibrating motor is arranged at the lower end of the right side of the outer surface of the shell. Supporting legs are arranged at the bottom of the outer surface of the shell. The camellia oil seed sorting machine is provided with the two vibrating screens of different bore diameters so that the screening requirement of people for camellia oil seeds of different diameters can be met, the labor amount of people is reduced, and the screening efficiency is improved.

Owner:HENGYANG ZHIYUAN AGRI TECH

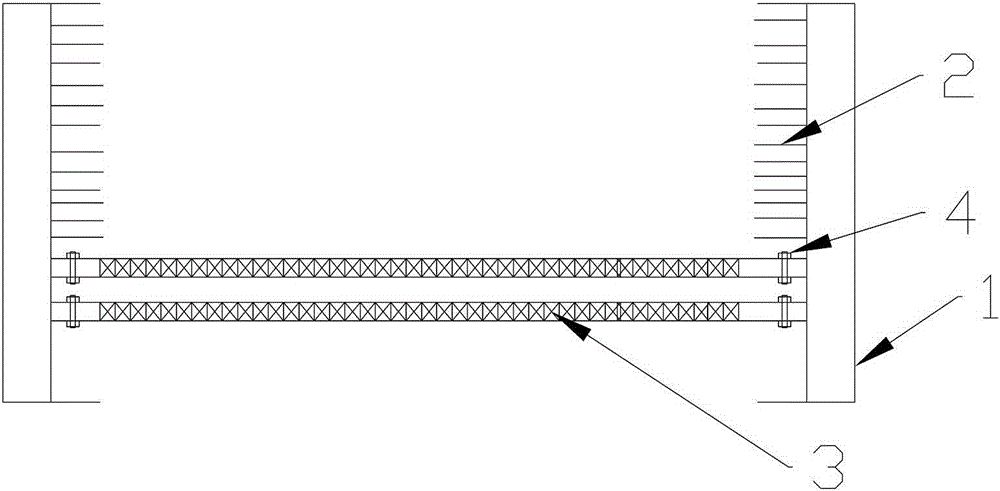

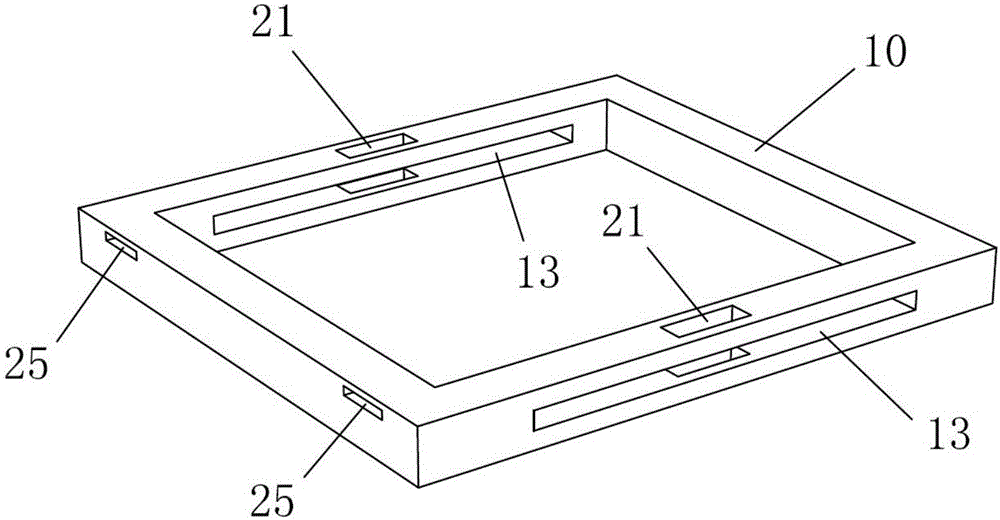

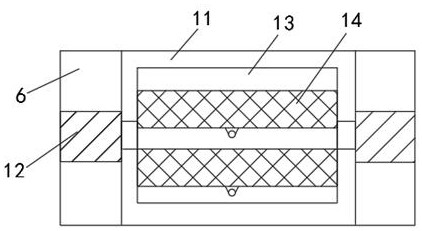

Screen for rice sieving machine

The invention relates to the technical field of rice sieving equipment, in particular to a screen for a rice sieving machine. The rice sieving machine comprises a screen frame and two screens, wherein limiting plates are symmetrically arranged at the two sides of the screen frame; multiple limiting plates are vertically and uniformly distributed on the screen frame; the distances between all the limiting plates at the same side are equal to the thicknesses of the screens; the limiting plates are provided with connecting holes; locking bolts are arranged in the connecting holes; the screens are provided with through holes corresponding to the connecting holes, and are connected with the limiting plates through the locking bolts; and all the screens are connected to the adjacent limiting plates. Compared with a traditional screen, the equipment only needs one type of screen to combine different types of screen holes to satisfy actual demands, so that the cost is saved for users, the installation trouble is reduced, and the screen is practical.

Owner:CHONGQING ZHIRUIDE TECH

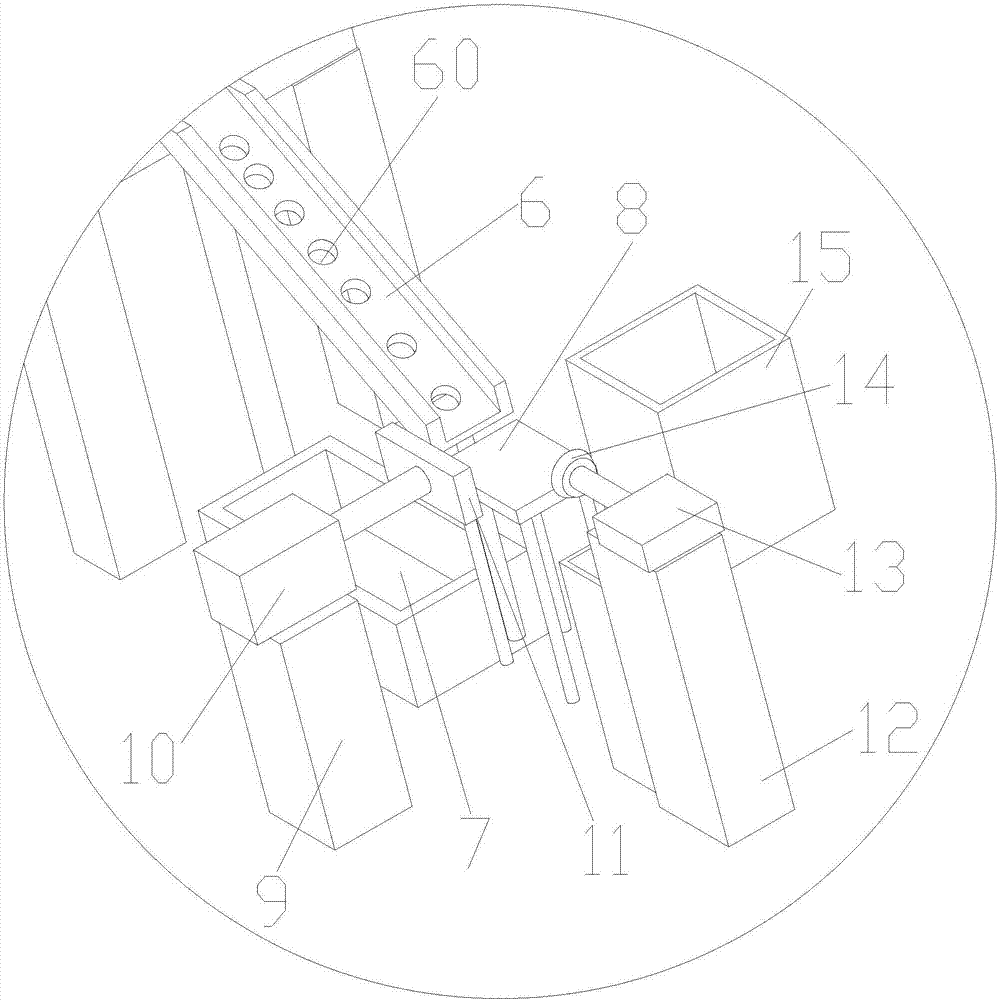

Automated production line used for mechanical part screening

The invention discloses an automated production line used for mechanical part screening, and relates to the technical field of mechanical part processing. The automated production line comprises a support frame and a support table. A feeding device is arranged on the support frame. A conveyor belt is arranged on the support table. A hydraulic drive and a mobile base are arranged on the support frame. An adjusting mechanism is arranged at the bottom of the mobile base. A discharge block is arranged at the end part of the adjusting mechanism. A connection plate is welded on the support frame. A screening box is arranged between the connection plate and the support table. A screening plate is arranged in the screening box. The discharge block is located above the screening plate. The screening plate is provided with a first screening hole. A tilting table is arranged on the screening plate. A through hole is horizontally arranged in the screening box. An insertion plate is arranged in the through hole. The insertion plate is arranged on the side of the screening plate. The insertion plate is fixedly connected with the screening box. A first aggregate tank and a second aggregate tank are arranged under the screening box. The automated production line provided by the invention can replace the screening plate according to the volume of a mechanical part, adjusts the size of the screening hole to meet mechanical part screening needs, and has a wide application range.

Owner:合肥亿福自动化科技有限公司

Mushroom screening device

InactiveCN106944357ASimple structureImprove screening efficiencySortingArchitectural engineeringMushroom

The invention relates to a mushroom screening device. The bottom frame is provided with a discharge tray fixed on a support block; the center of the discharge tray is provided with a first blanking hole; the lower end of the first blanking hole is provided with a first transmission channel ; The lower end of the first transmission channel is provided with a conveyor belt; the lower end of the conveyor belt is provided with a second transmission channel located on one side of the chassis, and a first collection frame is provided below the second transmission channel; a second discharge hole is opened in the second transmission channel The lower end of the second transmission channel is provided with a support panel; one side of the support panel is provided with a pusher cylinder, and the front end of the pusher cylinder is provided with a push plate; the second base is located on the side of the support panel opposite to the second transmission channel. A suction cylinder is provided on the upper end of the base, and an electric suction cup is provided at the front end of the suction cylinder; a second collection frame is provided on the opposite side of the first base on the support panel; The third collection frame; the lower end of the support panel is provided with a weight sensor, and the invention can screen mushrooms conforming to the shape and weight.

Owner:SUZHOU JINGWEI AGRI PROD

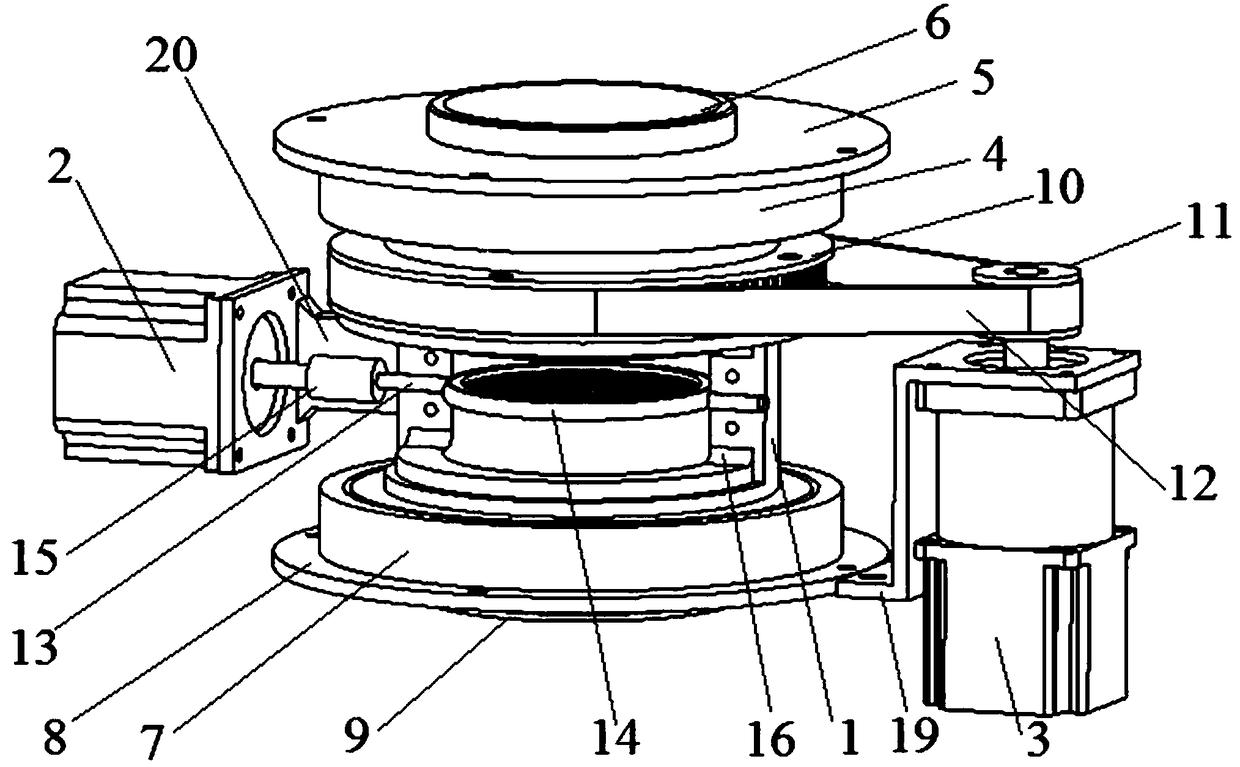

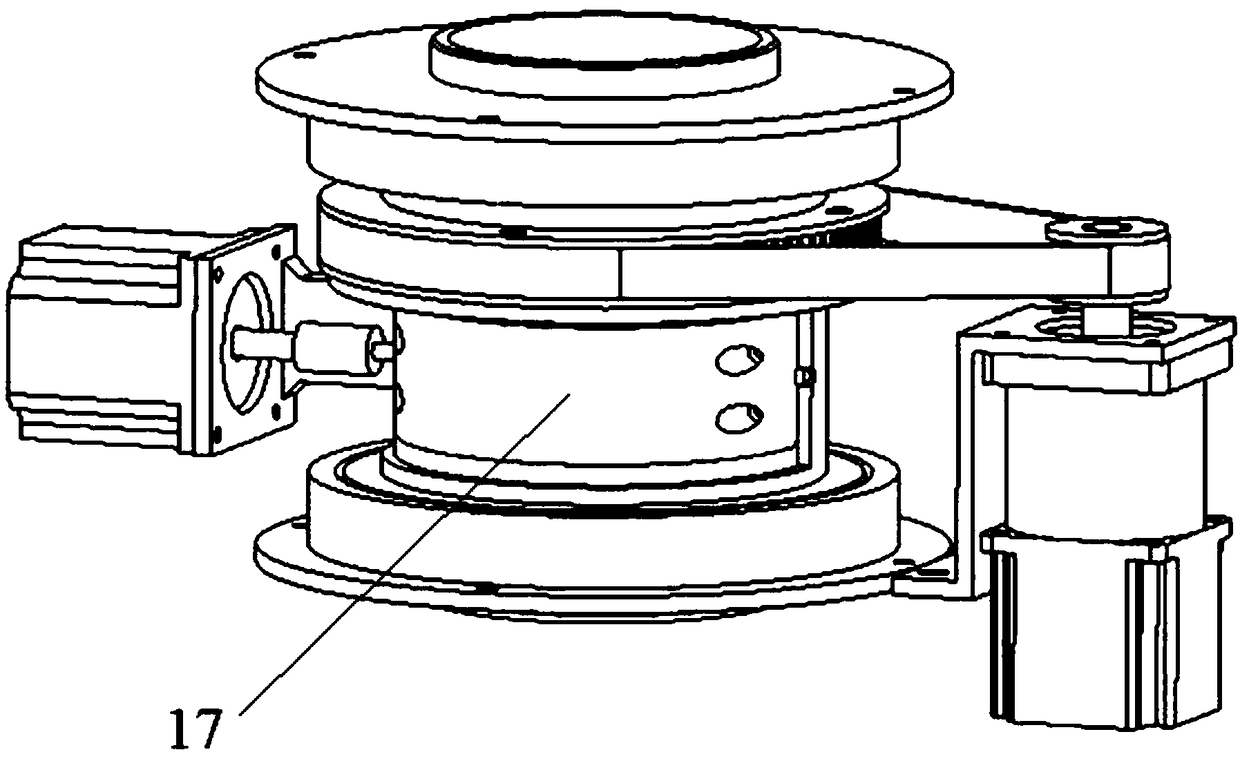

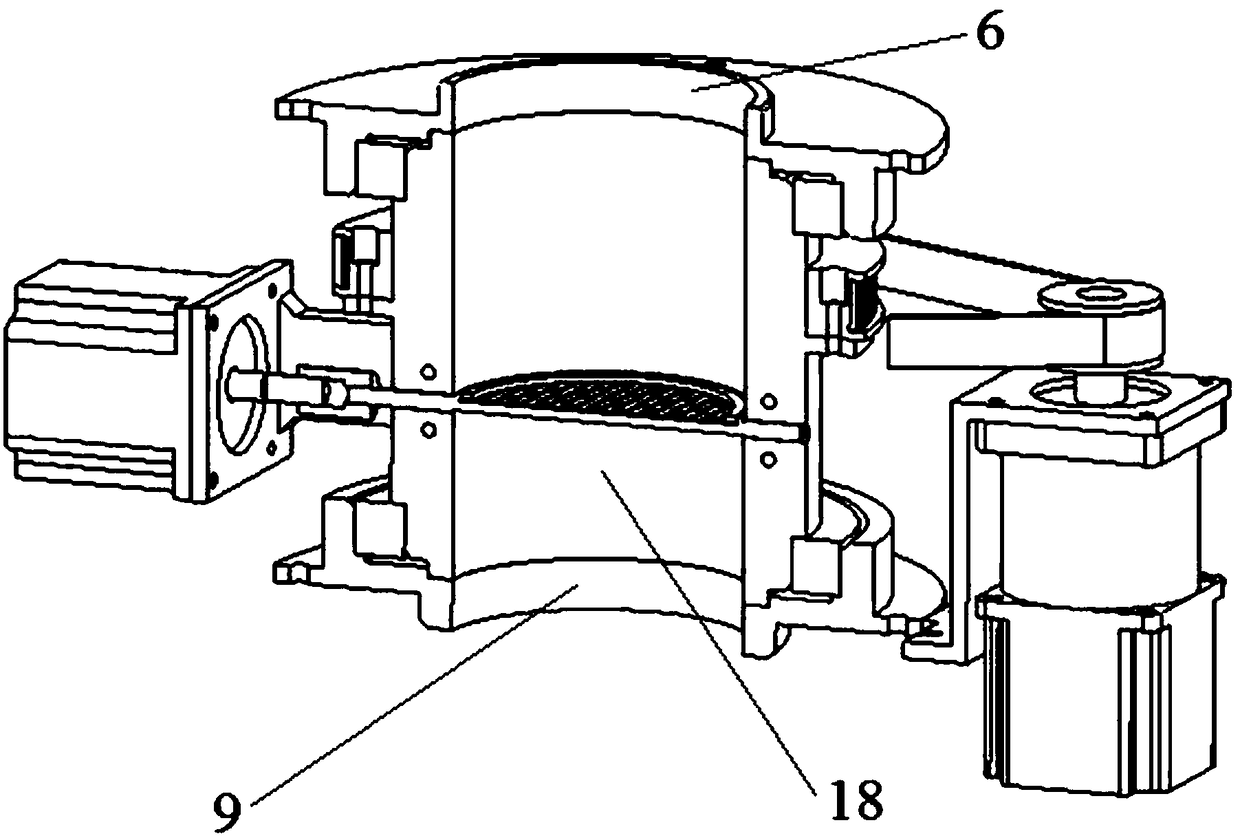

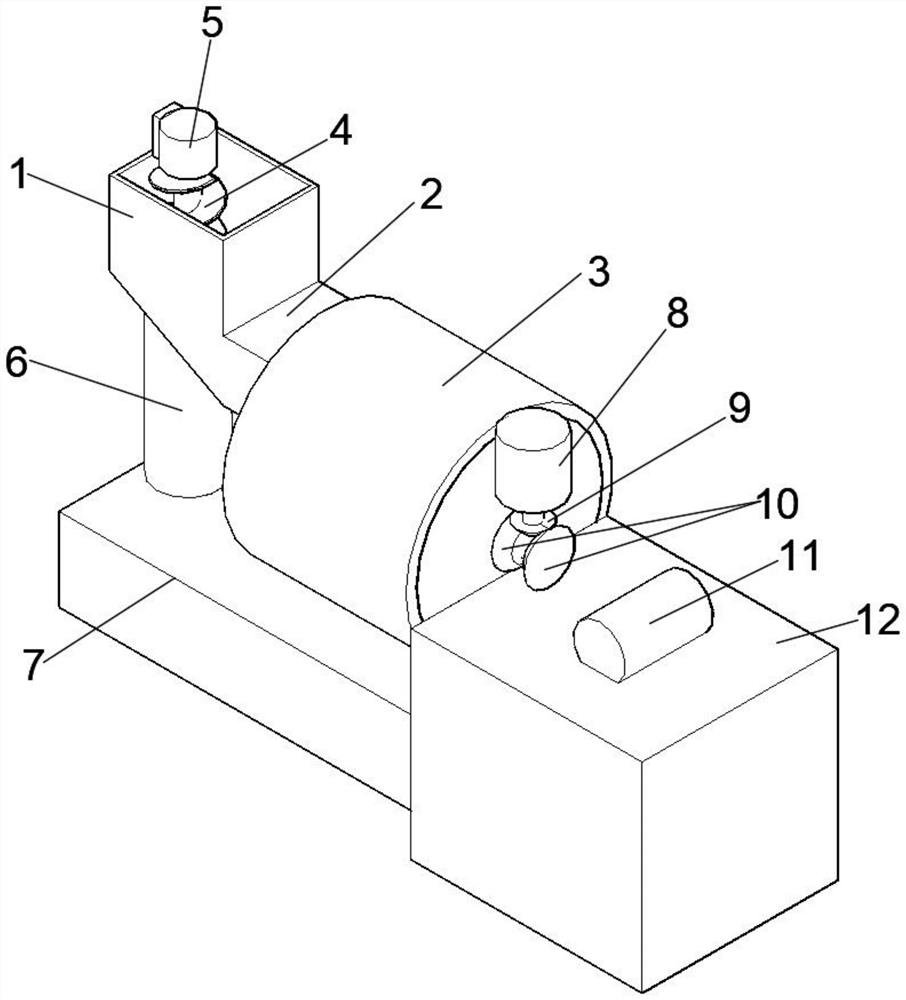

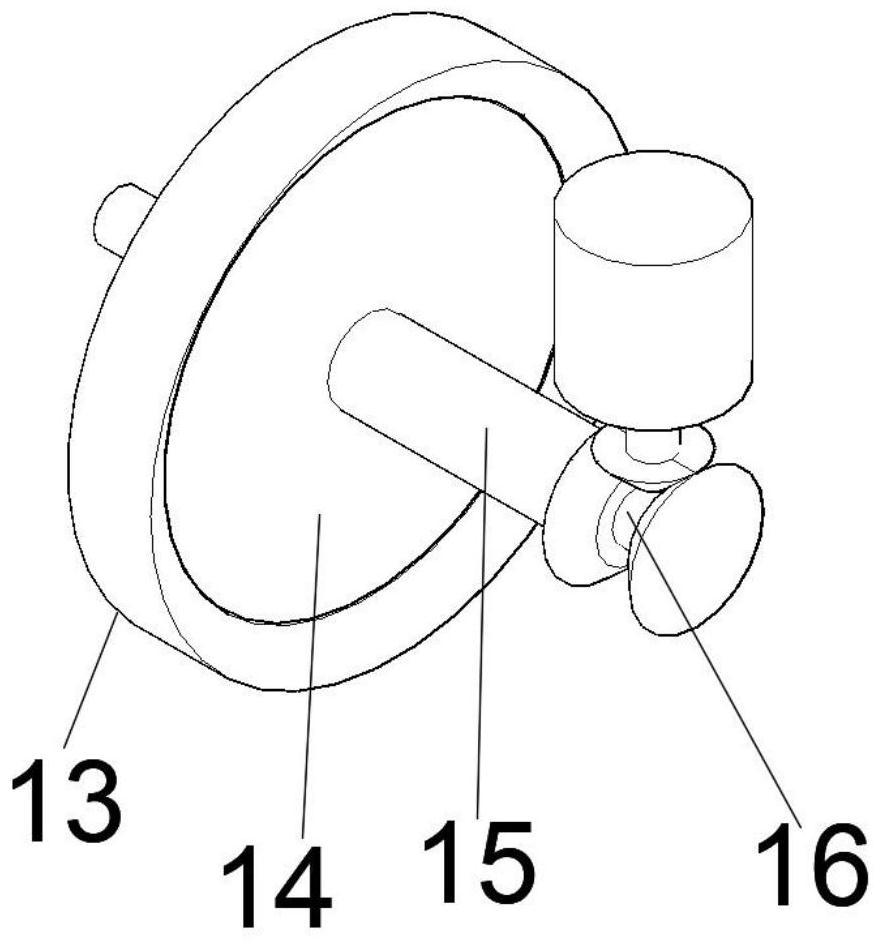

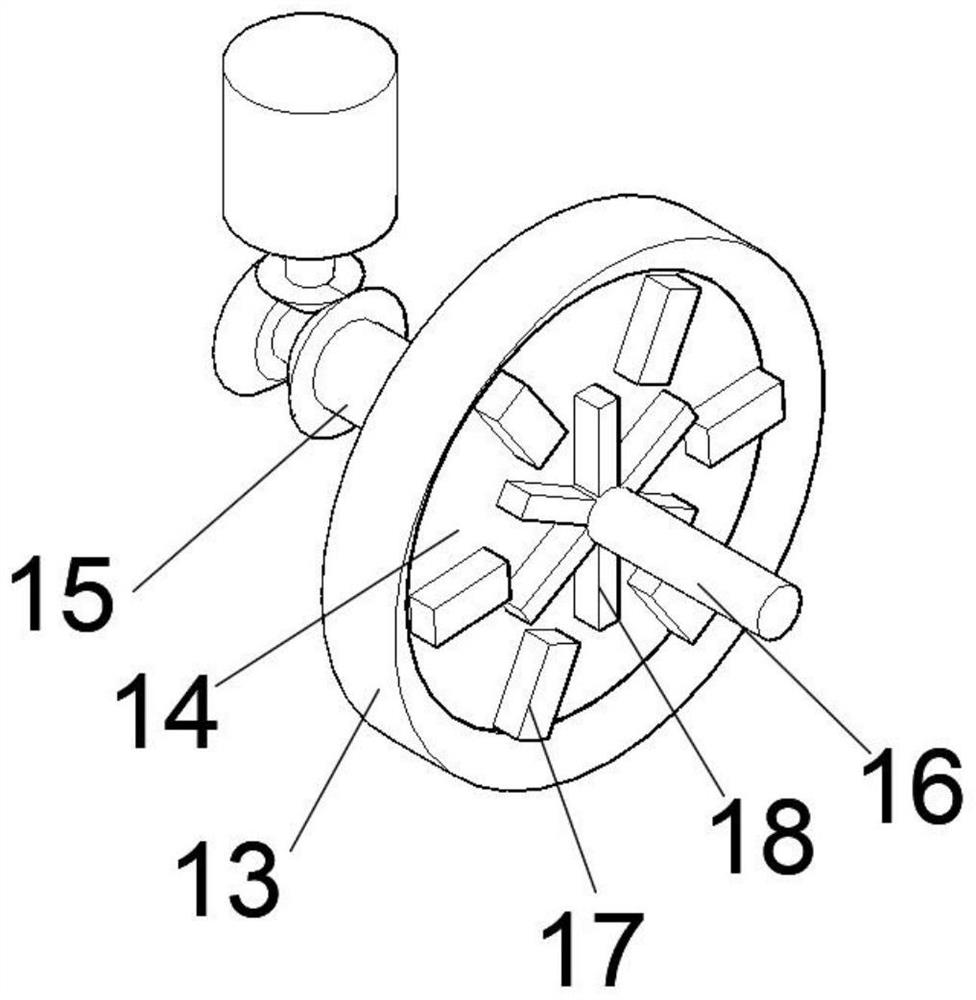

Differential rotating type wet screening instrument

PendingCN110102401AEliminate traditional manual screeningImprove screening efficiencyWet separationGear wheelDrive motor

The invention discloses a differential rotating type wet screening instrument, and belongs to the technical field of coal sample screening. The instrument comprises a base, wherein a water collectinglayer is arranged at the upper part of the top part of the base; a wet screening layer is arranged on the top part of the water collecting layer; a driving mounting rack, a hollow rotating shaft, a water feeding pipe, a driving motor and a bevel gear set are fixedly connected to the center of the top part of the base; the wet screening layer comprises an outer wall barrel; a planetary gear set comprising a sun gear, a planetary wheel, planet carriers and an inner gear ring is arranged in an inner chamber of the outer wall barrel; the planet carriers at the upper side and the lower side of theplanetary wheel are fixedly connected to the inner sidewall of the outer wall barrel through connecting rods; a hollow extending shaft is fixedly inserted through the middle part of the sun gear; a screening net device fixedly sleeves the outer wall of the inner gear ring; spraying devices are arranged at the upper side and the lower side of the screening net device; and the spraying devices fixedly sleeve the outer wall of the hollow extending shaft. The differential rotating type wet screening instrument is high in screening efficiency, and capable of independently defining and screening bystages, inhibiting flying dust, and easily screening.

Owner:ANHUI UNIV OF SCI & TECH

Dryer for agricultural breeding

InactiveCN111426182AImprove drying efficiencyIncrease diversitySievingSeed and root treatmentElectric machineryAgricultural engineering

The invention discloses a dryer for agricultural breeding. The dryer comprises a screening box and a conveying box, wherein the right end of the top of the inner cavity of the screening box is fixedlyconnected to an ultraviolet-ray lamp tube; lower ends of two sides of the inner cavity of the screening box are fixedly connected to supporting plates; the top ends of the supporting plates are movably connected to a vibrating screen through springs; the right end of the bottom of the vibrating screen is fixedly equipped with a vibrating motor; the left end of the bottom of the inner cavity of the screening box is fixedly connected to a heating wire; the right end of the bottom of the inner cavity of the screening box is fixedly connected to a baffle plate; and the upper end of the left sideof the screening box is fixedly connected to a fan support base. The middle end of the left side of the conveying box is fixedly equipped with a conveying motor, and spiral conveying needs of seeds can be met through action of a rotary shaft and a spiral conveying blade; and circulatory drying needs of seeds inside the screening box and the conveying box can be met through action of the heating wire, a fan and a pipeline. The structures are matched, so that seed drying efficiency is effectively improved, and benefits of enterprises are met.

Owner:郭汉云

Two-stage rotary combined multi-layer sieve

PendingCN108620330AMeet screening needsTo achieve the purpose of screening dust and impurity removalSievingGas current separationEngineeringSieve

The invention relates to a two-stage rotary combined multi-layer sieve. The two-stage rotary combined multi-layer sieve comprises a rack, a hanging frame, a sieve body, an air-draft feeding system anda power transmission system. The sieve body is arranged on the hanging frame. A hanging rod is arranged on the hanging frame. The upper end of the hanging rod is spherically hinged to the rack, and the lower end of the hanging rod is spherically hinged to the hanging frame. The power transmission system is arranged at the lower end of the hanging frame and drives the hanging frame and the sieve body to make planar rotational motions. The sieve body comprises two sieve boxes which are of the same structure. According to the two-stage rotary combined multi-layer sieve, the two sieve boxes are arranged, a plurality of layers of sieve cells which operate at the same time are arranged in each sieve box, and a uniform distribution device is arranged, so that grain evenly enters the different sieve cells to be screened, and accordingly, large impurities and small impurities in the grain are removed; and meanwhile, an air draft system is arranged to extract light fine impurities, such as dust, in the grain, and thus, the purposes of scanning and dust and impurity removing are achieved; and the two sieve boxes and the multiple layers of sieve cells are arranged, so that the impurity removal efficiency is improved, and the screening requirement of large grain depots is met.

Owner:郑州中粮科研设计院有限公司 +1

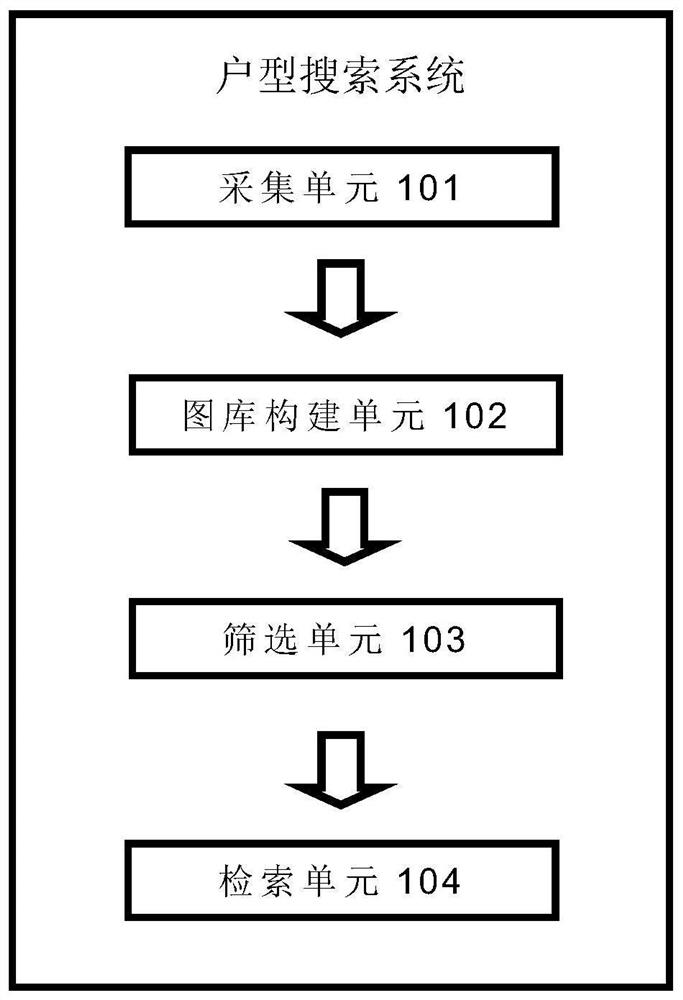

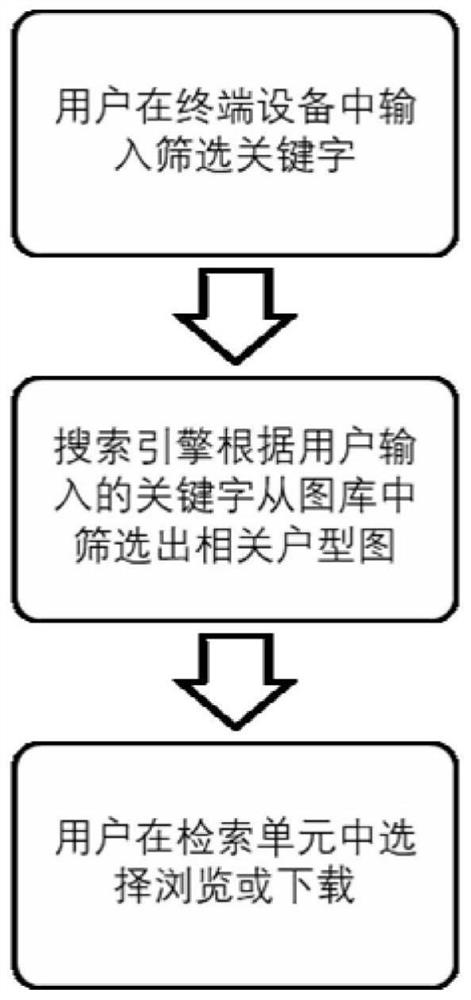

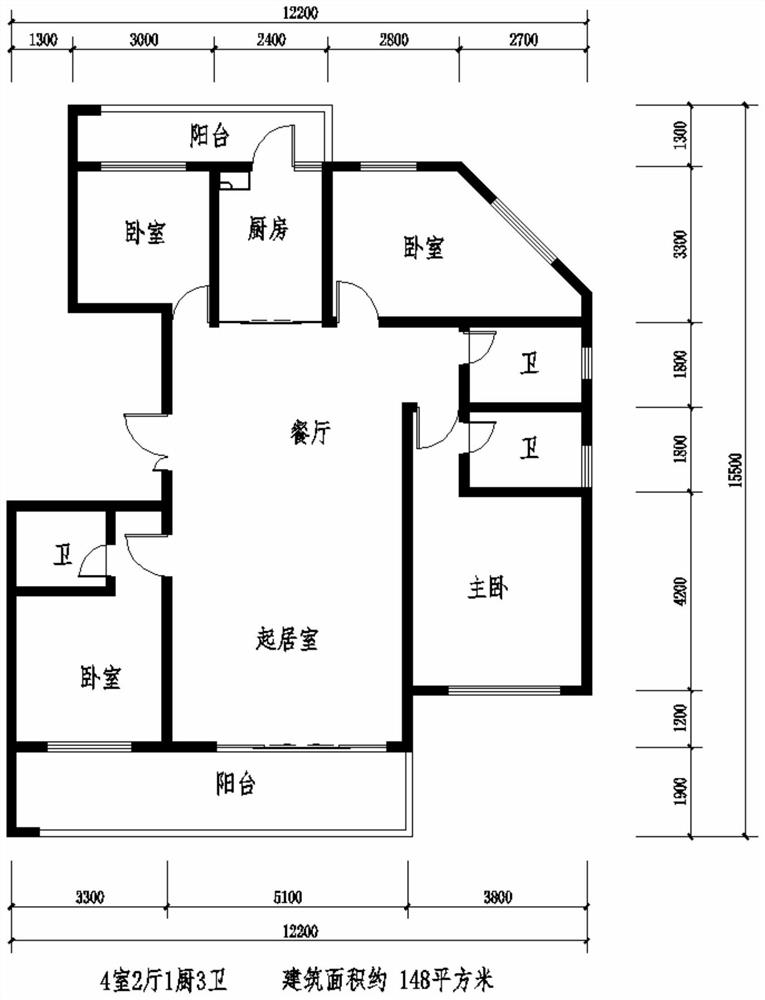

House type characteristic index automatic extraction method and system based on computer vision

ActiveCN112232131AMeet screening needsDigital data information retrievalSpecial data processing applicationsComputer graphics (images)Industrial engineering

Owner:云南省设计院集团有限公司

Sitter for plastic functional master batch

InactiveCN107186909APlay a double-stage stirring effectImprove the mixing effectSievingScreeningMasterbatchElectric machinery

The invention discloses a stirrer for plastic functional master batch. The stirrer comprises a housing, wherein an inner cavity of the housing is movably equipped with a first rotary shaft and a second rotary shaft in sequence from top to bottom; the outer surface of the first rotary shaft and the outer surface of the second rotary shaft are fixedly connected with a first stirring blade and a second stirring blade separately; the first rotary shaft and the second rotary shaft are in transmission connection through a belt; and the inner cavity of the housing is fixedly connected with a first partition and a second partition in sequence. According to the stirrer for the plastic functional master batch disclosed by the invention, the first rotary shaft and the second rotary shaft are movably mounted in the inner cavity of the housing from top to bottom in sequence, and the outer surface of the first rotary shaft and the outer surface of the second rotary shaft are fixedly connected with the first stirring blade and the second stirring blade separately, so that the dual-stage stirring effect on master batch can be achieved, and the master batch stirring effect is effectively improved; and meanwhile, the first rotary shaft and the second rotary shaft are driven by a group of second motors, so that power consumption cost and producing manufacturing cost of the stirrer are effectively reduced, and benefits of the enterprises are met.

Owner:长兴佳能高分子材料有限公司

A kind of concrete aggregate separation device and separation method thereof

Owner:内蒙古自治区水利水电勘测设计院有限公司

Particulate matter screening device used for salt manufacturing equipment and screening method of particulate matter screening device

InactiveCN112387577AImprove screening effectImprove screening qualitySievingScreeningParticulatesElectric machine

The invention discloses a particulate matter screening device used for salt manufacturing equipment. The particulate matter screening device comprises a truss, a fixed box is installed at the top of the truss, an air bellow is installed on one side of the fixed box, a driving motor is installed at one end of the fixed box, one end of the driving motor is connected with a reverser, a screening roller is arranged on the inner side of the fixed box, multiple sets of first screens are installed on the outer side of the screening roller at equal intervals, and a blocking strip is installed on the side, close to the first screens, of the outer side of the screening roller. A feeding barrel is installed on one side in the truss, a screening groove is formed in the screening roller, a screening inner barrel is arranged in the screening groove, multiple sets of second screens are mounted on the outer side of the screening inner barrel at equal intervals, and vibration motors are connected between the two sides of the screening groove and the inner walls of the two sides of the screening roller. The particulate matter screening device can well screen salt particulate matter, can keep salt particles dry, avoids adhesion and meanwhile is suitable for screening treatment of water-soluble fertilizer and wide in application range.

Owner:广东久鼎智能科技有限公司

Multi-stage screening machine for aquatic products

Owner:顺祥食品有限公司

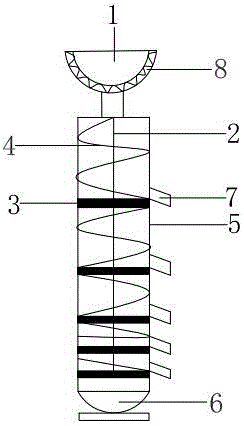

Spiral vibrating type classifying screen

InactiveCN106269473AReduce the chance of missingFine screening resultSievingScreeningDrive motorEngineering

The invention discloses a spiral vibrating type classifying screen. The spiral vibrating type classifying screen comprises a feeding hopper, a driving motor and a vibrating screen, and the vibrating screen is divided by a plurality of screen plates into a plurality of sub vibrating screens; a corresponding barrel is connected to the exterior of each sub vibrating screen, and one barrel, one screen plate, one sub vibrating screen and a corresponding center shaft form one screening compartment; and the hole diameters of screen holes of each screening compartments are the same, and the hole diameters of screen holes of the screening compartments are sequentially reduced from top to bottom. By means of the spiral vibrating type classifying screen, the spiral sub vibrating screens and the screen plates are adopted, screen holes are formed in the sub vibrating screens and the screen plates, and the sub vibrating screens and the screen plates are combined. The spiral sub vibrating screens conduct screening while conducting transporting, and screened materials are screened for the first time. When conveyed to the screen plates, the materials are screened for the second time, and the screened materials enter the next screening compartment. The sub vibrating screens and the screen plates both vibrate under the effects of the driving motor, double guarantees are achieved, the rate of leakage of wee materials is decreased, and the screening result is more exquisite.

Owner:CHENGDU DAHONGLI MACHINERY

Screening device for coal mining

PendingCN114558771AImplement filteringReduce processing stepsSievingScreeningMining engineeringCrusher

The invention discloses a screening device for coal mining. The screening device comprises a feeding port, and a conveying pipe is installed at the bottom of the feeding port; the crushing mechanism communicates with the bottom end of the conveying pipe, the crushing mechanism comprises a transversely-arranged crushing cylinder, and a crushing assembly is installed in the crushing cylinder; the screening mechanism communicates with one side of the bottom end of the crushing barrel, the screening mechanism comprises a screening chamber, and a coarse screening net and a fine screening net are sequentially and obliquely arranged in an inner cavity of the screening chamber; the circulating mechanism comprises a circulating chamber, the circulating chamber communicates with the screening chamber and is located above the fine screening net, the other end of the circulating chamber communicates with the bottom of the feeding opening through a feeding barrel, and a spiral conveying belt is rotationally connected into the feeding barrel; the whole device can achieve screening and filtering, unqualified raw materials are circularly crushed again, machining procedures are reduced, and the production efficiency is improved.

Owner:周园

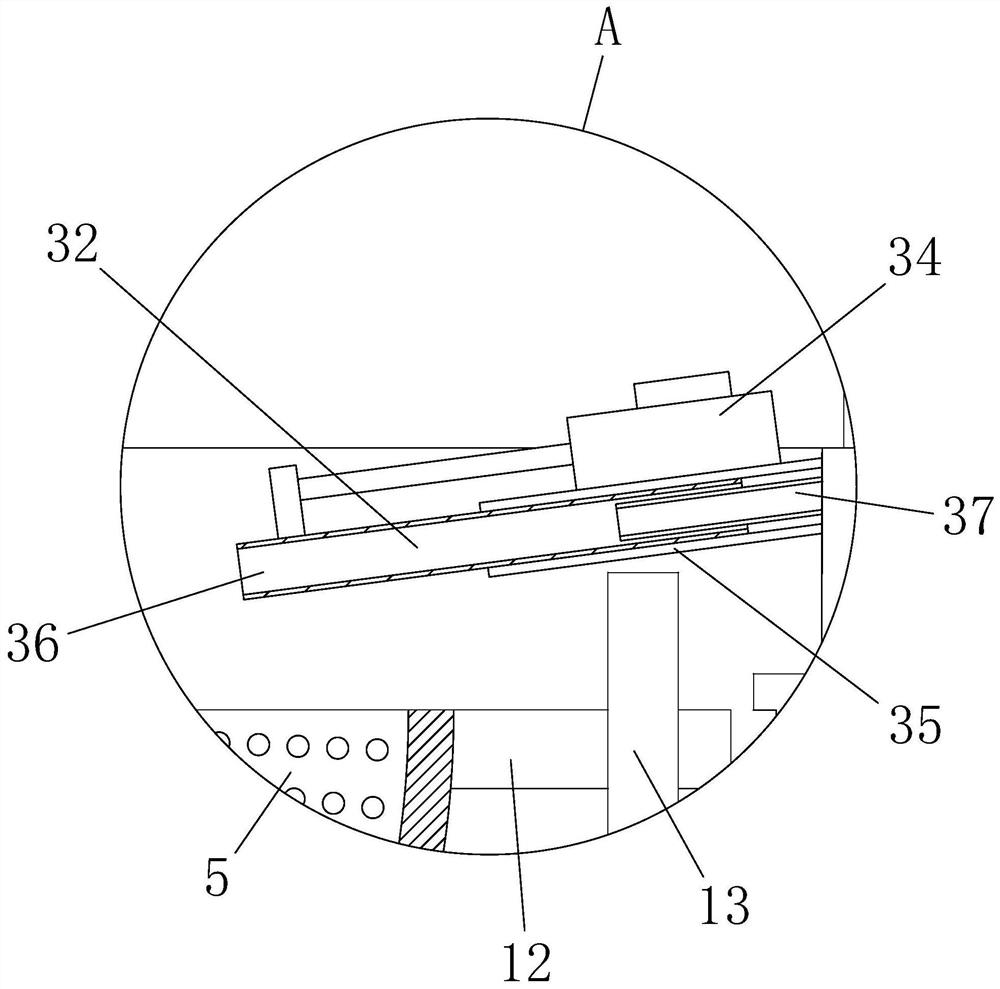

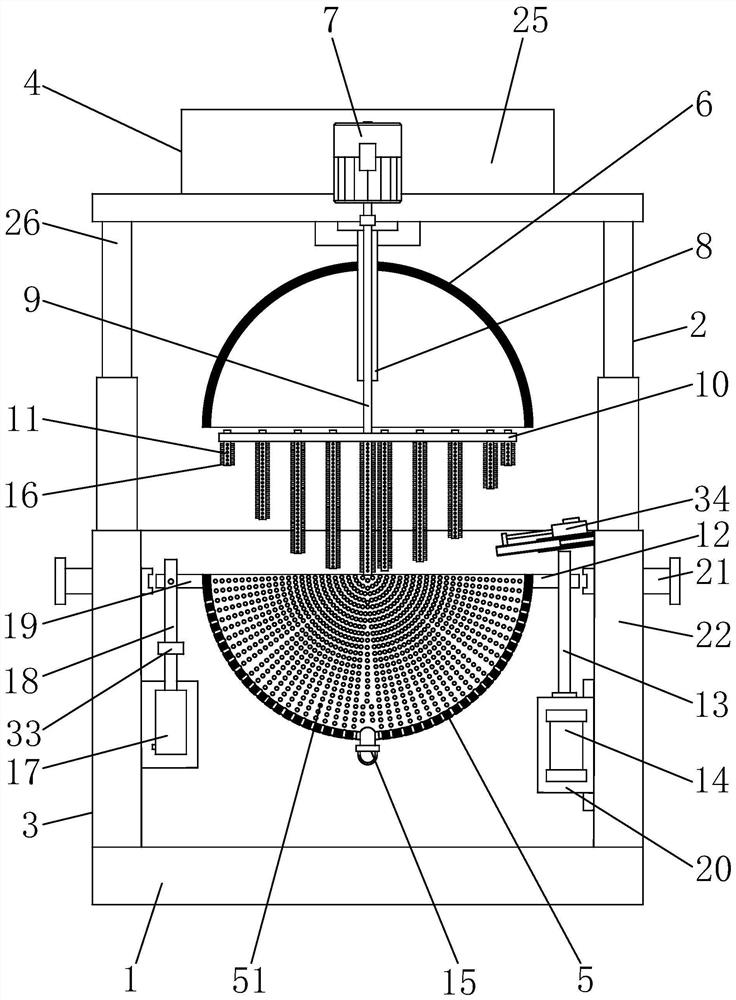

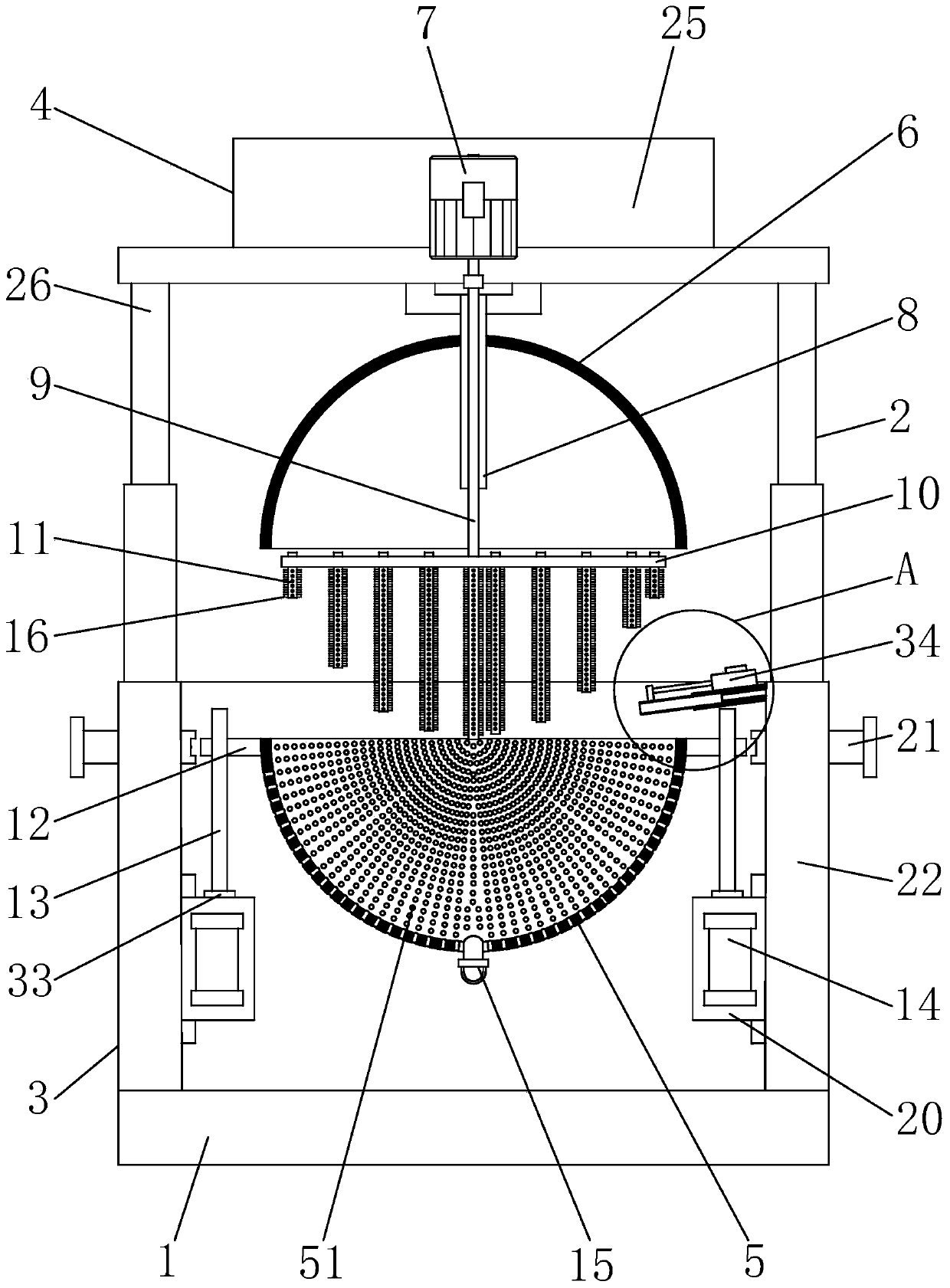

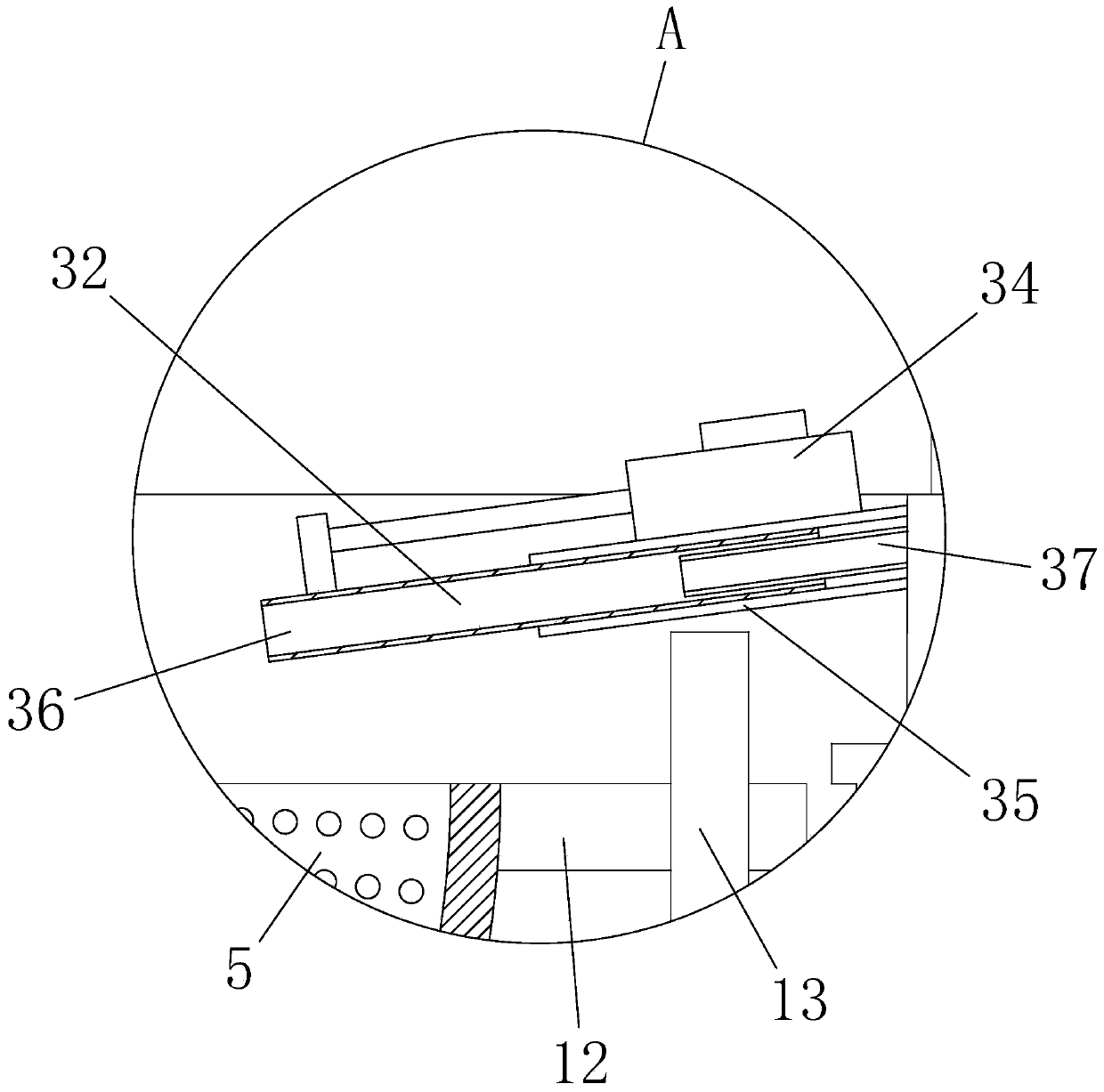

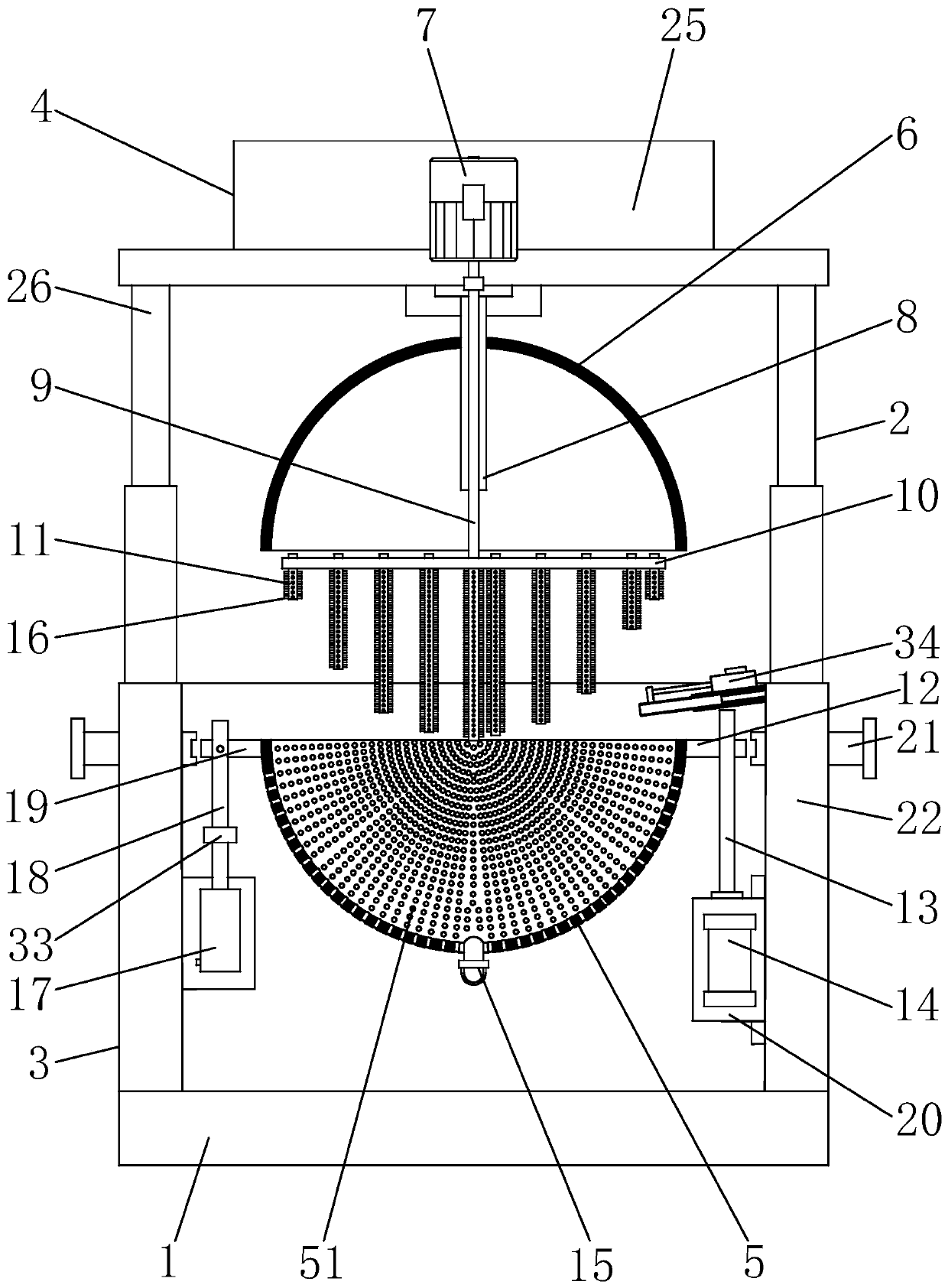

Concrete aggregate separation device and separation method thereof

The invention discloses a concrete aggregate separation device and a separation method thereof. The device comprises a base, a separation platform, a separation pot, a protective cover, a weight measuring mechanism, a feeding mechanism, a stirring assembly and a controller, wherein the separation platform comprises a fixing frame and a lifting frame; the separation pot is installed in the fixing frame and is used for separating concrete aggregates; the protective cover is mounted on the lifting frame and covers the separation pot; the weight measuring mechanism is used for detecting the real-time weight of the concrete aggregates; the feeding mechanism is arranged on the fixing frame, and the discharging end is an obliquely telescopic end; the stirring assembly comprises a driving mechanism, a limiting pipe, a driving rod, a positioning plate and a plurality of stirring rods; and the controller is used for feeding, stirring and separating the separating pot through the driving mechanism, the lifting frame and the telescopic end. According to the concrete aggregate separation device and the separation method thereof, dust generated by separation is prevented from overflowing, so that operation safety and health of operators are guaranteed, and air pollution is avoided; and utilization rate of aggregate separation is improved, so that manual feeding is avoided, and operation safety is improved.

Owner:内蒙古自治区水利水电勘测设计院有限公司

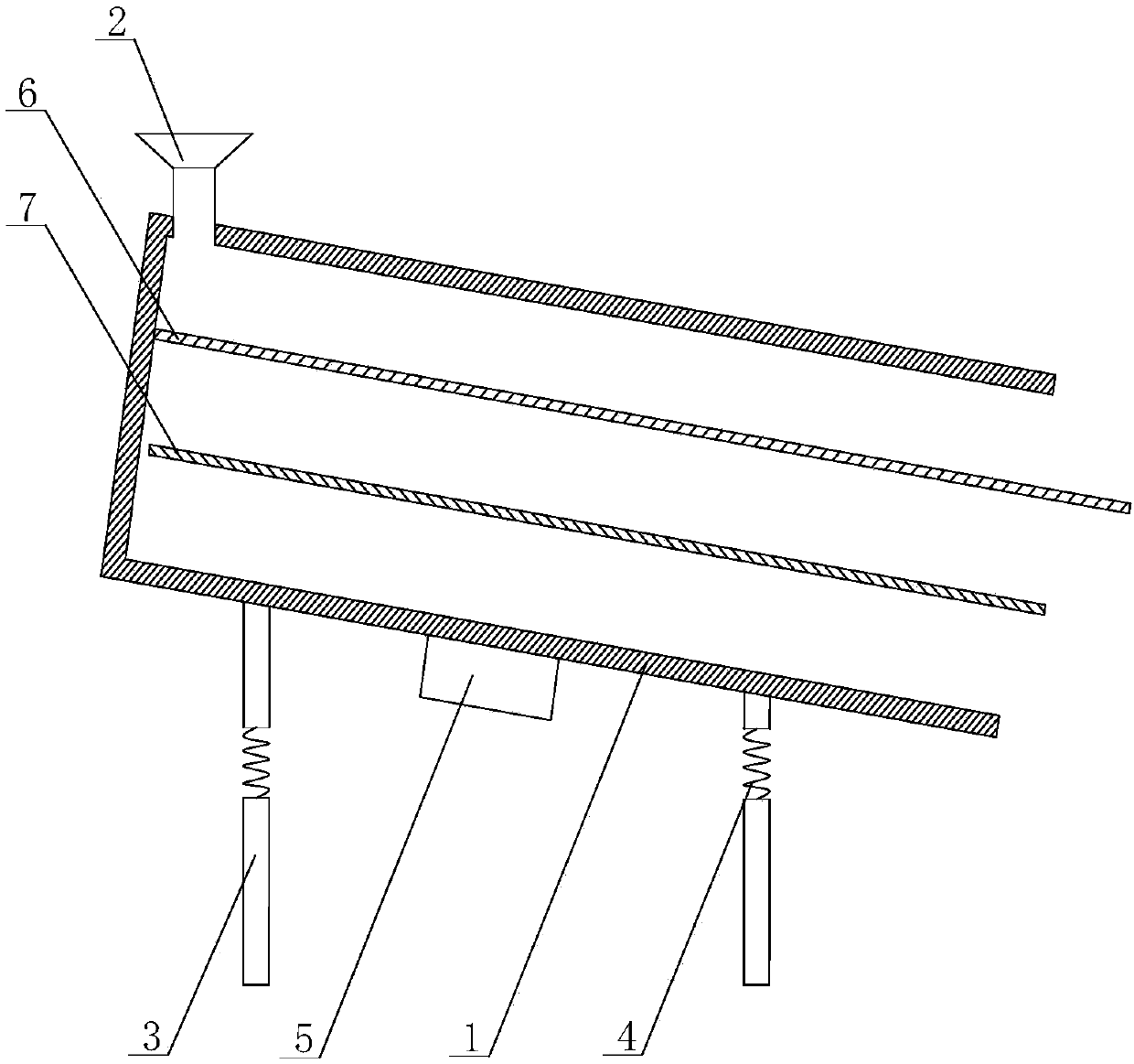

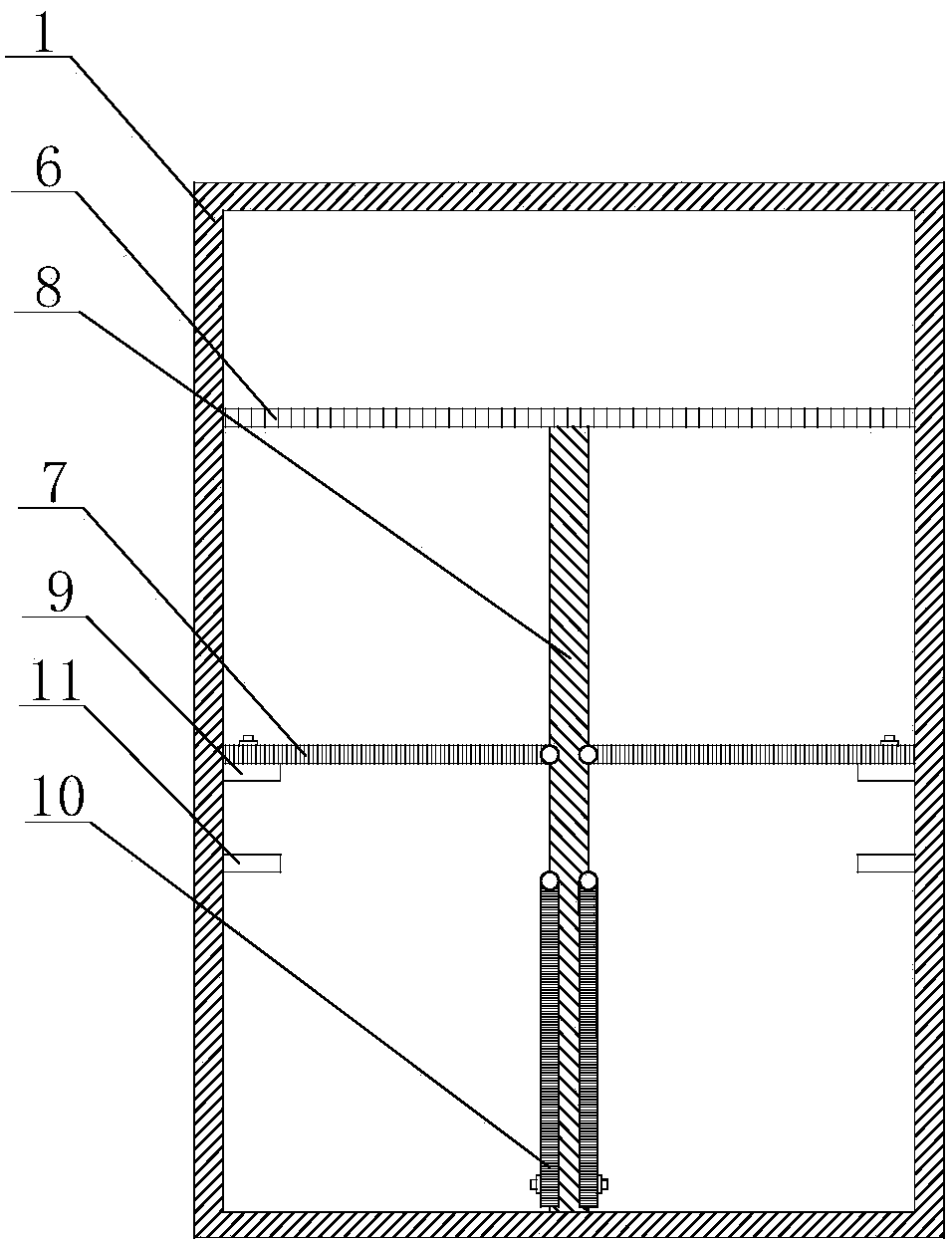

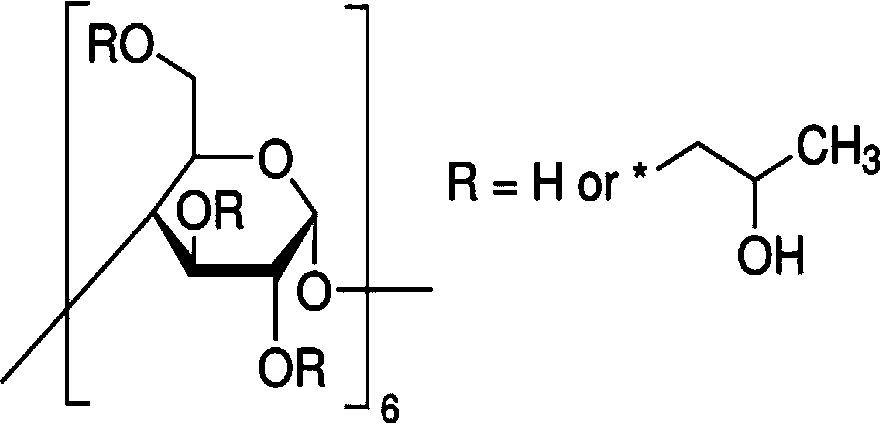

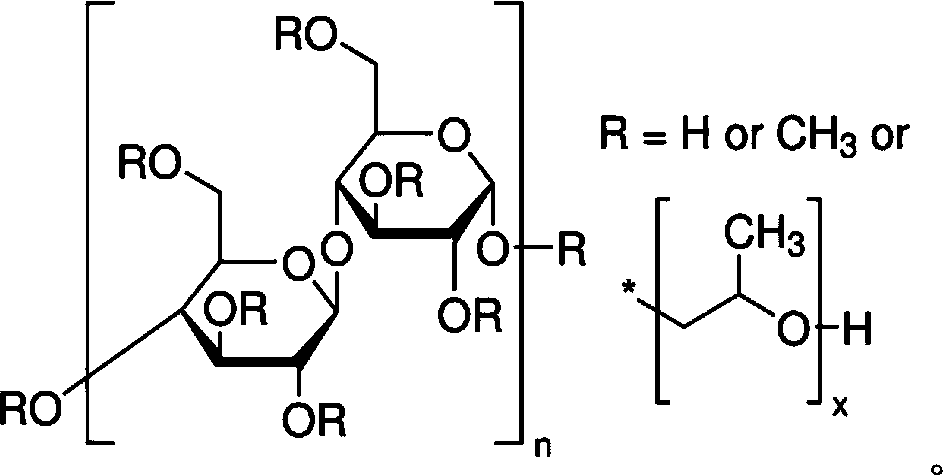

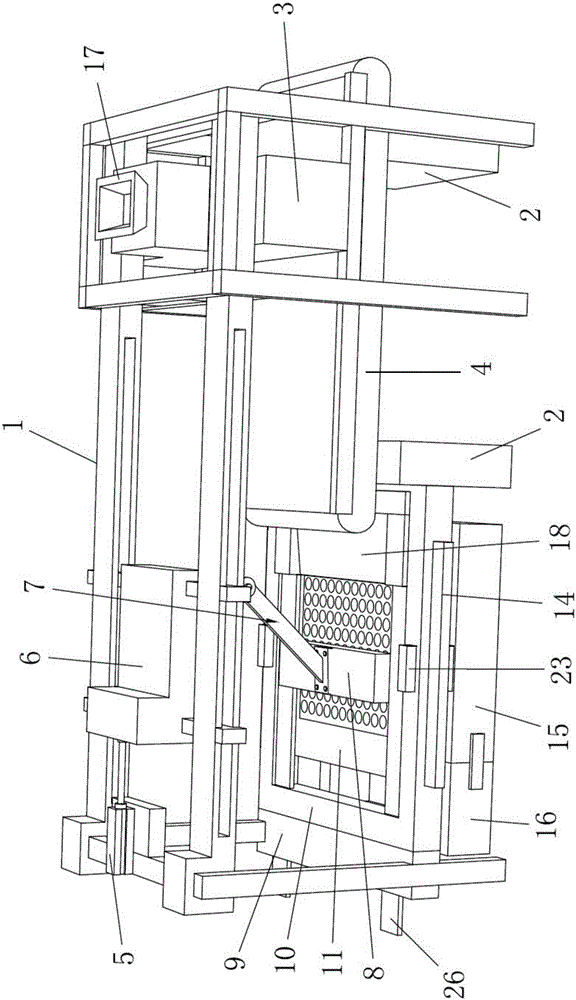

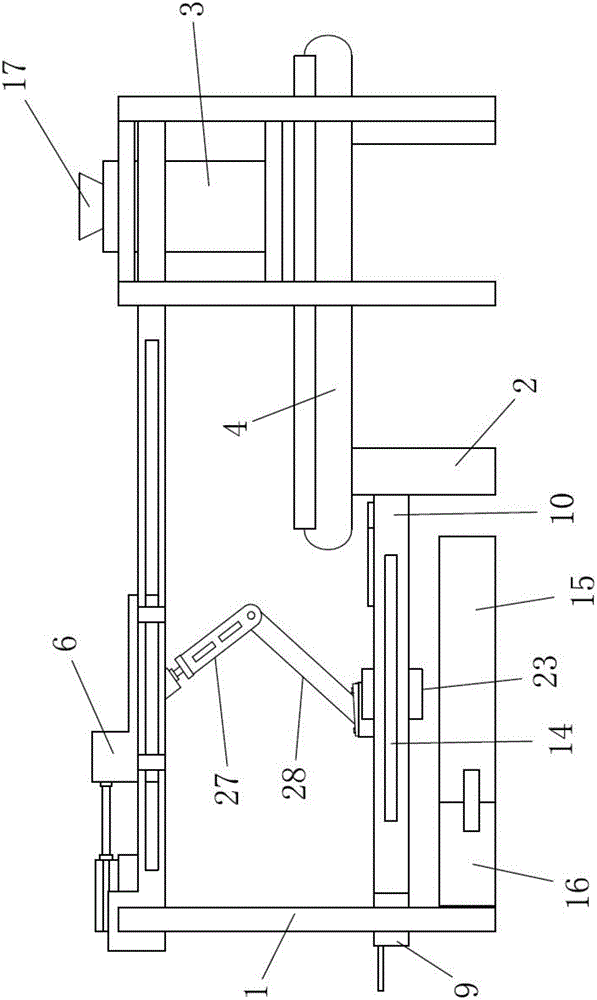

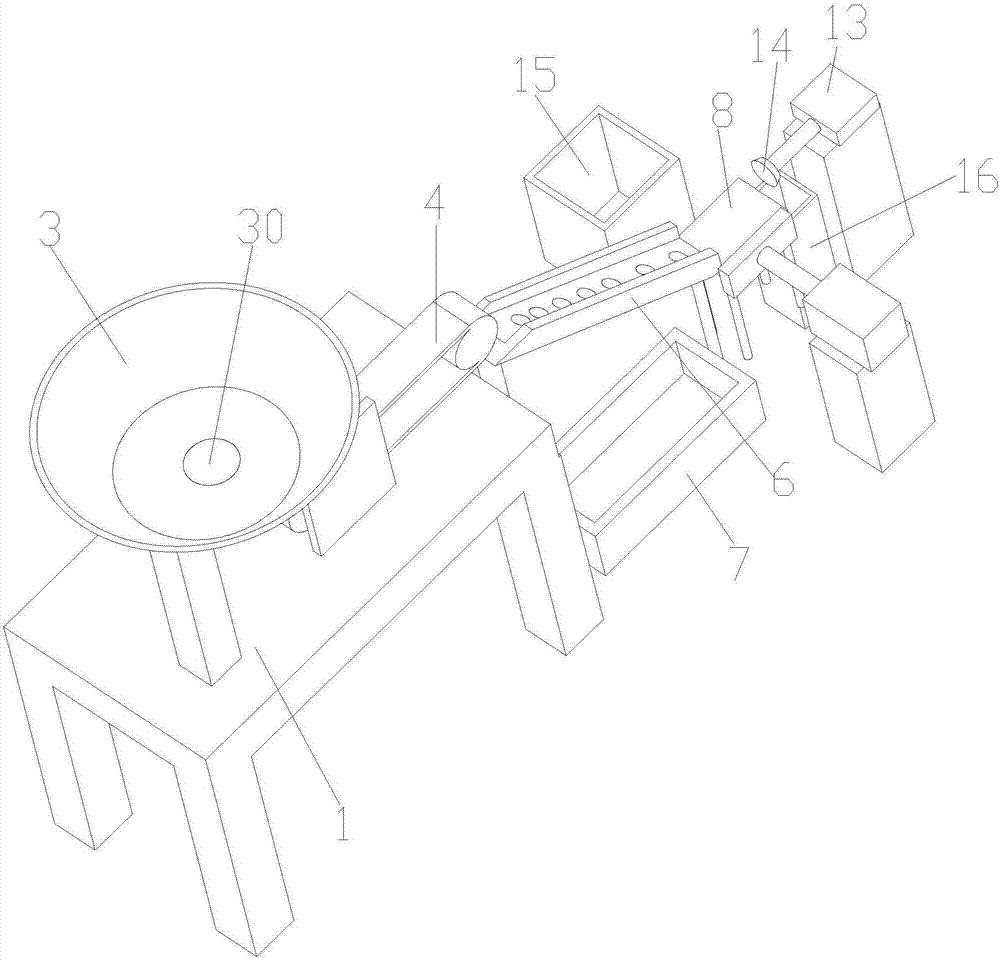

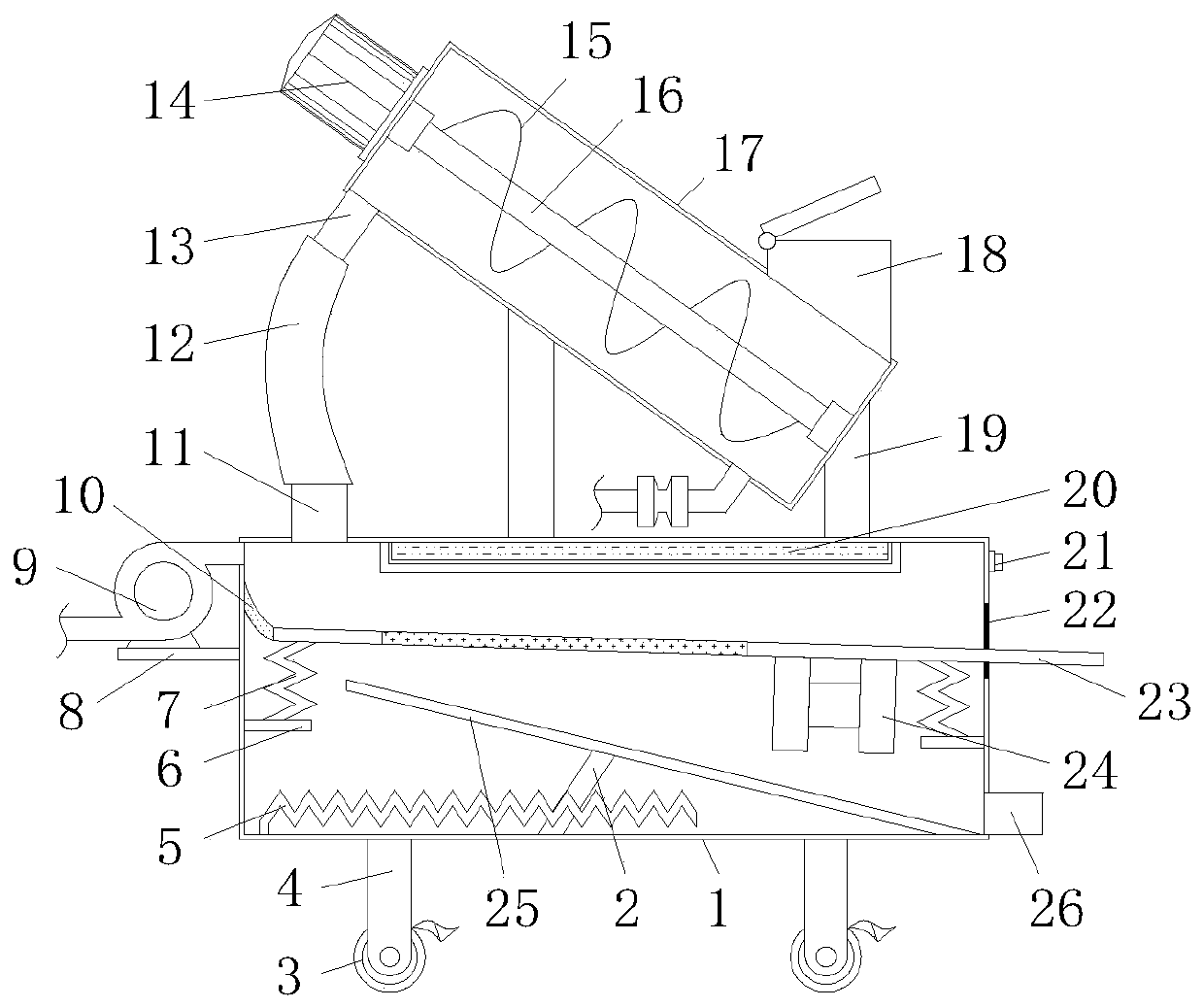

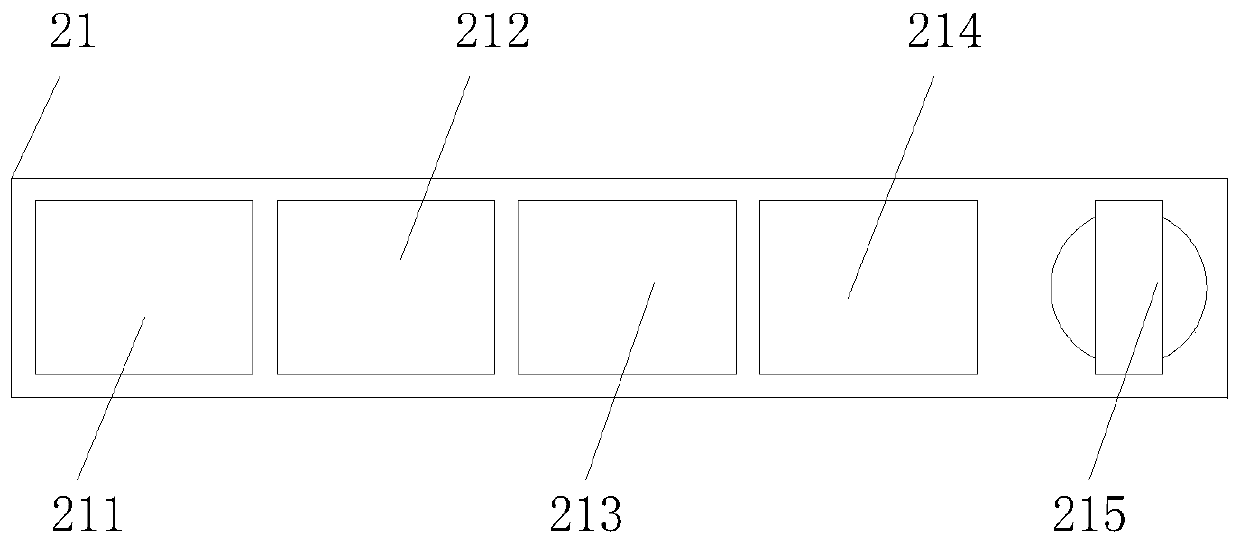

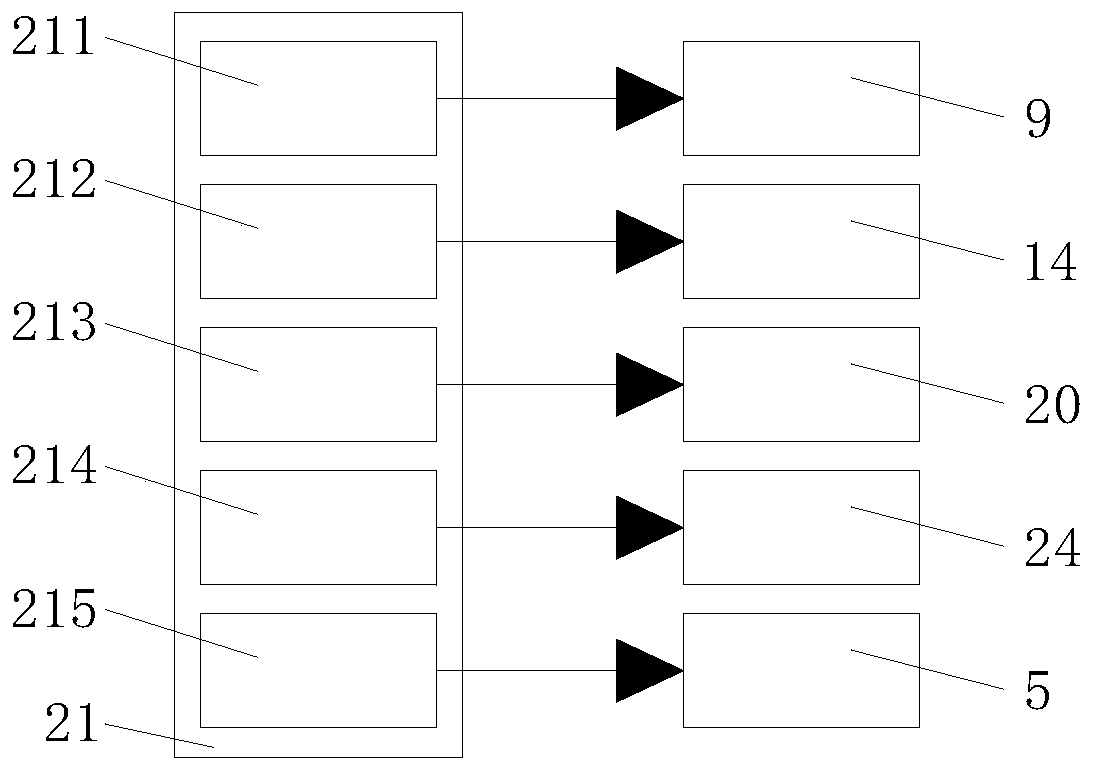

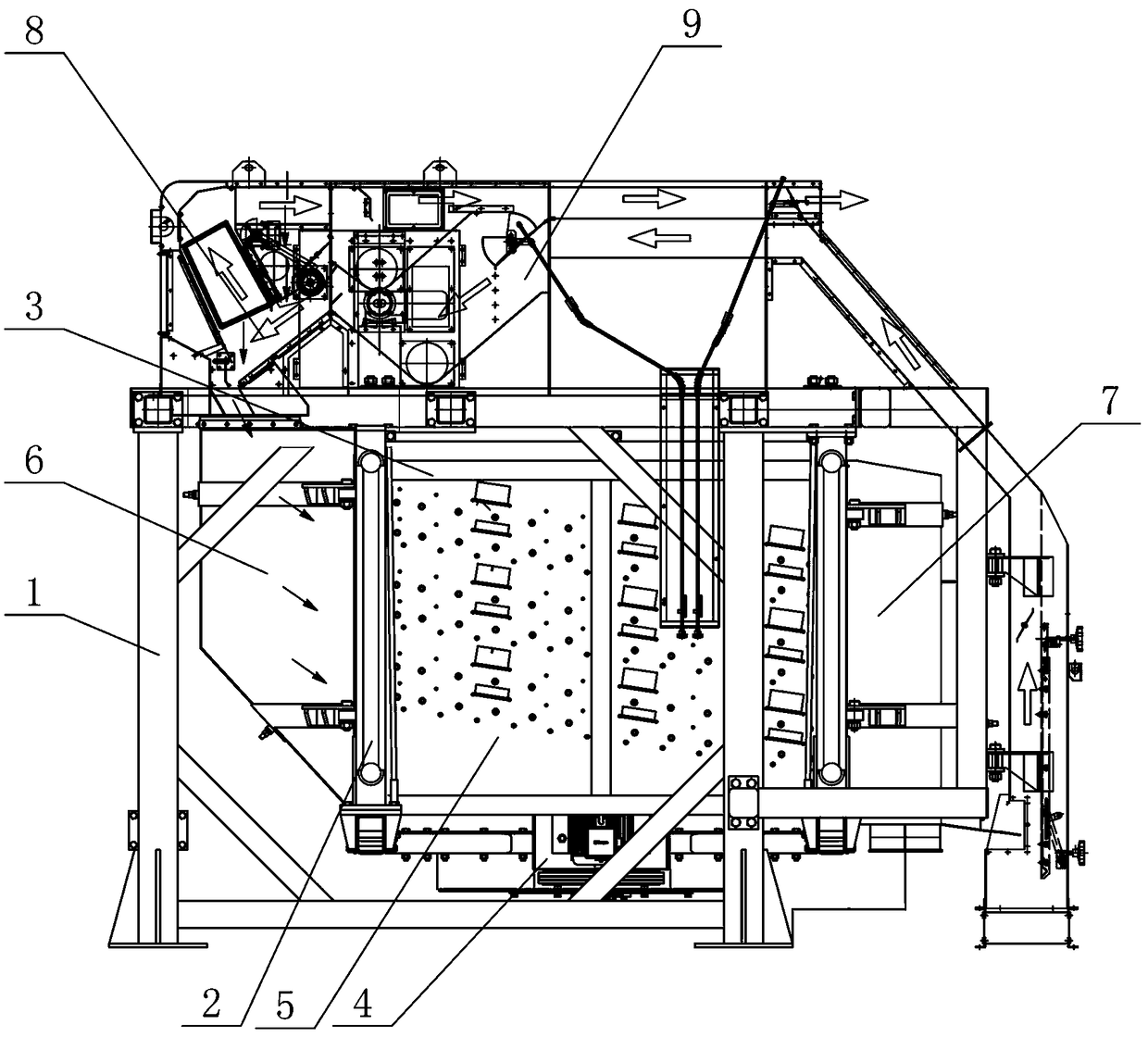

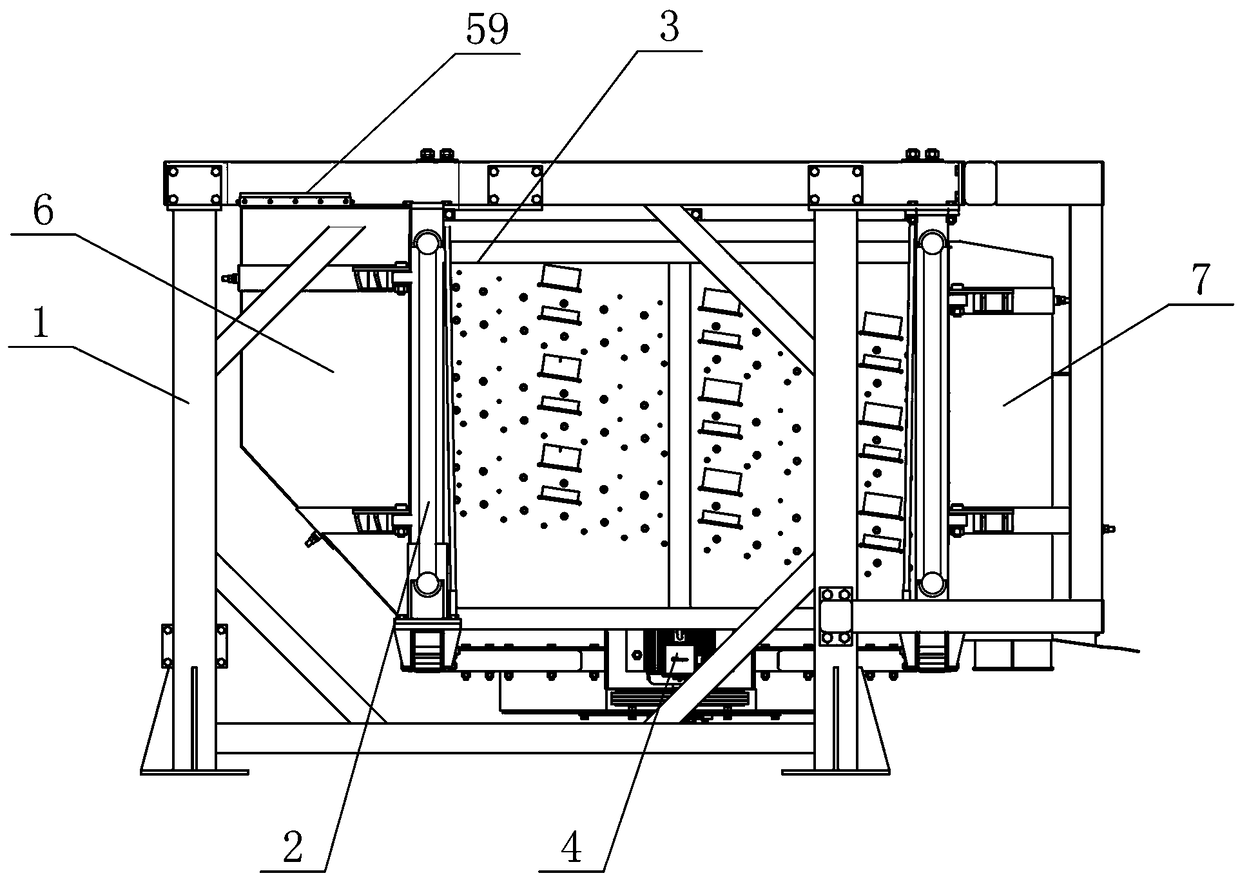

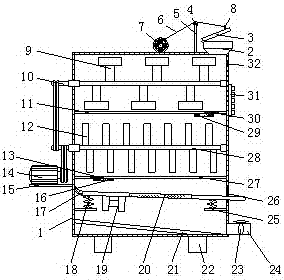

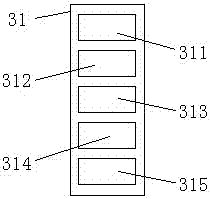

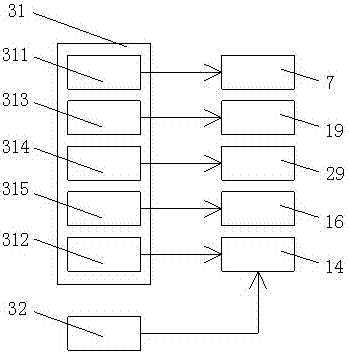

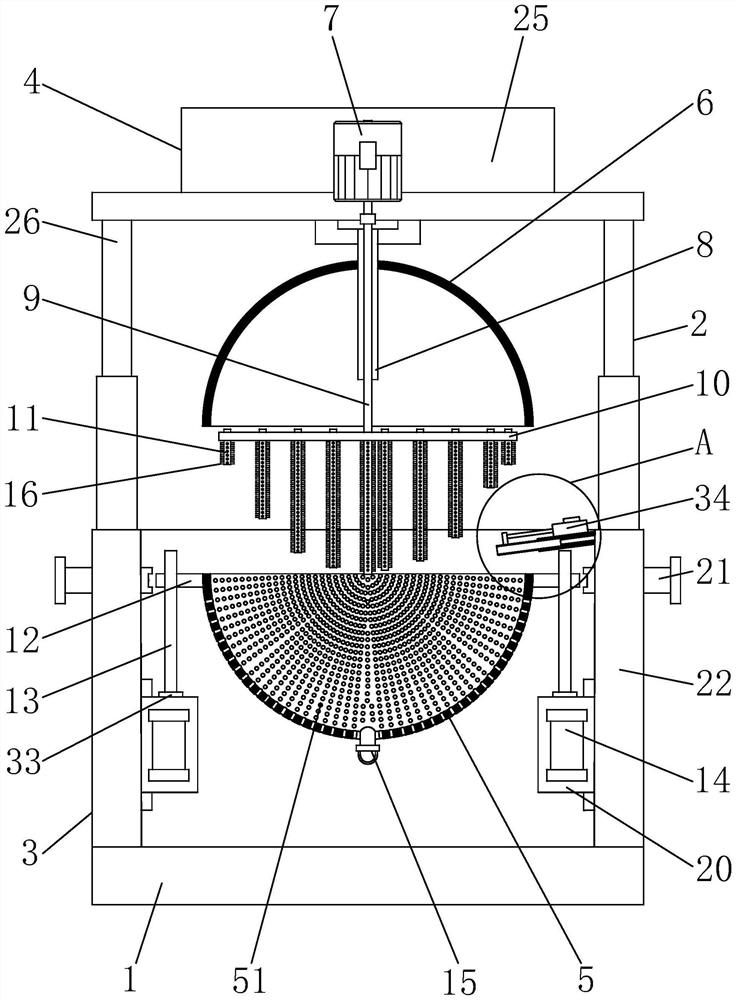

Catalysis alcoholysis method used for producing and preparing [beta]-thymidine

PendingCN112375113AImprove efficiencySatisfy the needs of alcoholysisBioreactor/fermenter combinationsSequential/parallel process reactionsProcess engineeringRaw material

The invention discloses a catalysis alcoholysis method used for producing and preparing [beta]-thymidine. The catalysis alcoholysis method comprises a raw material tank, a first reaction tank, a second reaction tank and a third reaction tank, wherein the right side of the raw material tank communicates with the left side of a mixing and material adding tank; the lower end of the mixing and material adding tank communicates with the upper end of a large sieving device through a pipeline; the right end of the first reaction tank, the right end of the second reaction tank and the right end of thethird reaction tank are independently connected with the left end of a first catalysis tank, the left end of a second catalysis tank and the left end of a third catalysis tank; in addition, the upperend of the first reaction tank, the upper end of the second reaction tank and the upper end of the third reaction tank are connected with the lower end of the large sieving device; and in addition, the lower end of the first catalysis tank, the lower end of the second catalysis tank and the lower end of the third catalysis tank are connected with the upper end of a finished product cabin. The alcoholysis method used for producing and preparing the [beta]-thymidine has various catalysis ways, is high in efficiency and can meet alcoholysis requirements under different temperatures. Meanwhile, asieving system is arranged so as to be more convenient in use, and the market utilization requirements at present can be met.

Owner:JIANGXI CHENGZHI BIOENG

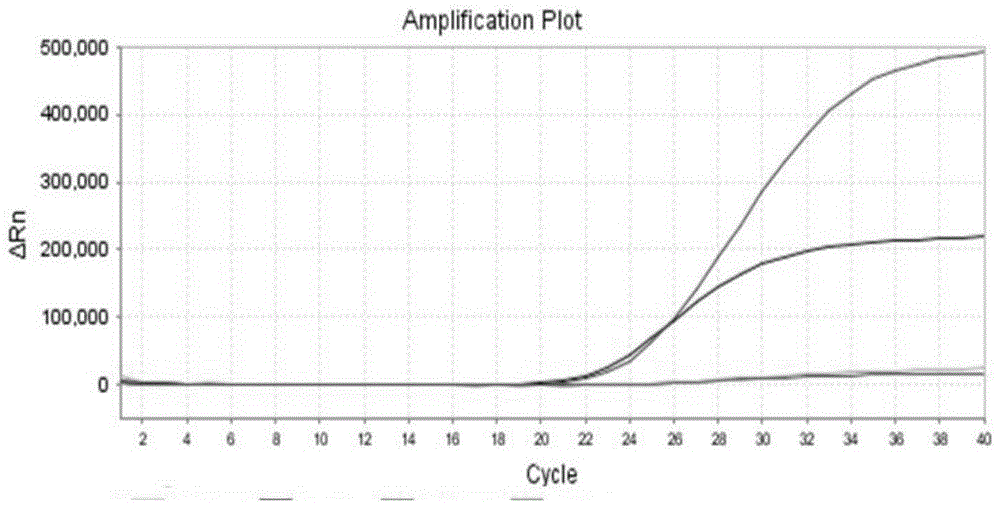

Primers, probes and kits for detecting g6pd deficiency gene mutation

ActiveCN104450925BMeet screening needsReduce testing costsMicrobiological testing/measurementDNA/RNA fragmentationGene mutationDetection rate

The invention relates to primers for detecting gene mutation caused by G6PD deficiency disease. The primers are as shown in SEQ ID NO: 1-32. The invention further relates to probes for detecting gene mutation caused by G6PD deficiency disease. The probes are as shown in the sequences SEQ ID NO: 33-67. The invention further relates to a kit for detecting gene mutation caused by G6PD deficiency disease. The kit comprises a PCR reaction liquid I, a PCR reaction liquid II and a PCR reaction liquid III. The kit for detecting gene mutation caused by G6PD deficiency disease provided by the invention has the advantages of high coverage rate, high detection rate of female heterozygote, low cost and high accuracy.

Owner:亚能生物技术(深圳)有限公司

Hanging type inertia rotary sieve machine

PendingCN110694891AReduce noiseHigh working reliabilitySievingScreeningDrive wheelClassical mechanics

The invention provides a hanging type inertia rotary sieve machine comprising a rack and a sieve body hung on the rack through a hanging mechanism. The hanging type inertia rotary sieve machine is characterized in that the sieve body is arranged to be an upper sieve frame and a lower sieve bracket; a rear door is hinged to the rear end of the sieve frame, and a discharge part is hinged to the front end of the sieve frame; the sieve frame is internally provided with a plurality of bosses or clamping grooves symmetrically; a sieve plate is placed on each symmetrical boss or clamping groove; thesieve bracket comprises front and rear vertical plates; a crossbeam is connected between the front and rear vertical plates; a mounted bearing is arranged in the middle of the crossbeam and is rotationally connected with the middle of a vertical rotary shaft; an eccentric disc or a partial heavy wheel is fixed to the upper end of the vertical rotary shaft; and a partial heavy wheel is fixed to thelower end of the vertical rotary shaft and is connected with a driving wheel on a power machine output shaft through a driving belt. The movement locus of the sieve body is in a plane round shape ora plane oval shape, noise is lowered, the complete machine does not walk or jump any longer, working is high in reliability and stable, the number of layers of the sieve plates can be increased or decreased as needed, the sieve plates are replaced, and sieving needs are met.

Owner:腾翎机械科技(云南)有限公司

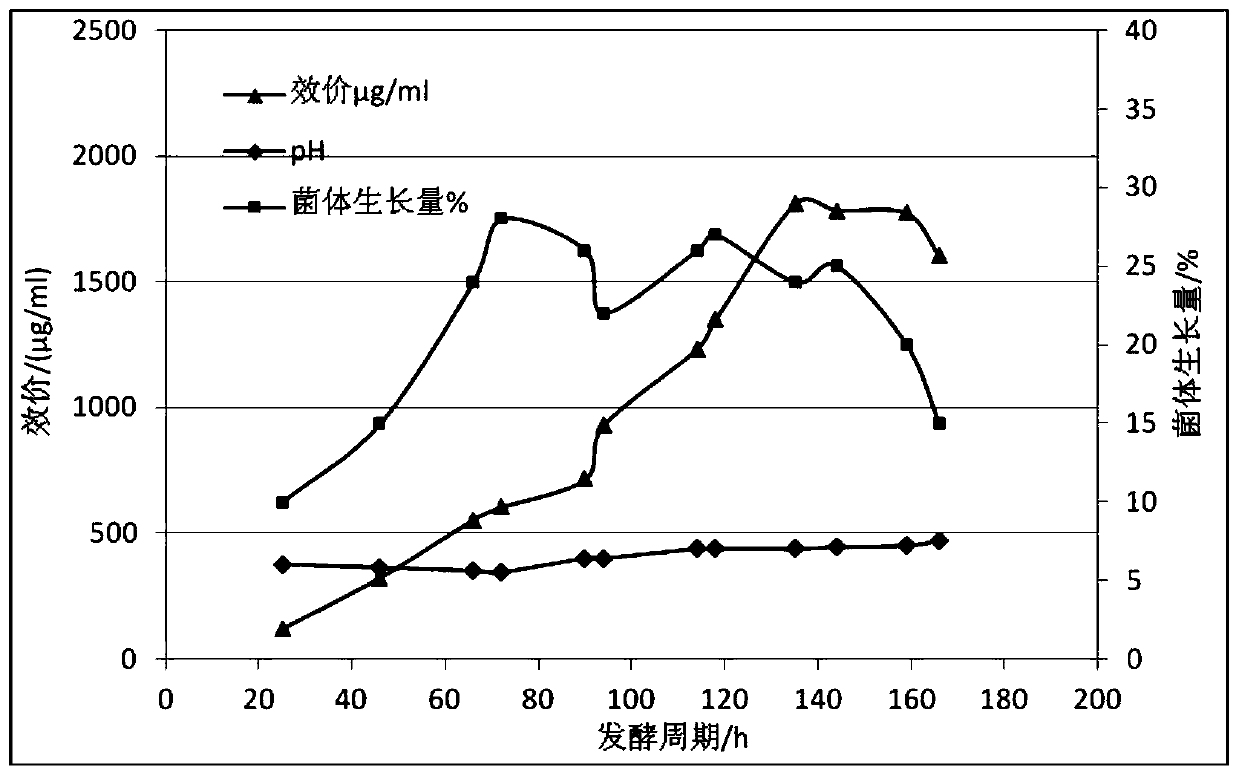

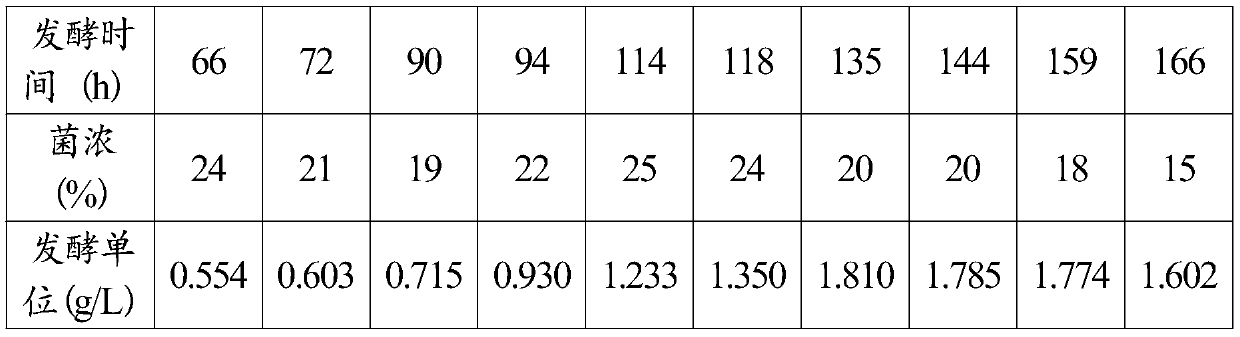

Scleroderma, application, fermentation medium and preparation method of PF1022A

ActiveCN110964646AGrow fastReduce concentrationFungiMicroorganism based processesBiotechnologyMicroorganism

The invention discloses a Rosellinia strain, its application, a fermentation medium and a preparation method of PF1022A. The Rosellinia strain has been preserved in the China General Microbiological Culture Collection Center, and the preservation number is CGMCC No. 18132. The Rosellinia strain is used for production of PF1022A, and has advantages of fast mycelium growth, low mycelium concentration, short fermentation time and high fermentation unit.

Owner:CHENGDU UNIV

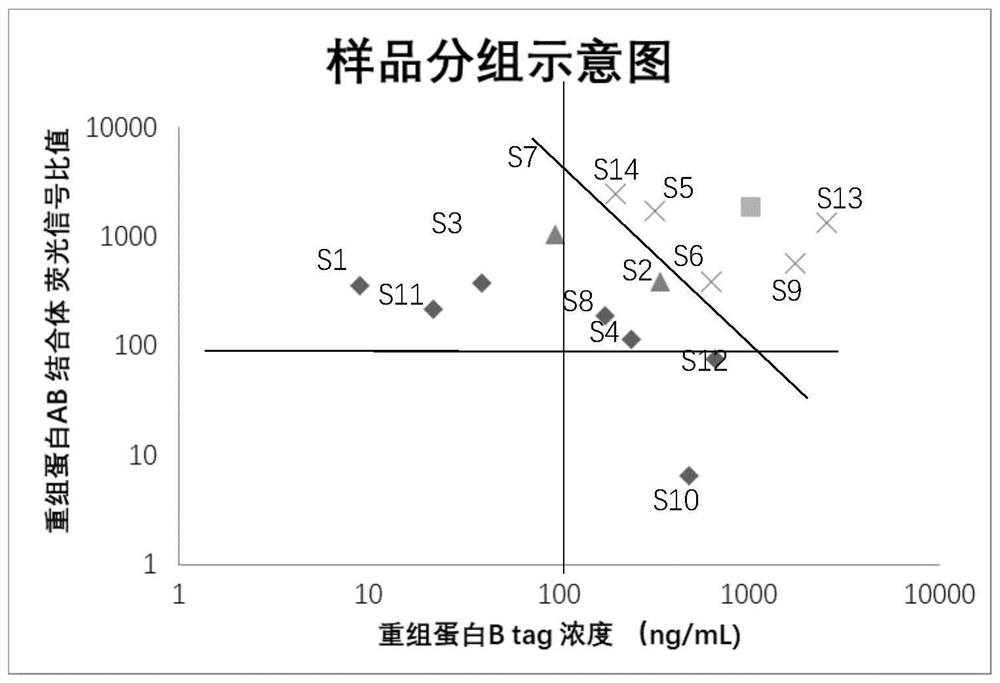

Method for detection of biological activity and titer of co-expressed recombinant human protein based on multiple time-resolved fluorescence techniques

ActiveCN108645828BMeet screening needsLow costBiological testingFluorescence/phosphorescenceHuman proteinsCell strain

The invention discloses a co-expressed recombinant human protein biological activity and titer detection method based on multiple time-resolved fluorescence techniques, which includes the following steps: 1. Any two or three of the following methods are adopted: method 1, Competition method to determine one or two recombinant human proteins; method two, sandwich method to determine one or two recombinant human proteins; method three, sandwich method to determine two recombinant human protein fusion protein conjugates; two, set the fluorescence wavelength, read Take the fluorescence value; 3. Data processing: get the standard curve according to the ratio of the fluorescence and the concentration of the standard, and calculate the sample concentration; 4. Sorting the samples: assign the detection values of the above method to the X, Y and Z axis coordinates of the sample to obtain the sample Position in the coordinate system; define an acceptable standard interval, and all samples falling within this interval meet the requirements. The invention can systematically and high-throughput evaluate the activity / titer of each component of the recombinant human protein produced by co-expression, so as to support production cell line clone screening and purification process optimization.

Owner:SHANGHAI WUXI BIOLOGIC TECH CO LTD

Utilization method of traditional Chinese medicine screening machine

InactiveCN107716280ASimple and efficient operationSave operating timeSievingScreeningHerbEngineering

The invention discloses a method for using a traditional Chinese medicine screening machine. (A) Loosen the fixing screw, rotate the first rotating screen to the first limiting plate, and fix the first rotating screen on the first limiting plate; (B) Turn on the vibrating motor and pour the medicinal materials to be screened from the feed port; (C) The soil and sand separated from the medicinal materials fall onto the first rotary screen for further screening, and part of the soil and sand are screened out After the stone, the smaller medicinal materials, soil, and sand fall to the bottom of the box; (D) Loosen the fixing screws, rotate the first rotating screen to a position parallel to the partition, and pass the fixing screws through the first Screw holes, fixing screw holes and tighten. The operation of the present invention is very simple and fast, which meets the requirements for efficiency in the production process, saves operating time and reduces the workload; at the same time, the operation of the present invention is very flexible, and according to the conditions of different medicinal materials to be screened, the screen can be quickly adjusted to obtain Good screening effect.

Owner:周孝劼

Crushing device for food processing

InactiveCN113617431AAdjustable spacingReduce sizeSievingDispersed particle filtrationAgricultural engineeringStructural engineering

The invention discloses a crushing device for food processing, and belongs to the technical field of crushing devices. The crushing device comprises a crushing box body, wherein a feeding hopper is arranged at the upper end of the crushing box body, a discharging hopper is arranged at the lower end of the crushing box body, an air purifying mechanism is arranged on one side of the crushing box body, a crushing mechanism is arranged in the crushing box body, the crushing mechanism comprises two sets of crushing rollers erected in the crushing box body, the crushing rollers are driven by a second motor to crush raw materials, and a distance between the two sets of crushing rollers can be adjusted, so that the size of crushed particles is controlled, the requirements of different sizes are met, the applicability is high, the crushing rollers and the second motor move by moving a fixing plate and finally are fixed in fixing screw holes through fixing bolts, then the fixing plate is fixed, the operation is simple, the adjustment is convenient, and the requirements of different sizes of finished food products are met.

Owner:田金举

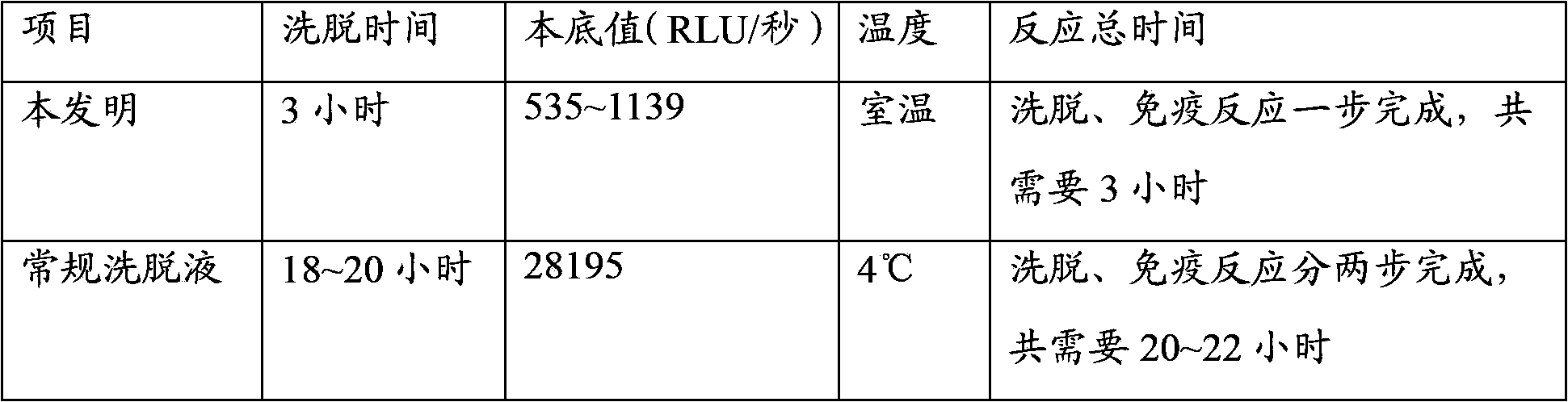

Protein eluent for dried blood spots on filter paper

InactiveCN102680678BHigh and stable elution rateLow costMaterial analysisBlood filter paperDried blood

The invention discloses an efficient protein eluent, which comprises a surfactant, a stabilizer, an assistant stabilizer and a buffer. Preferably, the protein eluent disclosed by the invention further comprises an antiseptic. The protein eluent can effectively elute the proteins on the dried blood spots on filter paper, can remarkably reduce the interference of other substances in whole blood on immunodetection, and has the characteristics of strong specificity, low cost and good preparation easiness, therefore, the protein eluent has extensive application prospect in newborn disease screening featured by the use of protein as detection marker and of immunodetection techniques.

Owner:BEIJING YUANDE BIO MEDICAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Catalysis alcoholysis method used for producing and preparing [beta]-thymidine Catalysis alcoholysis method used for producing and preparing [beta]-thymidine](https://images-eureka.patsnap.com/patent_img/0c58cd73-f1b4-474a-b648-8f16472fc128/HDA0002763725290000011.png)

![Catalysis alcoholysis method used for producing and preparing [beta]-thymidine Catalysis alcoholysis method used for producing and preparing [beta]-thymidine](https://images-eureka.patsnap.com/patent_img/0c58cd73-f1b4-474a-b648-8f16472fc128/HDA0002763725290000012.png)