Multi-stage screening machine for aquatic products

A technology for aquatic products and screening machines, which is applied in the directions of filter screen, solid separation, grid, etc., can solve the problems of low utilization rate of equipment and single use, and achieve the effect of ensuring interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

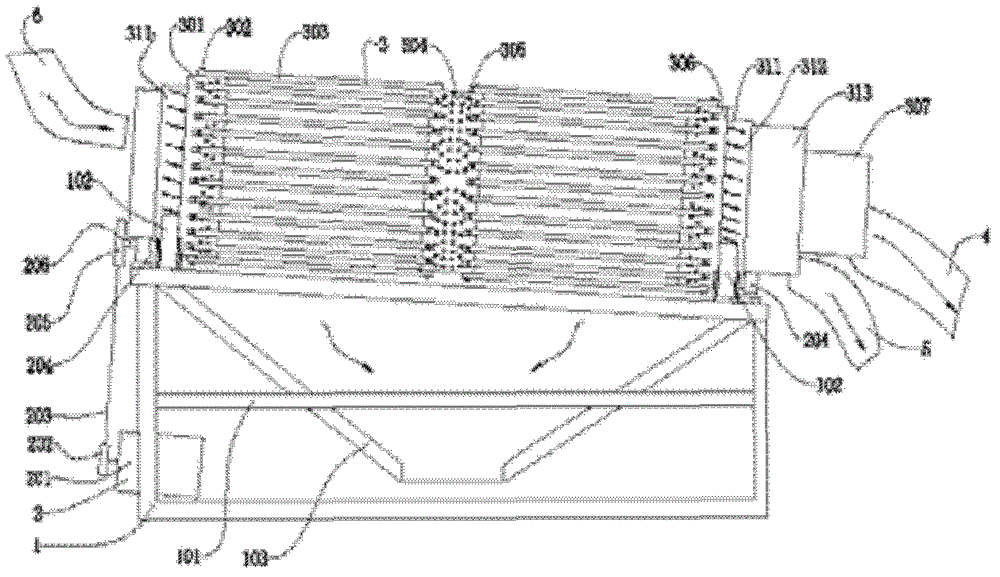

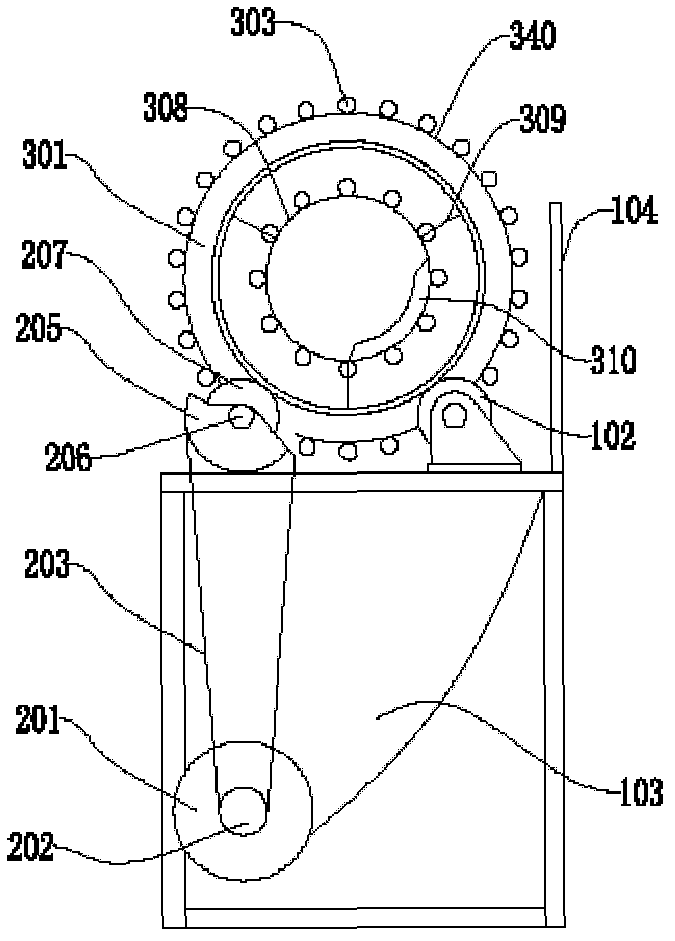

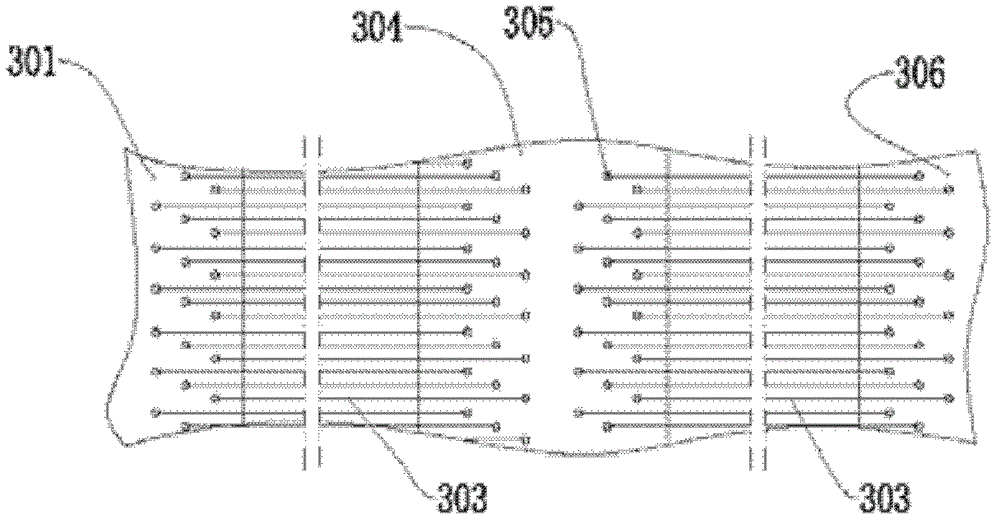

[0029] Such as figure 1 As shown, a multi-stage screening machine for aquatic products of the present invention includes a frame 1 , a power transmission device 2 mounted on the frame 1 and a cage 3 mounted on the frame 1 .

[0030] The frame 1 includes a frame body 101 , two support rollers 102 installed on the top surface of the frame body 101 , a hopper 103 , and a baffle plate 104 vertically installed on the top surface of the frame body 101 . The frame body 101 is welded into a frame structure with profiles. The baffle plate 104 is adjacent to the support roller 102 and is located at one side of the drum 3 to prevent the aquatic products inside from being thrown out when the drum 3 rotates. The receiving hopper 103 is installed in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com