Screening type crushing device for food processing

A technology for food processing and crushing devices, applied in sieves, solid separation, separation methods, etc., can solve the problems of affecting the screening efficiency, staying on the screen, reducing production efficiency, etc., achieving high-efficiency screening efficiency, easy adjustment, The effect of high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

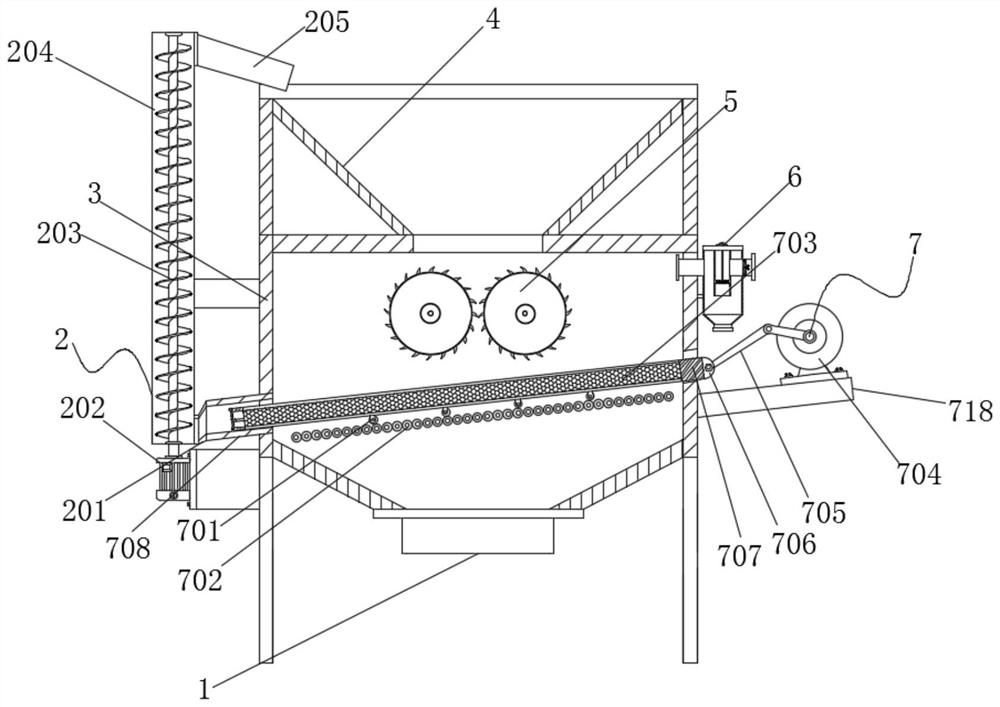

[0034] A screening type crushing device for food processing, comprising a crushing box 3 and a screening mechanism 7, the upper end of the crushing box 3 is provided with a feed hopper 4, the lower end of the crushing box 3 is provided with a discharge hopper 1, and the crushing box 3 One side of 3 is provided with cleaning mechanism 6, and the interior of crushing box 3 is provided with crushing mechanism 5;

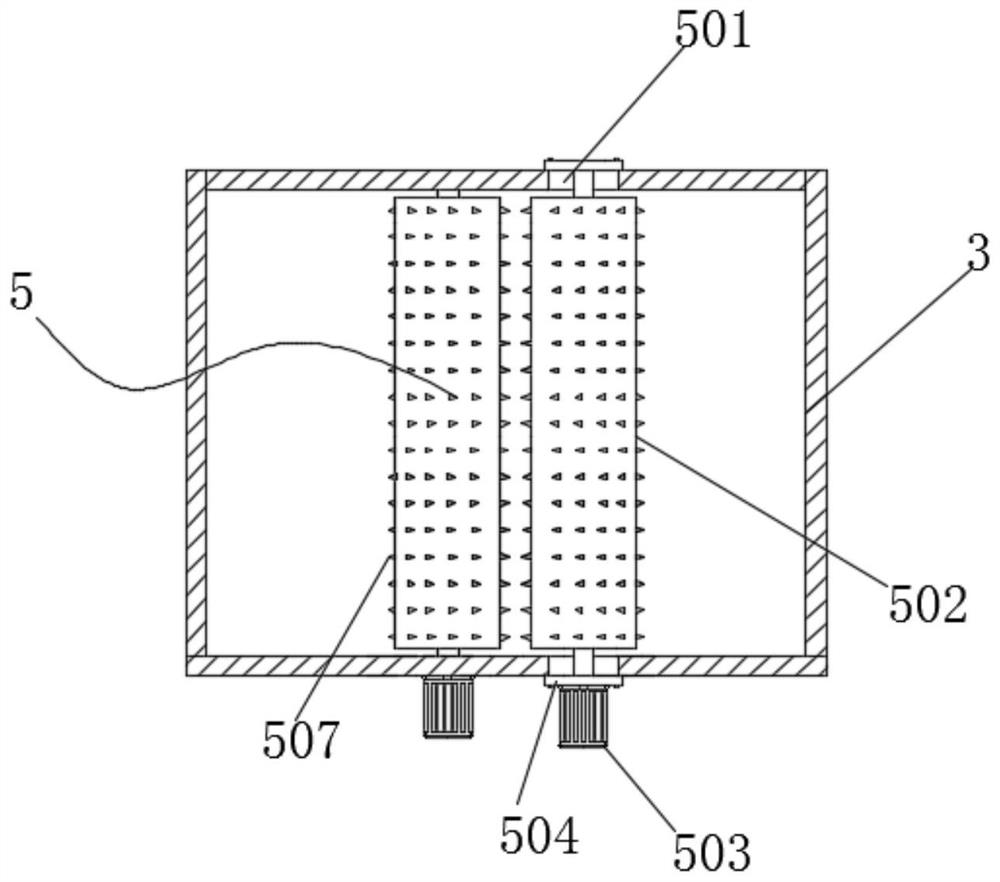

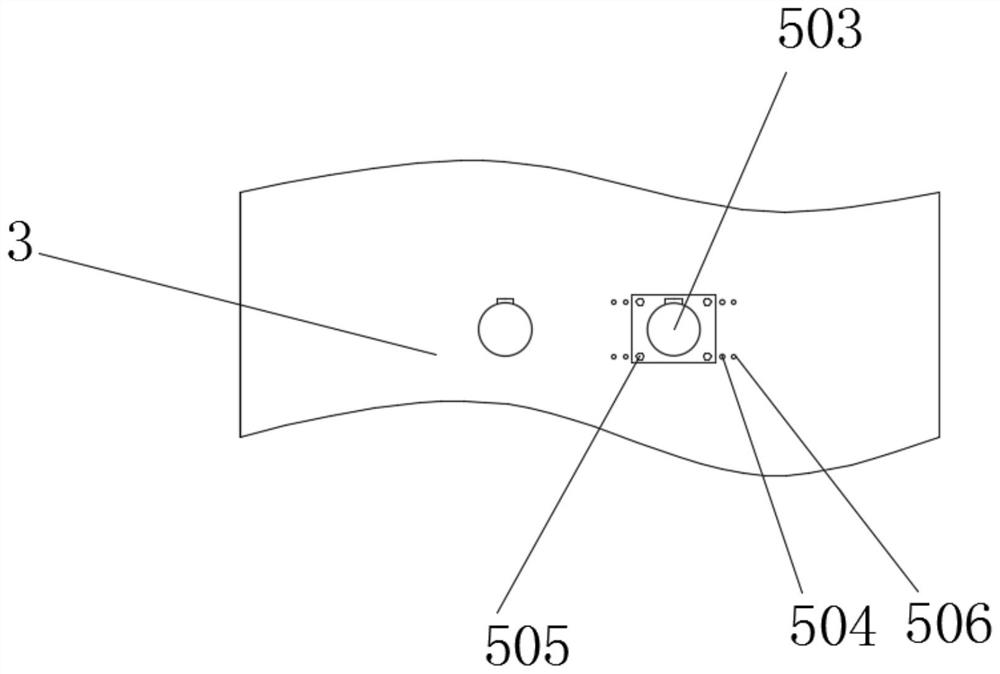

[0035] The crushing mechanism 5 includes crushing rollers 502 erected inside the crushing box 3. The crushing rollers 502 are provided with two groups. The plate 504 and the fixed plate 504 are arranged on the outer wall of the crushing box 3, the outer wall of the crushing box 3 close to the fixed plate 504 is provided with a first notch 501, and the end of the crushing roller 502 protruding from the crushing box 3 is provided with a second motor 503 , the fixed plate 504 is provided with fixed bolts 505, the outer wall of the crushing box 3 is provided with multiple g...

Embodiment 2

[0038] As an option, see figure 1 , Figure 4 and Figure 5 , a screening type crushing device for food processing, the air purification mechanism 6 includes a dust collection cylinder 603 fixed on the outside of the crushing box 3, an inlet pipe 608 is arranged on the left side of the dust collection cylinder 603, and the inlet pipe 608 communicates with the crushing Inside the box body 3, an outlet pipe 605 is arranged on the right side of the dust collection cylinder 603, and an exhaust fan 609 is arranged inside the outlet pipe 605. One end of the outlet pipe 605 extending into the dust collection cylinder 603 is connected with an air outlet cylinder 604, and the air outlet cylinder 604 is vertically arranged in the middle of the dust collection cylinder 603, the upper end of the dust collection cylinder 603 is fixedly provided with an upper cover 607, the inside of the air outlet cylinder 604 is provided with a filter screen 6010, and the outside of the filter screen 601...

Embodiment 3

[0043] As an option, see figure 1 , Figure 6-9 , a screening type crushing device for food processing, the screening mechanism 7 is arranged below the crushing mechanism 5;

[0044] The screening mechanism 7 includes a sliding frame plate 707 erected inside the crushing box body 3. The sliding frame plate 707 is arranged obliquely. The lower ends of the two frame sides of the sliding frame plate 707 are provided with multiple sets of rollers 701. The lower ends of the rollers 701 are provided with roller shafts 702. , the roller shaft 702 is evenly arranged along the inclination direction of the sliding frame plate 707, the roller shaft 702 is rotatably connected to the inner wall of the crushing box 3, the two sides of the sliding frame plate 707 are provided with chute 712, and the chute 712 is set on the side of the crushing box 3 On the inner wall, the inside of the sliding frame plate 707 is provided with a screening net 703, and the outside of the screening net 703 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com