Patents

Literature

48results about How to "Good screening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

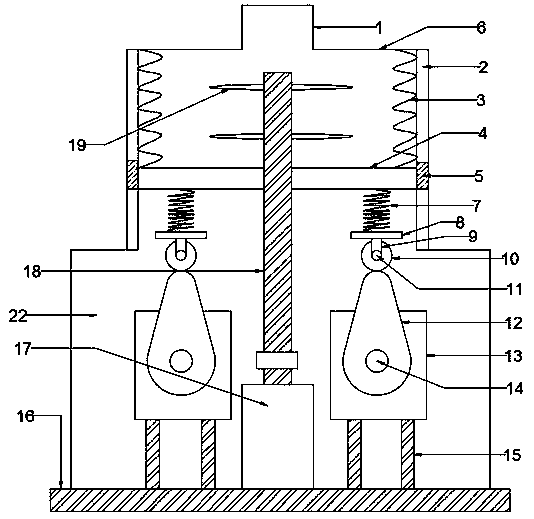

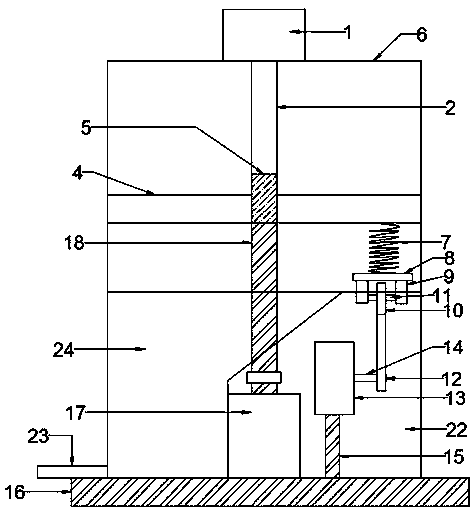

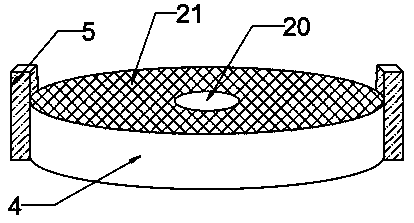

Vibratory screening mechanism for vertical sand making machine

The invention discloses a vibratory screening mechanism for a vertical sand making machine. The vibratory screening mechanism comprises a vibratory screening box, two vibration mechanisms, a rotatingmechanism and a base, wherein a screening plate and a first spring are arranged in the vibratory screening box, the vibration mechanism comprises a first motor, a cam, a driven wheel and a second spring, the rotating mechanism comprises a second motor, a rotating shaft and an impeller, the vibration mechanisms and the rotating mechanism are arranged below the vibratory screening box, the rotatingmechanism is arranged between the two vibration mechanisms, and the base is arranged below the vibration mechanisms and the rotating mechanism. The vibratory screening mechanism has the advantages ofbeing simple in structure and better in vibratory screening effect, and the vertical sand making machine using the vibratory screening mechanism is high in crushing efficiency and good in crushing quality.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

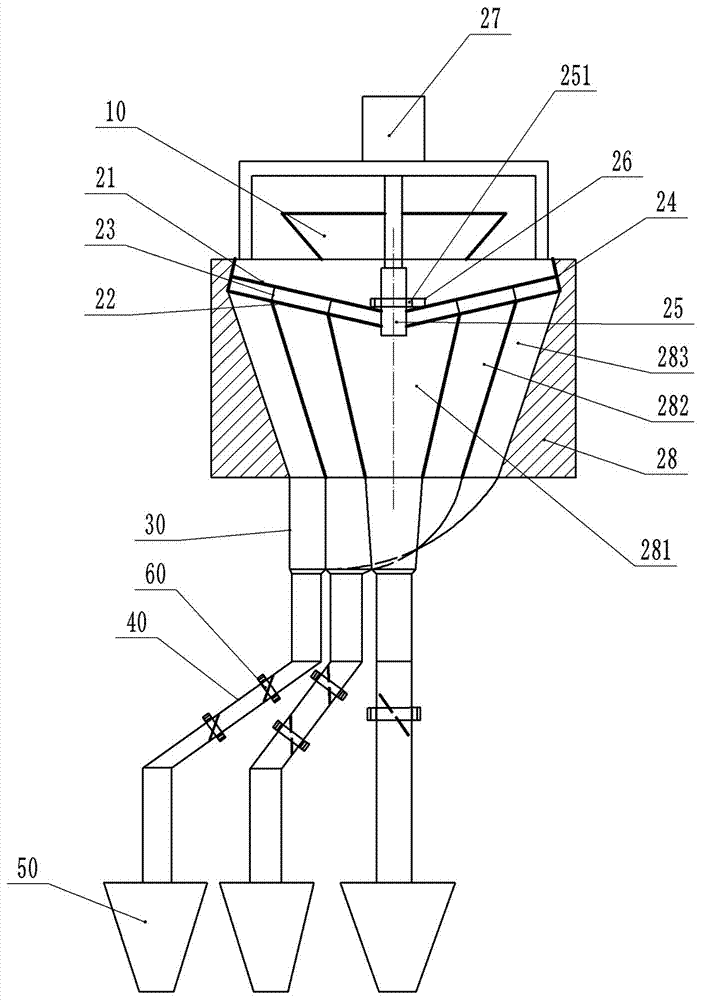

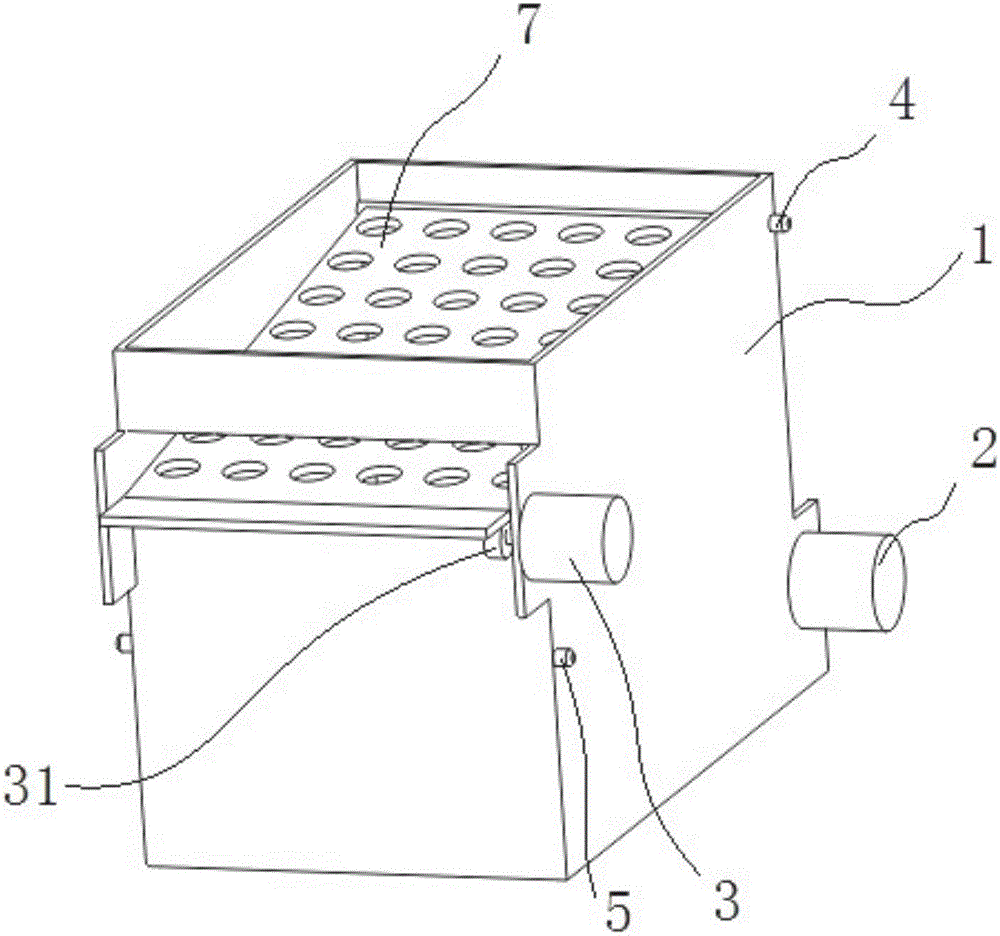

Organic fertilizer screening plant

The invention discloses an organic fertilizer screening plant which comprises a feeding hopper, a separating mechanism, a receiving hopper, a feeding pipe, a discharging hopper and a conveying mechanism which are sequentially connected. The separating mechanism comprises a separating screen, a motor and a collecting chamber, the separating screen is in a bucket shape, a center shaft is connected to the middle portion of the separating screen, the motor and the center shaft are coaxially connected, and a cam is rotationally connected to the center shaft; the separating screen comprises an upper screen plate and a lower screen plate which are fixedly connected, screen holes in the upper screen plate are gradually decreased from the center to the edge; small screen holes, middle screen holes and large screen holes are sequentially formed in the lower screen plate from the center to the edge, and a small cavity, a middle cavity and a large cavity are arranged in the collecting chamber; and the conveying mechanism comprises an annular groove, a ring rotationally connected with the annular groove and blades arranged in an inclined manner in the axial direction of the feeding pipe, and the blades are fixed to the ring. Compared with the prior art, the organic fertilizer screening plant can rapidly screen organic fertilizer according to the organic fertilizer particle size, and meanwhile, the screened organic fertilizer can be prevented from generating blockage in the feeding pipe.

Owner:习水县和平有机肥业有限公司

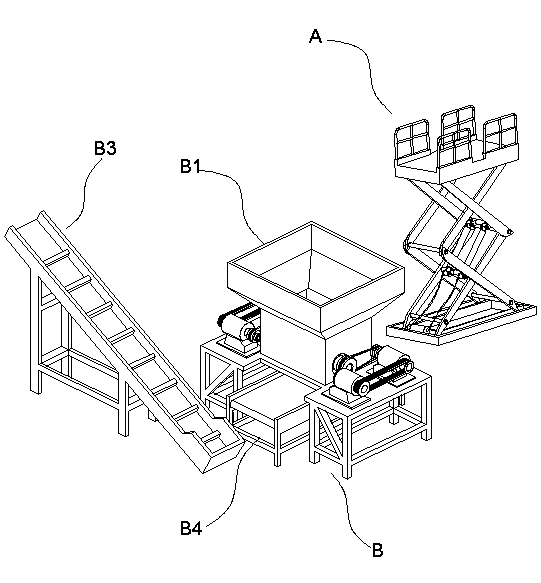

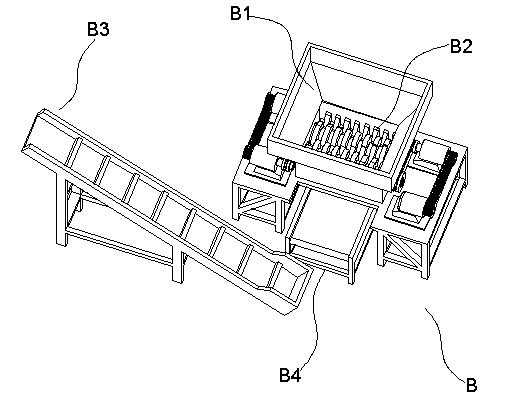

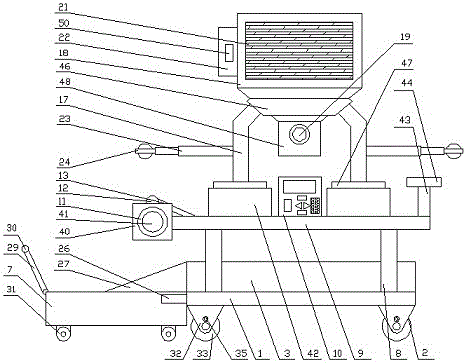

Method and device for separating low-value substances from valuable substances in scraped car

ActiveCN103894388AEasily brokenGood screening effectSolid waste disposalElectronic waste recyclingMagnetic separatorAutomotive engineering

The invention discloses a method and a device for separating low-value substances from valuable substances in a scraped car. The method comprises the following steps: (a) lifting the scraped car by a fork-type lifting platform, and feeding the scraped car into a top feeding hole of a double-shaft tearing machine; (b) tearing the scraped car by the double-shaft tearing machine, and then transporting the scraped car to a feeding hole of a control crusher through a conveyor belt; (c) throwing the scraped car into the control crusher for crushing, wherein the granularity of the crushed car material is controlled at 2cm to 5cm; (d) conveying the crushed car material into a magnetic separator so as to separate an iron magnetic substance; (e) conveying the car material without the iron magnetic substance into a vibration sieve for vibrating; (f) conveying the vibrated car material into a vortex separator for separating copper and aluminum. By the device and the method, the scraped car can be well crushed, the low-value substances such as iron, copper, aluminum and plastics in waste electronic elements of the scraped car can be efficiently separated, the valuable substances such as rare precious metal can be concentrated, and the scraped car can be efficiently recycled.

Owner:GEM CO LTD +1

Plastic particle screening device and method

InactiveCN107855258AGood screening effectLow viscositySievingScreeningGastric tube feedingMotor drive

The invention discloses a plastic granule screening device. The cylinder cover is provided with a feed port, and the upper end of the feed port is connected with a feed hopper, and the lower end of the feed port is connected with a material whose lower end points to a rotating tube. plate, and the lower end of the cylinder is provided with a lower outlet, the cylinder is uniformly provided with air outlets, and the inner wall of the cylinder is provided with a filter, and the lower end of the cylinder is provided with supporting legs. The screening method is as follows: S1 receiving material, S2 feeding and S3 refueling. When the power is turned on, the plastic particles enter from the feeding hopper, and then slide along the material plate to the vicinity of the rotating tube, and fall onto the coarse sieve plate. The motor drives The rotating tube rotates, so that the blowing tube and the bristles can clean and evenly brush the plastic particles, which is convenient for the separation of plastic particles of different sizes. At the same time, with the help of the bristles, there is an external force, and the plastic particles are not easy to stick to the coarse sieve plate. Screening The effect is better, and the plastic particles are blown to the plastic particles through the rotating tube and the blowing tube for continuous drying, which reduces the viscosity, facilitates sieving, and improves the sieving effect.

Owner:项正一

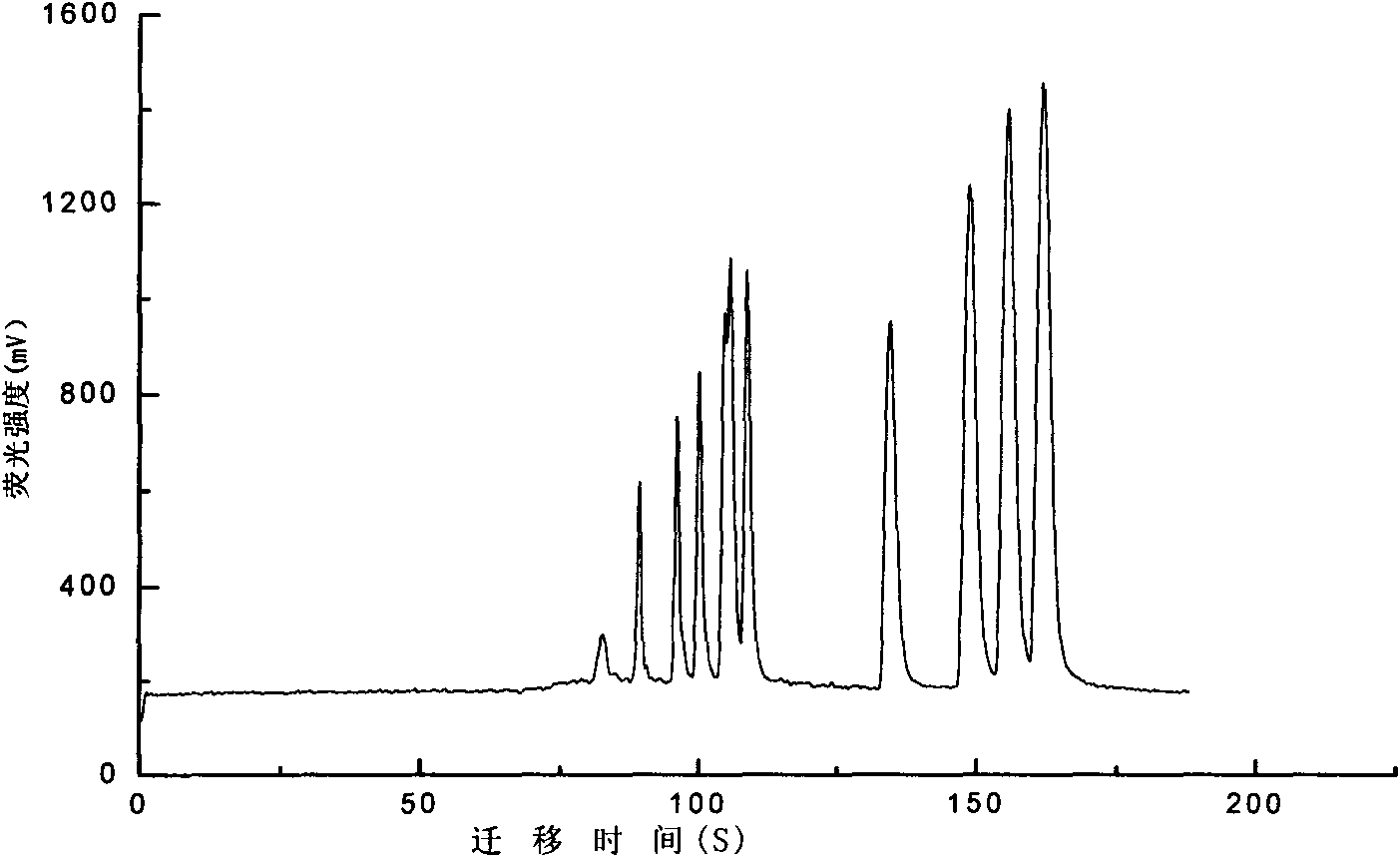

Method for modifying DNA microfluidic chip micro-channel with mixed screening medium

InactiveCN101654654AThe operation steps are simple and easyGood screening effectMicrobiological testing/measurementFluorescence/phosphorescenceMicrofluidic chipBiology

A method for modifying a DNA microfluidic chip micro-channel with a mixed screening medium belongs to the technical field of DNA microfluidic chip electrophoretic analysis. and includes following steps: preparing a mixed screening medium of polyvinylpyrrolidone and hydroxyethyl cellulose as a modifier and modifying the DNA microfluidic chip micro-channel with the modifier. The method has easy operation. When the DNA microfluidic chip with the modified micro-channel is analyzed of DNA segments, the biochemical sample DNA screening effect is good; the analysis time is short and modifier servicelife is long. The invention is especially adapted to modifying the micro-channel of the DNA microfluidic chip to make the modified chip become the qualified and efficient DNA electrophoretic analysisimplement.

Owner:EAST CHINA NORMAL UNIVERSITY

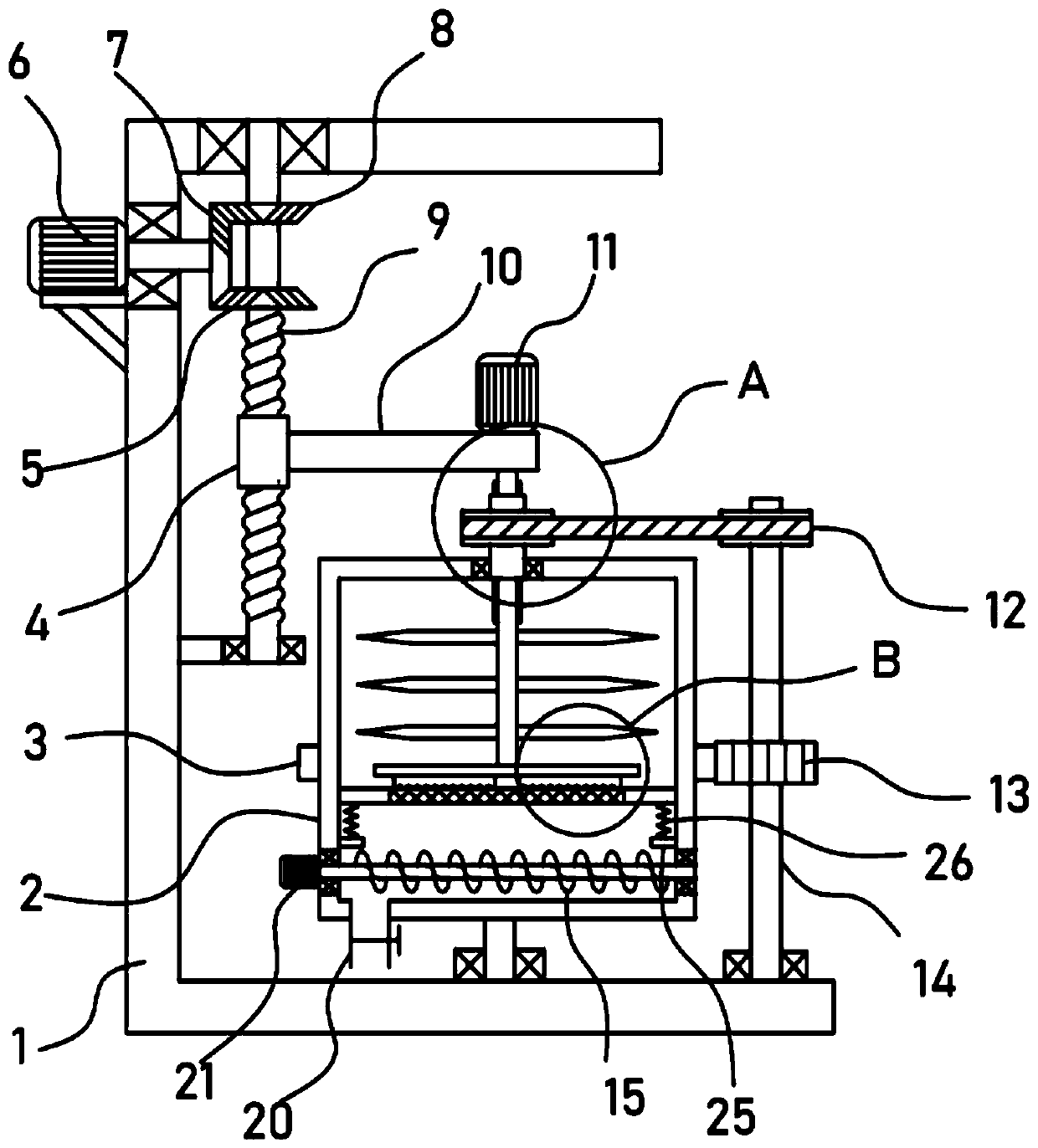

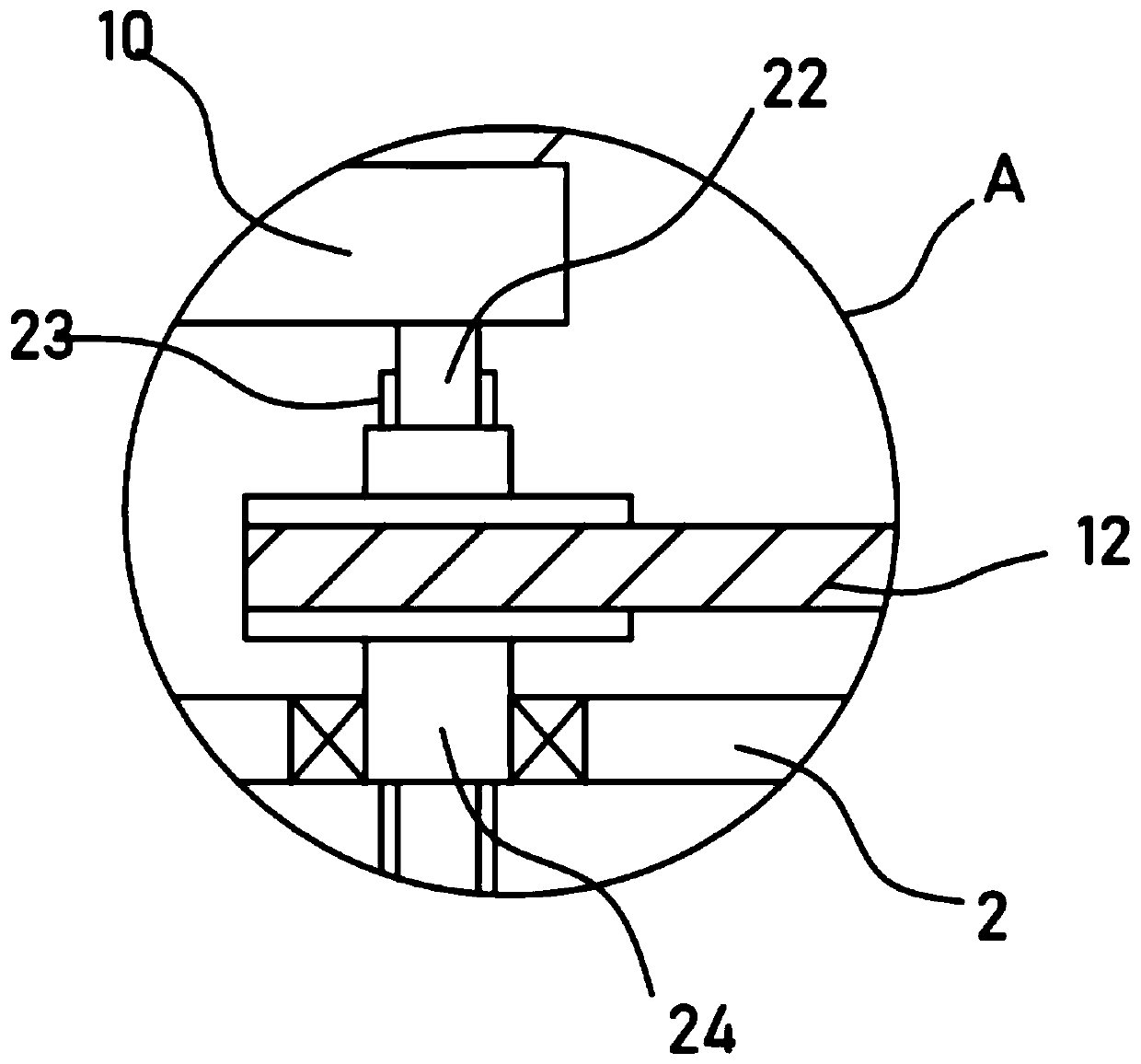

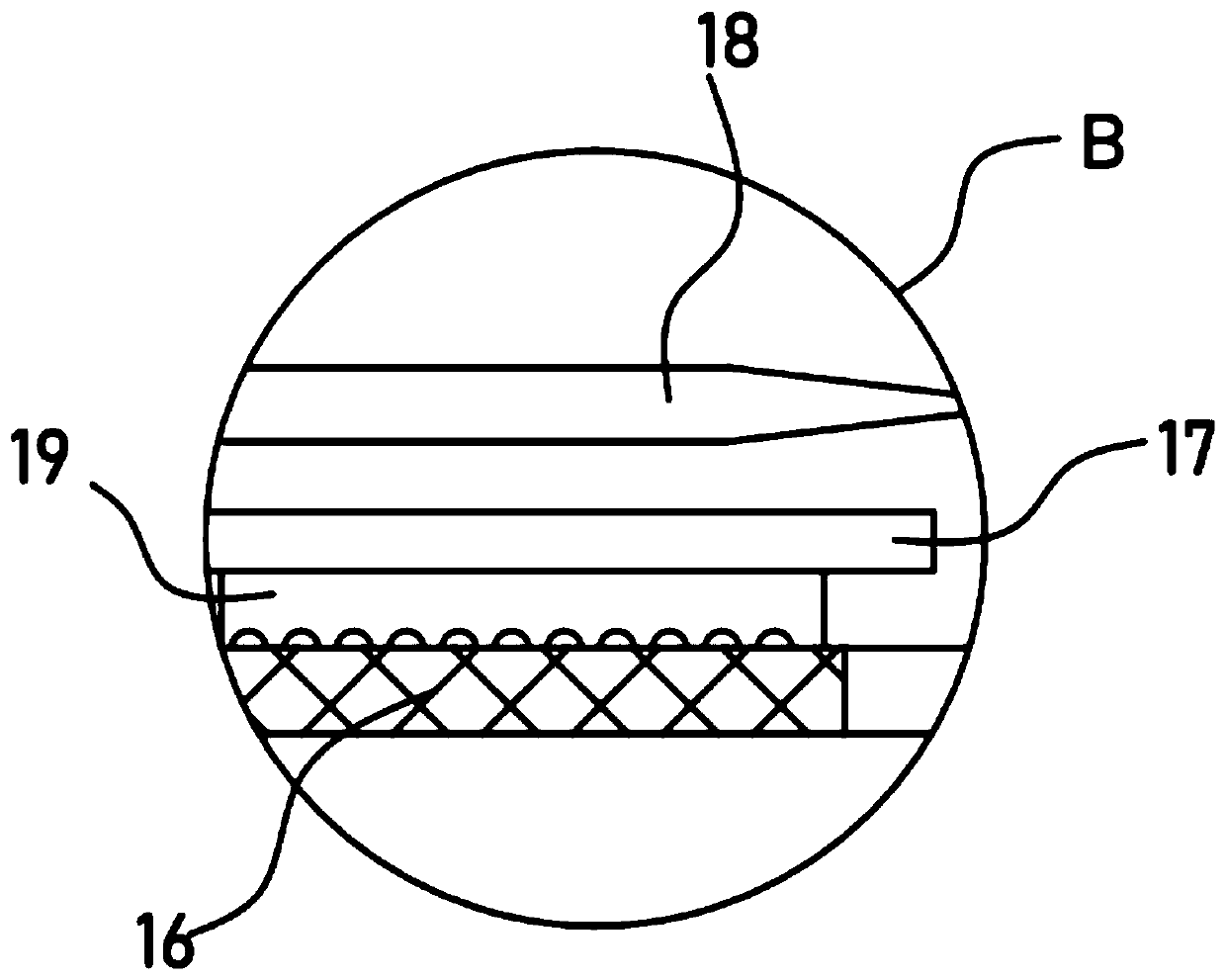

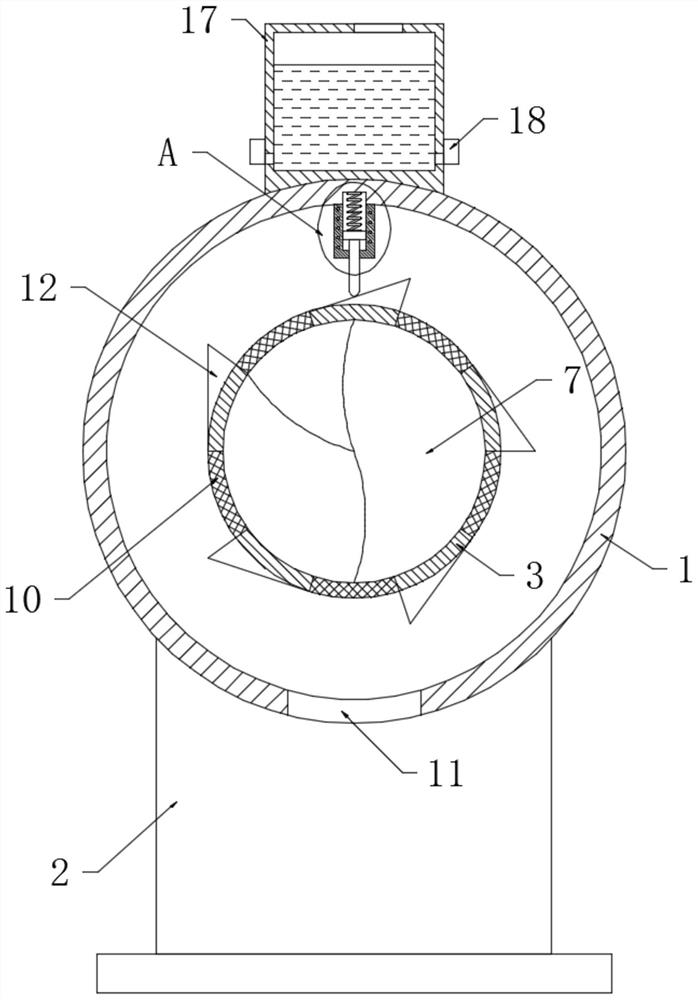

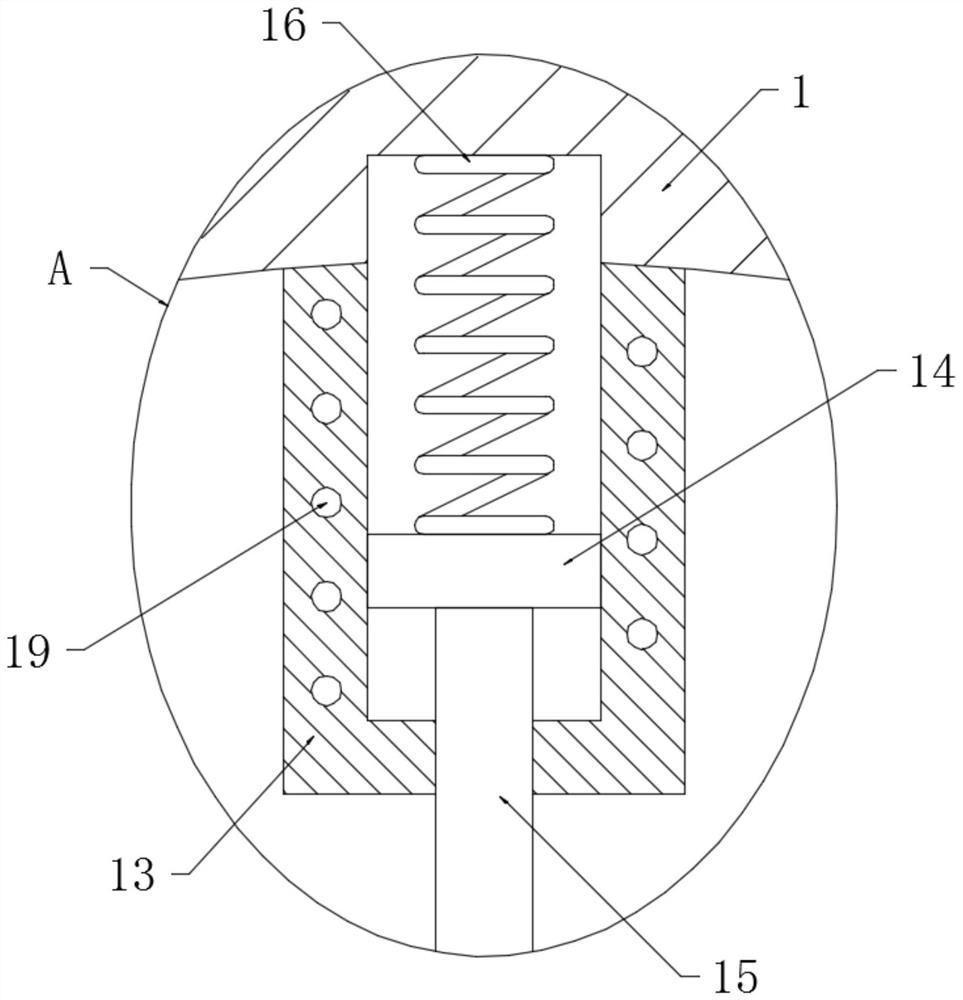

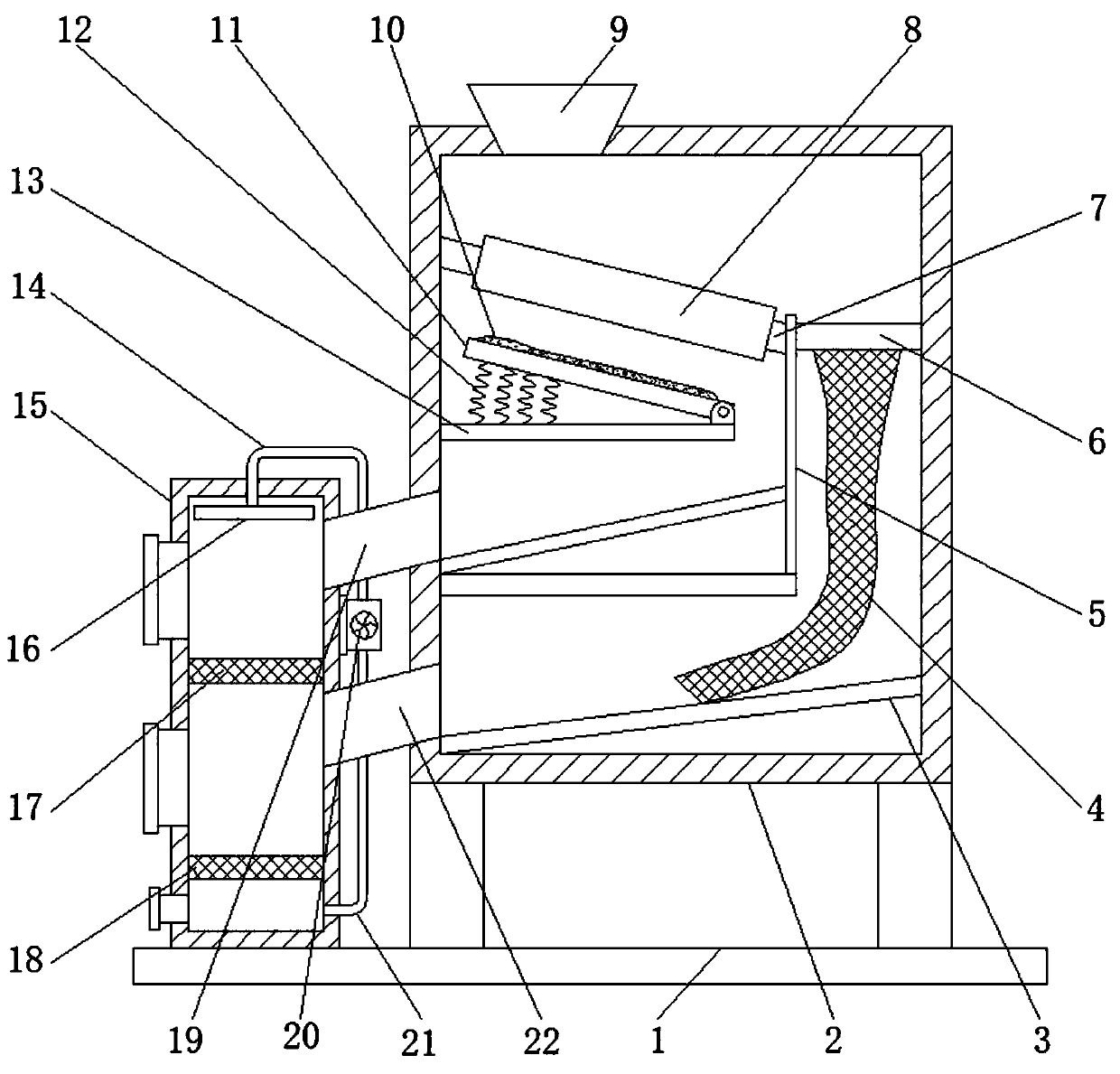

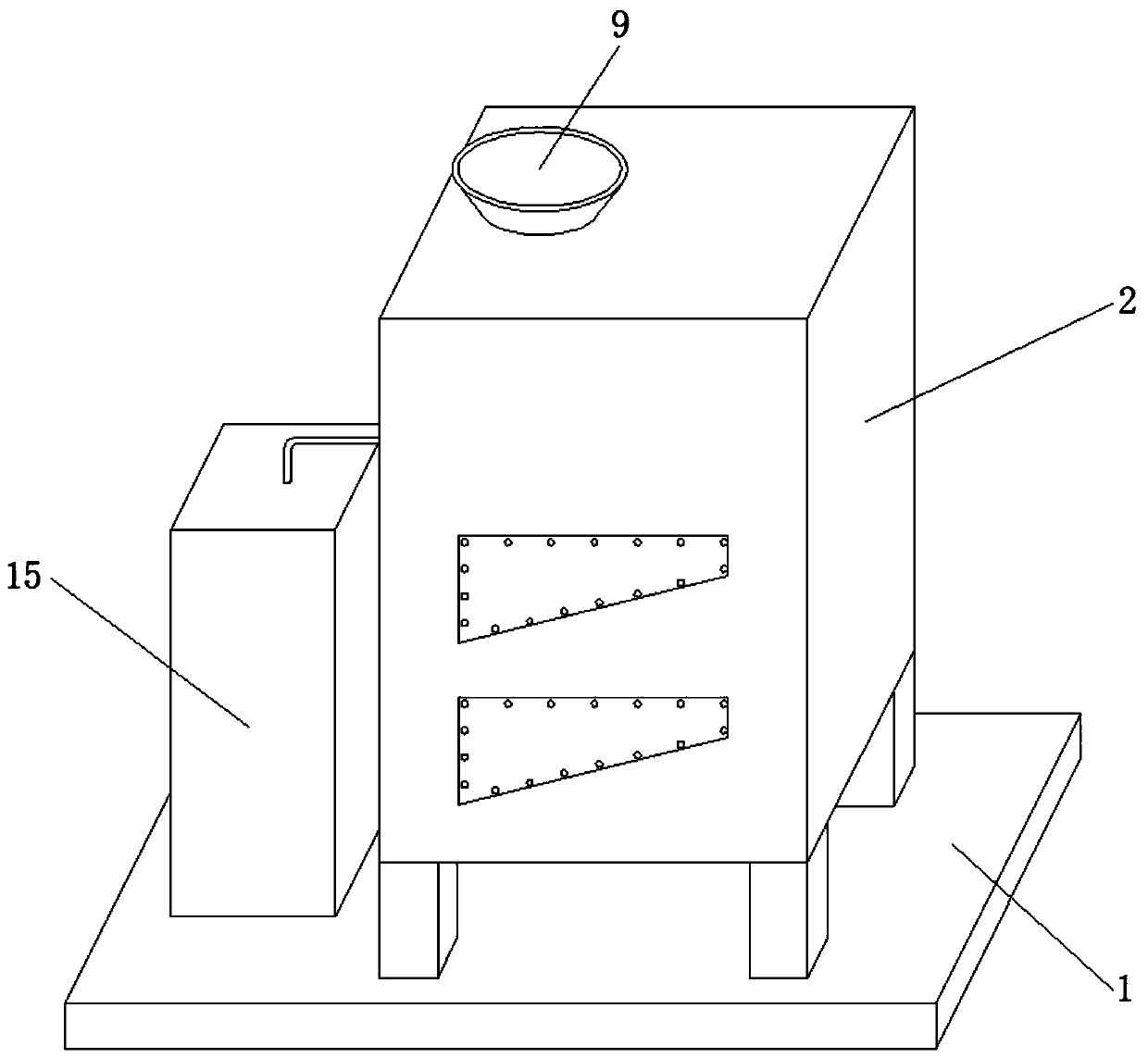

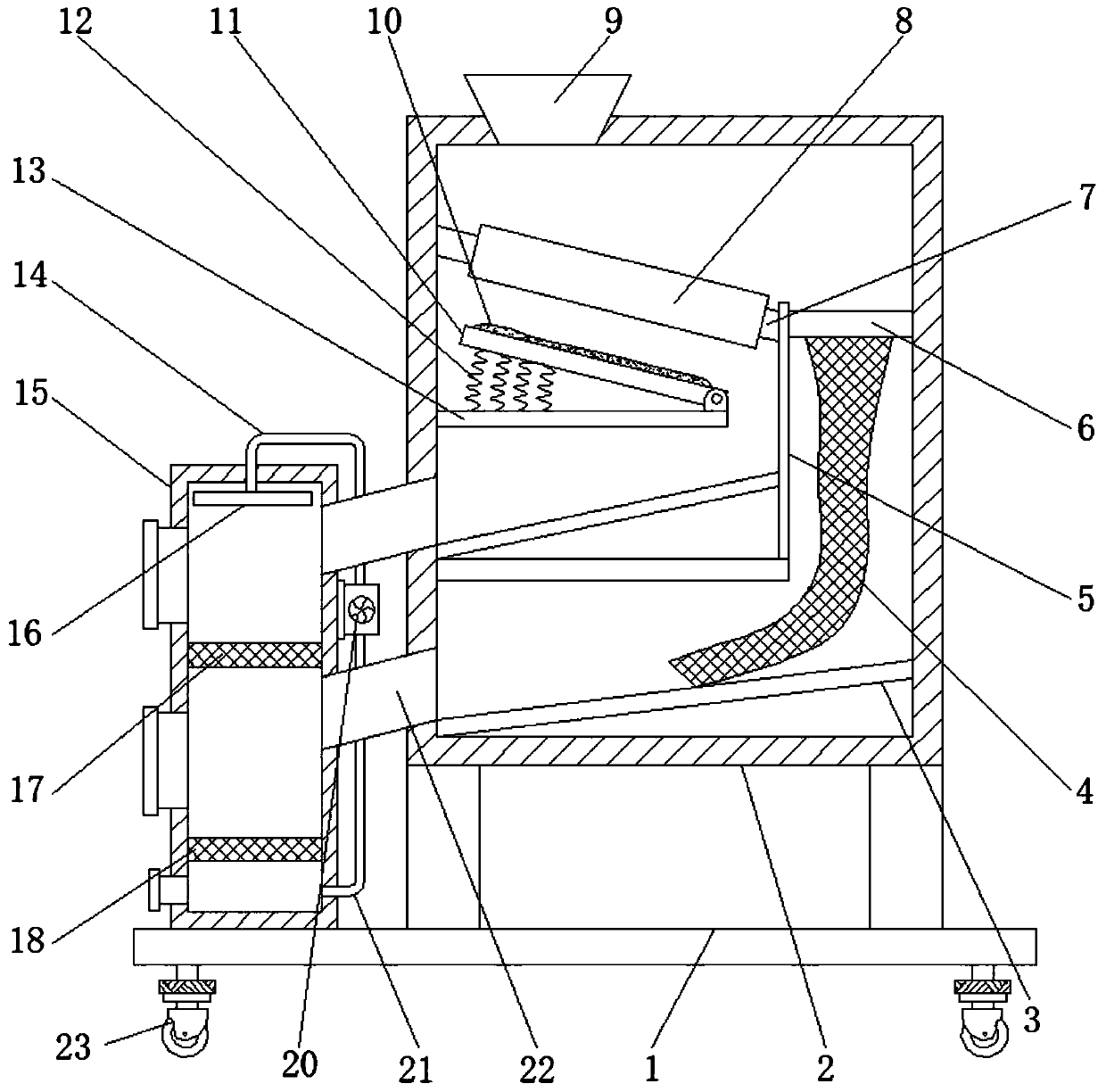

Grain raw material refining device for feed production

InactiveCN110523488AGood screening effectRealize the effect of rotary cutting and crushingSievingFeeding-stuffFeed processingEngineering

The invention discloses a grain raw material refining device for feed production, and relates to the technical field of feed processing machinery. The grain raw material refining device comprises a supportinging frame, a crushing barrel is rotatably arranged on the supportinging frame, and a crushing mechanism for crushing the grains is rotatably arranged in the crushing barrel. A reciprocating mechanism for driving the crushing mechanism to vertically move relative to the crushing barrel is arranged on the supporting frame, and a sieve plate supporting by an elastic supporting piece is arranged in the crushing barrel. Through the arranged crushing mechanism, the rotary cutting and crushing effect on the rain raw materials in the crushing barrel is achieved, the up-down reciprocating motion of the crushing mechanism is realized under the driving of the reciprocating mechanism, and at the moment, the grains at different vertical height positions in the crushing barrel can be fully crushed and refined. An arranged dispersing mechanism can stir and disperse the grains on the sieve plate, so that the efficient screening effect of the sieve plate on the crushed grains is guaranteed, andthe grains on the sieve plate can be thoroughly crushed by the blades.

Owner:毛保林

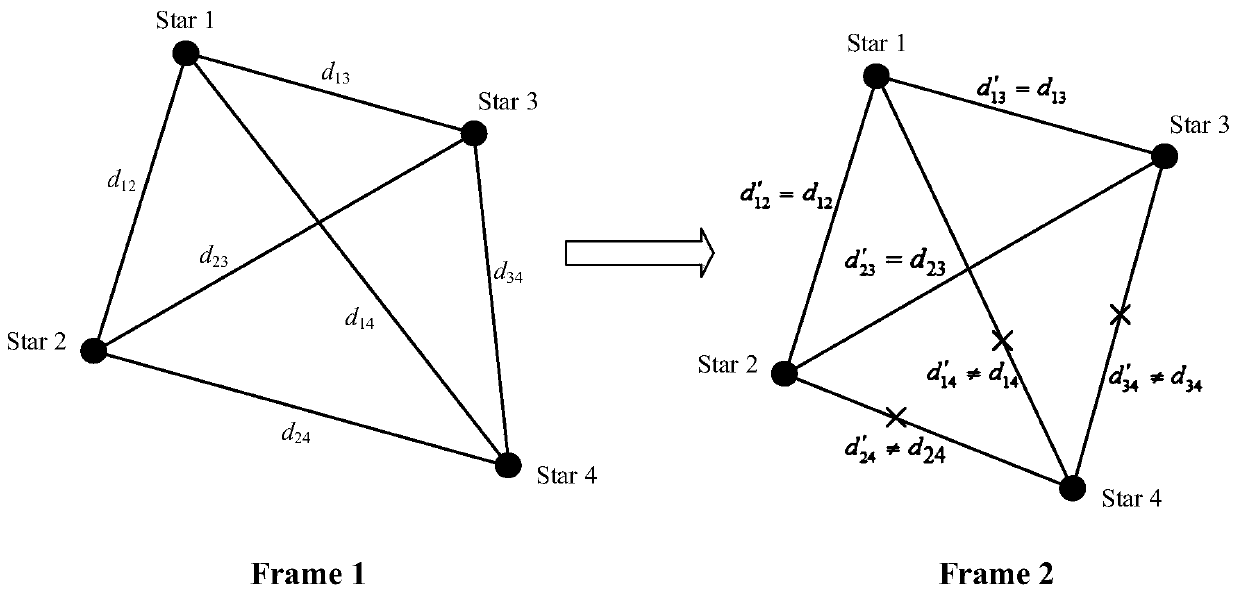

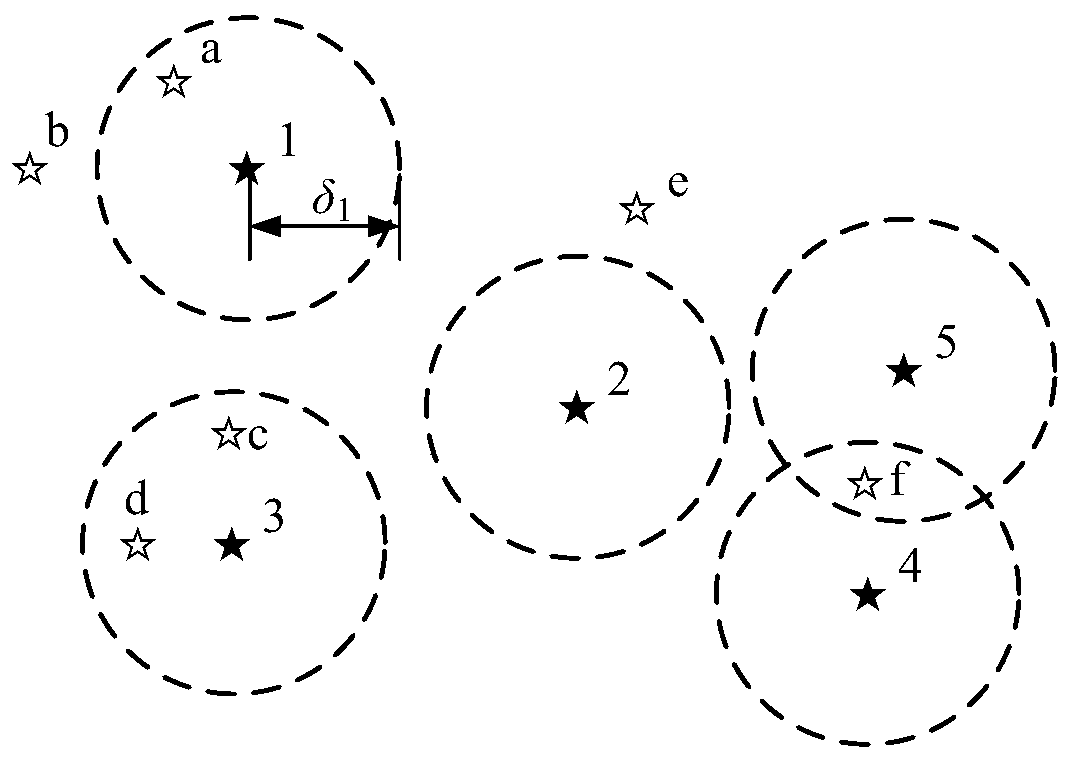

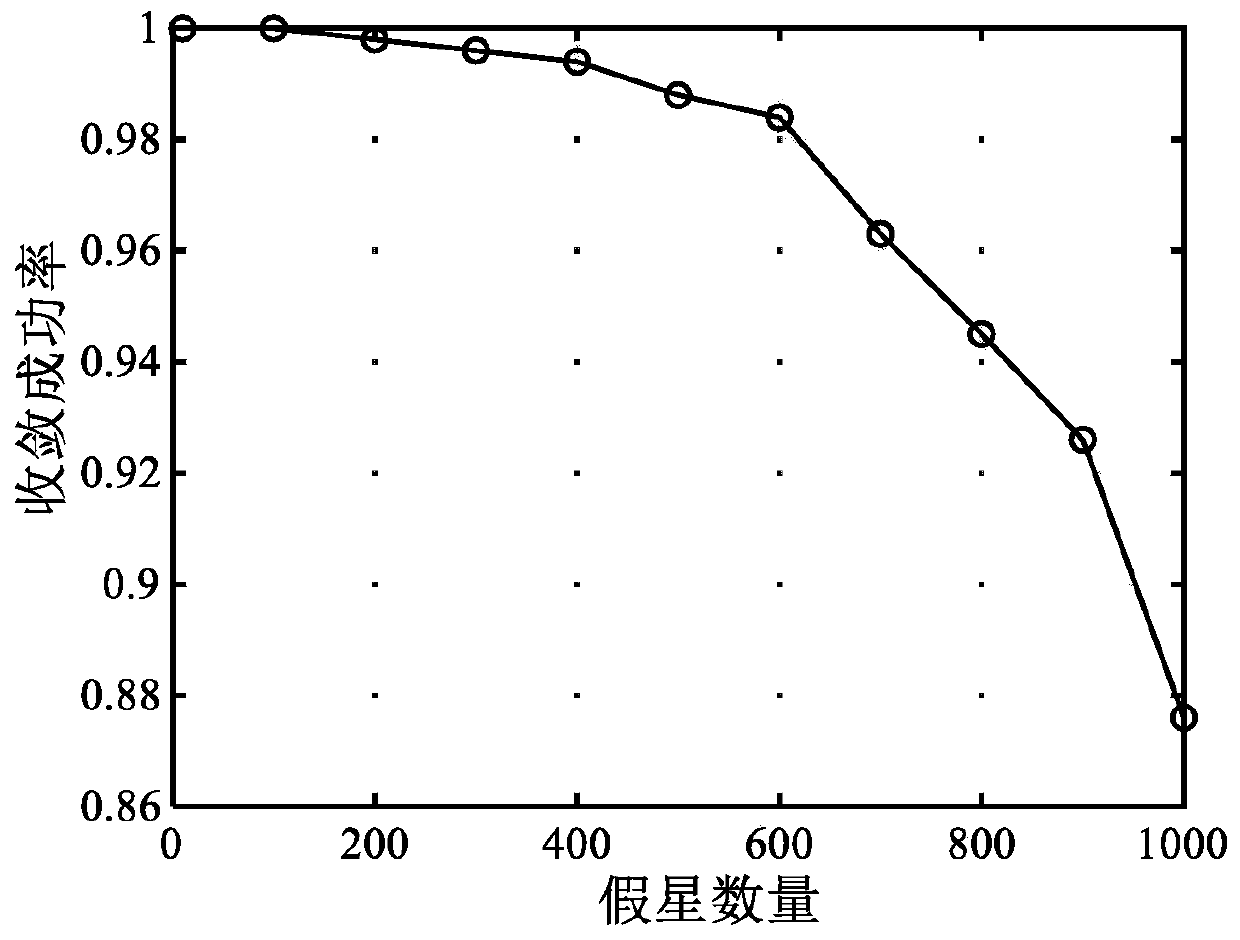

Star sensor artificial star screening method based on angular distance screening

ActiveCN109724591AHigh speedEasy to identifyNavigational calculation instrumentsNavigation by astronomical meansAngular distanceScreening method

The invention discloses a star sensor artificial star screening method based on angular distance screening. The method comprises the following steps: (1) all star points in a first frame of a star mapare recorded as initial star points; (2) starting from a second frame, corresponding relations between each star point and the initial star points are established by utilizing a star tracking method;(3) the angular distances between other frames and the initial frame are compared, the angular distances are screened according to angular distance changes, and an angular distance screening matrix is updated; (4) star pairs corresponding to the screened angular distances are used to vote for each star point, and the star points with the excessively low vote numbers are screened; and (5) each frame is output by the screened star points and is sent to a subsequent star map recognition module. The method has the following advantages: (1) the convergence success rate is high, and the convergencesuccess rate is over 98% within 600 artificial stars; (2) the convergence speed is high, and all the artificial stars can be screened by only at most 10 frames of the star map on average; (3) the adaptability to the number of the artificial satellites is high, and all the artificial stars can be screened from the star map with no less than 700 artificial stars; and (4) the screening of the artificial stars does not depend on shape information of the star points.

Owner:BEIHANG UNIV

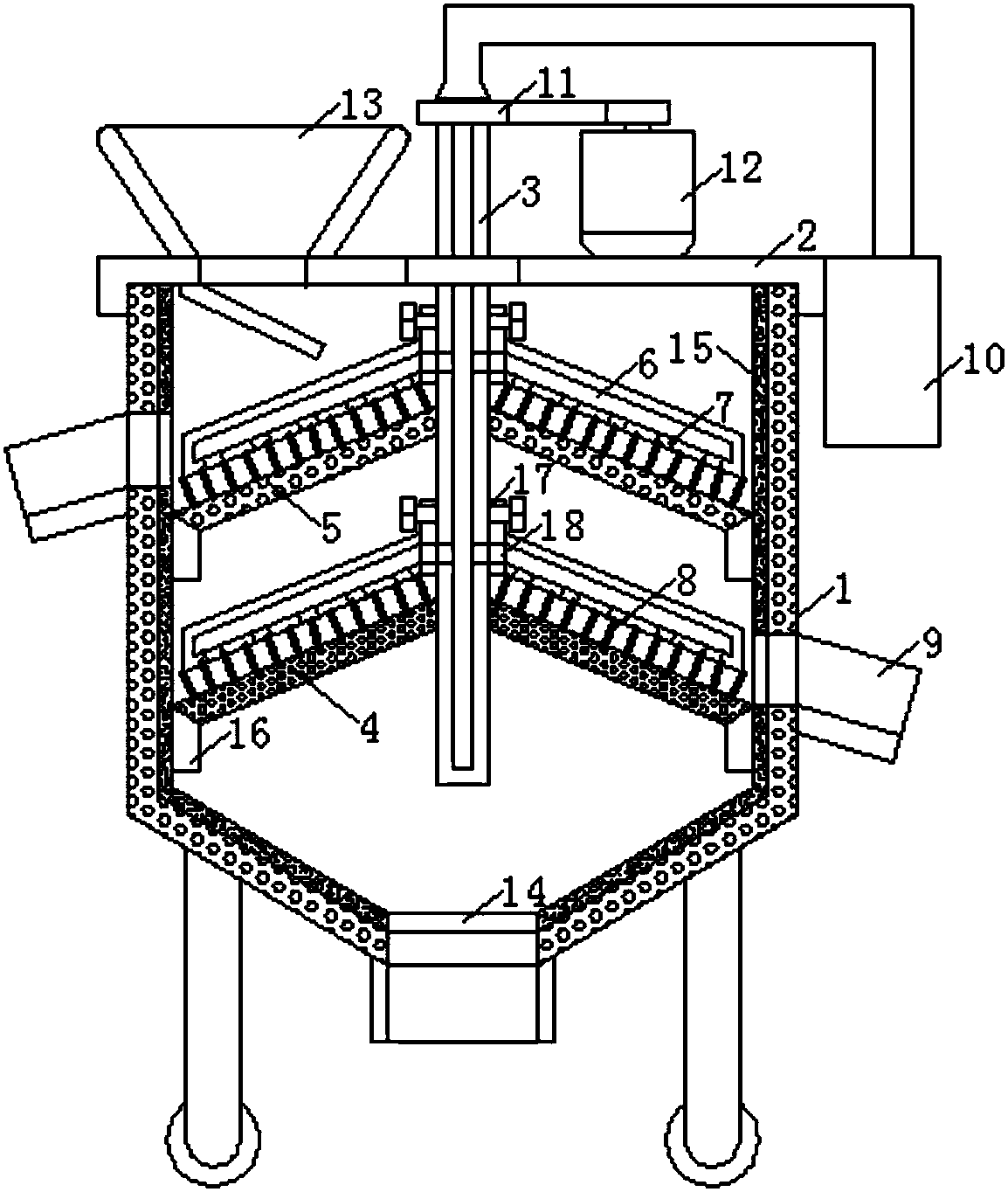

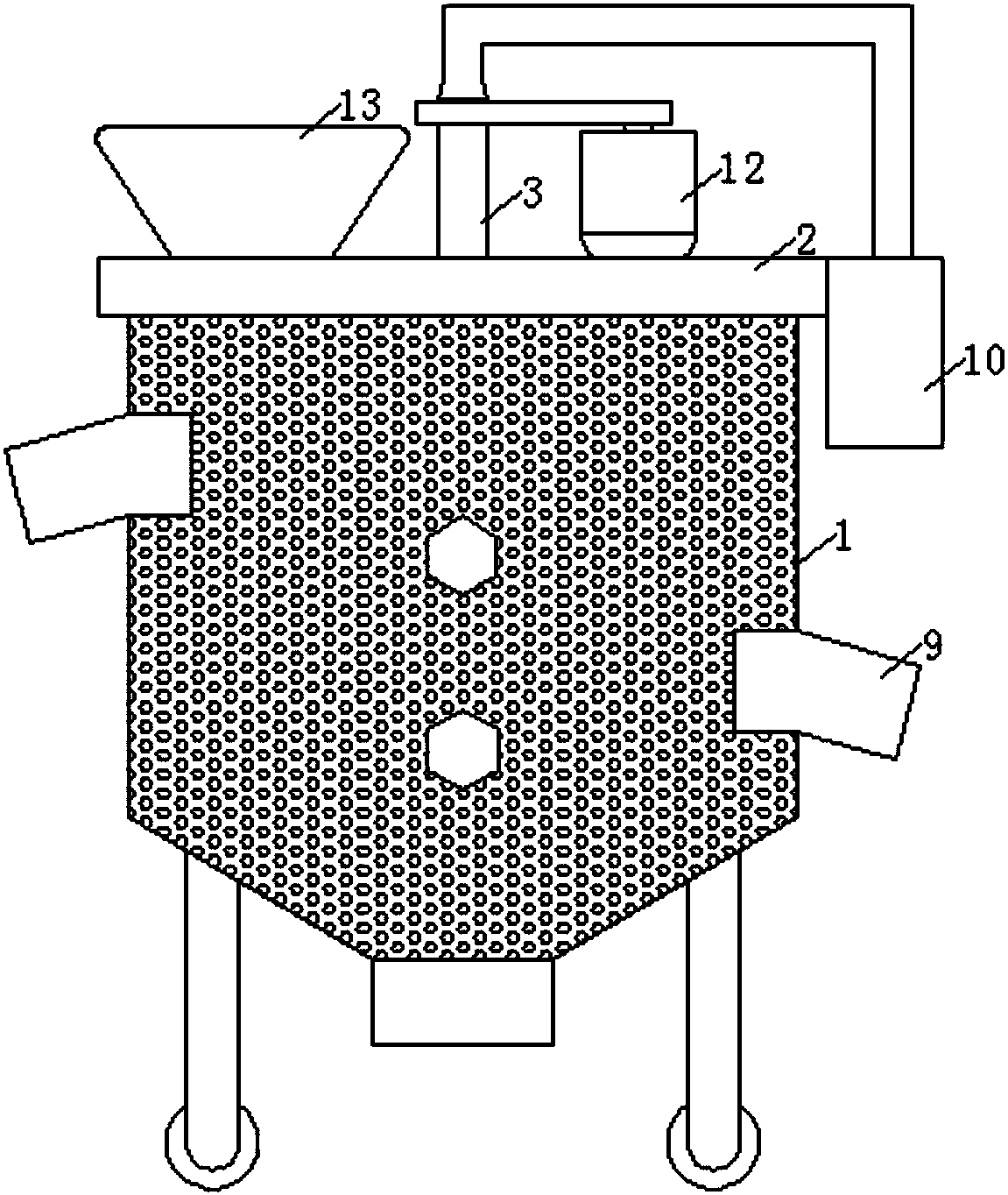

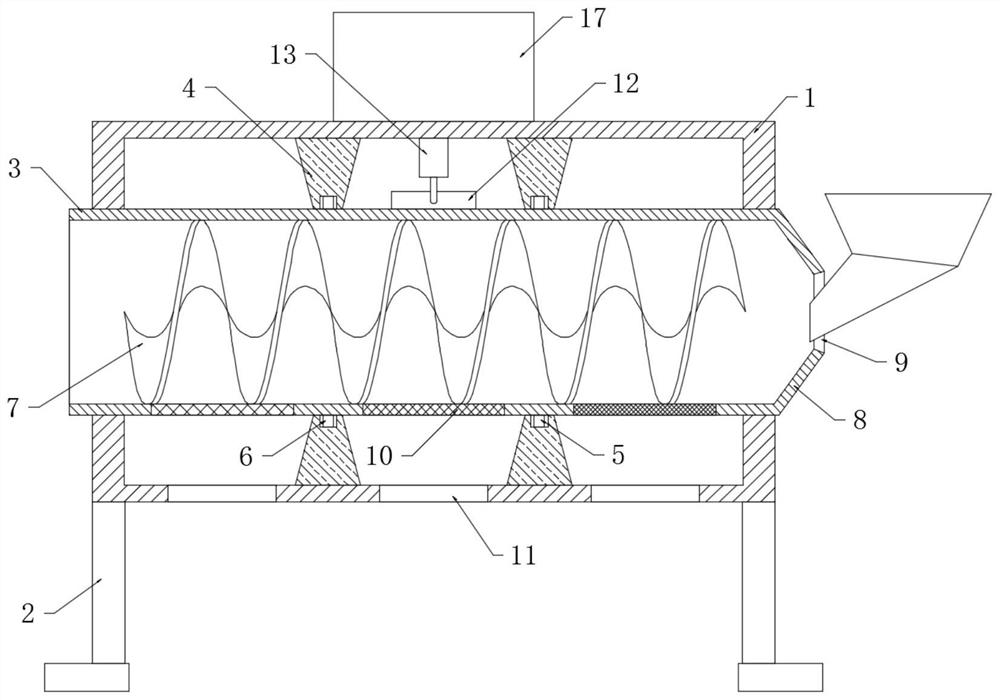

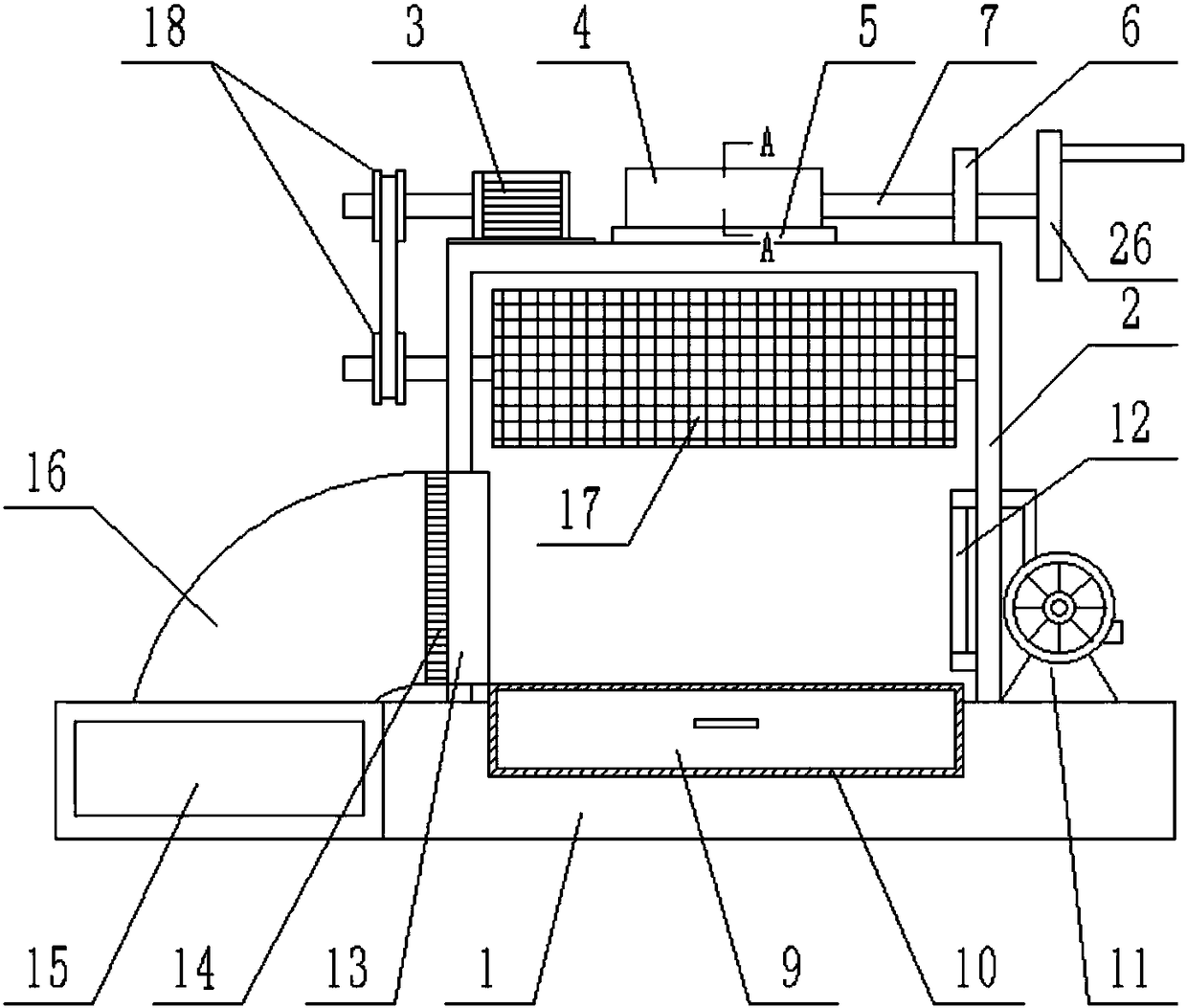

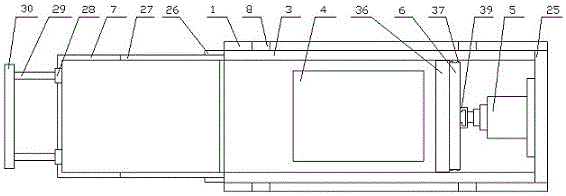

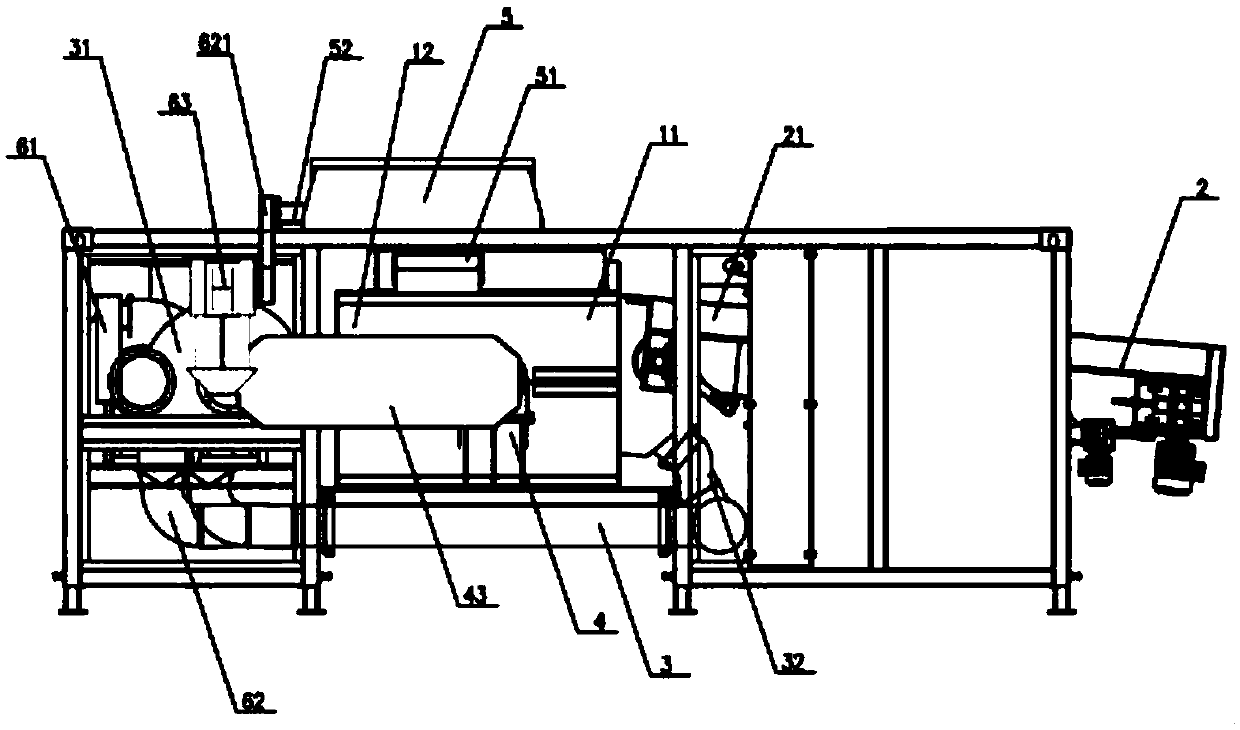

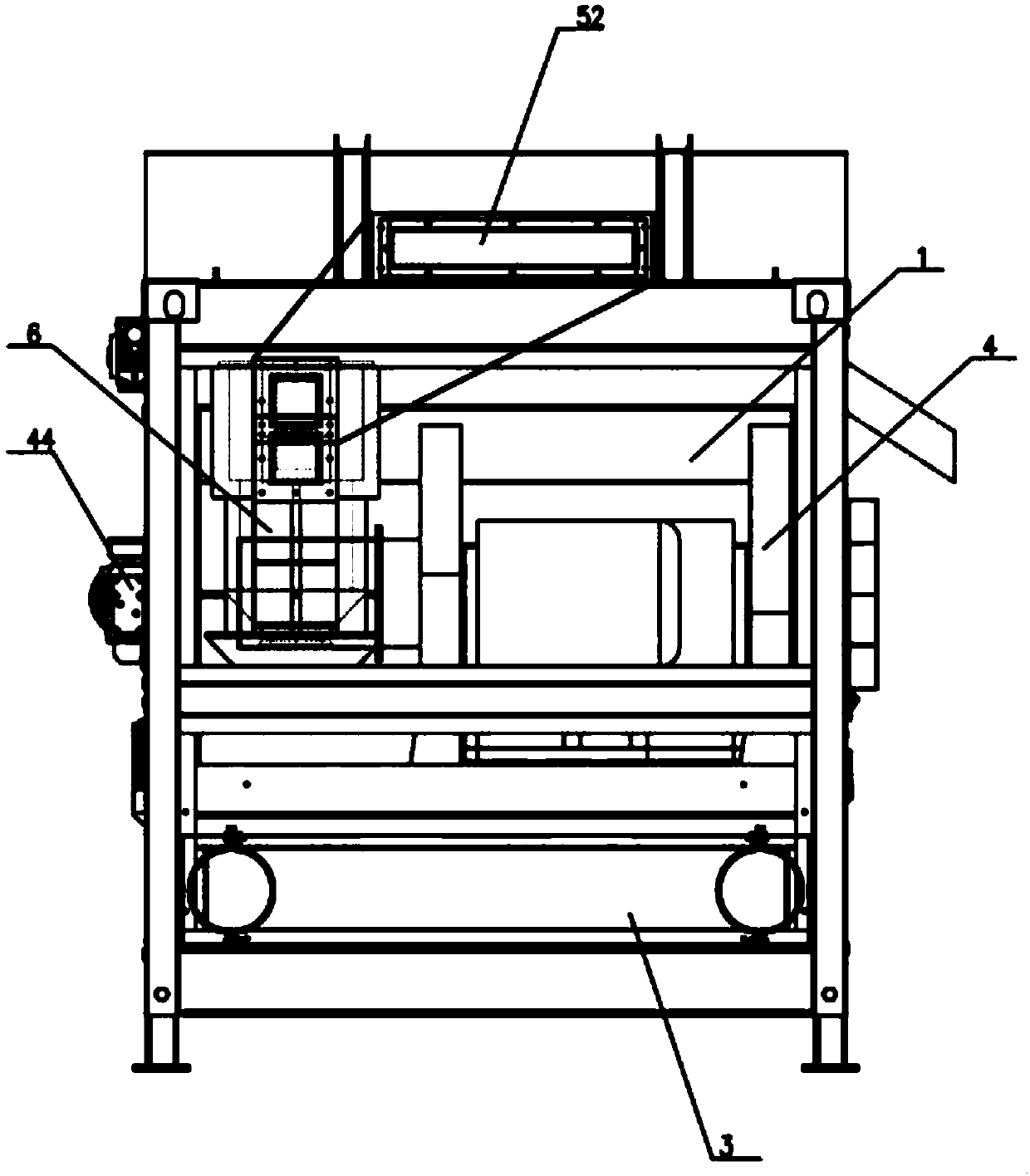

Environment-friendly efficient mineral aggregate screening machine for mining production

PendingCN112871627AGood screening effectReduce pollutionSievingScreeningProcess engineeringStructural engineering

The invention discloses an environment-friendly efficient mineral aggregate screening machine for mining production. The environment-friendly efficient mineral aggregate screening machine for mining production comprises a cylindrical machine box, the machine box is transversely arranged, the outer wall of the machine box is fixedly connected with a fixing frame, and the box walls of the two sides of the machine box are rotationally connected with a cylindrical transversely-arranged screening barrel in a penetrating mode. Two annular partition plates are fixedly connected to the inner wall of the machine box and evenly divide the space in the machine box into three parts, an annular sliding groove is formed in the inner annular face of each annular partition plate, two annular guide rails are fixedly connected to the outer wall of the screening barrel, and the two annular guide rails are in sliding connection with the two annular sliding grooves correspondingly. The environment-friendly efficient mineral aggregate screening machine for mining production has the advantages that in the working process of the screening machine, due to the action of springs, when the screening barrel rotates, an inclined face on a lifting table continuously lifts and then lowers a push rod, the push rod sequentially collides with multiple screens, the springs give elastic potential energy to the push rod, certain vibration is generated when the push rod collides with the screens, clamped materials on meshes of the screens are vibrated off, and the screening efficiency is prevented from being influenced by screen blockage.

Owner:姚蓓琳

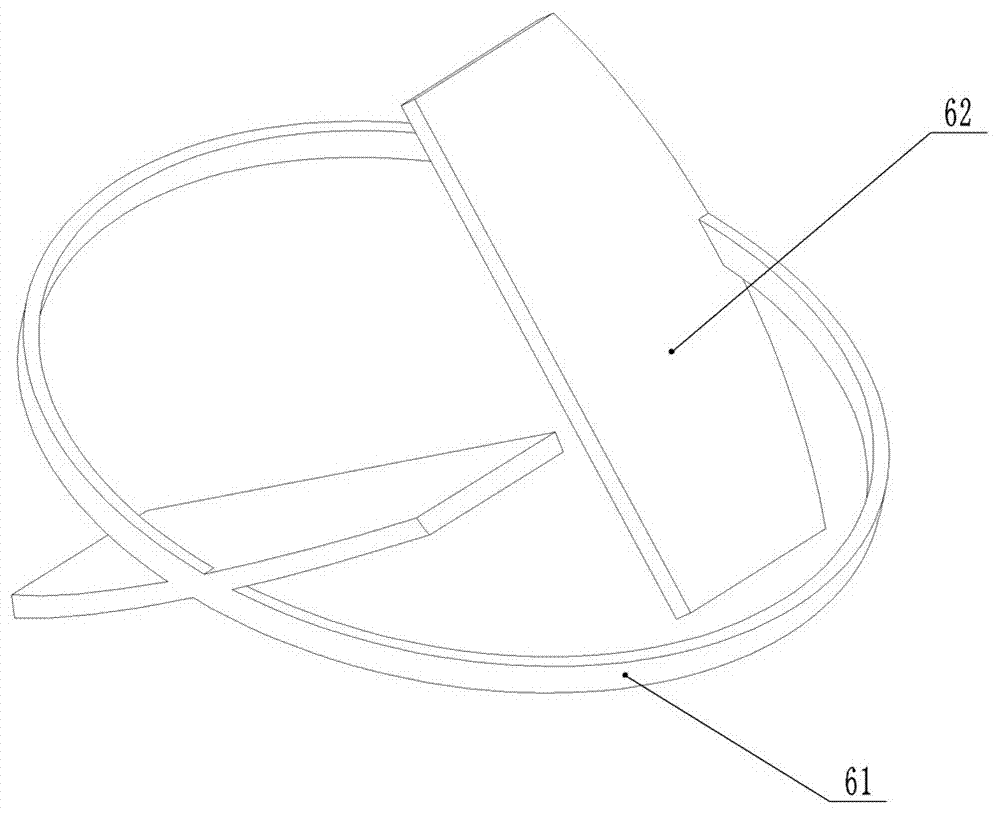

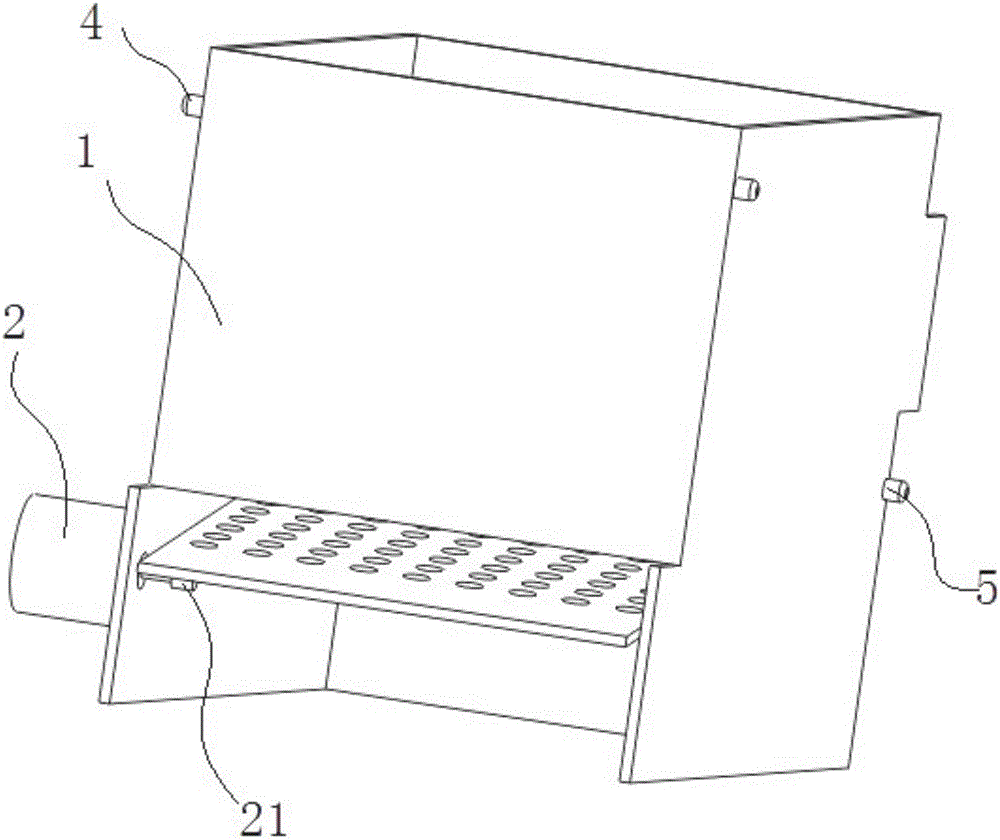

Separation device for rice husks and brown rice

InactiveCN106733589AImprove screening efficiencyGood screening effectSievingScreeningRice productEngineering

The invention discloses a separation device for rice husks and brown rice. The separation device comprises a device body. A feeder is arranged on the left side of the top end of the device body. An air blowing mechanism is arranged on the right side of the top end of the device body. A cleaning door is arranged at the lower end of the left side of the device body. A discharging hopper is arranged at the lower end of the right side of the device body. A base is arranged at the bottom end of the device body. A separation bin is arranged at the upper end of the interior of the device body. An oblique discharging plate is arranged at the lower end of the interior of the device body. The husked rice separation device can be used for separating rice husks and brown rice, the screening efficiency is high, the screening effect is good, impurities such as gravel and dust in the rice can be screened before the rice is milled through a rice mill, it is ensured that rice faces are clean, the quality of finished rice products is sufficiently ensured, the application range is wide, and practicability is high.

Owner:HARBIN MIMI RICE IND TECH CO LTD

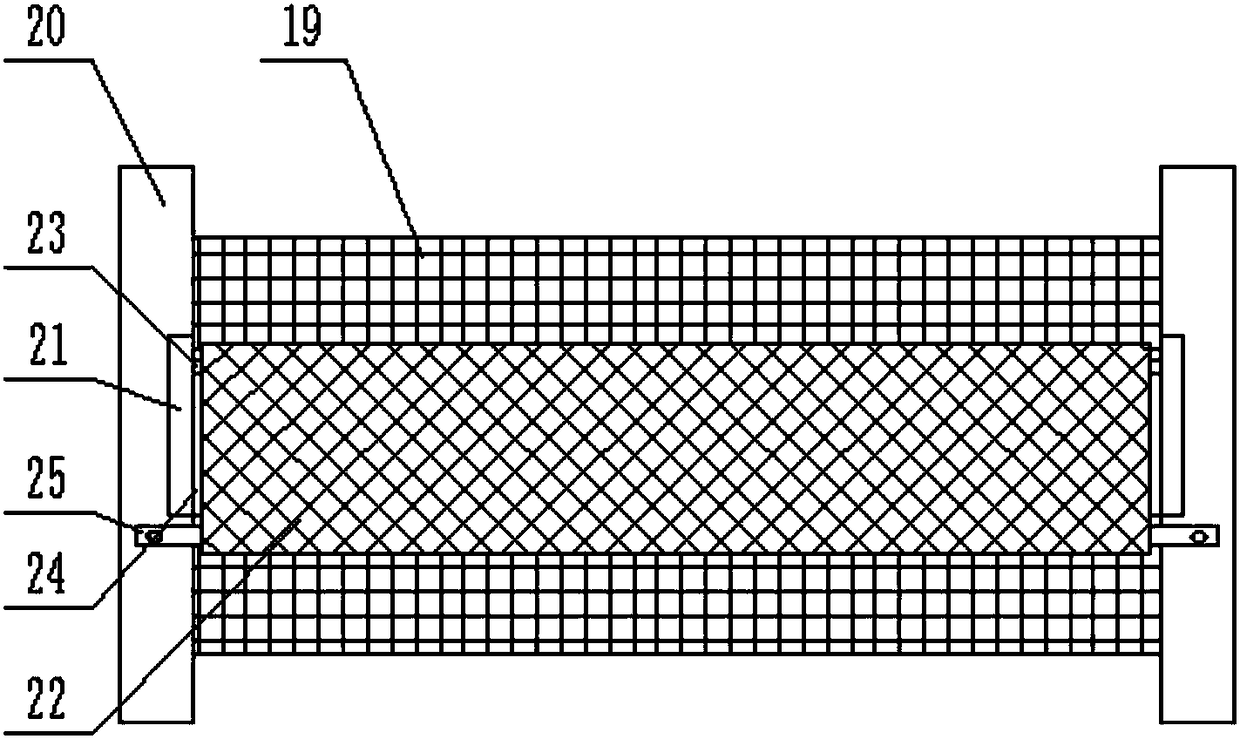

Vibrating screening device

The invention relates to a screening device, in particular to a simple vibrating screening device of grain. The vibrating screening device comprises a taper screen. Screen walls are arranged on the periphery of the screen. A rotating shaft is fixed vertically in the center of the screen. The screen walls are connected with the rotating shaft through connecting rods. A stepped shaft is arranged above the rotating shaft. A semi-sphere protrusion is arranged on the protruding lower surface of the stepped shaft. A shaft sleeve connected with the stepped shaft is arranged below the stepped shaft and is fixed on a machine frame. Four protruding blocks are evenly distributed on the upper surface of the shaft sleeve. The protruding blocks correspond to the protrusion in position. According to the technical scheme, the screening device is simple in structure, low in cost and good in screening effect.

Owner:CHONGQING DAYE FOOD

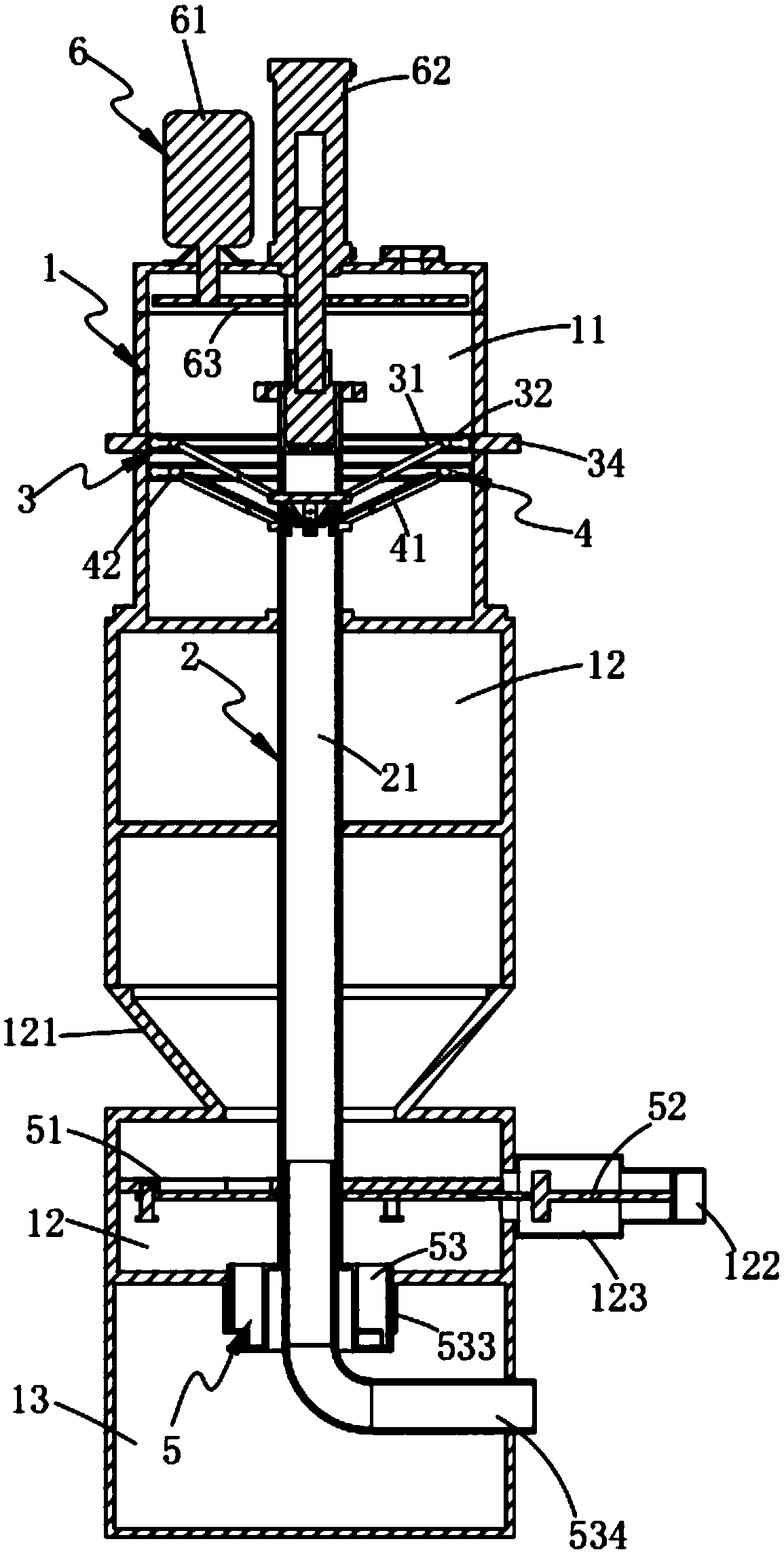

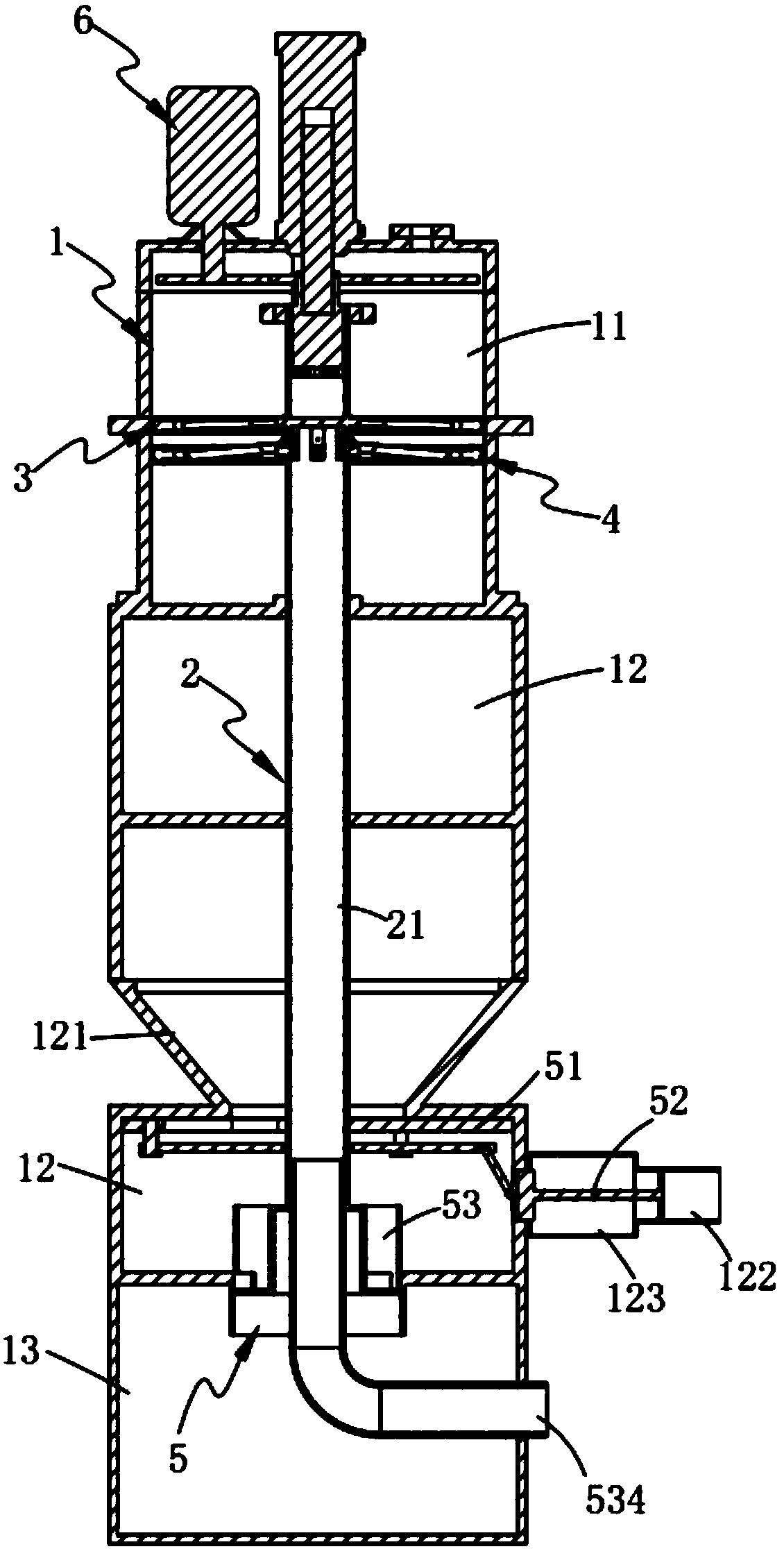

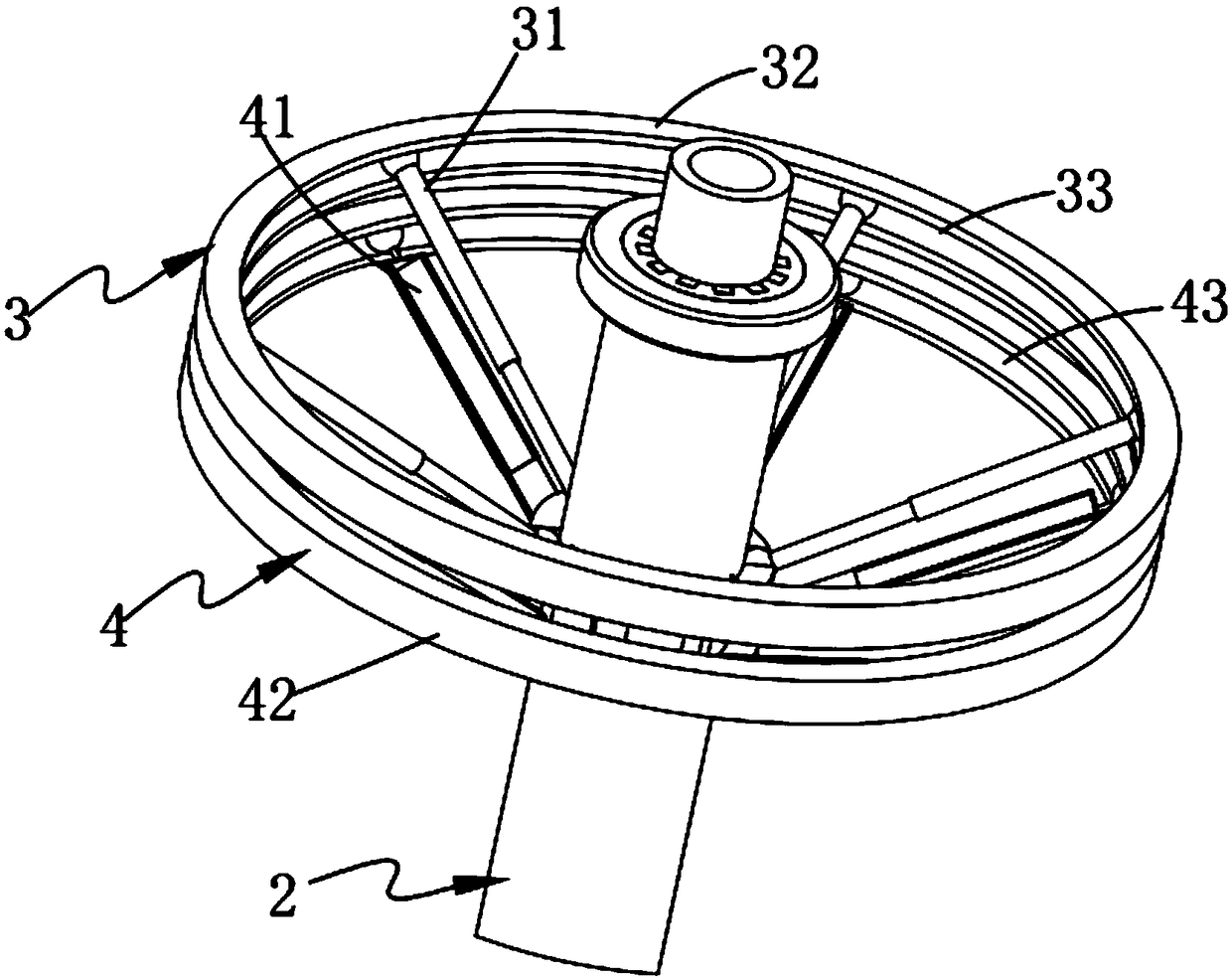

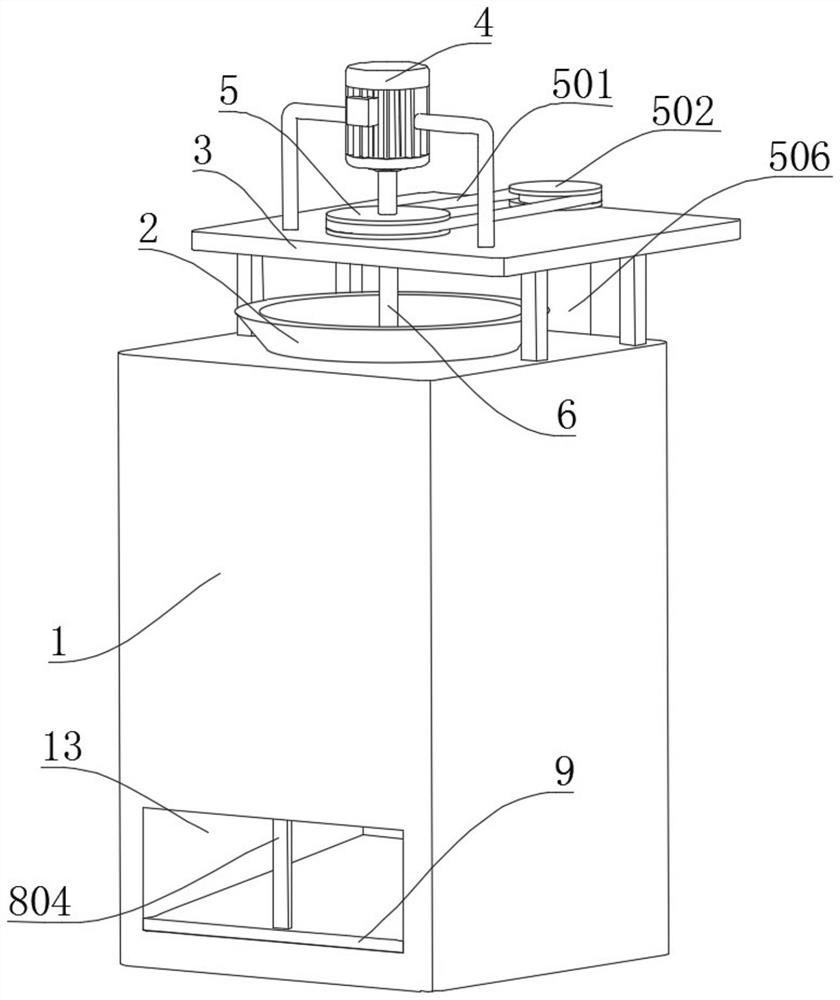

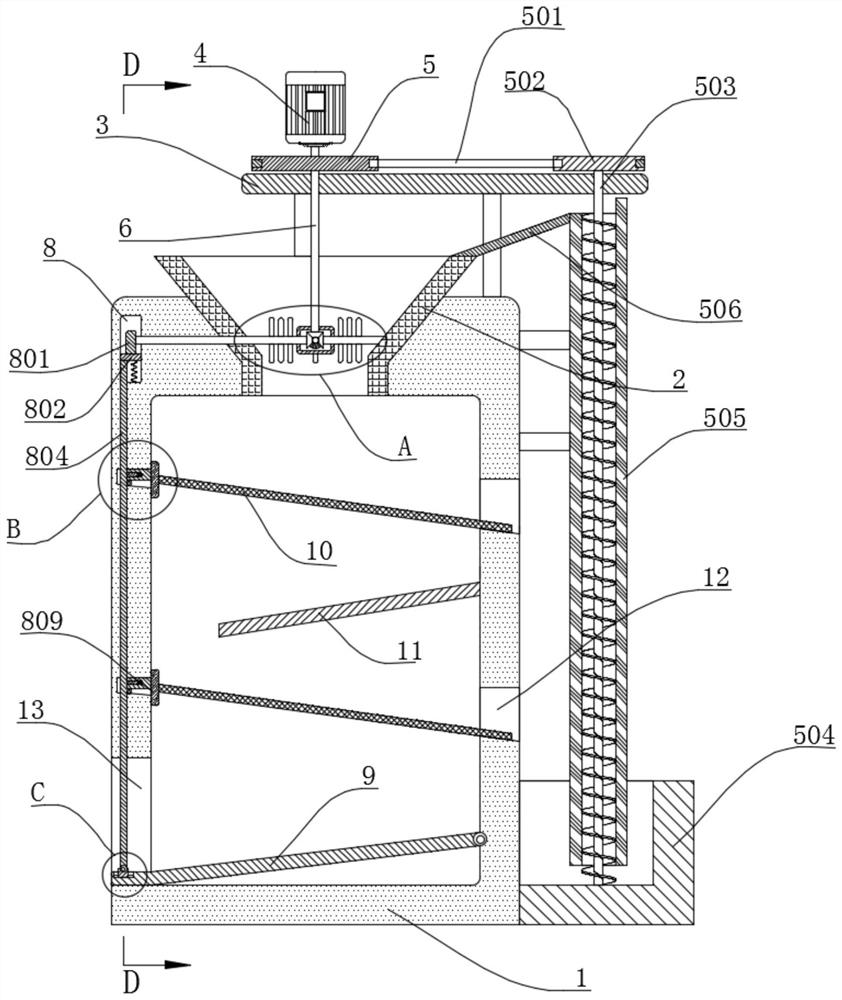

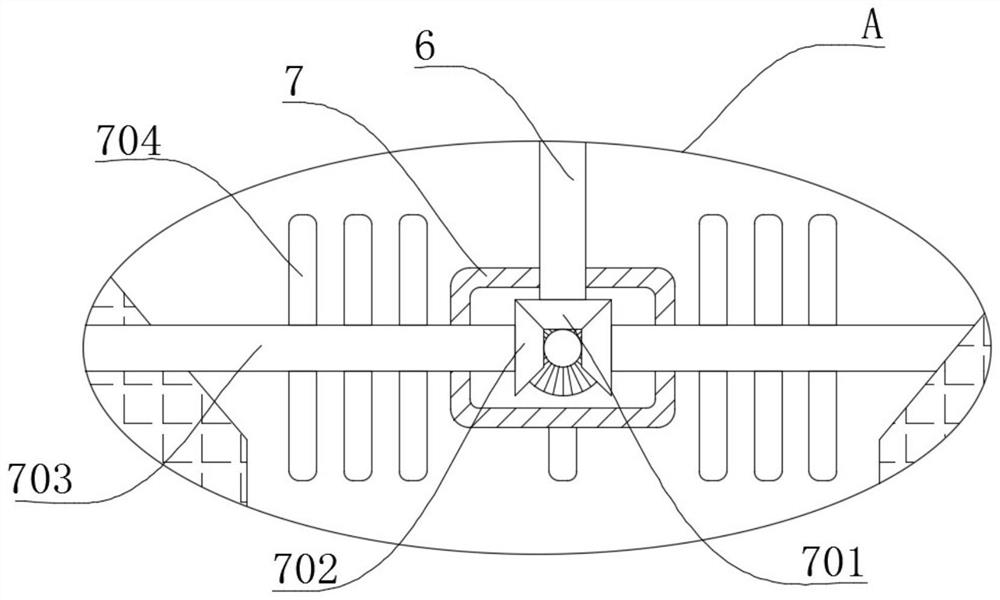

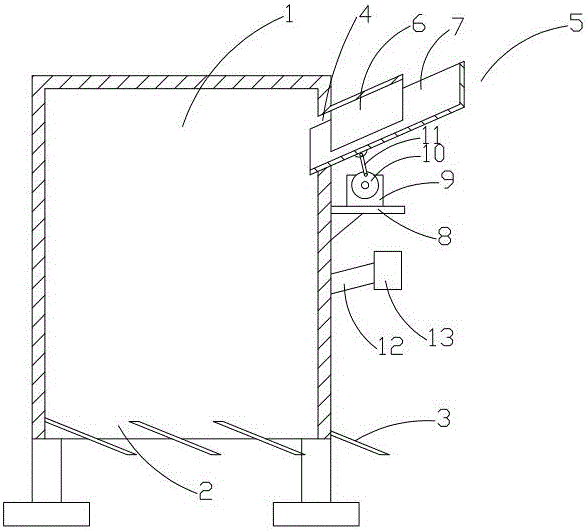

Automatic sludge processing device and method

InactiveCN108455819AAvoid secondary mixingGood screening effectSludge treatment by de-watering/drying/thickeningSludgeWastewater

The invention provides an automatic sludge processing device and method. The device comprises a processing box, a screening area, a layering area and an outputting area are sequentially divided from top to bottom in the processing box, and a main shaft is vertically and rotatably arranged in the processing box; a screening mechanism is arranged in the screening area, and a feeding mechanism is arranged in the screening area and located below the screening mechanism; a layering mechanism is arranged in the layering area, and a driving mechanism is arranged on the top of the processing box; according to the equipment, waste impurities containing water are output to the screening area, and the waste impurities are stirred and screened by a magnetic rotary screening rod, so that magnetic metalin the waste impurities is absorbed by the screening rod, then the waste impurities which are precipitated and layered are pressed, water is discharged, the separating discharging of the magnetic metal and waste water in the waste impurities is achieved, and the automatic discharging of waste water with magnetic metal in the waste impurities is achieved.

Owner:浙江明境环保科技集团有限公司

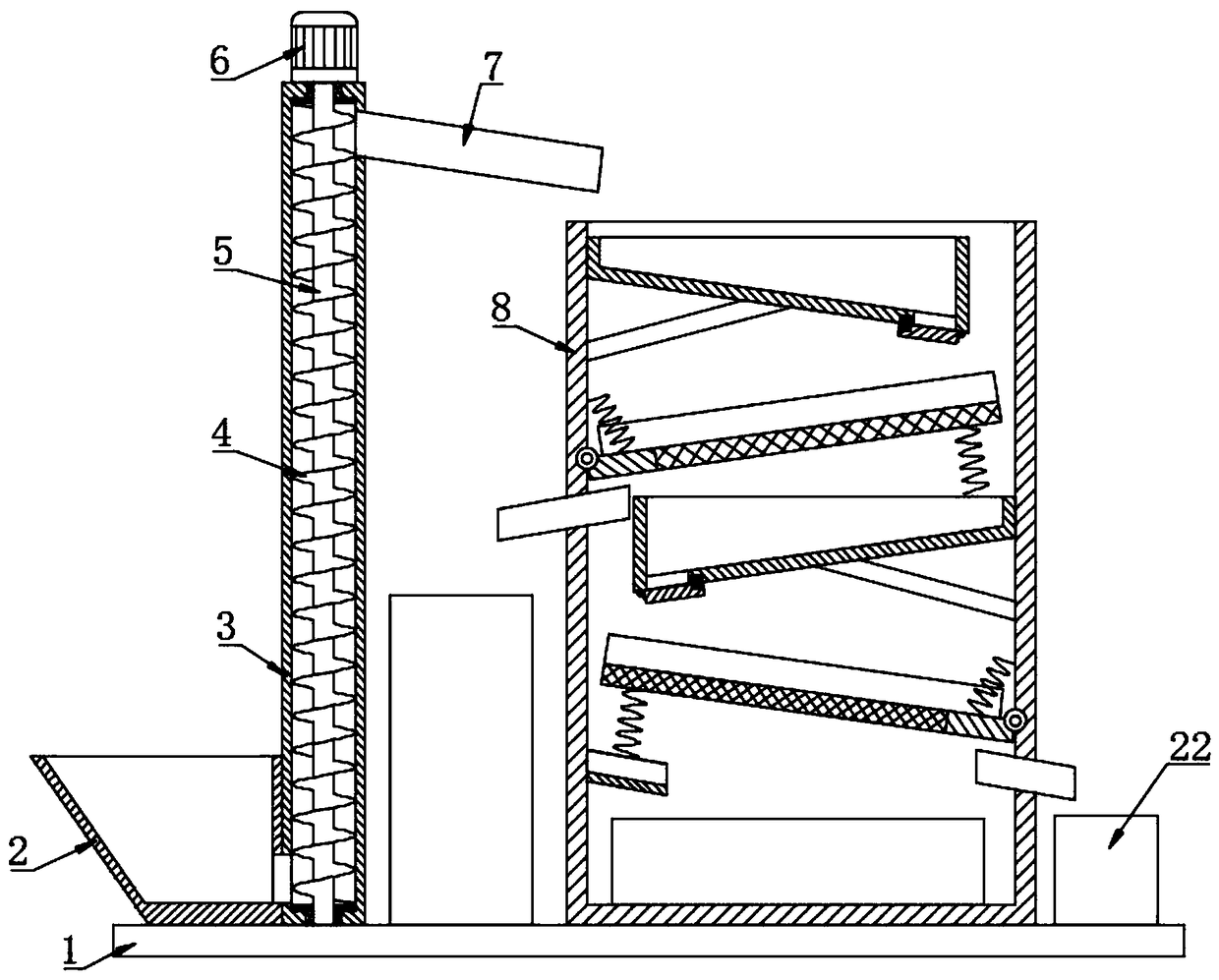

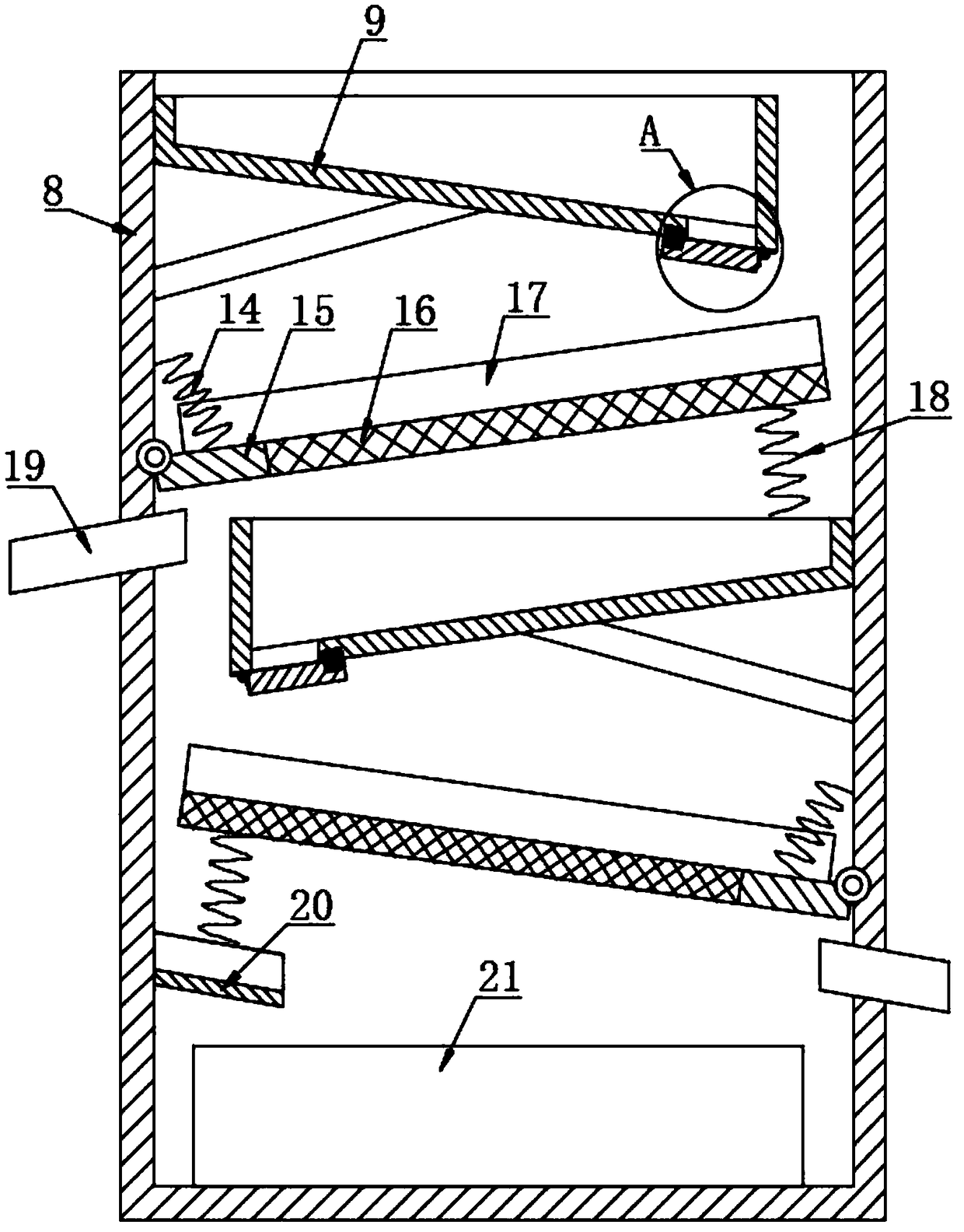

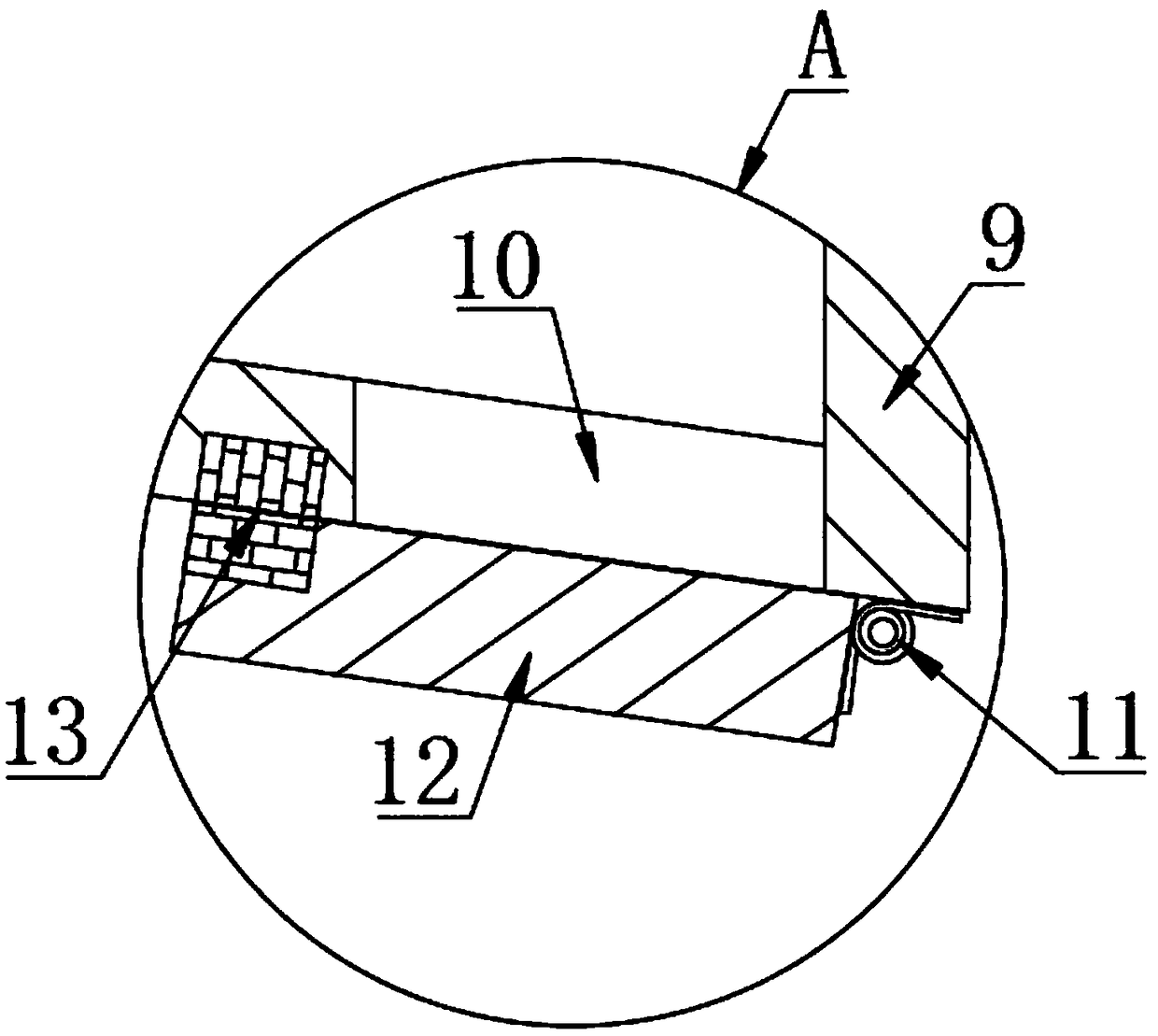

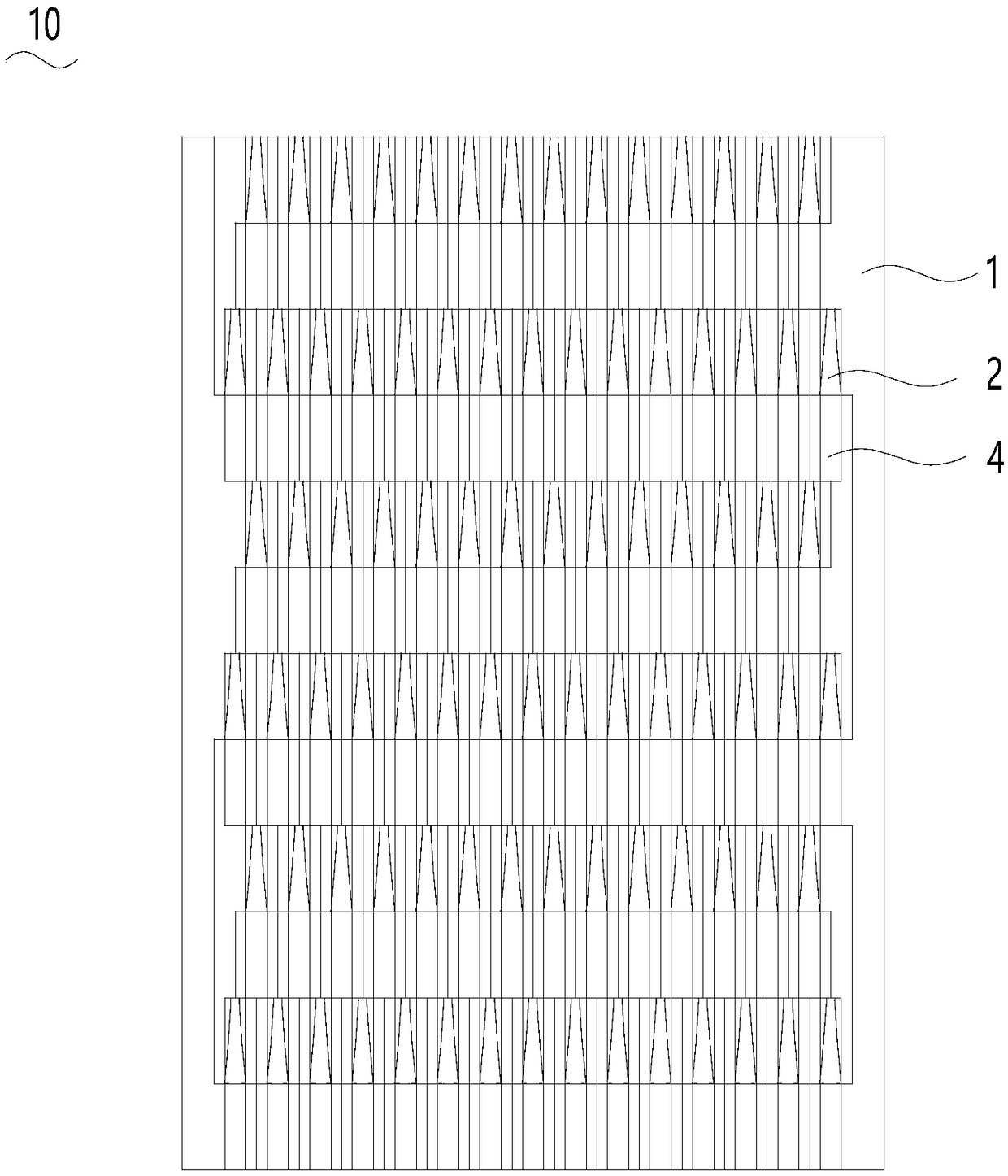

Self-vibration type corn grading device

The invention discloses a self-vibration type corn grading device. The device comprises a base, wherein a grading box is fixedly arranged at the top of the base, an upper gathering box and a lower gathering box are arranged in the grading box, the upper gathering box and the lower gathering box are connected with the left side wall and the right side wall in the grading box respectively through supports; the bottom wall of the upper gathering box is inclined towards the lower right portion, a discharging opening is formed in the right side of the bottom wall of the upper gathering box, a baffle matched with the discharging opening is hinged to the lower right corner of the upper gathering box, a torsion spring is further connected to the hinged position between the baffle and the corresponding gathering box; magnetic attraction components matching with each other are each fixedly inlaid in the upper left corner of the baffle and the bottom wall of the upper gathering box; and an upperinclined plate and a lower inclined plate are further arranged in the grading box, the upper inclined plate and the lower inclined plate are hinged to the left side wall and the right side wall of thegrading box respectively. According to the device, the gathering boxes are arranged, when corns gather together then fall onto a net plate, gravity of the right end of the net plate suddenly increases, so that the net plate can swing up and down to screen, screening effect is good, a vibration motor and the like do not need to be additionally arranged in the screening process, screening is carried out automatically, and energy is saved.

Owner:江苏东台三仓润丰现代农业产业园有限公司

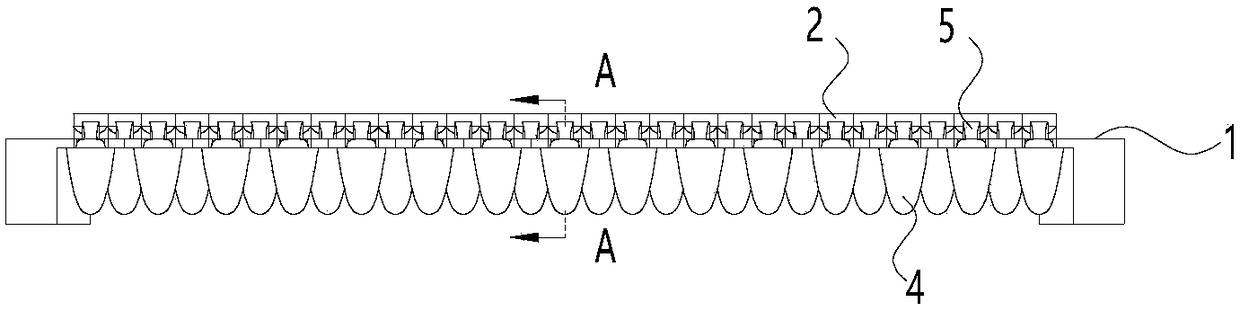

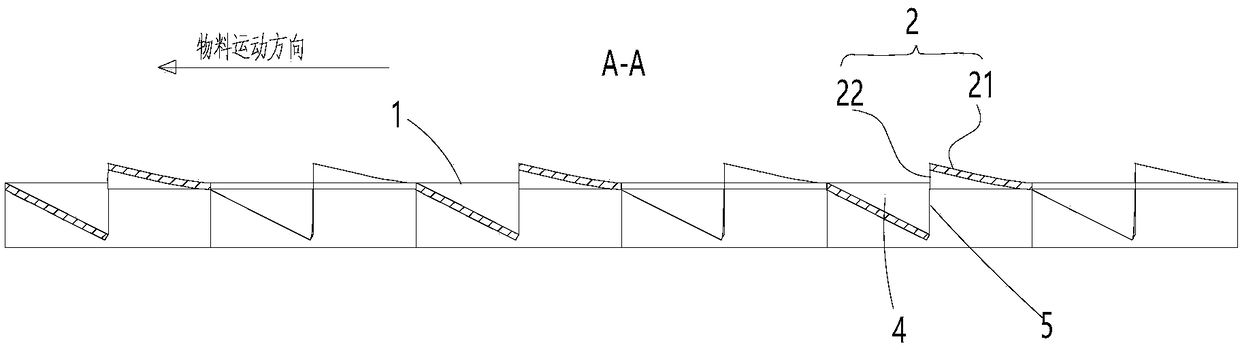

Irregular mixed material screening device

The invention discloses an irregular mixed material screening device. The irregular mixed material screening device comprises a frame, a vibration motor, and a vibration screen arranged on the frame;the vibration screen comprises a screening net plate; the screening net plate comprises a substrate; the substrate is provided with multiple discharge holes; the screening net plate further comprisesmultiple grooves downwards recessed from a plane of the substrate, and multiple convex parts projected on the plane of the substrate; the back end parts of the grooves communicate with the discharge holes; and the depths of the grooves are gradually reduced from back to front. The irregular mixed material screening device has the advantages of good screening effect, tidy materials, difficult blockage of screening holes, no deformation of the screening net plate, and efficient and reliable overall equipment operation.

Owner:云南吉星德亿科技有限公司

Sweet potato grading screening device capable of reducing damage

InactiveCN110813745AGood screening effectRemove dust and dirtSievingGas current separationHorticultureEngineering

The invention discloses a sweet potato grading screening device capable of reducing damage. The sweet potato grading screening device comprises a base plate. The sweet potato grading screening deviceis characterized in that support legs are arranged on the outer wall of the top of the bottom plate, and a screening box is welded to the outer walls of the tops of the support legs; a concave hole isformed in the outer wall of the top of the screening box, a feeding hopper is welded to the inner wall of the concave hole, and a baffle is arranged on the outer wall of one side of the screening box; a vertical plate is welded to the outer wall of the top of the baffle, inclined rods distributed at equal intervals are arranged on the outer wall of one side of the vertical plate, the outer wallsof the inclined rods are rotationally connected with screening rollers, and inclined plates are correspondingly welded to the outer wall of one side of the vertical plate and the inner wall of one side of the screening box; and a fixing plate is arranged on the inner wall of one side of the screening box, and an ear seat is welded to the outer wall of the top of the fixing plate. By the adoption of the sweet potato grading screening device capable of reducing damage, fast screening of sweet potatoes with different sizes is effectively achieved, the screening effect is better, the buffering effect on the sweet potatoes can be achieved, it is effectively guaranteed that damage to the sweet potatoes in the screening process is avoided, and the sweet potato grading screening device capable ofreducing damage is more practical.

Owner:湖南心海圆农业发展股份有限公司

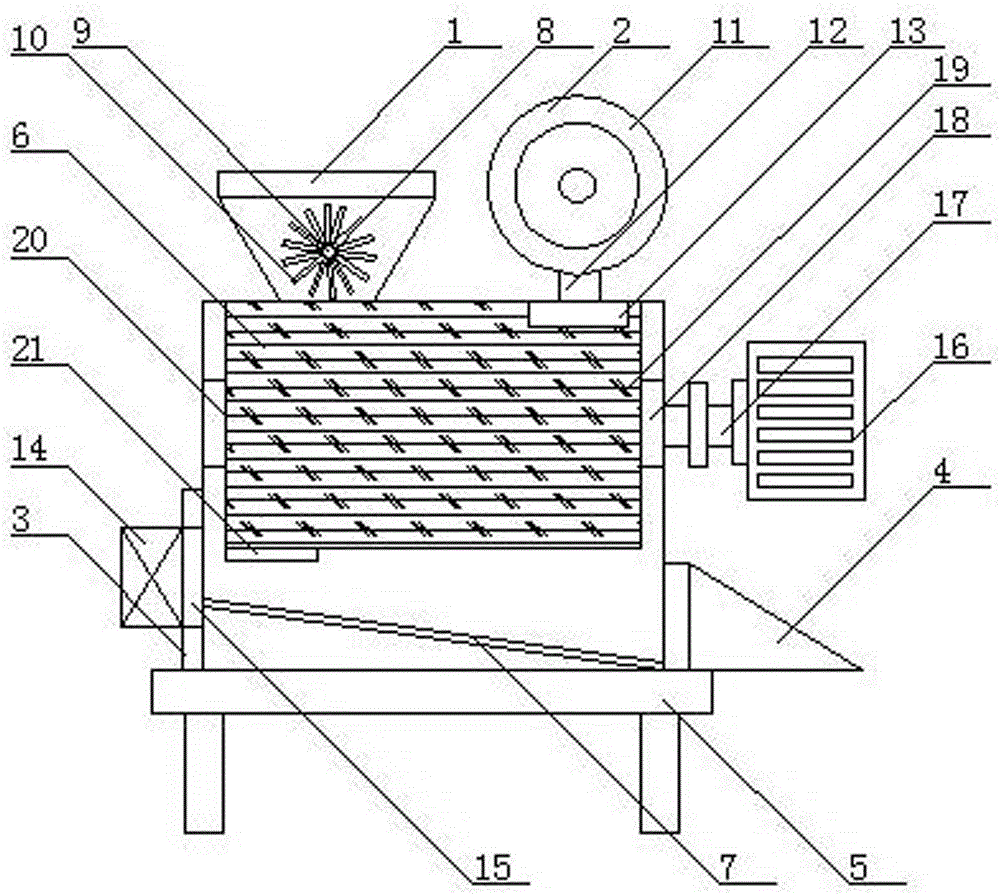

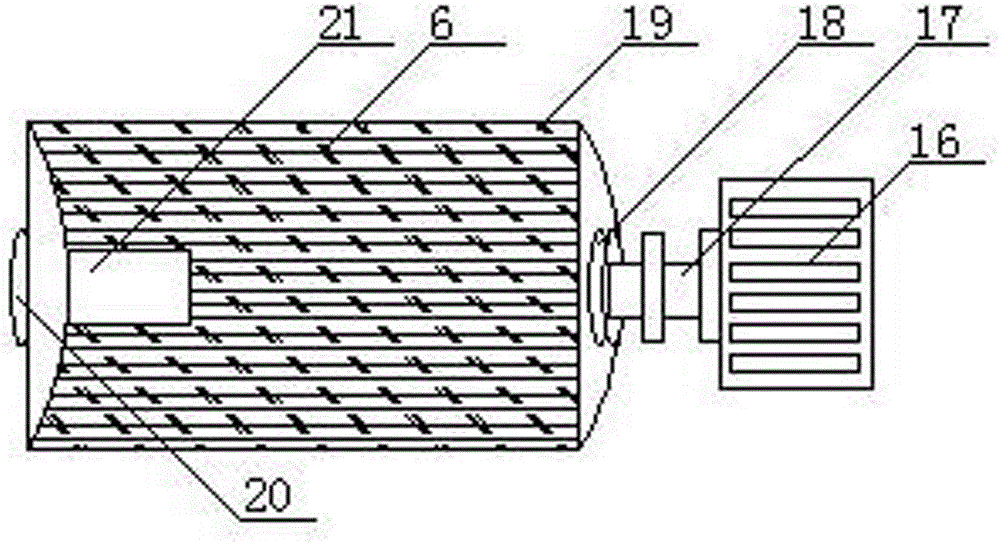

Drum type dry corn kernel screening device for agriculture

InactiveCN108080269ASimple structureGood screening effectSievingGas current separationDrive motorAgriculture

The invention discloses a drum type dry corn kernel screening device for agriculture. The drum type dry corn kernel screening device comprises a device body. A base is arranged on the bottom of the device body. A screening cavity is formed above the base. A drive motor is arranged on the top of the screening cavity. A feeding opening is formed in the top of the screening cavity. The device body isprovided with a material collecting bin. A fan is arranged on the base. A dust collecting bin is arranged on the left side of the device body. The device body is provided with a screening mechanism.The drum type dry corn kernel screening device is simple in structure, materials are screened in a rolling manner, the screening effect is good, the screening speed is high, the positions of the materials in a drum change fast, the good screening effect is achieved, moreover, in the screening and feeding process, by means of the effect of discharging paddles, blocking of the feeding opening is effectively avoided, moreover, dust in the materials are treated in the whole process, the quality obtained after screening is improved, the use effect is good, and practicality is high.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

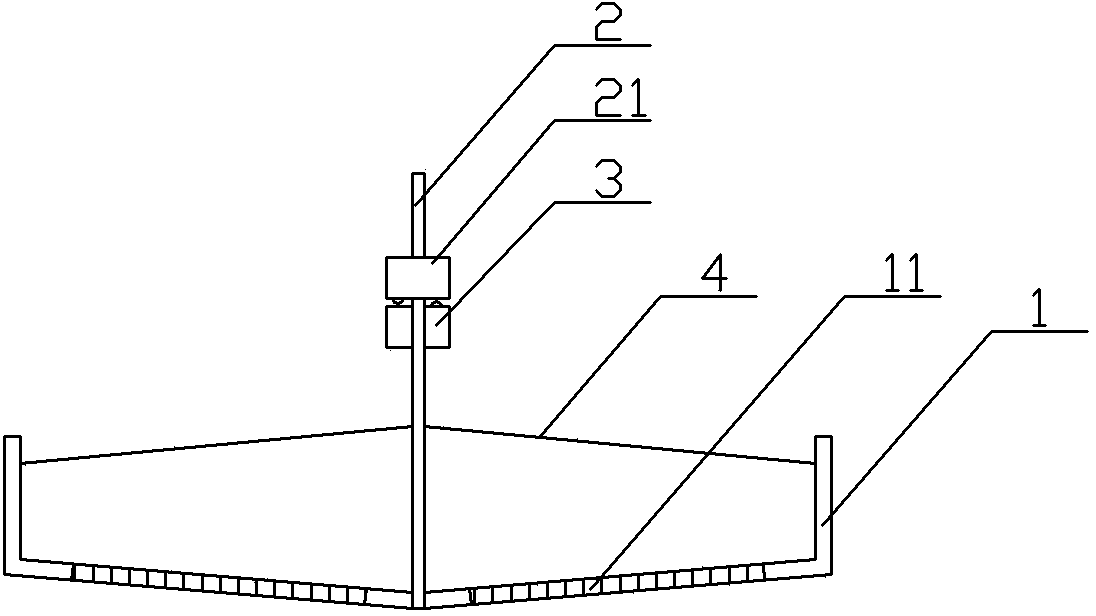

Sand screening device with automatic feeding and discharging functions

ActiveCN105710032AGood screening effectReduce frictionSievingScreeningElectric machineryElectric energy

The invention discloses a sand screening device with the automatic feeding and discharging functions. The sand screening device comprises a base frame. An edge baffle and a pressure sensor are arranged on the upper portion of the base frame. A multi-stage oil cylinder is arranged on one side of the base frame and matched with a discharging plate. The base frame is connected with a middle frame through a set of stand columns. A controller is arranged in the middle of the middle frame. A sand screening motor is arranged at one end of the middle frame and matched with a screen. The middle frame is matched with a feeding hopper through a support. A feeding motor is arranged on the lower portion of the feeding hopper and matched with a feeding wheel. A solar cell panel and an accumulator are arranged on the upper portion of the feeding hopper. The accumulator is electrically connected with lighting lamps at the ends of an extending-and-contracting rod. The electric sand screening manner is adopted in the sand screening device with the automatic feeding and discharging functions, automatic sand screening and discharging can be achieved, the workload of construction workers is relieved greatly, the sand screening quality is guaranteed while efficiency is improved, the solar lighting function is achieved, and part of electric energy is saved.

Owner:山西宏厦建筑工程第三有限公司

Building waste screening device

InactiveCN110340019AGood screening effectReduce collisionGas current separationWind forceAdaptive capacity

The invention relates to the field of building waste recycling, in particular to a building waste screening device which comprises a sorting chamber, a throwing device, a wind force device and a medium-heavy object sorting device. A first separation zone and a second separation zone are arranged in the sorting chamber; the throwing device is used for conveying materials to the first separation zone; the wind force device utilizes a wind force for raising the materials thrown out from the first separation zone; and the medium-heavy object sorting device comprises a double-layer sorting cylinder, a negative pressure mechanism, a fan and a cylinder drive mechanism. The building waste screening device can be used for separating building wastes into heavy substances, medium-heavy substances andlight substances according to the needs so as to have a good screening effect; the heavy substances cannot collide with the double-layer sorting cylinder in the screening process, so that the servicelife of the double-layer sorting cylinder is prolonged; in the screening process, a material throwing angle and a material throwing force of the throwing device can be adjusted according to the needs, so that an adaptive capacity of the equipment is greatly improved; and by using the building waste screening device, an equipment load can be effectively reduced, and the winnowing efficiency is improved.

Owner:长兴睿锋科技有限公司

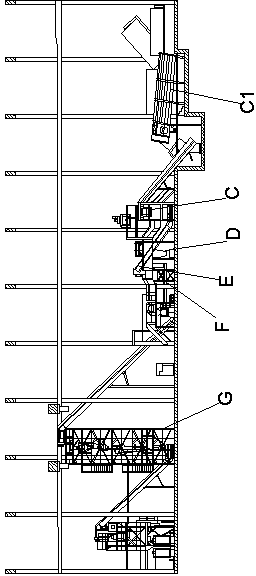

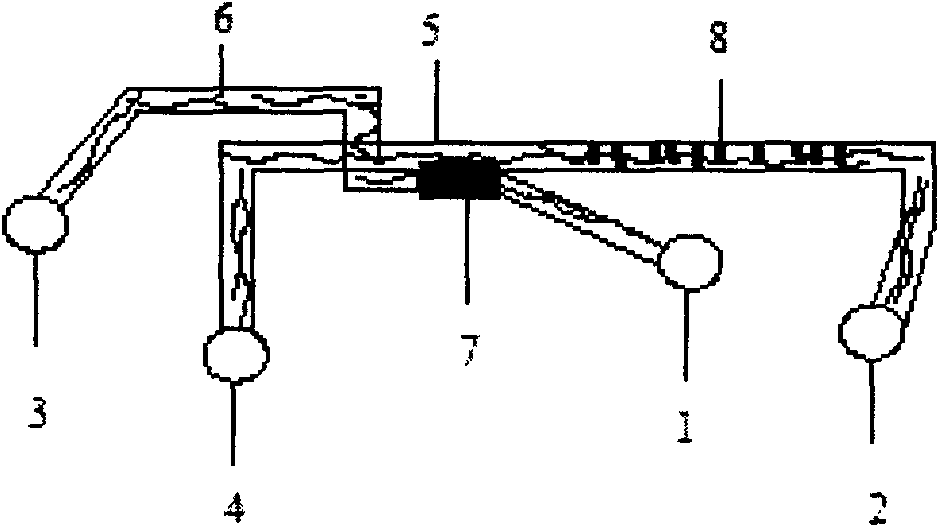

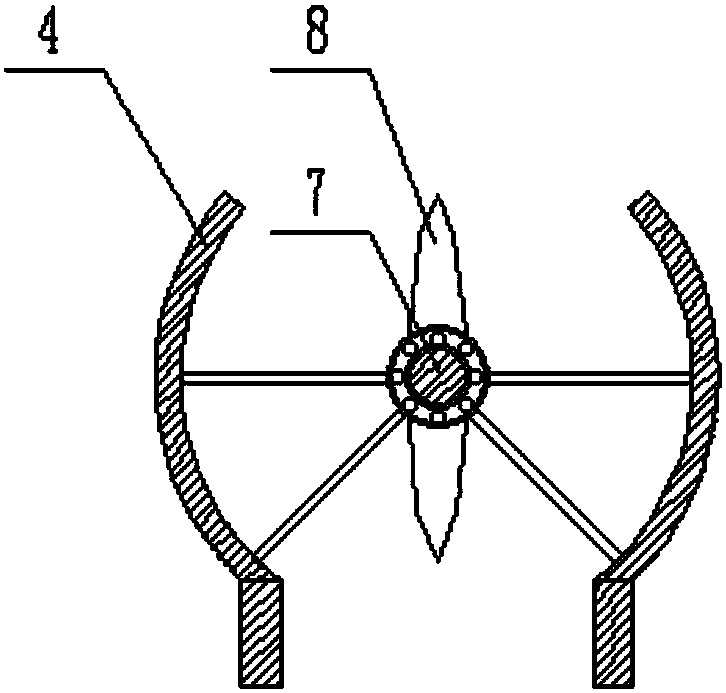

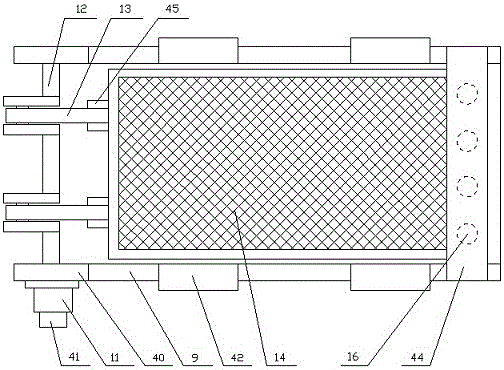

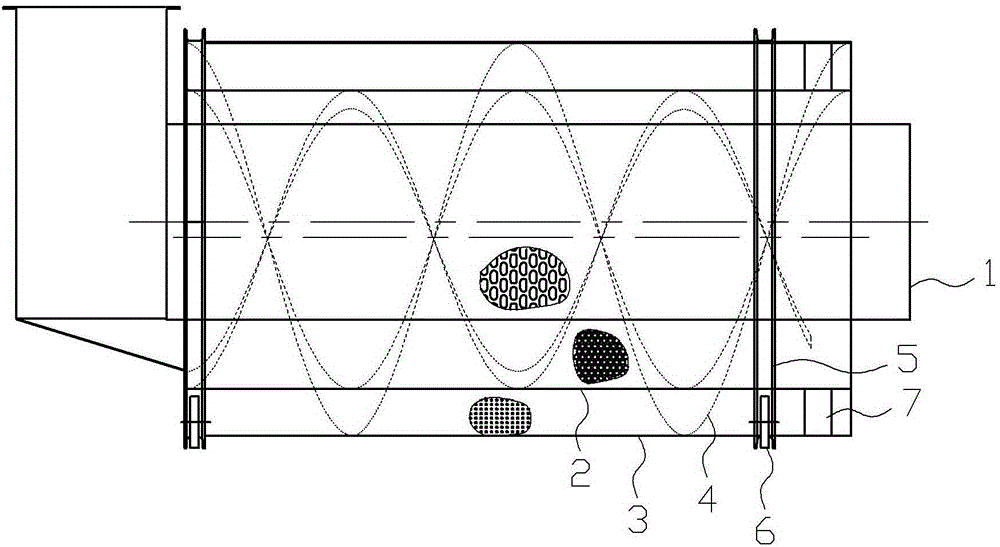

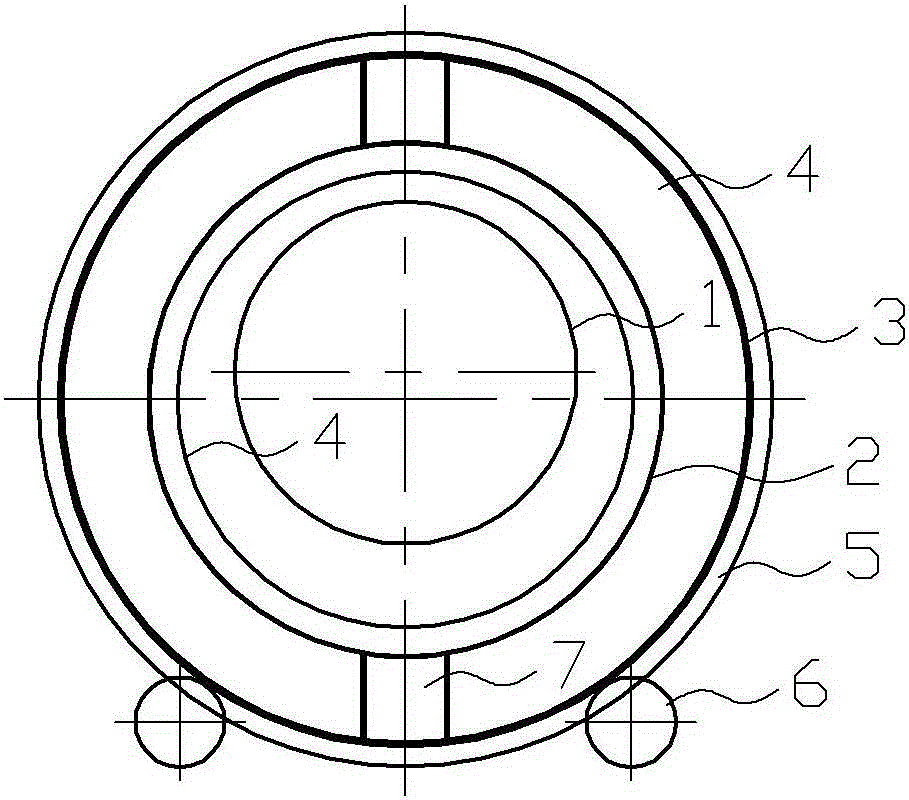

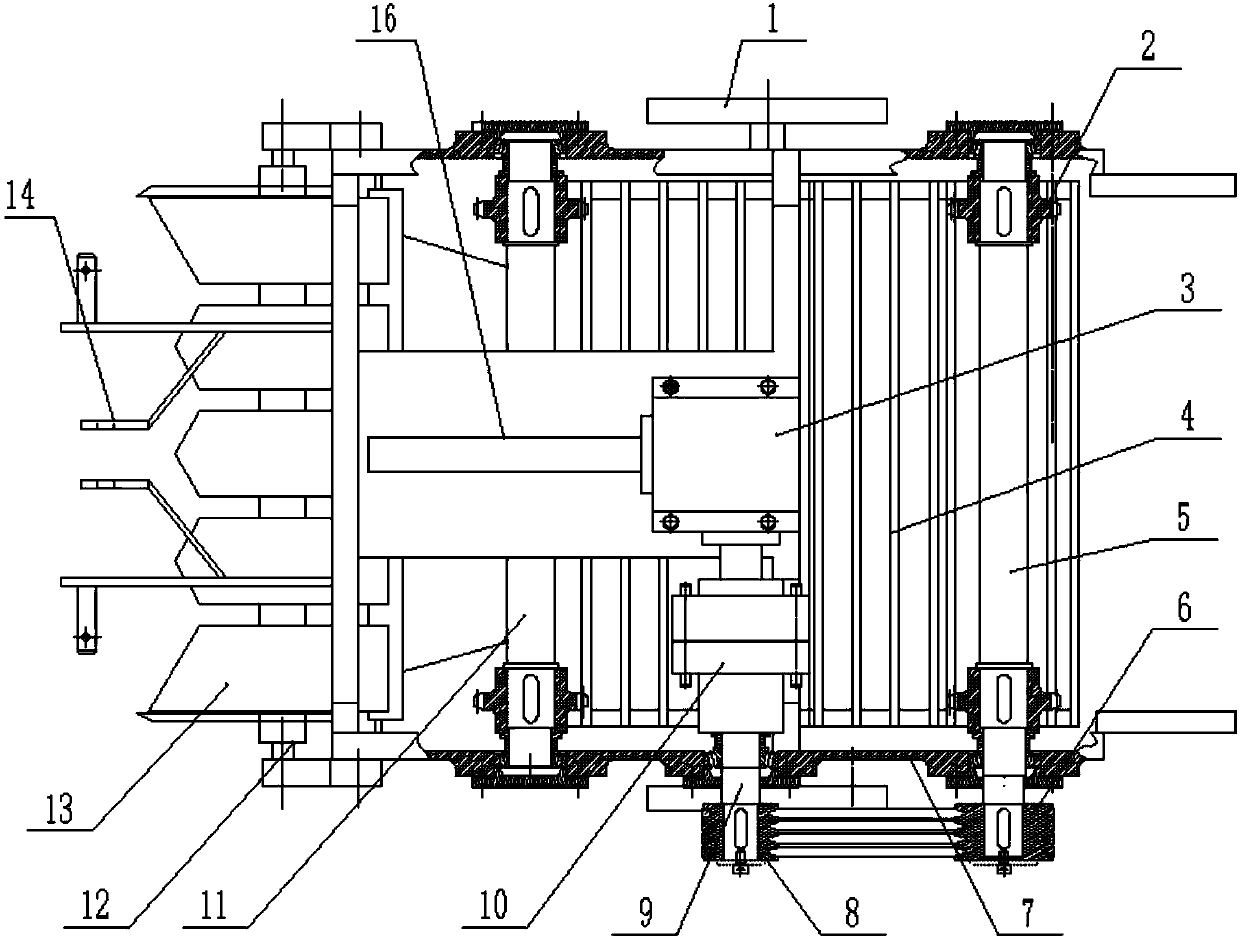

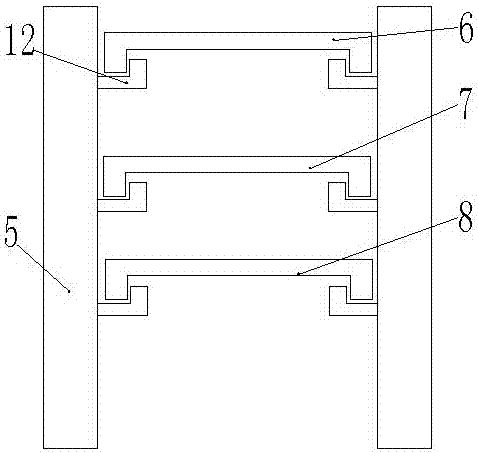

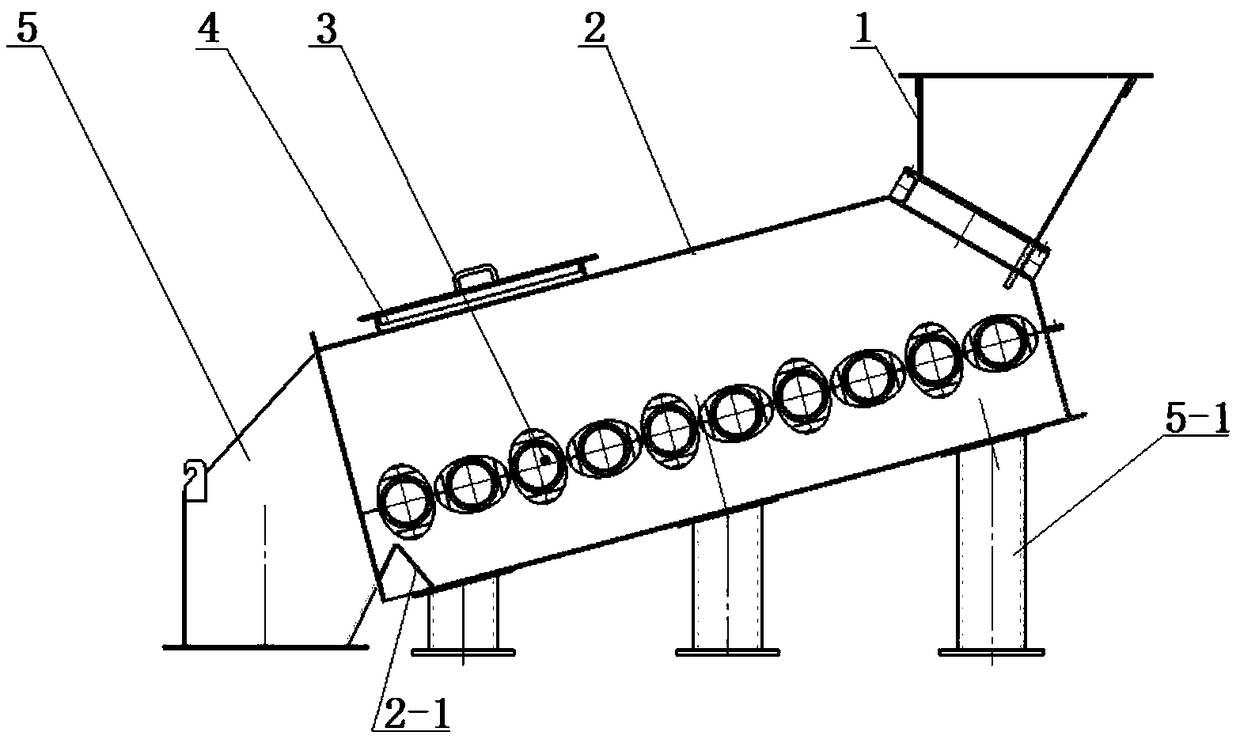

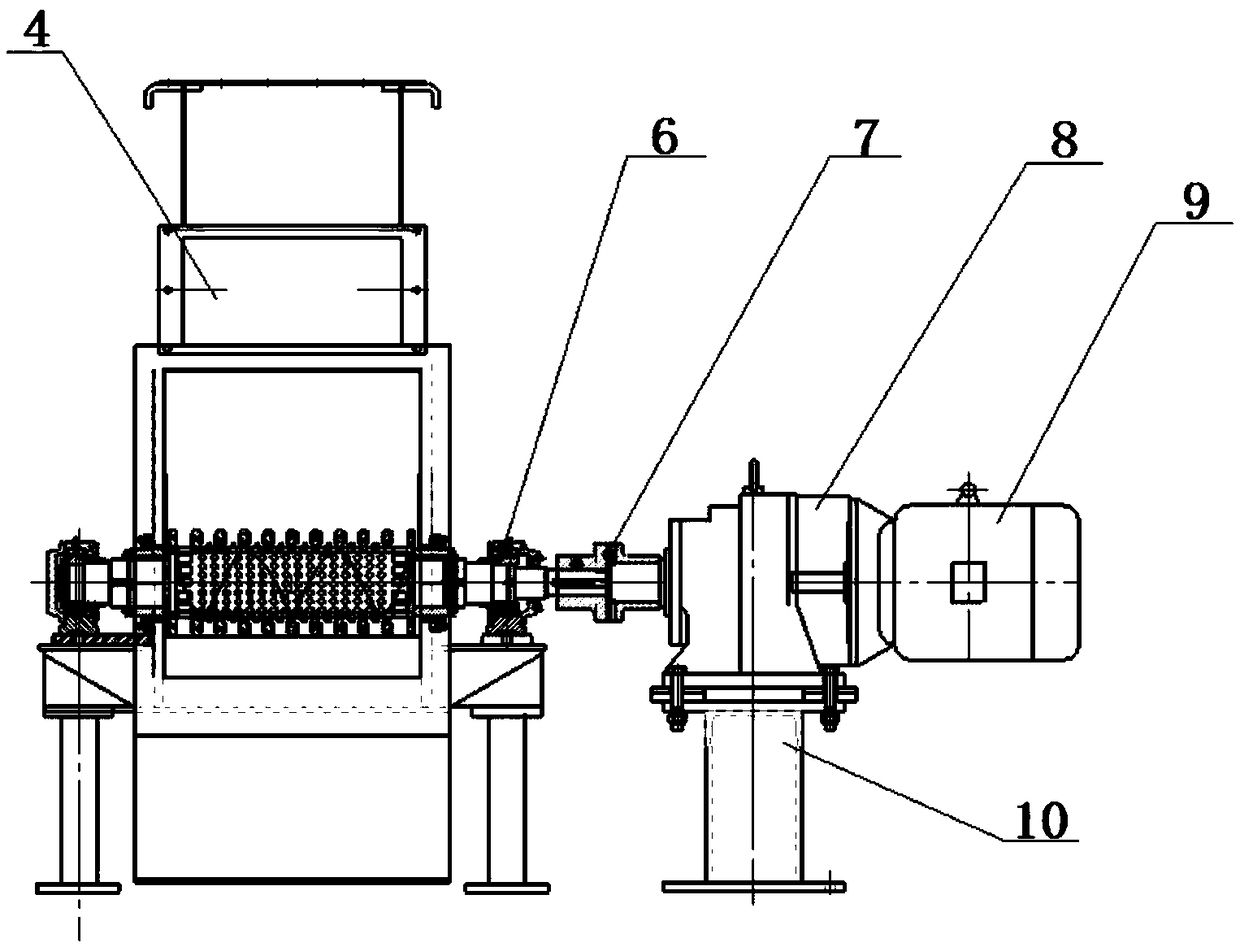

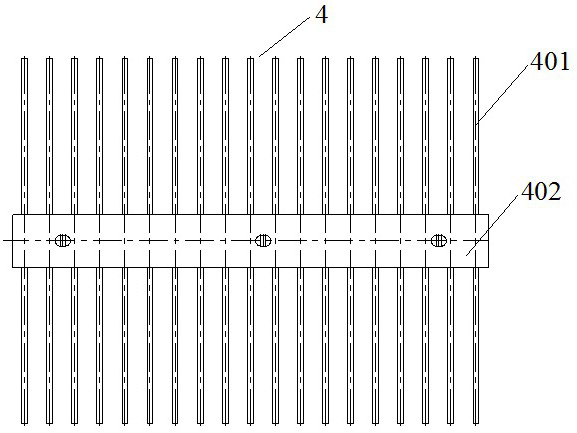

Corn thresher with roller screen

ActiveCN105191586ACompact and reasonable structureGood screening effectThreshersEngineeringMechanical engineering

A corn thresher with a roller screen comprises a corn thresher screen drum (1) and a cleaning device. The cleaning device is composed of an inner cleaning screen drum (2) and an outer cleaning screen drum (3) which are each shaped like a cylinder and are each provided with a spiral delivery sheet (4) surrounding the inner wall, an annular guide rail (5) is arranged on the outer wall of the outer cleaning screen drum (3) in a surrounding mode, rolling wheels (6) are arranged on a rack of the corn thresher, the inner cleaning screen drum (2) and the outer cleaning screen drum (3) are relatively fixed and arranged on the periphery of the corn thresher screen drum (1) in a sleeving mode, and the cleaning device can be driven by the rolling wheels (6) to rotate around the corn thresher screen drum (1). The corn thresher with the roller screen has the advantages of being compact and reasonable in structure, good in screening effect and clean in grain separation.

Owner:黑龙江省德峰机械制造有限公司

Urban building construction sand screening device

PendingCN113351474AImprove screening effectGood screening effectSievingScreeningHollow coreThree-phase electric power

The invention discloses an urban building construction sand screening device. The device comprises a device shell, a feeding hopper, a mounting plate, a three-phase motor, first discharging ports, a second discharging port, a screen, a rotating shaft, a feeding anti-blocking mechanism, a shaking mechanism, a lifting mechanism and a discharging mechanism. The device shell is of a hollow structure, the feeding hopper is fixedly connected with the top wall of the device shell in a penetrating manner, the two first discharging ports are formed in the side wall of the device shell, the second discharging port is formed in the side wall of the device shell, the mounting plate is fixedly connected with the upper surface of the device shell through a support, the three-phase motor is fixedly connected with the upper surface of the mounting plate through a support, and an output shaft of the three-phase motor is welded to the rotating shaft. The device has the advantages that the screening effect of the screening device is better, multiple times of screening can be automatically conducted, manual operation is avoided, the labor intensity is reduced, and meanwhile feeding and discharging accumulation and blockage can be effectively prevented.

Owner:张亮

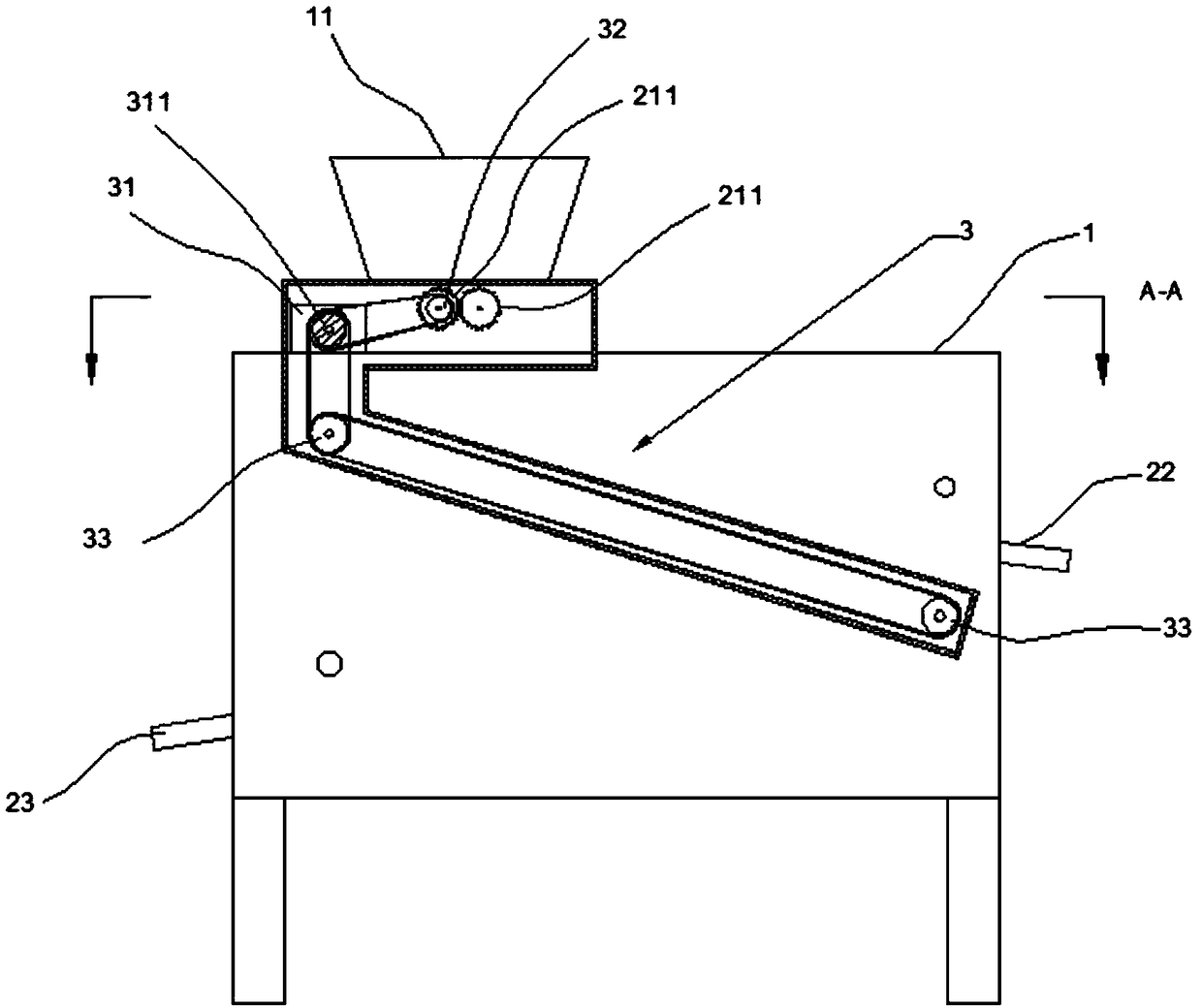

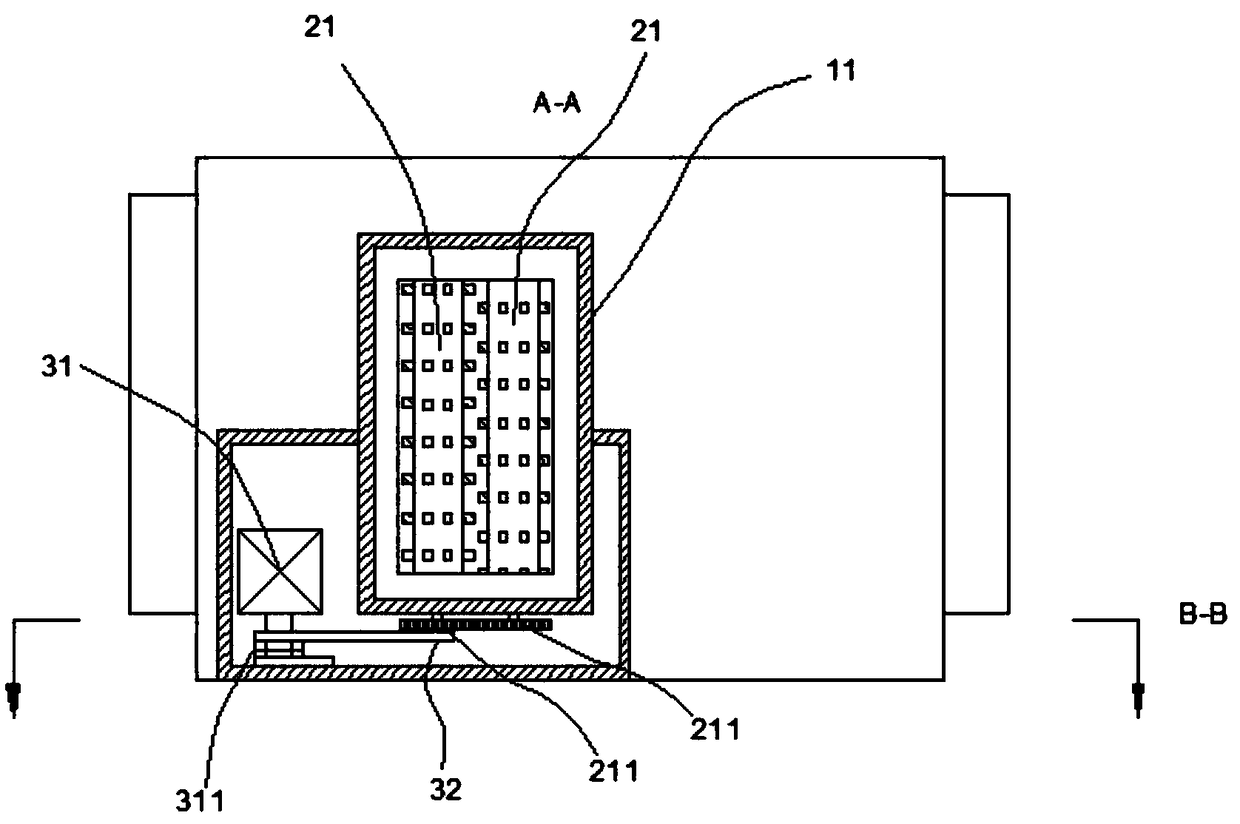

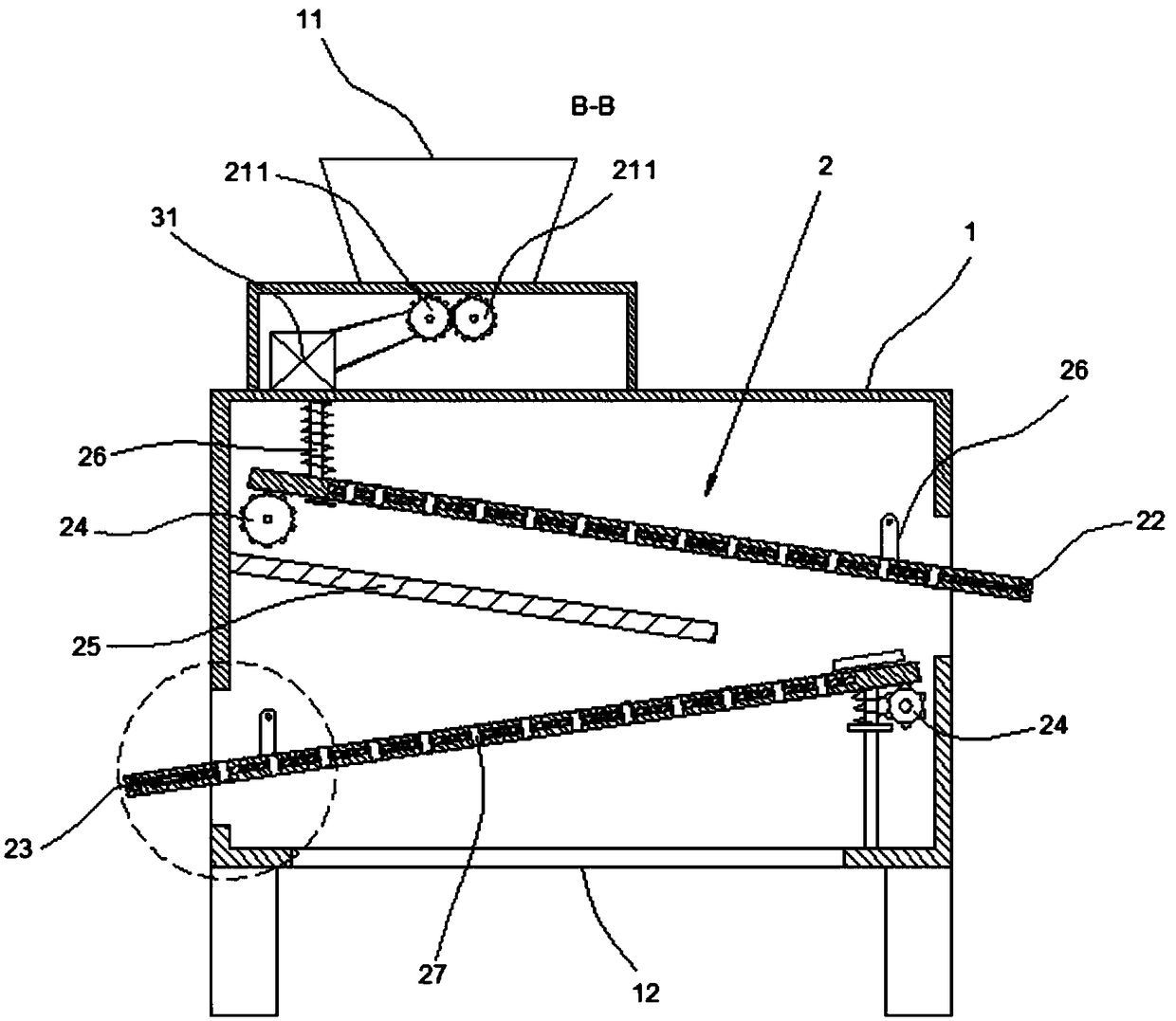

Tea sifting and grading machine

InactiveCN106622959AGood screening effectAvoid accumulationPre-extraction tea treatmentGas current separationDrive motorAgricultural engineering

The invention discloses a tea sifting and grading machine and relates to the technical field of tea processing. The tea sifting and grading machine comprises a box. An opening is formed in the lower end of the box. A plurality of oblique guiding plates are arranged at the opening at equal intervals. A feed inlet is formed in the upper end of the box, and a feed hopper is arranged at the feed inlet. The feed hopper comprises a fixed component and a movable component, and the fixed component is fixedly mounted on the box while the movable component is inserted into the fixed component. A mounting rack is fixedly arranged on the box. A drive motor is fixedly mounted on the mounting rack. An eccentric wheel is connected to a rotary shaft of the drive motor and connected with the movable component through a connecting rod. An air inlet pipeline is further arranged on the box and provided with an air blower in a connected mode. According to the tea sifting and grading machine, materials are fed uniformly, and the sifting and grading effects are good.

Owner:宜宾市产品质量监督检验所

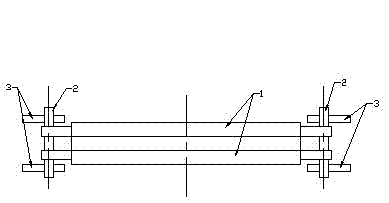

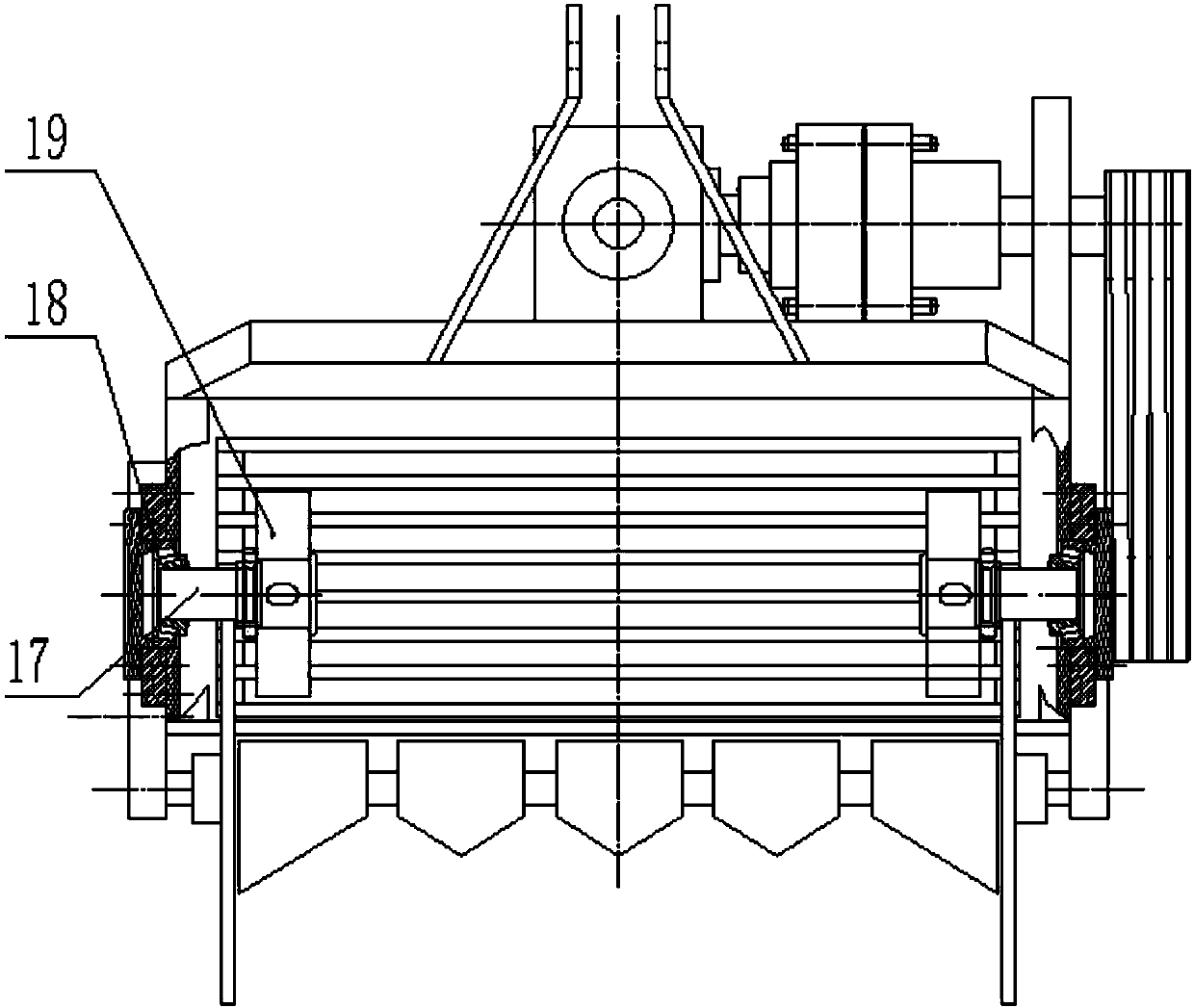

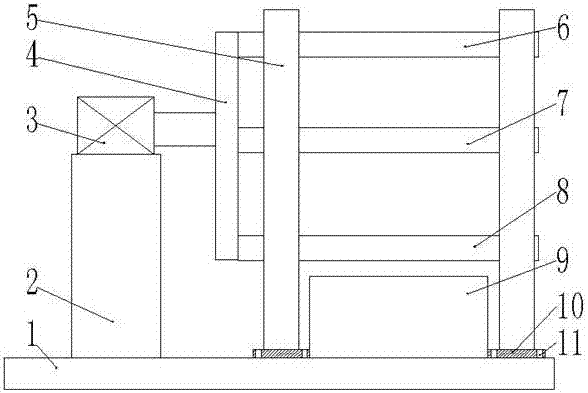

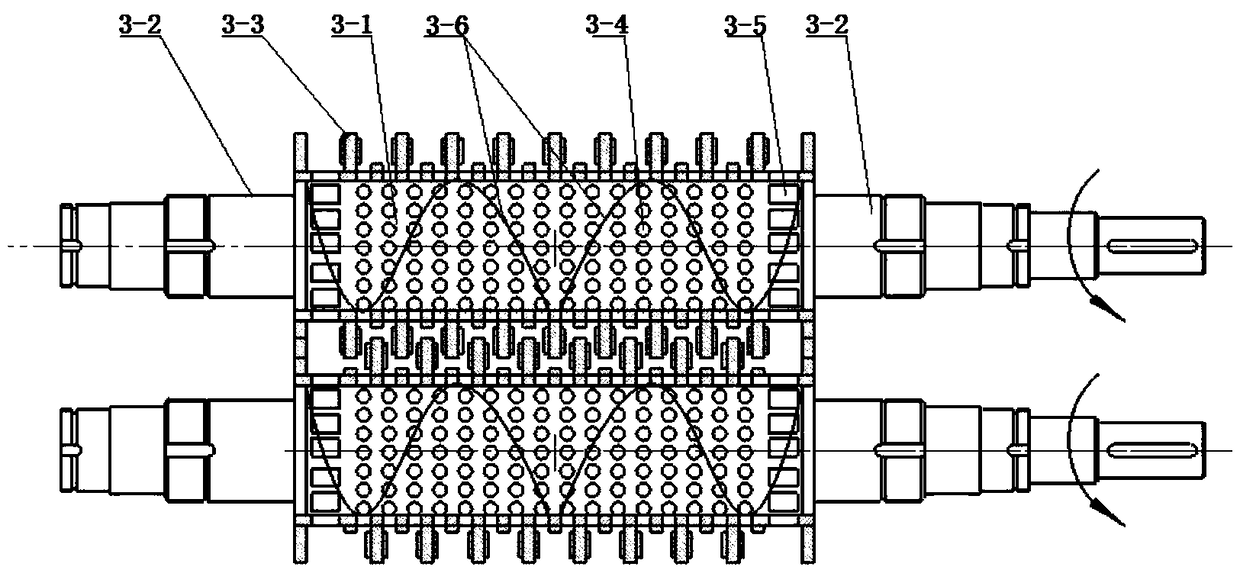

Double-shaft rocking sieve

The invention relates to a double-shaft rocking sieve which relates to a papermaking and artificial board industry and is used for sieving materials in a material preparing work section. The double-shaft rocking sieve comprises a plurality of layers of parallel sieve plates and the sieve plates are flexibly suspended on a fixing framework; each one of two sides of each sieve plate is respectively provided with a rotary shaft for connecting each sieve plate in a penetrated mode; and each rotary shaft is provided with an overweight block. According to the double-shaft rocking sieve, the rotary shafts at the two sides of the sieve plate and the overweight blocks are arranged so that the whole sieve plate can rock stably and the sieving effect is good; and meanwhile, the middle part of the whole sieve plate is not blocked by a rotary shaft part so that the sieving area is large, the efficiency is high and the material mobility is good.

Owner:JIANGSU DATANG MACHINERY

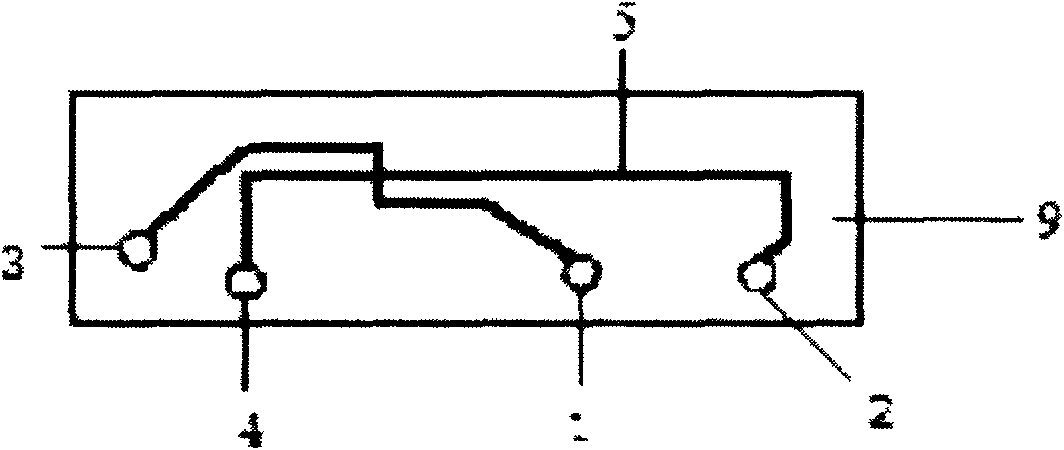

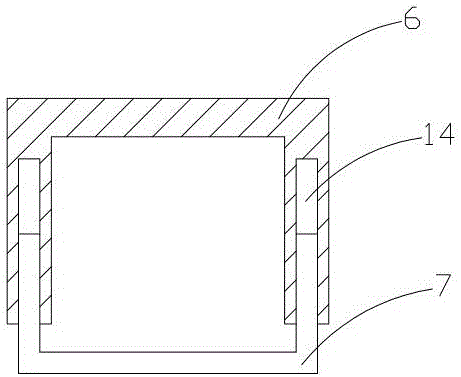

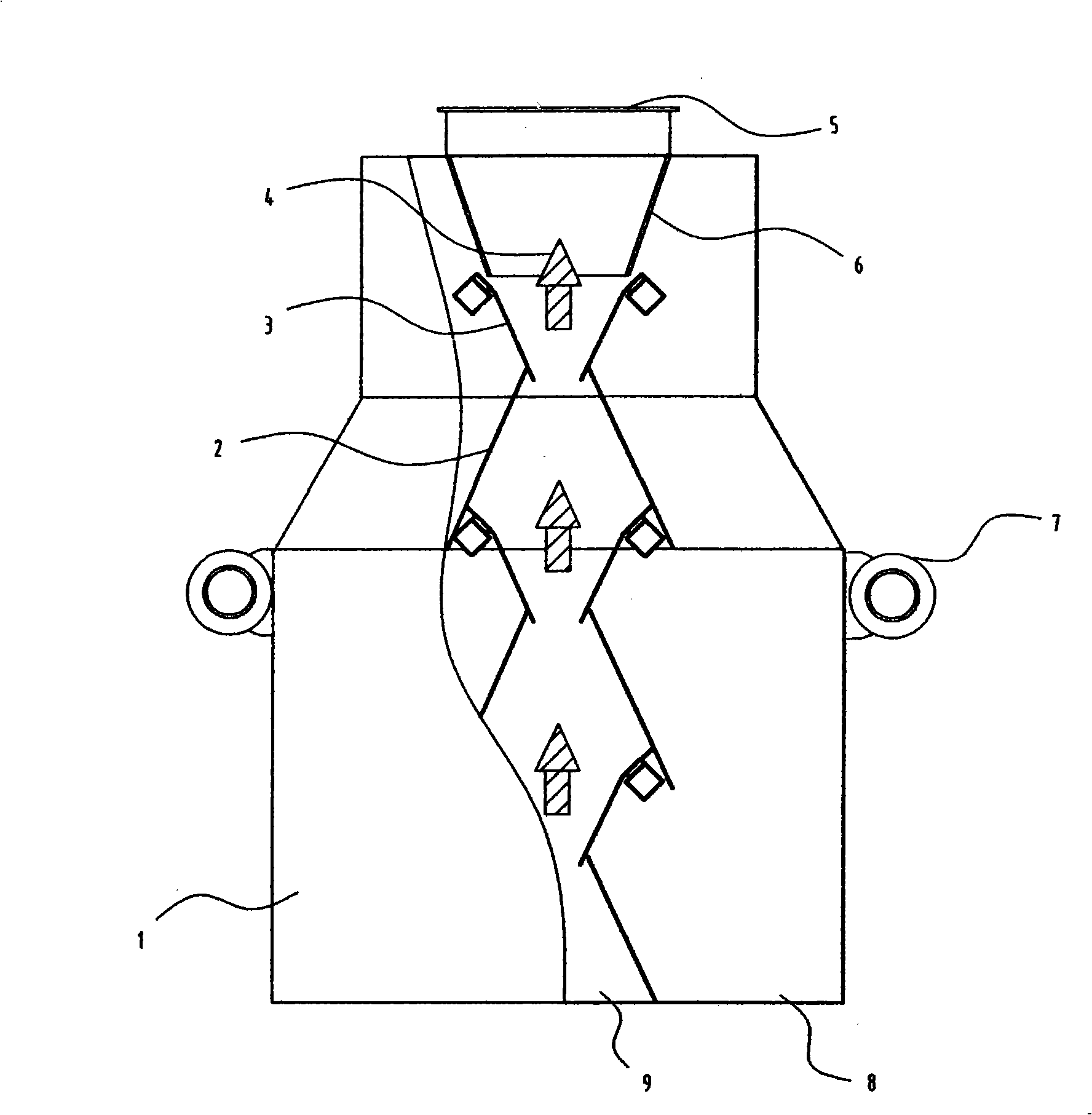

Vertically-arranged impact screen

InactiveCN101293245AGood screening effectHighlight substantive featuresSievingScreeningEngineeringSieve

The invention provides an industrial screen, in particular to a technical proposal of an erect impact screen; the technical proposal includes a feeding port and a box including a discharge hole of plus mesh and a discharge hole of undersieves, and sieve plates are arranged in the box; the proposal is that: at least two impact screen separation units are vertically arranged in the box in an up and down way; the impact screen separation units are provided with distributors, the tops of the cross sections of which take a conical shape, at the position of the central lateral plane of the box from top to bottom, two sieve plates, which are symmetrical by taking the central lateral plane of the box as an axle, are arranged at the two sides of the middle lower part in a V-shaped way, and two guide boards of the material under the screen, which are symmetrical by taking the central lateral plane of the box as an axle, are arranged at the lower parts of the two sieve plates in an inverted V-shaped way. The discharge hole of the plus mesh is the space between the impact screen separation units and the two guide boards of the material under the screen, and the discharge hole of the undersieves is the space between the two guide boards of the material under the screen and the side wall of the box.

Owner:孙功民

Soil remediation and screening device

The invention discloses a novel soil remediation and screening device. The soil remediation and screening device comprises a box body, and the box body is of an up-down penetrating structure. A first screening plate is arranged on one side wall in the upper portion of the box body in a downwards-inclining mode through first articulation pieces, a second screening plate is arranged on the other side wall in the lower portion of the box body in a downwards-inclining mode through second articulation pieces, and one side wall in the box body is parallelly opposite to the other side wall in the box body. A first discharging passageway is formed in the side wall, corresponding to a discharge end of the first screening plate, of the box body, and the discharge end of the first screening plate is exposed out of the first discharging passageway. A second discharging passageway is formed in the side wall, corresponding to a discharge end of the second screening plate, of the box body, and the discharge end of the second screening plate is exposed out of the second discharging passageway. According to the soil remediation and screening device provided by the invention, the screening effect is remarkable, the blocking phenomenon is avoided, and blocking clearing does not need to be conducted in the screening process.

Owner:ZHEJIANG GREEN ART GARDEN & PARK ENG

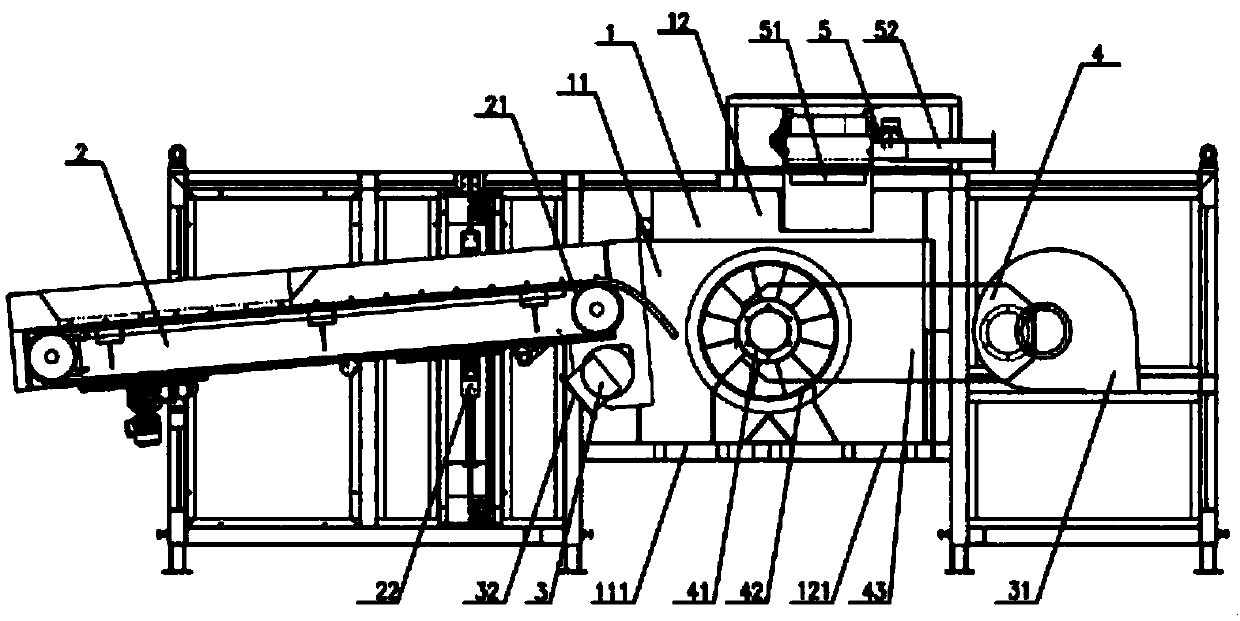

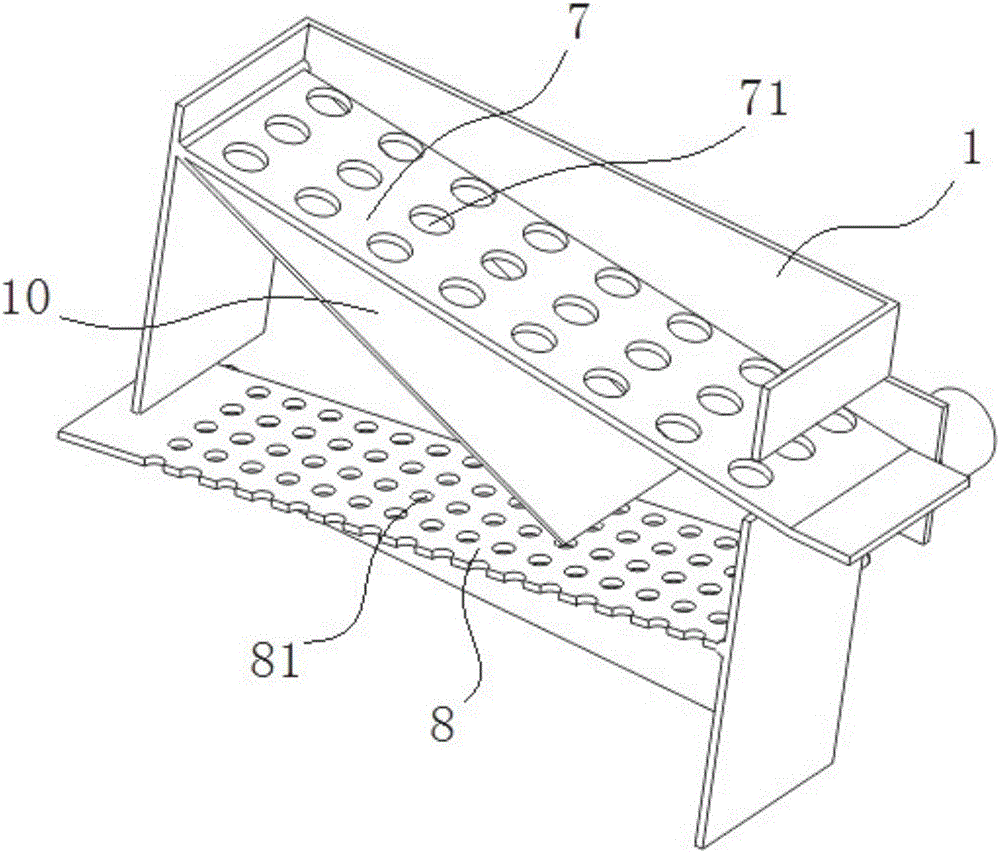

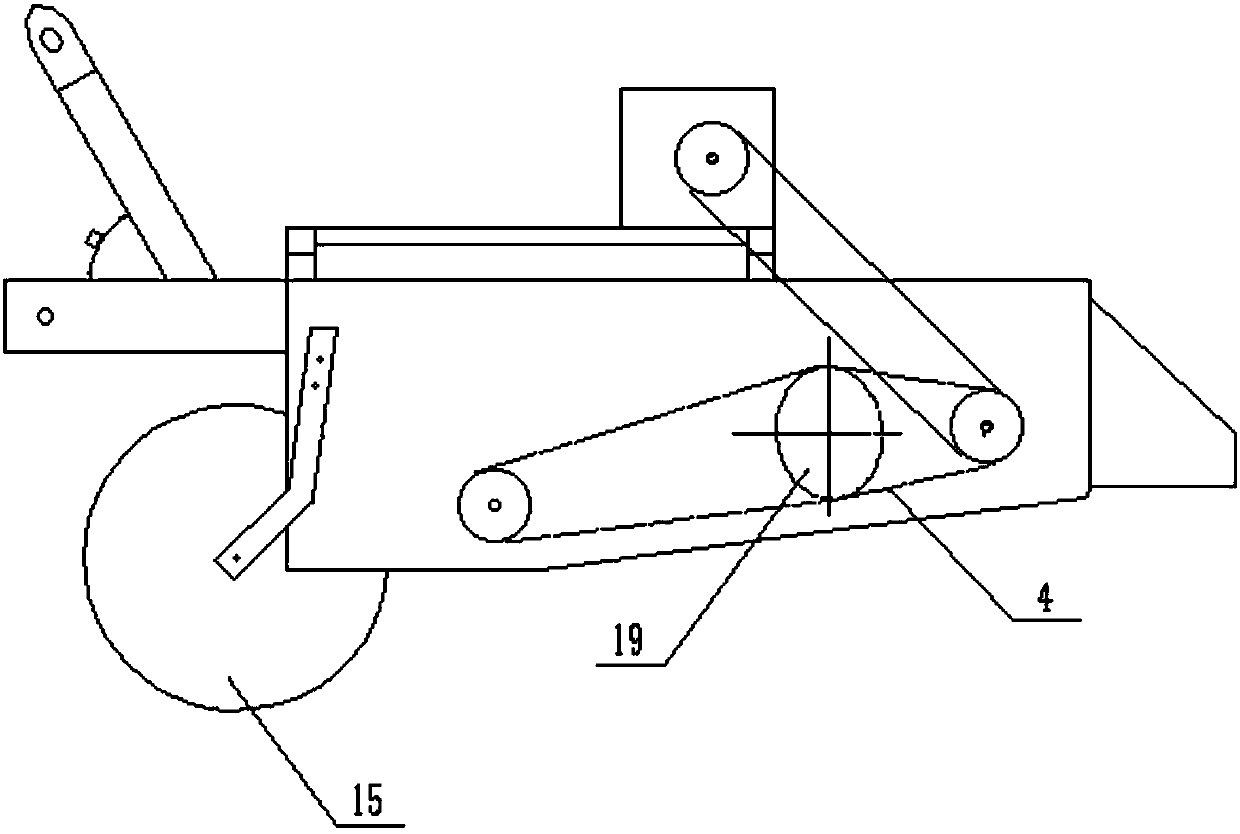

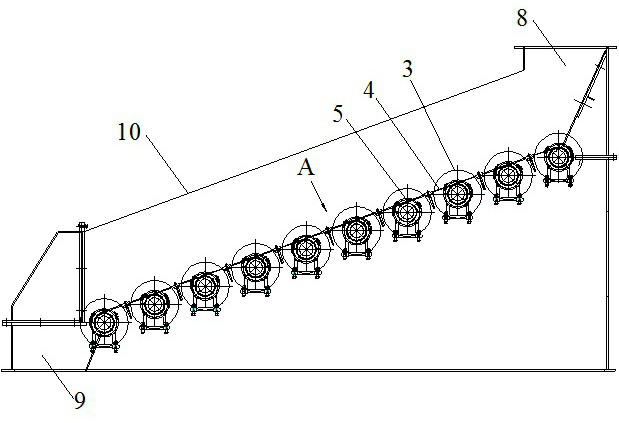

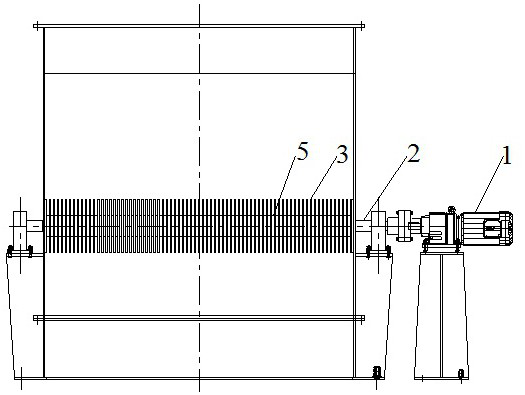

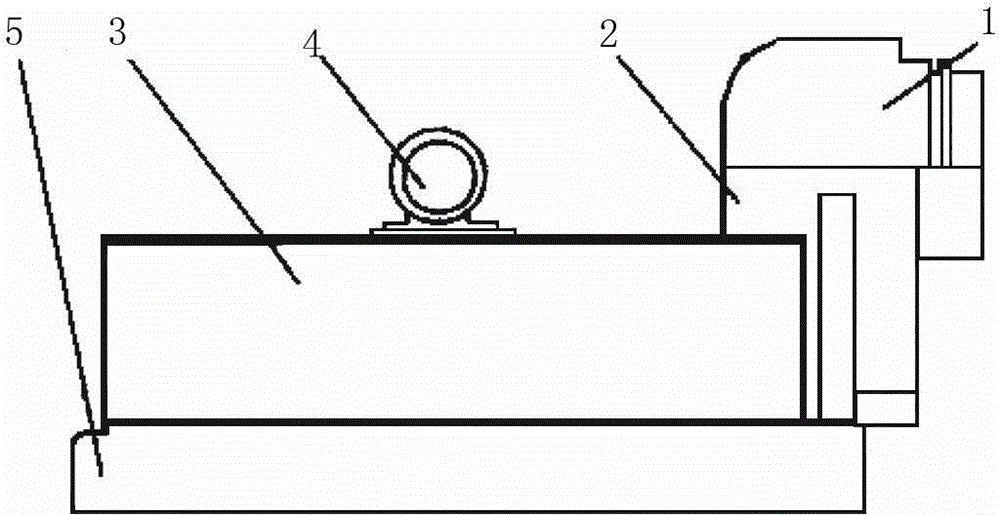

Potato harvesting machine

PendingCN107864737AGood screening effectRealize the screening effectDiggersAgricultural engineeringAgricultural science

The invention relates to the technical field of agricultural machinery, in particular to a potato harvesting machine. The potato harvesting machine is characterized by comprising a machine frame, wherein a shovel bucket part, a lifting and conveying part, a driving part and a shaking part are arranged on the machine frame; the shovel bucket part is fixedly arranged at the front end of the machineframe, and used for shoveling the potato out of a field, and the back end of the shovel bucket part is in contact with the lifting and conveying part; the lifting and conveying part comprises a drivenchain wheel and a driving chain wheel, the driven chain wheel is arranged at the front end of the machine frame, the driving chain wheel is arranged at the back end of the machine frame, the driven chain wheel is connected with the driving chain wheel by a lifting and conveying chain, and the lifting and conveying part is used for conveying the potato shoveled by the shovel bucket part; the shaking part comprises an eccentric wheel, the eccentric wheel is arranged in the middle part of the machine frame and is positioned between the driving chain wheel and the driven chain wheel, wheel teethare arranged on the eccentric wheel, and the eccentric wheel is in contact with the lifting and conveying part through the wheel teeth and is used for supporting the lifting and conveying chain. The potato harvesting machine has the advantages that the damage rate in the potato harvesting process is reduced, and the screening efficiency of potato and soil is improved.

Owner:LIAOCHENG UNIV

Screening mechanism of crusher

ActiveCN107282281AImprove screening efficiencyGood screening effectSievingScreeningHydraulic ramCrusher

The invention discloses a screening mechanism of a crusher. The screening mechanism comprises a base; the outer wall of the top of the base is connected with four support rod baseplates through fixed bolts; support rods are welded at the middle parts of the outer walls of the tops of the four support rod baseplates; the outer wall of one side of the top of the base is connected with a hydraulic oil cylinder support rod through a fixed bolt; the outer wall of the top of the hydraulic oil cylinder support rod is connected with a hydraulic oil cylinder through a fixed bolt; an extension rod of the hydraulic oil cylinder is near the support rods; and the outer wall of one side of the extension rod of the hydraulic oil cylinder is connected with a connecting rod through a fixed bolt. The screening mechanism is provided with multiple screens with different screen hole diameters for multistage screening; and when the screening work is performed, the screens can be driven by the hydraulic oil cylinder to shake back and forth to accelerate the screening efficiency, so that the screening effect is good, materials are not needed to reversely feed in a crushing box for multiple times of crushing, the workload of operators is reduced, and the material screening work efficiency is effectively improved.

Owner:XINXIANG DONGZHEN MACHINERY

Equine herpesvirus-1 and application thereof

PendingCN110885794AGood screening effectEasy to trainMicrobiological testing/measurementDsDNA virusesDiagnostic testA-DNA

The invention relates to equine herpesvirus-1 XJYM2019, protein of the virus and a vaccine based on the virus and protein thereof. The invention also relates to a DNA fragment comprising the gene of the virus and a genetic engineering vaccine based on the gene of the virus. Besides, the invention relates to an antibody reacting with the virus and a diagnostic test for detecting the virus or antibody against the virus.

Owner:XINJIANG AGRI UNIV

Screening machine with large screening area

PendingCN108636754AIncrease the screening areaGood screening effectSievingScreeningPower controlEngineering

The invention discloses a screening machine with a large screening area. The screening machine comprises a machine body and a power control machine; the machine body comprises a feeding inlet, a screening cavity, a coarse material discharging outlet and a plurality of fine material discharging outlets; the screening cavity is internally provided with a plurality of screening rollers, and the multiple screening rollers are obliquely arranged from the top end to the bottom end of the screening cavity; the included angle between every two adjacent screening rollers is 90 degrees; each screening roller comprises a screening barrel, a plurality of first screening holes, a rotary shaft, a plurality of elliptical screening sheets, a plurality of second screening holes and a guide sheet; and the top of the screening cavity is provided with a plurality of automatic material distribution devices. According to the screening machine with the large screening area, compared with traditional screening machines, the screening area is larger, the material blockage, locking and adhesion possibility is reduced, the screening efficiency and quality are improved, and noise is lowered.

Owner:四川皇龙智能破碎技术股份有限公司

Soil repairing screening device

The invention discloses a soil repairing screening device. The soil repairing screening device comprises a box body, a screening structure and a drive structure, a feeding hopper is arranged in the upper portion of the box body, a discharging opening is formed in the lower portion of the box body, the screening structure comprises a pair of breaking wheels, a first screening plate and a second screening plate below the feeding hopper from top to bottom, vibration wheels are arranged below the first screening plate and the second screening plate, the drive structure comprises a first motor, a first transmission wheel located on the same side of the box body and coaxial with the any breaking wheel and a second transmission wheel coaxial with the vibration wheels, and the first transmission wheel and the second transmission wheel are directly or indirectly in transmission connection with a third transmission wheel at the power output end of the first motor. The device is obvious in screening effect, blockage is avoided, and the device is rapid and portable.

Owner:NINGBO FEICHAI ROBOT TECH CO LTD

Composite screen and material screening method

PendingCN111604264AGood screening effectReduce noise pollutionSievingScreeningComposite materialEngineering

The invention discloses a composite screen and a material screening method. The composite screen comprises circular screen pieces, ratchet wheels, a driving shaft and spring screen plates, wherein thecircular screen pieces and the ratchet wheels are alternately connected to the driving shaft in series, the spring screen plates and the circular screen pieces are arranged in a crossed mode to forma composite screen surface, materials enter a screening chamber, materials smaller than first-stage screen cuts fall onto the spring screen plates, materials larger than the first-stage screen cuts flow to a discharging port, and primary material sieving is achieved; and materials smaller than second-stage screen cuts on the spring screen plates fall below the composite screen surface, materials larger than the second-stage screen cuts flow to the discharging port along the inclined screen surface formed by the spring screen plates, and meanwhile the composite screen surface generates periodicvibration along with rotation of the ratchet wheels, so that the materials obtain additional kinetic energy perpendicular to the screen surface. By means of the mode, the composite screen and the material screening method can improve the material loosening kinetic energy, wet and sticky materials can be well loosened, the screening penetrating kinetic energy of fine materials is improved, the screening efficiency is improved, and the good screening effect on coal, ore and fine wet and sticky materials is achieved.

Owner:常州国岱选煤科技有限公司

Vibrating screen

InactiveCN102909174AGood screening effectLarge amount of processingSievingScreeningEngineeringOil well

The invention discloses a vibrating screen, relates to a separating device, and particularly relates to a vibrating screen for separating an oil well fluid. The vibrating screen disclosed by the invention comprises a tube connector, a buffering box, a screening box, an exciter and a base, wherein the tube connector, the buffering box and the screening box are sequentially connected; the exciter is arranged on the upper part of the screening box; the base is arranged on the lower part of the screening box; an elastic material is arranged between the screening box and the vibrating screen; and the exciter is elliptical. The vibrating screen disclosed by the invention is used for screening rock debris in the oil fluid via the vibration of the elliptical exciter, and elliptical vibration is good in screening effect and high in treatment capacity because of having the characteristics of both circular vibration and linear rectilinear vibration; and the vibrating screen disclosed by the invention is simple in structure and strong in practicability.

Owner:SHAANXI QIYUAN TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com