Method and device for separating low-value substances from valuable substances in scraped car

A technology for scrapping cars and substances, applied in the direction of electronic waste recycling, solid waste removal, recycling technology, etc., can solve problems such as complex composition and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention discloses a device for separating low-value substances and precious substances in scrapped vehicles. machine D, vibrating screen E and eddy current separator F, wherein:

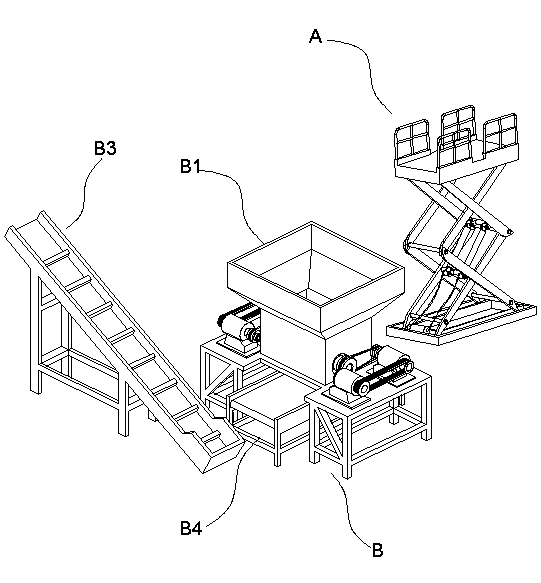

[0035] refer to figure 1 As shown, the scissor lift platform A lifts scrapped cars and sends them into the feed port B1 of the twin-shaft shredder B.

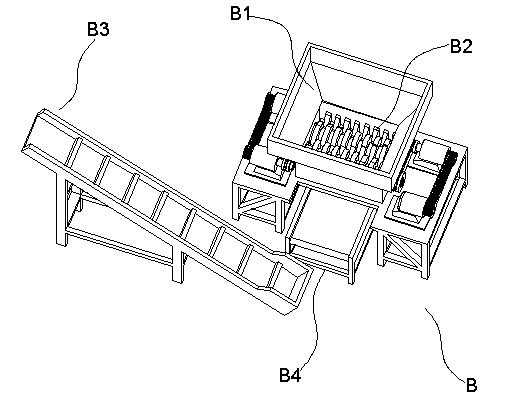

[0036] refer to figure 2 As shown, the application principle of the double-shaft shredder B is that two sets of rotary cutterheads B2 composed of high-grade alloy steel shear each other to shred various soft and hard materials, including scrap automobile materials. Strong force, sharp blade, capable of crushing with high efficiency. It mainly adopts a combined structure frame with extra-thick plate precision processing, and its caliber is large, so it can safely input large-scale raw materials such as scrapped cars.

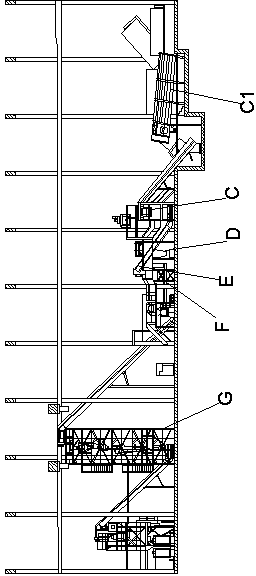

[0037] refer to image 3 As shown, the control crusher C is connected to the twin-shaft shredder B through the conve...

Embodiment 2

[0043] refer to Figure 5 As shown, compared with Embodiment 1, the difference is that it further includes a sampling device G for sampling the debris of scrapped automobiles, which is connected with the eddy current separator, which includes a stocker 1. The main material pipeline 2, the sampling pipeline 3, the crushing device 4 and the sampling bucket 5, in which:

[0044] The stocker 1 is used to store the slag of scrapped automobiles after crushing and sorting. In this embodiment, it is a storage hopper, and a main discharge port 11 is provided below it. The main discharge port 11 is connected with the main material The pipes 2 are connected; the side of the storage hopper is provided with a side discharge port 12; a scraper (not shown in the figure) is also provided in the storage hopper, and a driving device 13 is also provided on the storage hopper. In this embodiment, The driving device 13 is an electric motor, which can drive the scraper to rotate continuously in th...

Embodiment 3

[0049] refer to Figure 6 Shown, compared with embodiment two, its difference is:

[0050] It further includes a sample storage assembly, an observation assembly and a pulverizer 8, wherein:

[0051] The sample storage assembly includes sample storage hoppers 61, 62; the sample storage hopper 61 is provided with a sample discharge port 611 below, and the side is provided with a sample side discharge port 612; the sample storage hopper 61 is also provided with a driving device 613 and a The scraper (not shown in the figure) inside is constantly rotated under the drive of the driving device 613 . Similarly, a sample outlet is also provided below the sample storage hopper 62, and a sample side outlet (not shown in the figure) is provided on the side, and a driving device 623 and a scraper (not shown in the figure) are arranged on it. not shown), the scraper is driven by the driving device 623 to rotate continuously. In this embodiment, the driving devices 613, 623 are motors. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com