Separation device for rice husks and brown rice

A technology of paddy separation and separation chamber, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of unfavorable finished rice quality, affecting processing effect, guarantee, etc., and achieves the convenience of cleaning the inside of the fuselage and the screening efficiency High, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

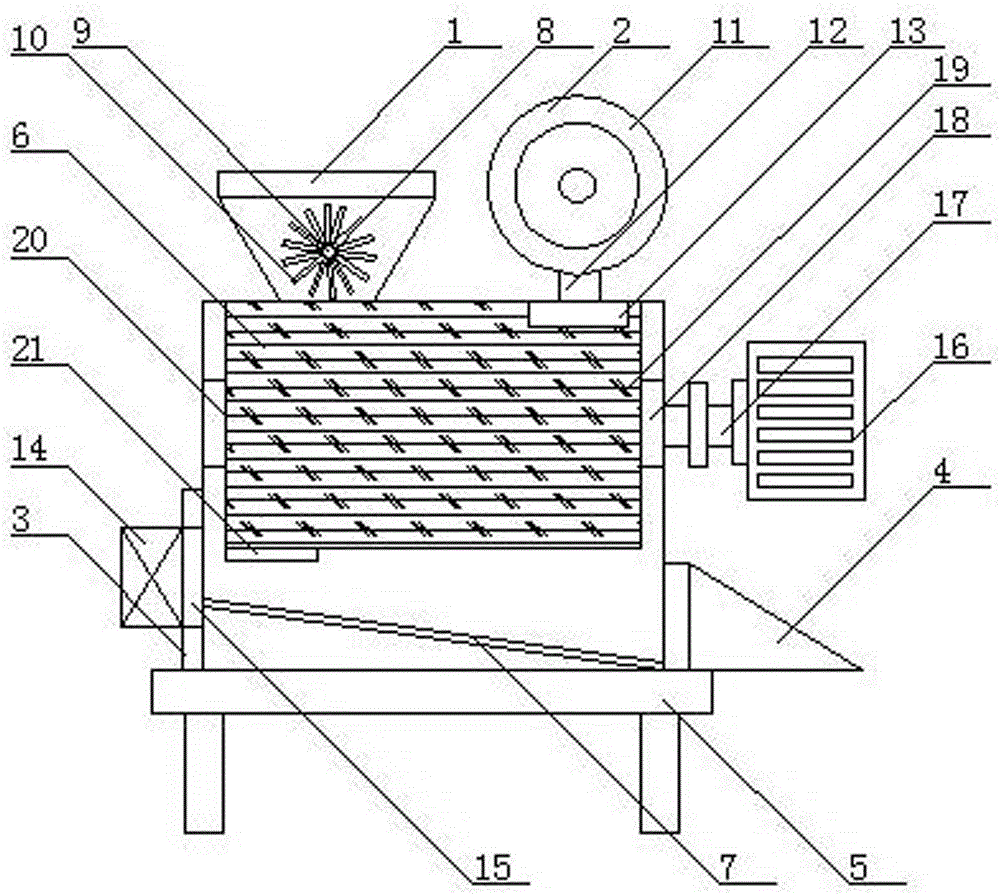

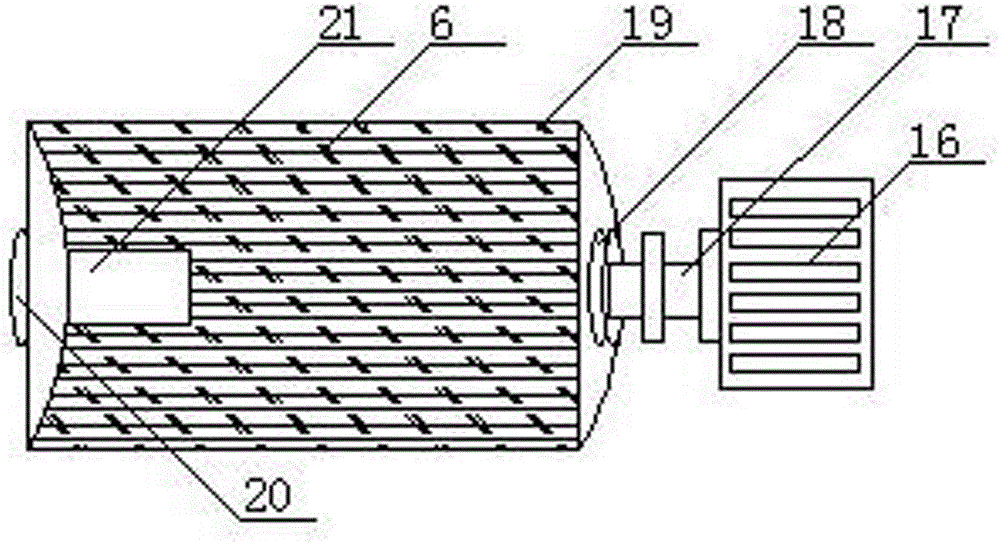

[0017] As shown in the figure, a kind of rice-rough separation device includes a fuselage, a feeder 1 is installed on the left side of the top of the fuselage, a blower mechanism 2 is installed on the right side of the top of the fuselage, and a cleaning door 3 is installed on the lower end of the left side of the fuselage. Body right lower end device discharge funnel 4, fuselage bottom device base 5, fuselage interior upper end device separation warehouse 6, fuselage interior lower end device inclined discharge plate 7.

[0018] A rotary feeder 8 is installed at the middle end of the feeder 1 , a rotating shaft 9 is installed at the middle end of the rotating feeder 8 , and a plurality of stirring rods 10 are installed around the outer circumference of the rotating shaft 9 .

[0019] The blower mechanism 2 is composed of a blower 11, an air inlet pipe 12, and an air inlet area 13. The bottom end of the blower 11 is connected to the air inlet area 13 through the air inlet pipe ...

Embodiment 2

[0023] Further, the inclined discharge plate 7 is inclined at 30-45° in the shape of left high and right low, and the right end of the inclined discharge plate 7 is connected with the discharge funnel 4 .

Embodiment 3

[0025] Further, the rotary feeder 8 is driven to rotate by the inertia of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com