Corn thresher with roller screen

A technology for thresher and corn, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of increased moisture content, difficult screening, corn mixed with ice and snow, etc., to achieve clean separation, saving equipment investment, and clean grain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

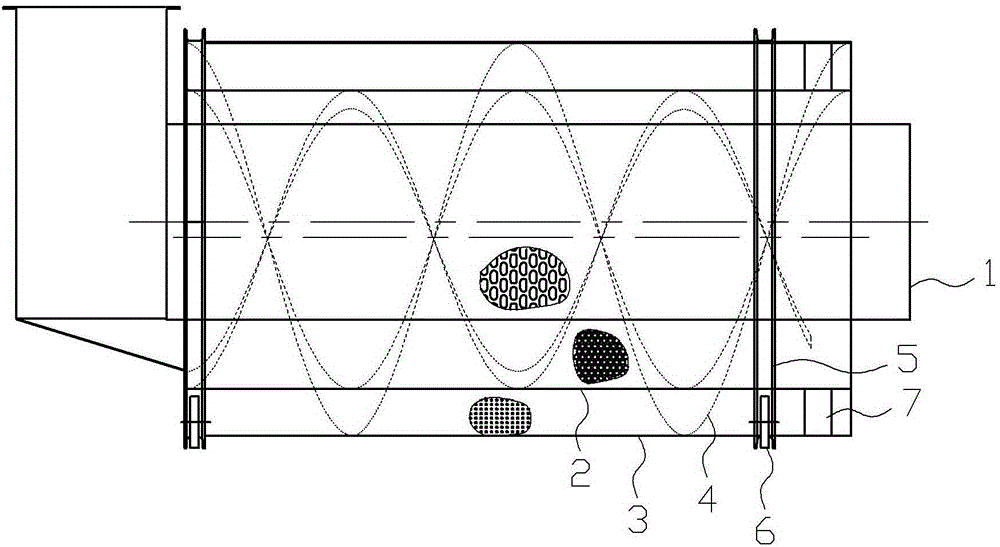

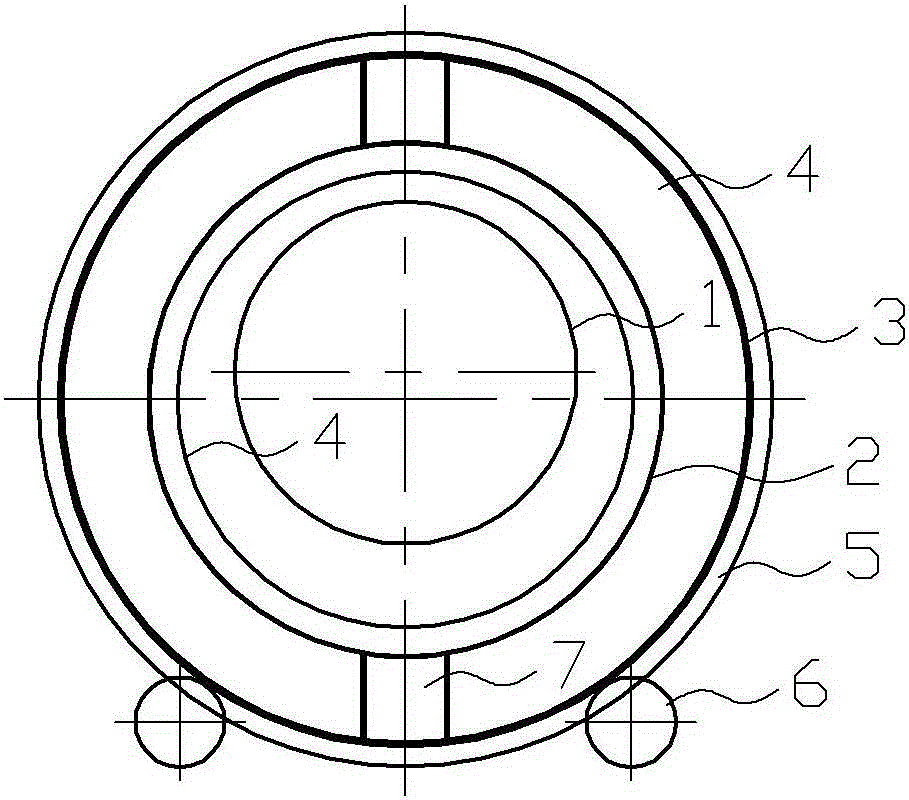

[0008] Such as figure 1 with 2 Shown, be provided with the corn thresher of rolling screen, comprise the corn thresher sieve cylinder 1 that is used for seed cob separation, described corn thresher is also provided with and is made of inner cleaning sieve cylinder 2 and outer cleaning sieve cylinder 3 Cleaning device, the inner cleaning sieve cylinder 2 and the outer cleaning sieve cylinder 3 are both cylinders, and the inner wall of the uniform ring is provided with a spiral conveying piece 4, and the outer wall of the outer cleaning sieve cylinder 3 is provided with a ring guide rail 5, corn thresher A roller 6 matching the ring guide rail 5 is arranged on the frame, the inner cleaning screen drum 2 and the outer cleaning screen drum 3 are relatively fixed and set on the periphery of the corn thresher screen drum 1, and the cleaning can be driven by the roller 6 The device rotates around the corn thresher sieve cylinder 1, and the corn kernels separated by the corn thresher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com