Grain raw material refining device for feed production

A technology for grains and raw materials, which is applied to the field of grain raw material refinement devices for feed production, can solve the problems of insufficient grain crushing and other problems, and achieve the effect of high-efficiency screening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

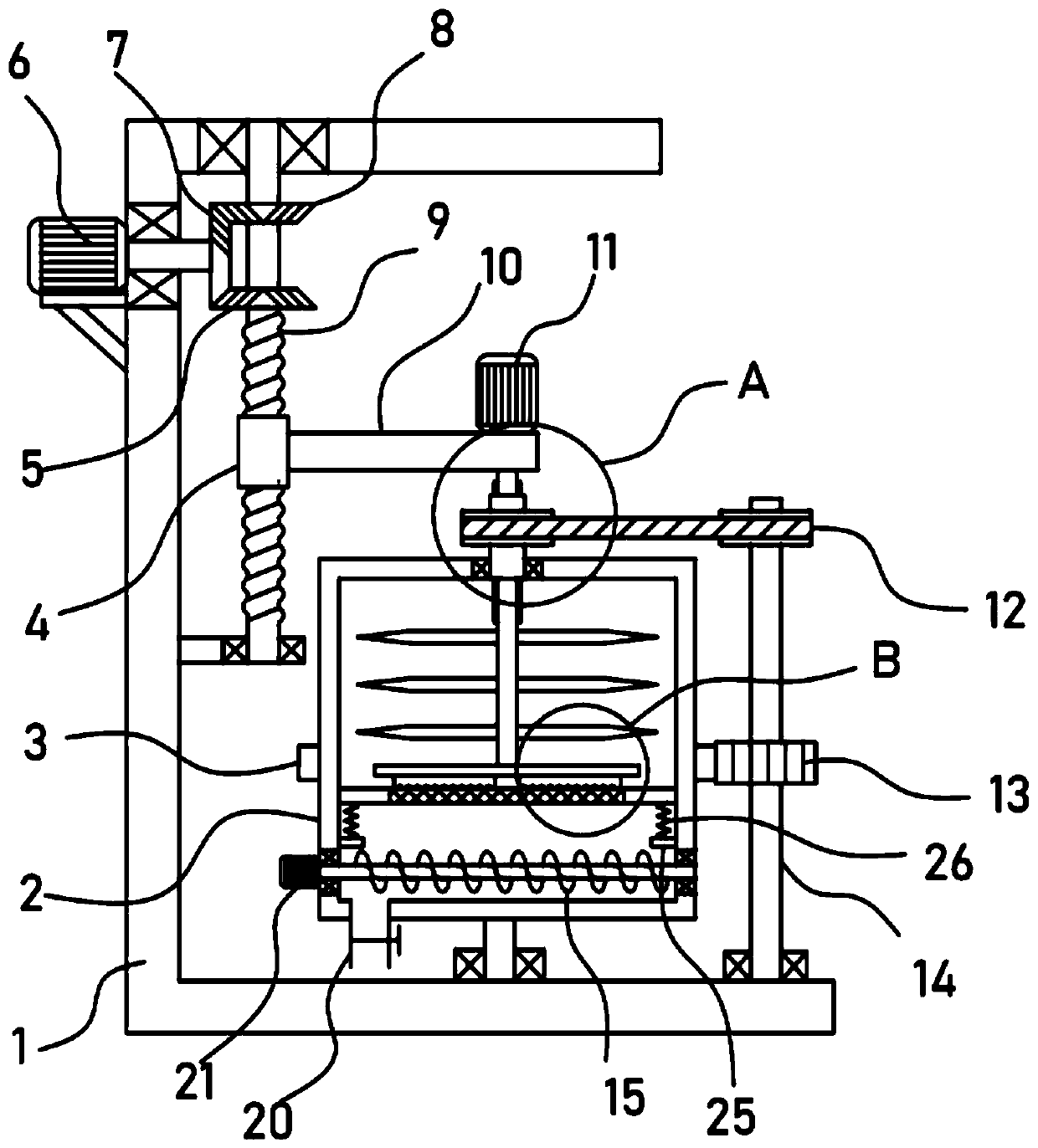

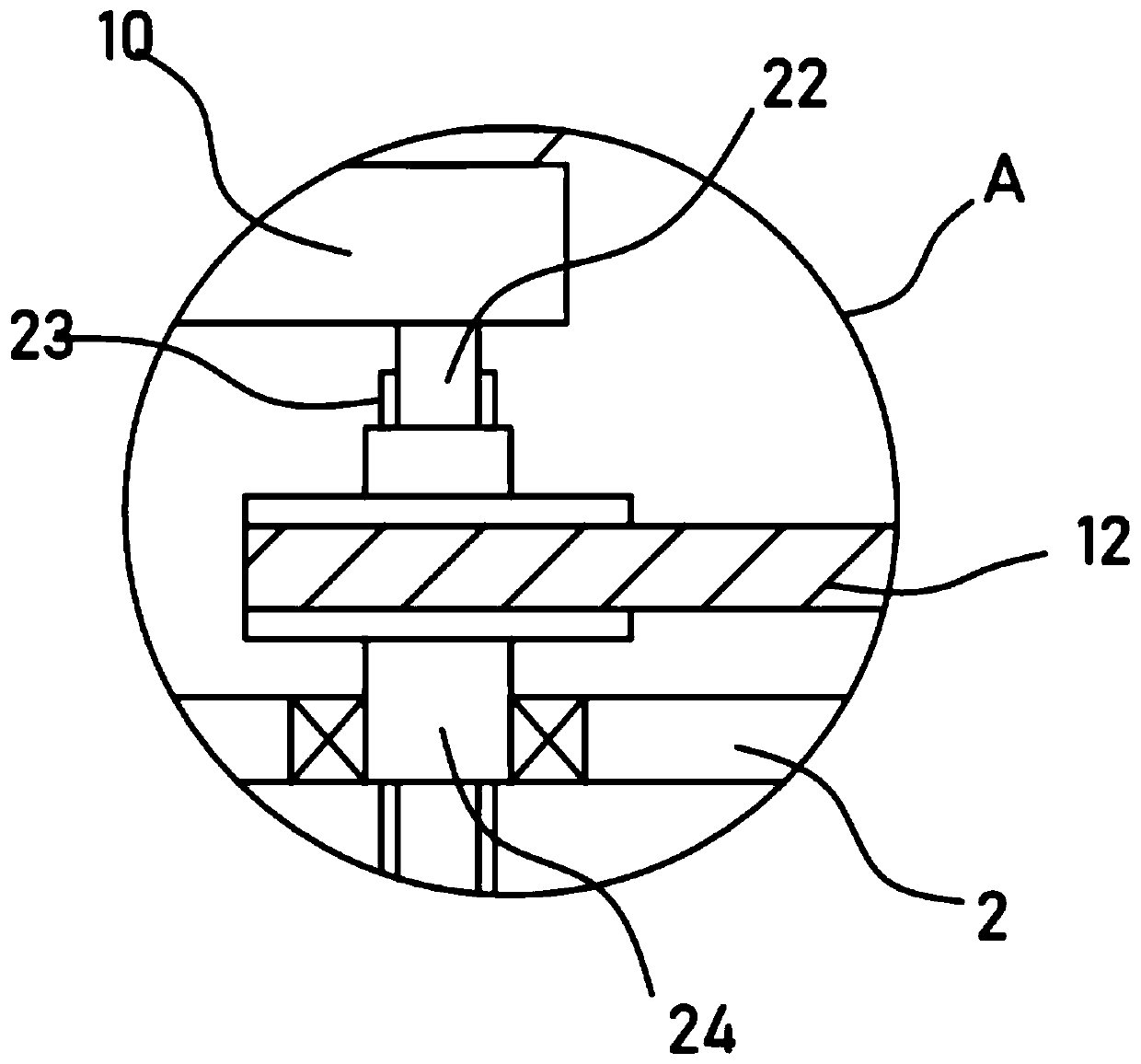

[0024] see Figure 1-4 , a grain raw material refining device for feed production, comprising a support frame 1, a crushing barrel 2 is rotatably installed on the support frame 1, a crushing mechanism for crushing grain is rotatably installed in the crushing barrel 2, and the support frame 1 is provided with a Based on the reciprocating mechanism that drives the crushing mechanism to move vertically relative to the crushing barrel 2, the crushing barrel 2 is provided with a sieve plate 16 supported by an elastic support, and a dispersing mechanism connected to the crushing mechanism is rotatably installed on the sieve plate 16. The support frame 1 is provided with a steering mechanism for driving the crushing bucket 2 to rotate.

[0025] The crushing barrel 2 in this device is used to store the grain components of the feed raw materials, and the grain raw materials are fully crushed through the set crushing mechanism, and the set reciprocating mechanism can drive the crushing ...

Embodiment 2

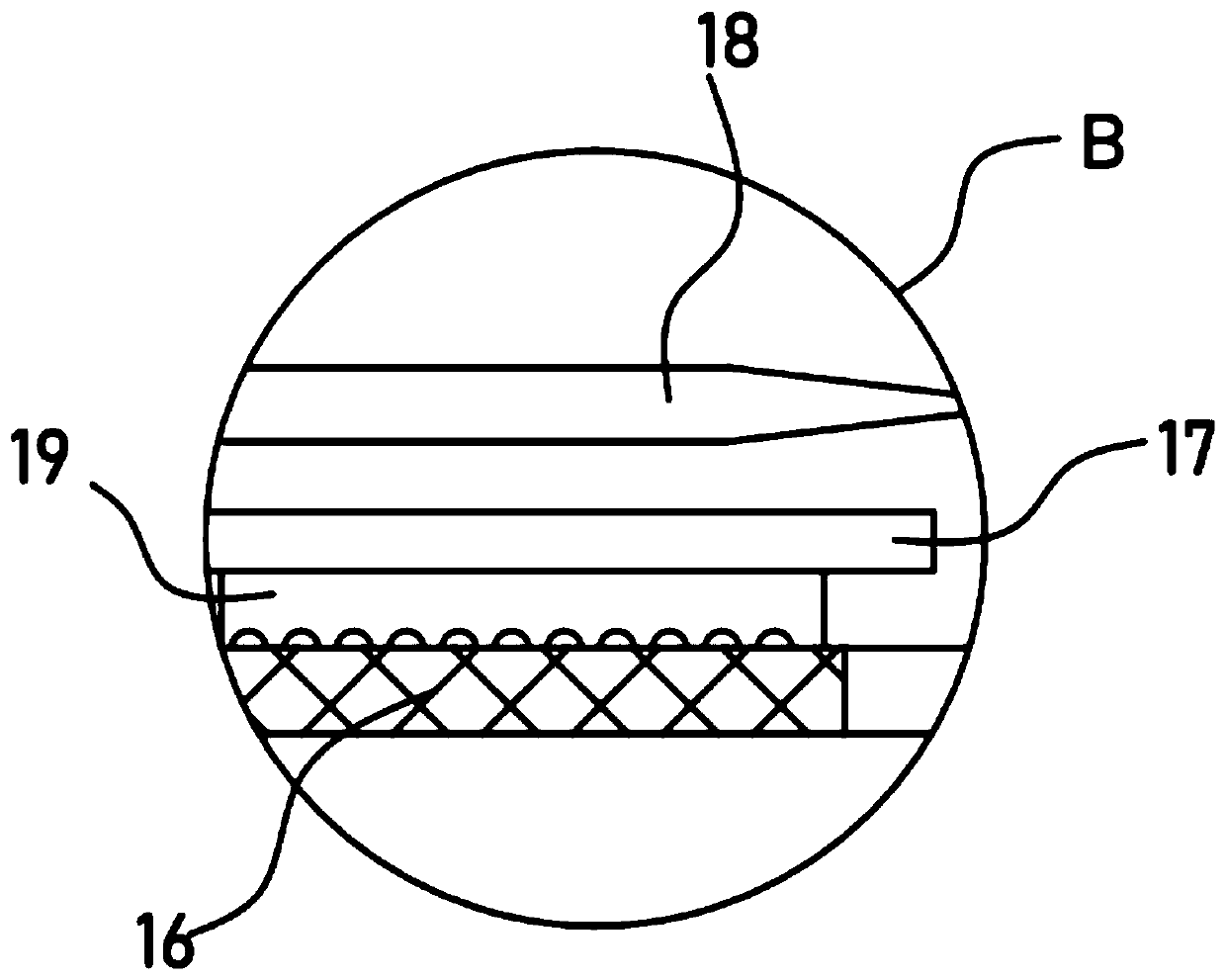

[0029] In order to further improve the crushing effect of the grains in the crushing barrel 2, on the basis of Embodiment 1, in addition, the device is also provided with a dispersion mechanism, which includes several rotating plates 17 distributed in the circumferential direction fixed on the bottom of the drive shaft 22, and the rotation The bottom surface of the plate 17 is fixed with a scraper 19 abutting against the upper surface of the sieve plate 16 , and several semicircular grooves 27 are uniformly opened on the scraper 19 .

[0030] During the rotation of the drive shaft 22, it drives the rotating plate 17 to rotate, and the rotating plate 17 drives the scraper 19 at the bottom to rotate. On the one hand, it plays a role in rotating and dispersing the grains inside the crushing barrel 2, and promotes the full screening of the grains. On the other hand, the scraper 19 can scrape the upper surface of the sieve plate 16 to promote fully refined grains to pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com