Screening machine with large screening area

A screening machine and screening technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of screen shaft damage, screen non-abrasion, wear, etc., so as to increase the screen area and reduce material blockage. , Strengthen the effect of screening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

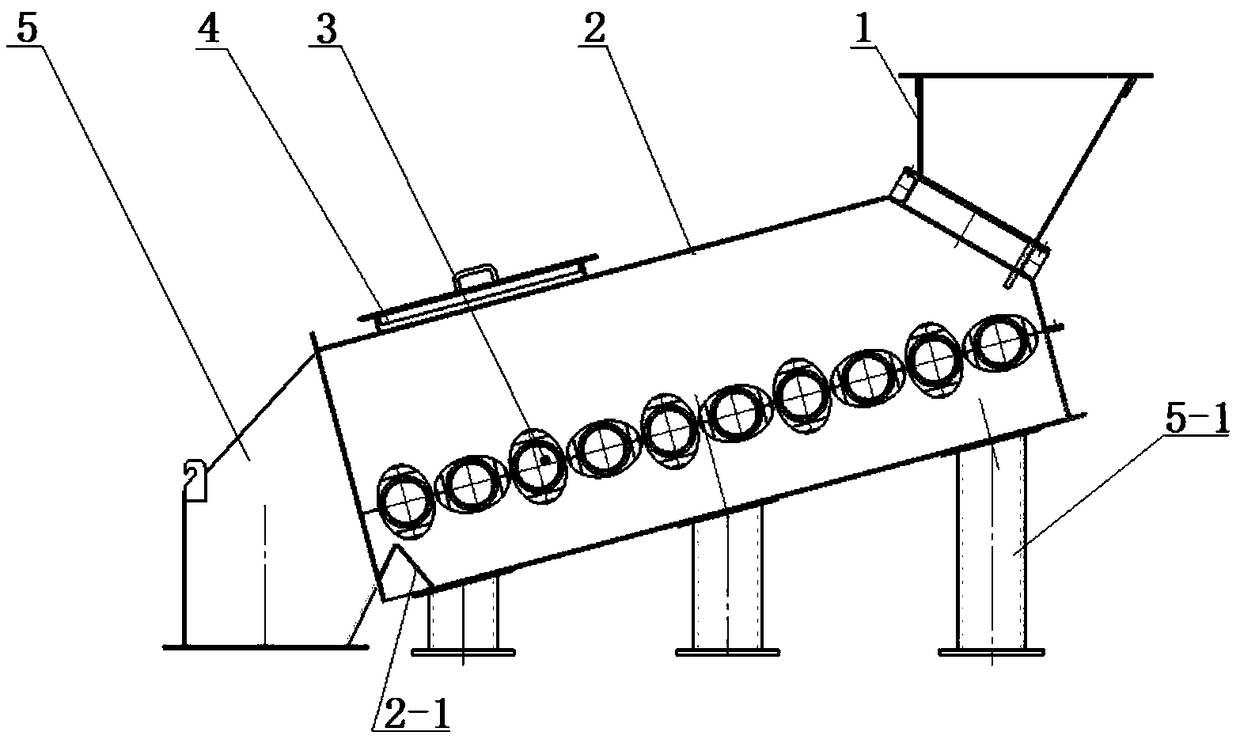

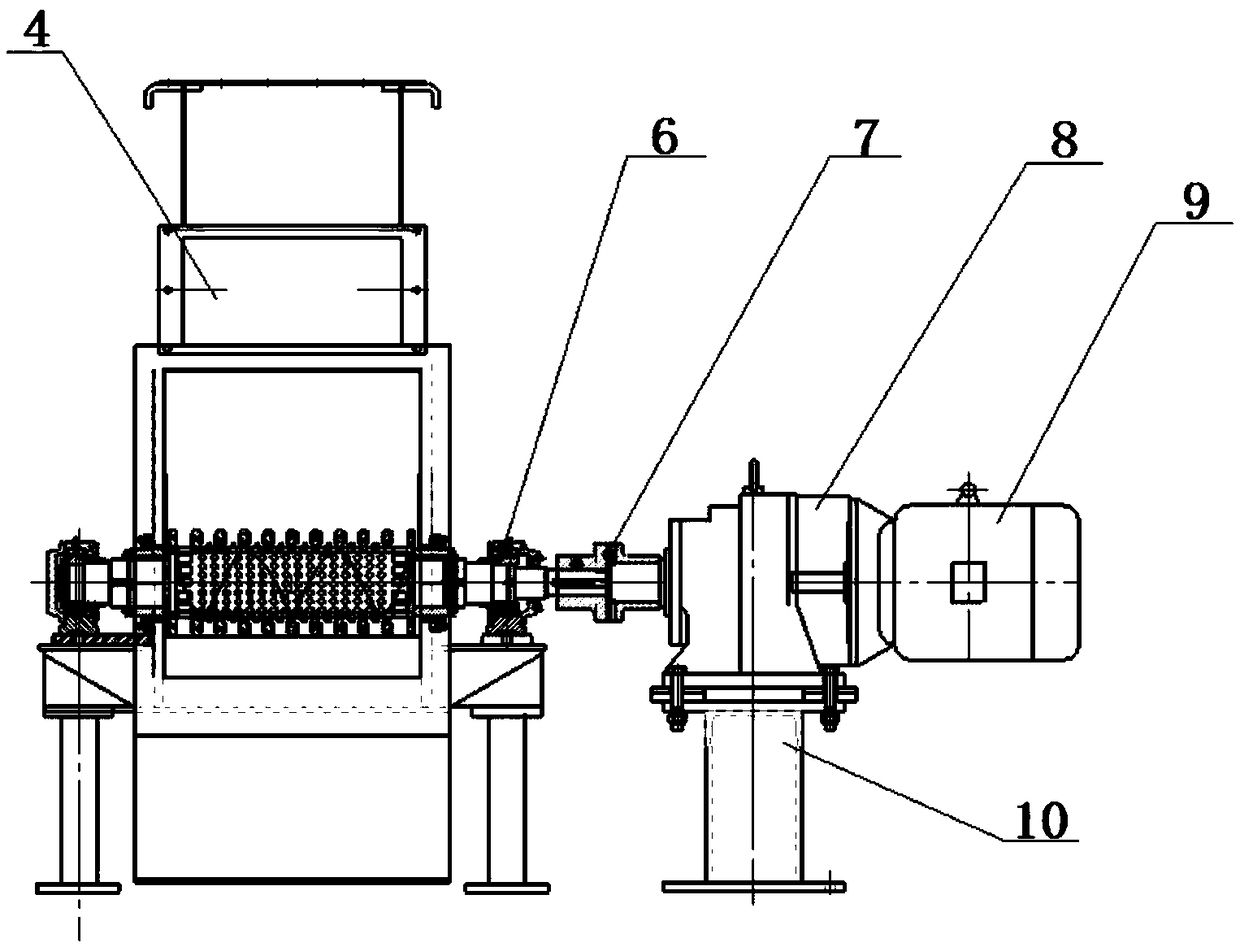

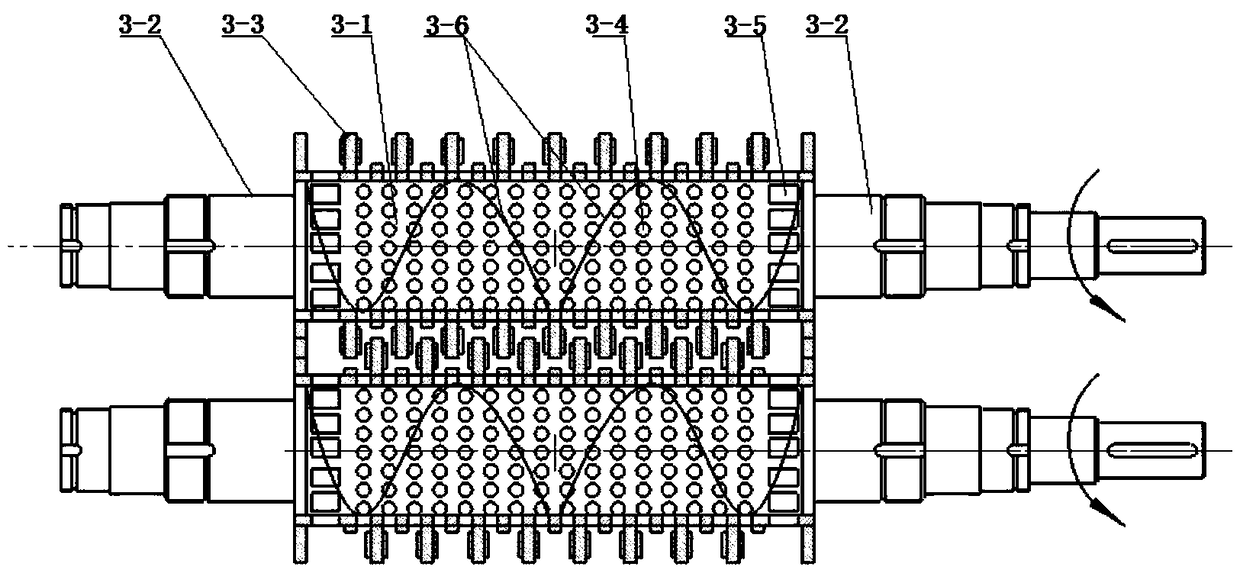

[0026] In this example, if Figure 1-4 As shown, a large screen surface screening machine includes a body and a power control machine; the body includes a feed inlet 1, a screening chamber 2, a coarse material discharge port 5 and a fine material discharge port 5-1; the described The screening chamber 2 is arranged obliquely and is provided with a feed port 1 and a coarse material discharge port 5 respectively at both ends, and the feed port 1 is located at a height of the coarse material discharge port 5; the bottom surface of the screening chamber 2 is formed by The feed port 1 to the coarse material discharge port 5 are arranged inclined downwards and the bottom surface is evenly arranged with a plurality of fine material discharge ports 5-1, and the bottom end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com