Soil repairing screening device

A technology of soil remediation and screening equipment, applied in the field of soil remediation, can solve the problems of easy blockage, poor screening effect, unrealistic and other problems, and achieve the effects of no blockage, high degree of automation, and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

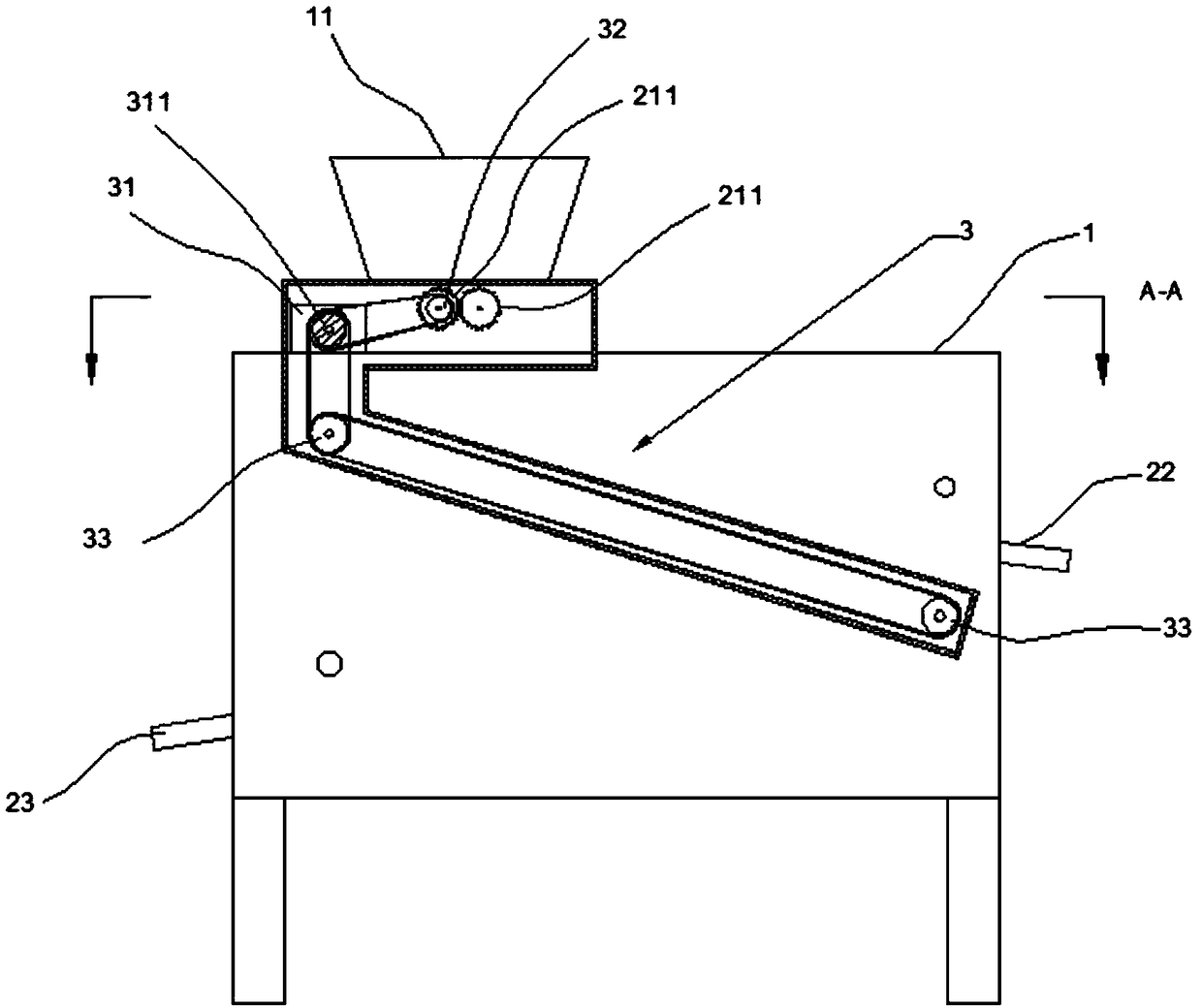

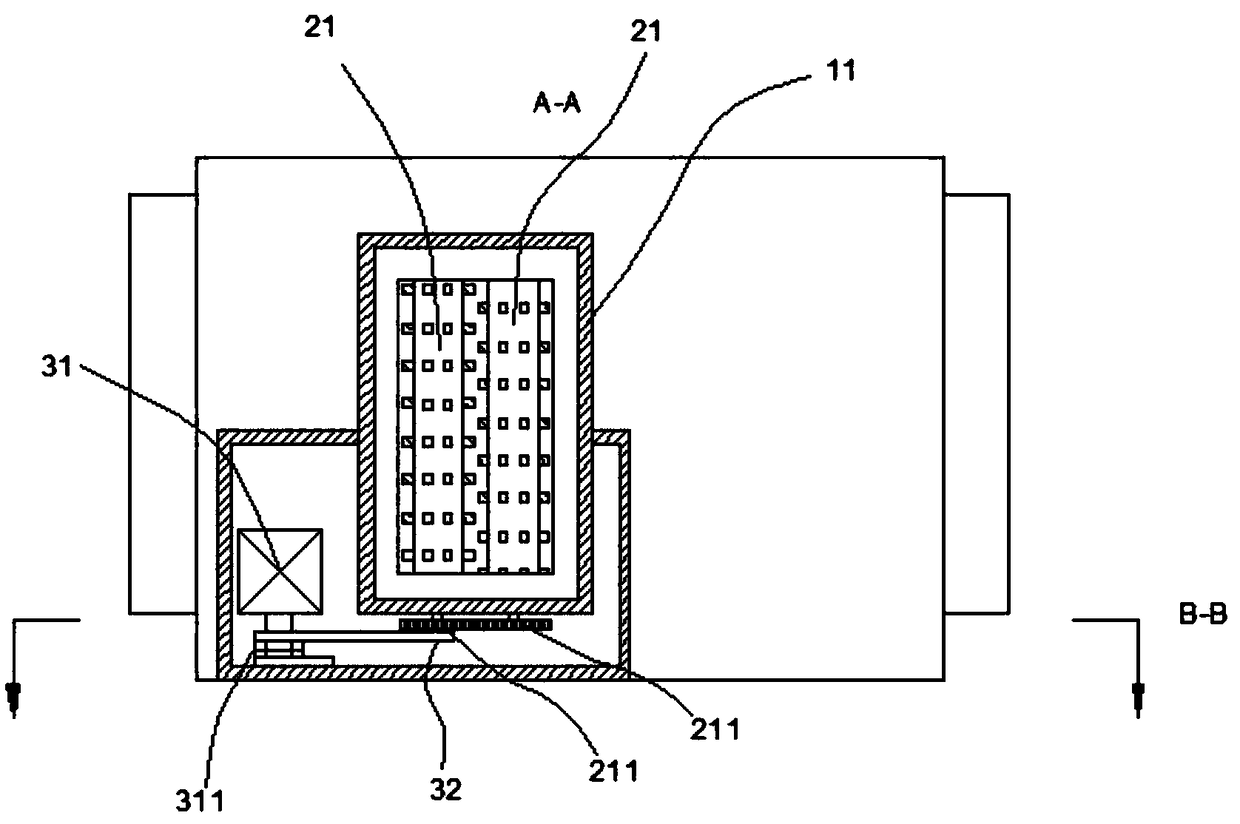

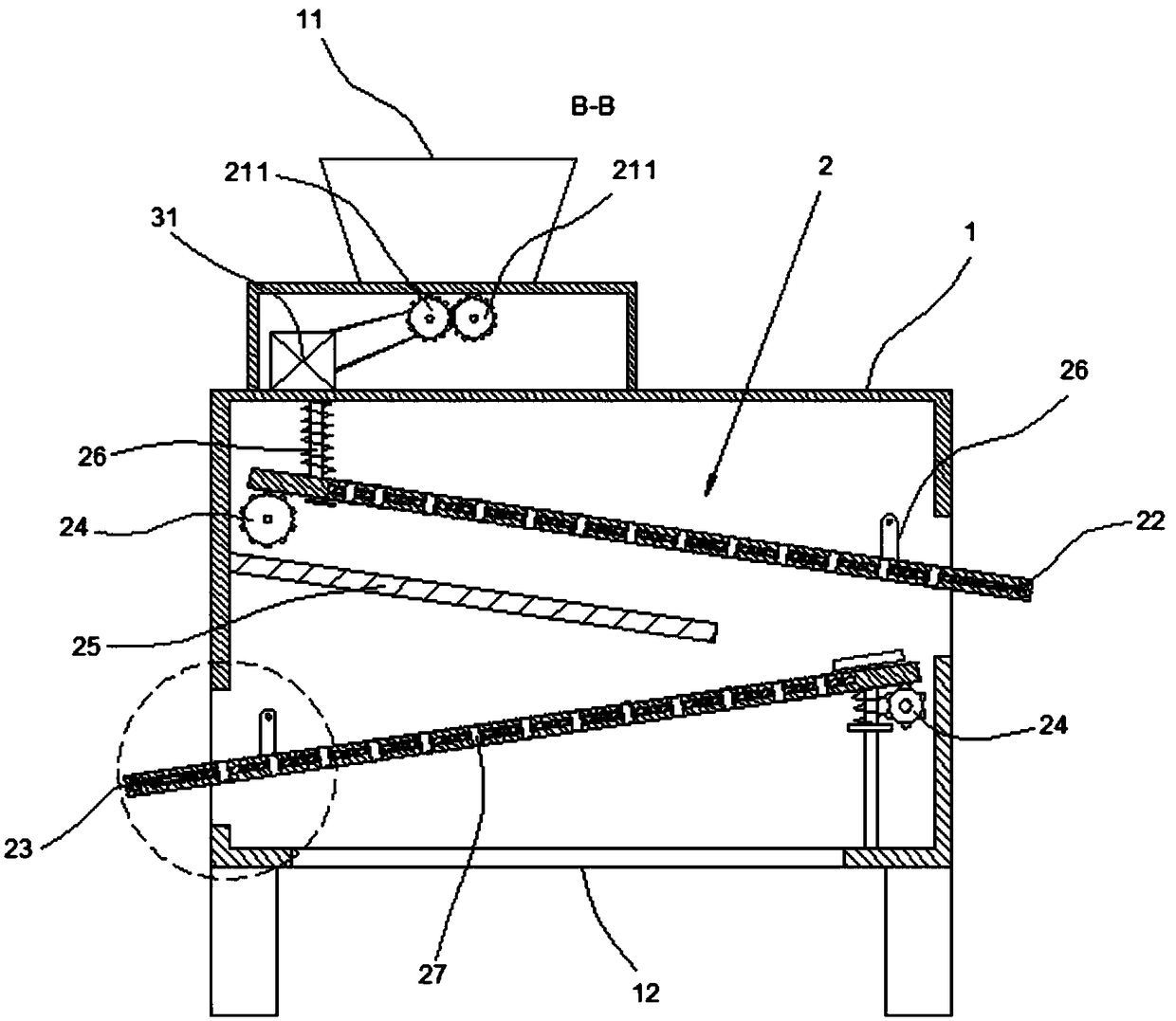

[0029] Such as Figure 1-3 As shown, the present embodiment provides a soil remediation and screening equipment, including a box body 1, a screening structure 2 and a driving structure 3, the box body 1 is provided with a feed hopper 11 above, and a discharge port 12 is provided below. The screening structure 2 includes a pair of crushing wheels 21, a first screening plate 22 and a second screening plate 23 arranged from top to bottom below the feed hopper 11, and the first screening plate 22 and the second screening plate Vibrating wheels 24 are respectively arranged below 23; the driving structure 3 includes a first motor 31, a first transmission wheel 32 coaxial with any crushing wheel 21 located on the same side of the box body 1, and a first transmission wheel 32 coaxial with the vibrating wheel 24. Two transmission wheels 33 , the first transmission wheel 32 and the second transmission wheel 33 are directly or indirectly in transmission connection with the third transmis...

Embodiment 2

[0031] Such as Figure 1-3 As shown, the present embodiment provides a soil remediation and screening equipment, including a box body 1, a screening structure 2 and a driving structure 3, the box body 1 is provided with a feed hopper 11 above, and a discharge port 12 is provided below. The screening structure 2 includes a pair of crushing wheels 21, a first screening plate 22 and a second screening plate 23 arranged from top to bottom below the feed hopper 11, and the first screening plate 22 and the second screening plate Vibrating wheels 24 are respectively arranged below 23; the driving structure 3 includes a first motor 31, a first transmission wheel 32 coaxial with any crushing wheel 21 located on the same side of the box body 1, and a first transmission wheel 32 coaxial with the vibrating wheel 24. Two transmission wheels 33 , the first transmission wheel 32 and the second transmission wheel 33 are directly or indirectly in transmission connection with the third transmis...

Embodiment 3

[0033] Such as Figure 1-3 As shown, the present embodiment provides a soil remediation and screening equipment, including a box body 1, a screening structure 2 and a driving structure 3, the box body 1 is provided with a feed hopper 11 above, and a discharge port 12 is provided below. The screening structure 2 includes a pair of crushing wheels 21, a first screening plate 22 and a second screening plate 23 arranged from top to bottom below the feed hopper 11, and the first screening plate 22 and the second screening plate Vibrating wheels 24 are respectively arranged below 23; the driving structure 3 includes a first motor 31, a first transmission wheel 32 coaxial with any crushing wheel 21 located on the same side of the box body 1, and a first transmission wheel 32 coaxial with the vibrating wheel 24. Two transmission wheels 33 , the first transmission wheel 32 and the second transmission wheel 33 are directly or indirectly in transmission connection with the third transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com