Patents

Literature

338 results about "During feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

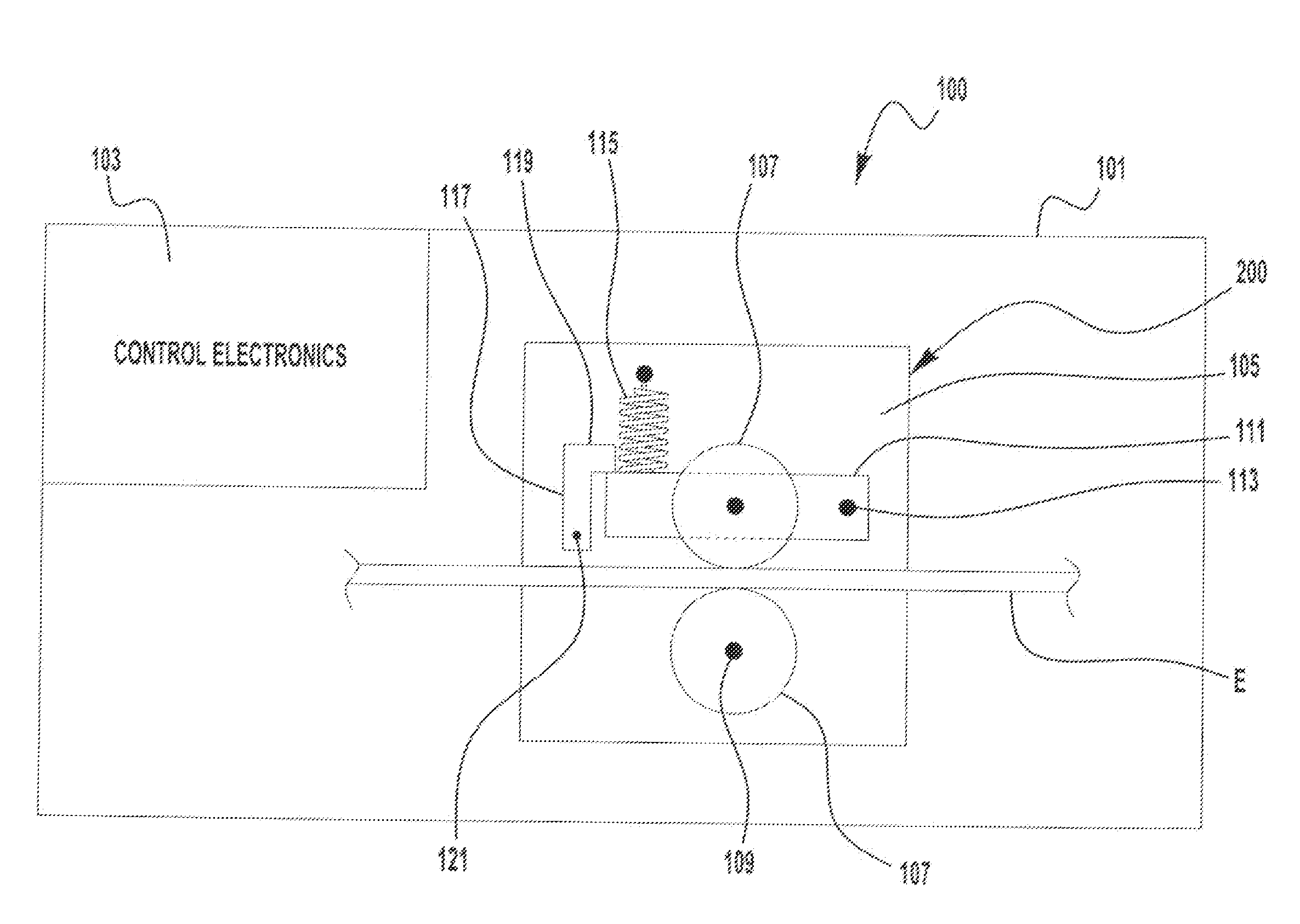

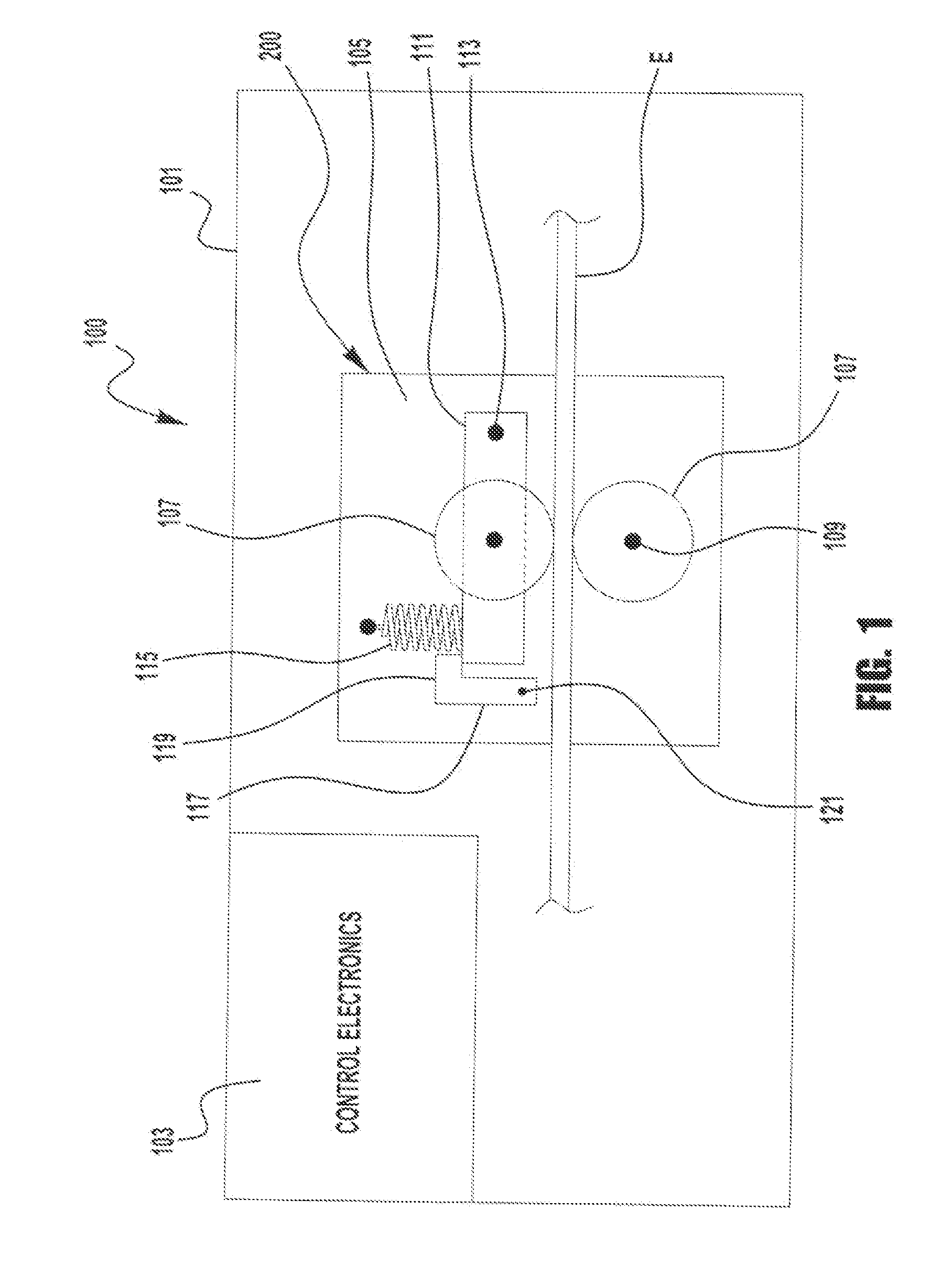

Enteral fluid delivery system and method for opeating the same

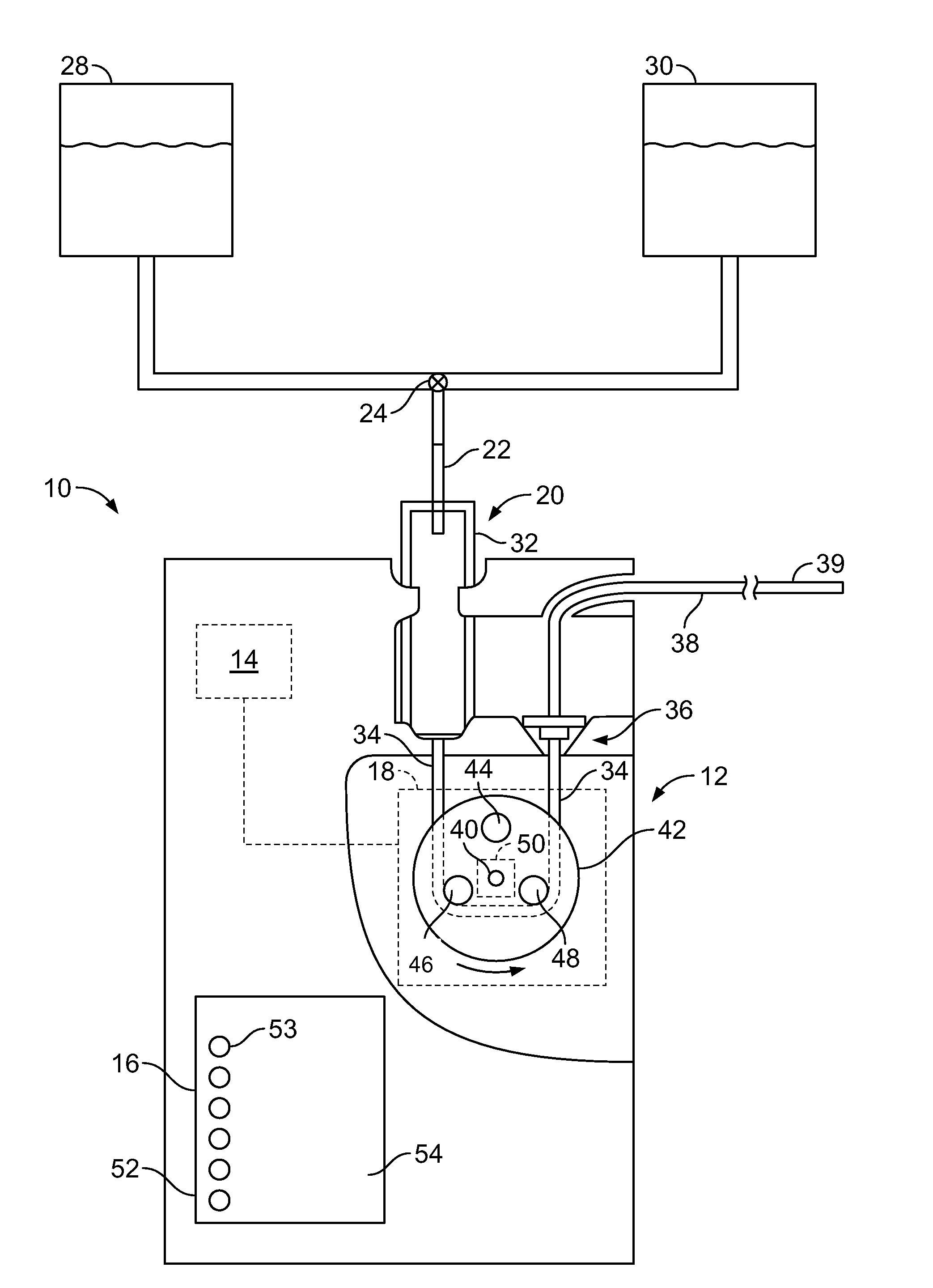

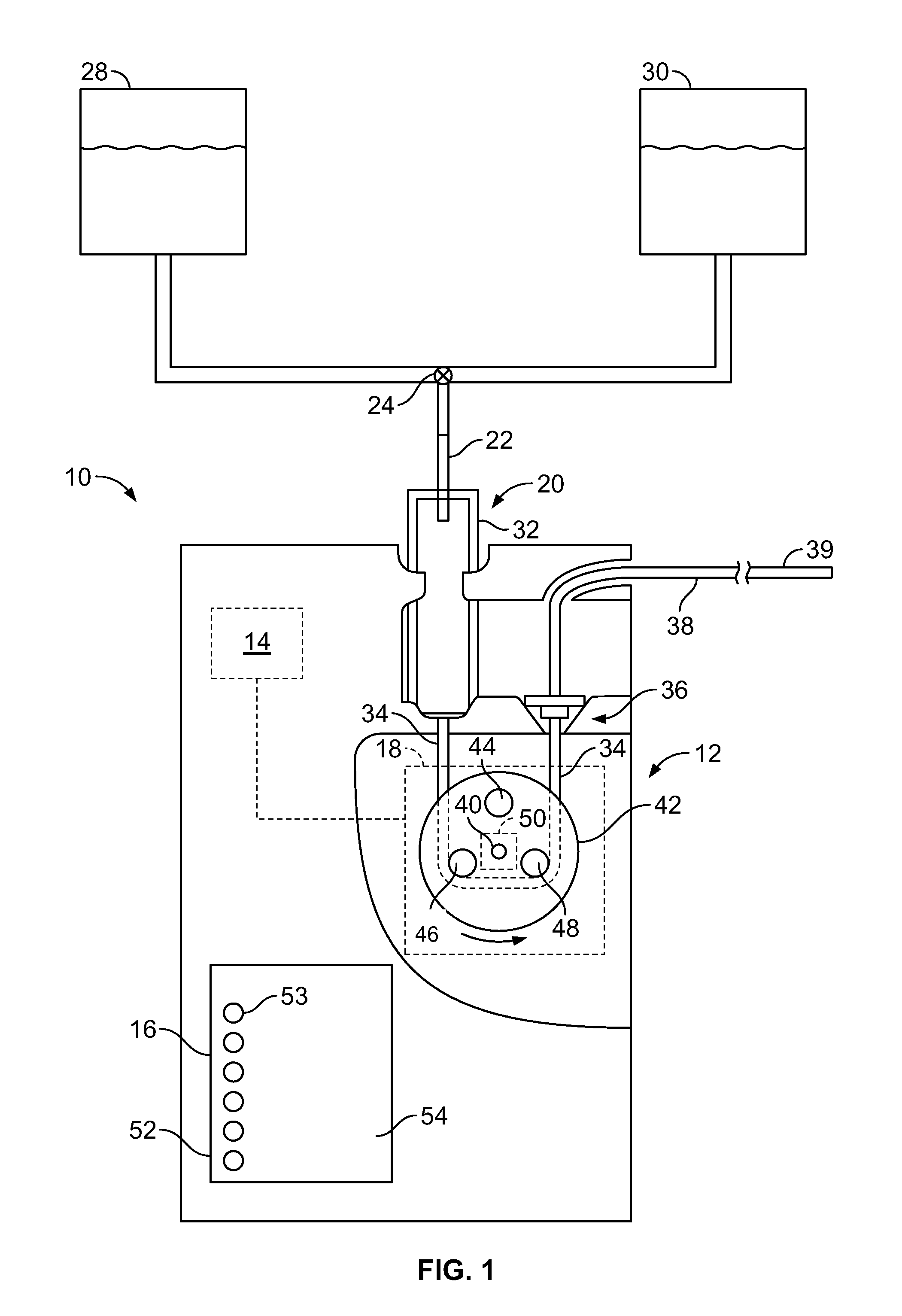

An enteral fluid delivery system includes a pump unit that includes a motor coupled to a rotor. The rotor is configured to receive a portion of a pump tube. The motor drives the rotor to pump enteral feed and flush fluids through the pump tube during feed and flush cycles, respectively. A processing unit is operatively connected to the pump unit and controls the pump unit during the feed and flush cycles. The processing unit is programmable to vary a flushing fluid flow rate at which the rotor pumps the flush fluid during a flush cycle. A user interface is operatively connected to the processing unit and enables a user to select between at least two different non-zero flushing fluid flow rates.

Owner:TYCO HEALTHCARE GRP LP

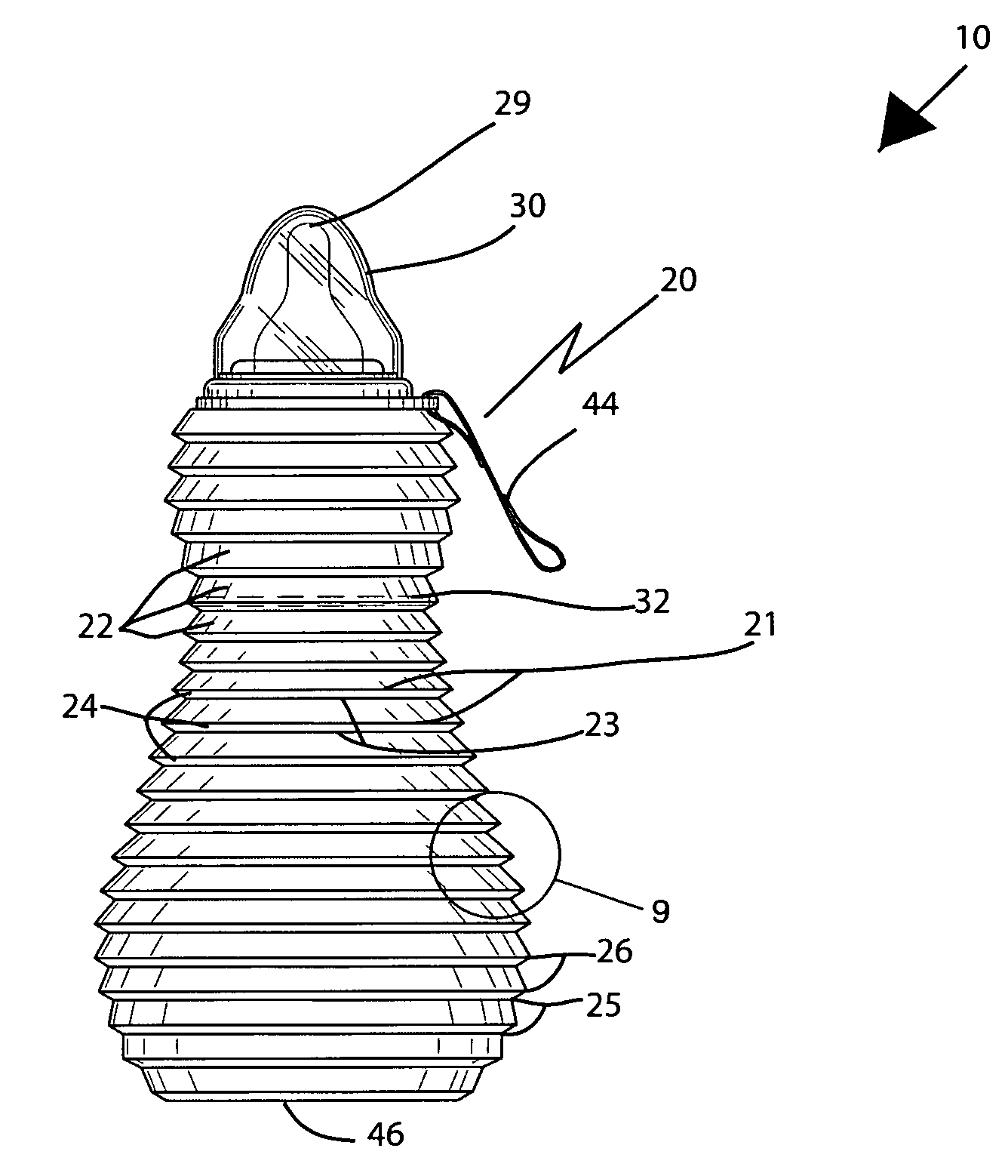

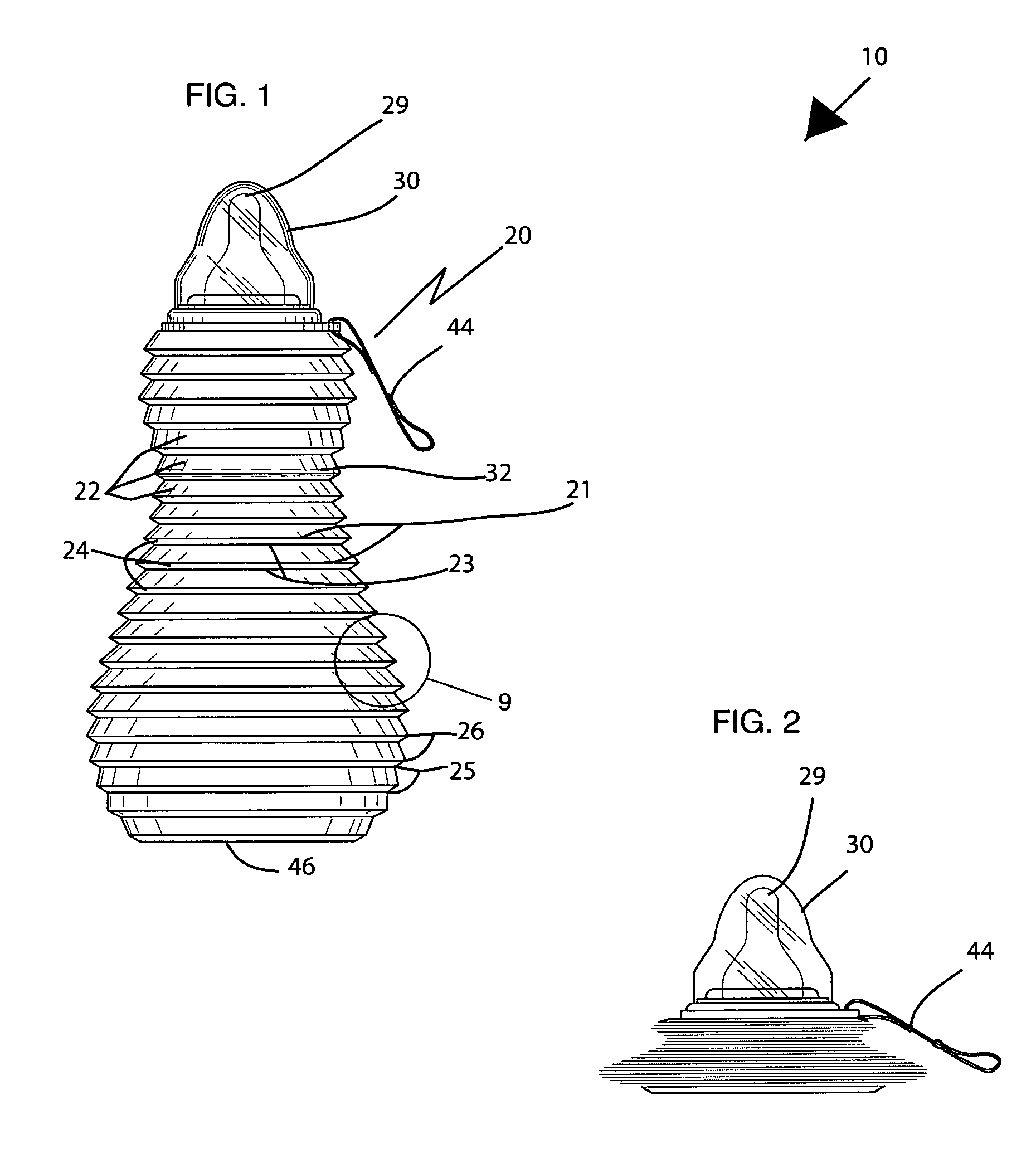

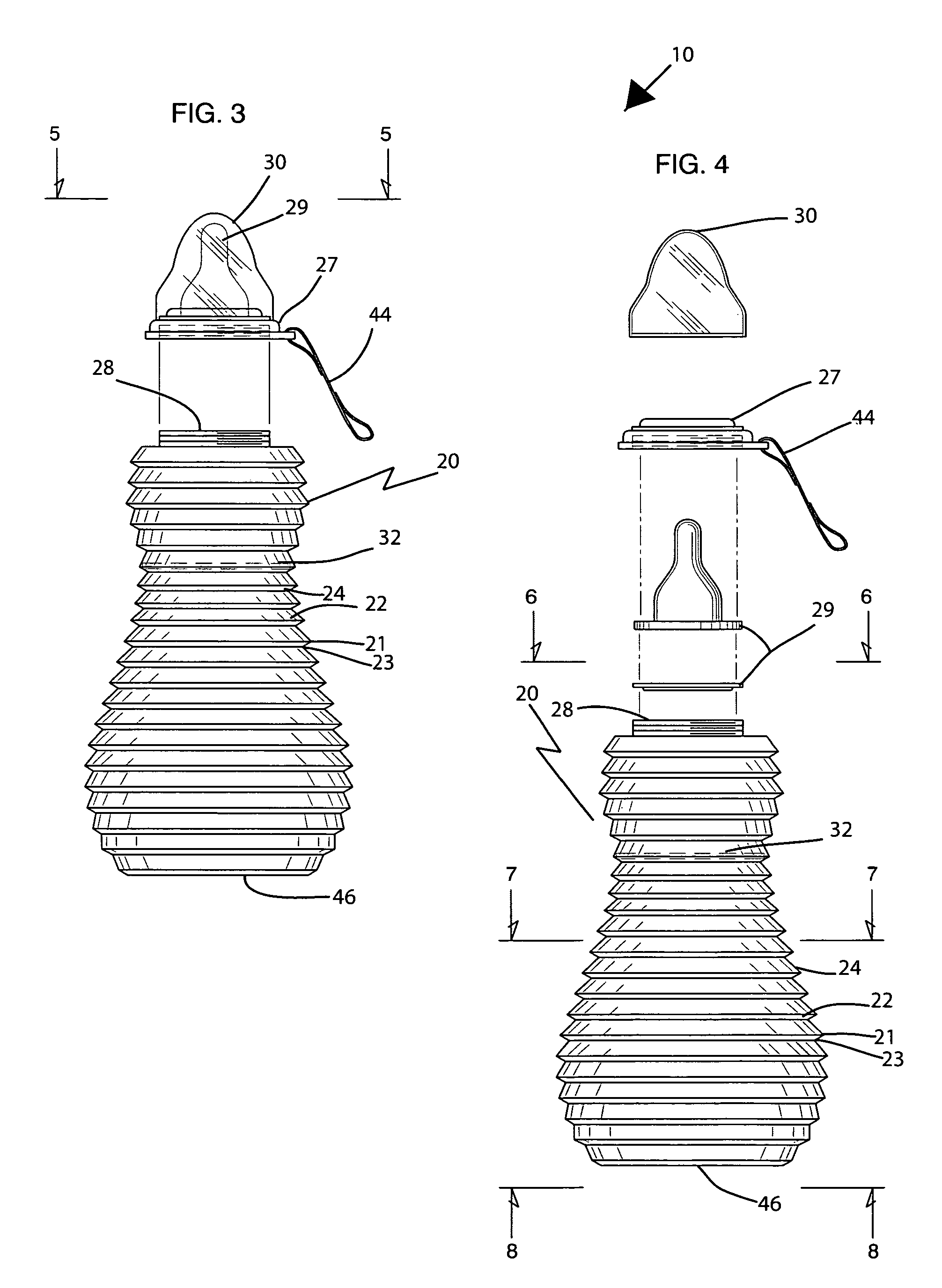

Collapsible baby bottle and associated method

A collapsible baby bottle for reducing air-intake during feeding operations includes a body formed from disposable material, a plurality of linear ridges concentrically spanning across a non-uniform circumference thereof, and a coupling threadably attached directly to a top opening of the body. The apparatus further includes a nipple removably attached directly to the coupling, a cap removably affixed directly to the coupling for protecting the nipple from undesirable foreign debris and fluids, and a mechanism for preventing formation of powder formula lumps when mixing the powder formula and water within the body so that a homogenous mixture of the powder formula and the water is obtained. The apparatus further includes a strap tethered directly to the coupling and spaced from the body and the nipple respectively, and a barcode removably affixed directly to a bottom surface of the body for identifying nutritional information about the powder formula.

Owner:EZ EXPRESSIONS LLC

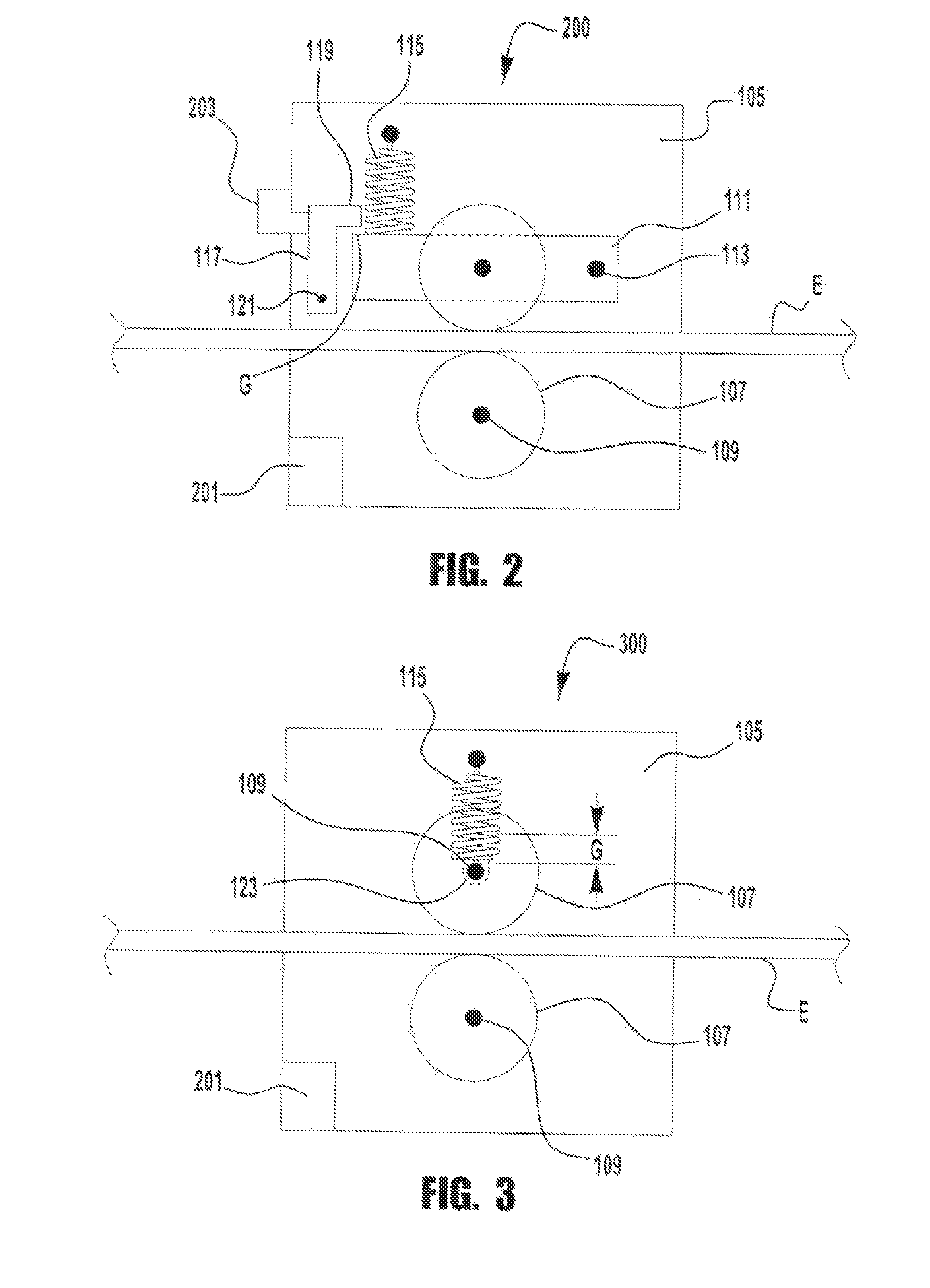

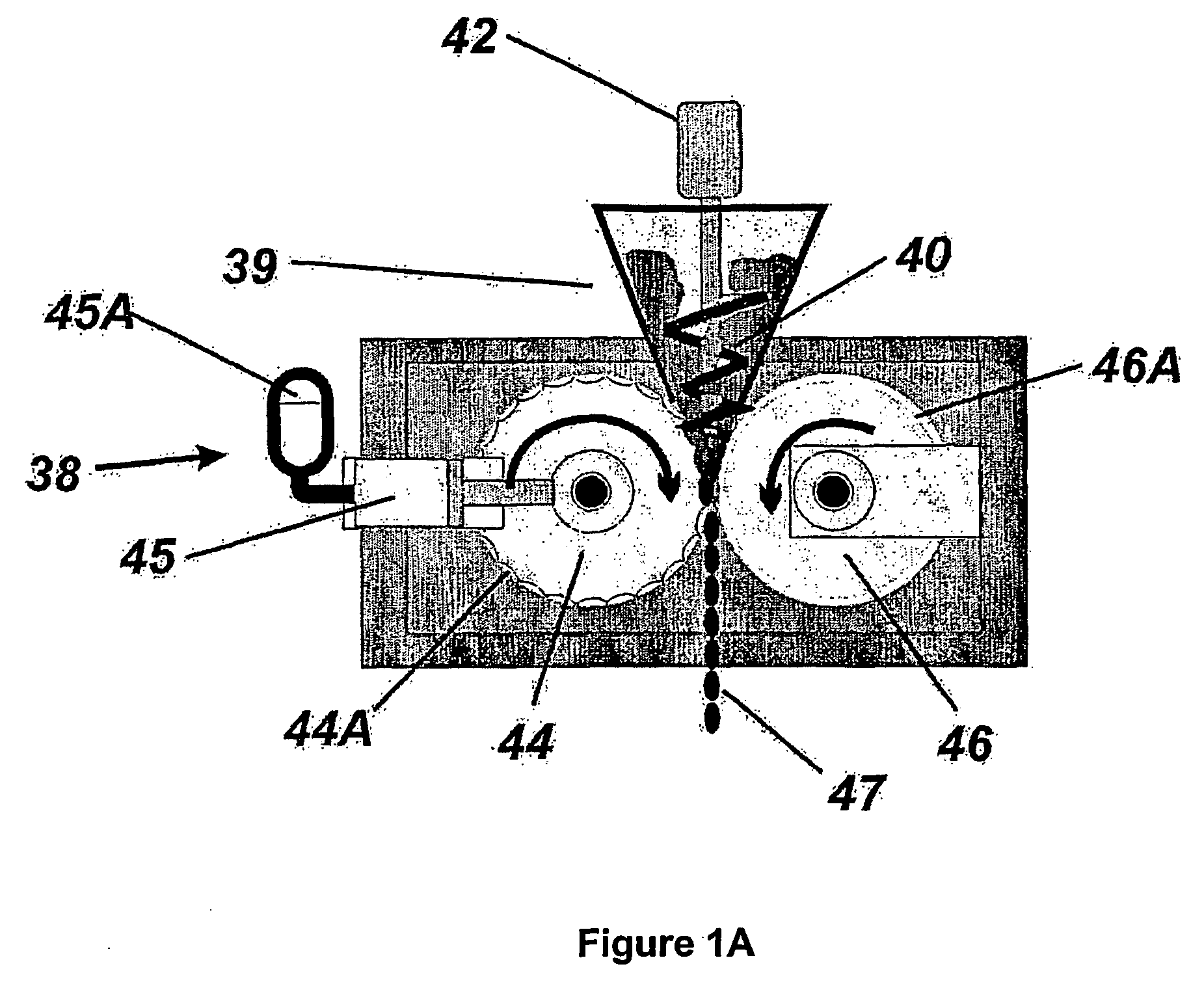

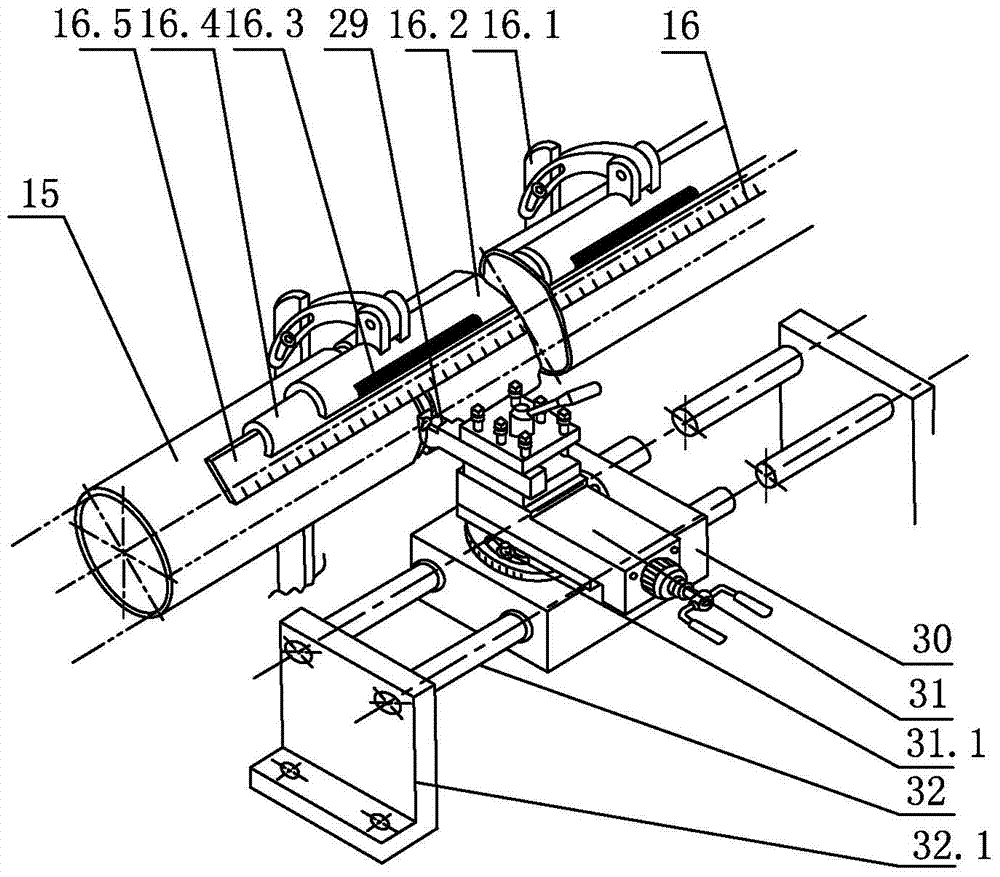

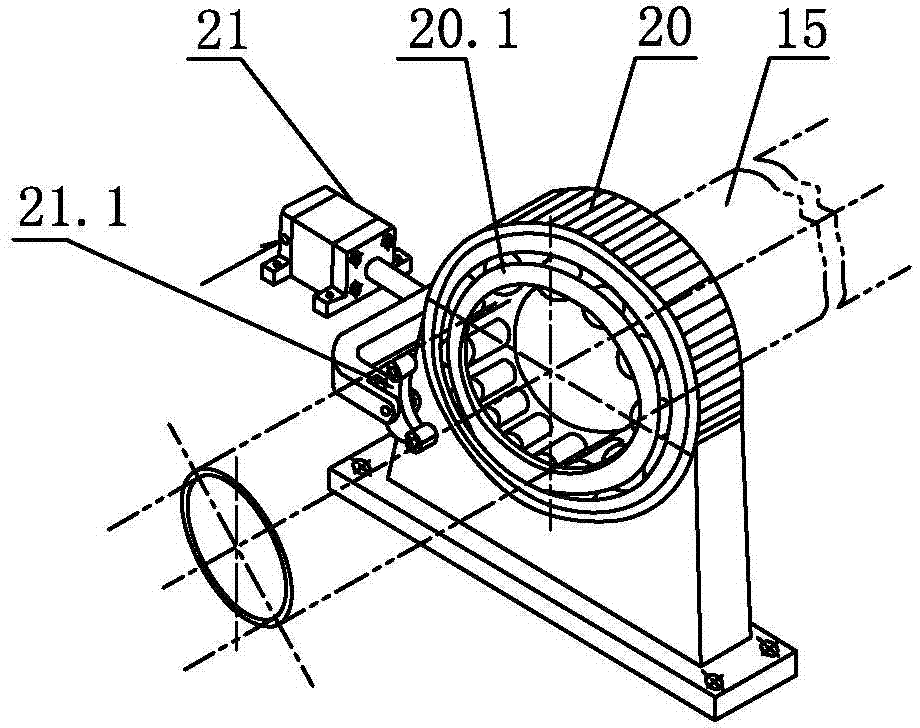

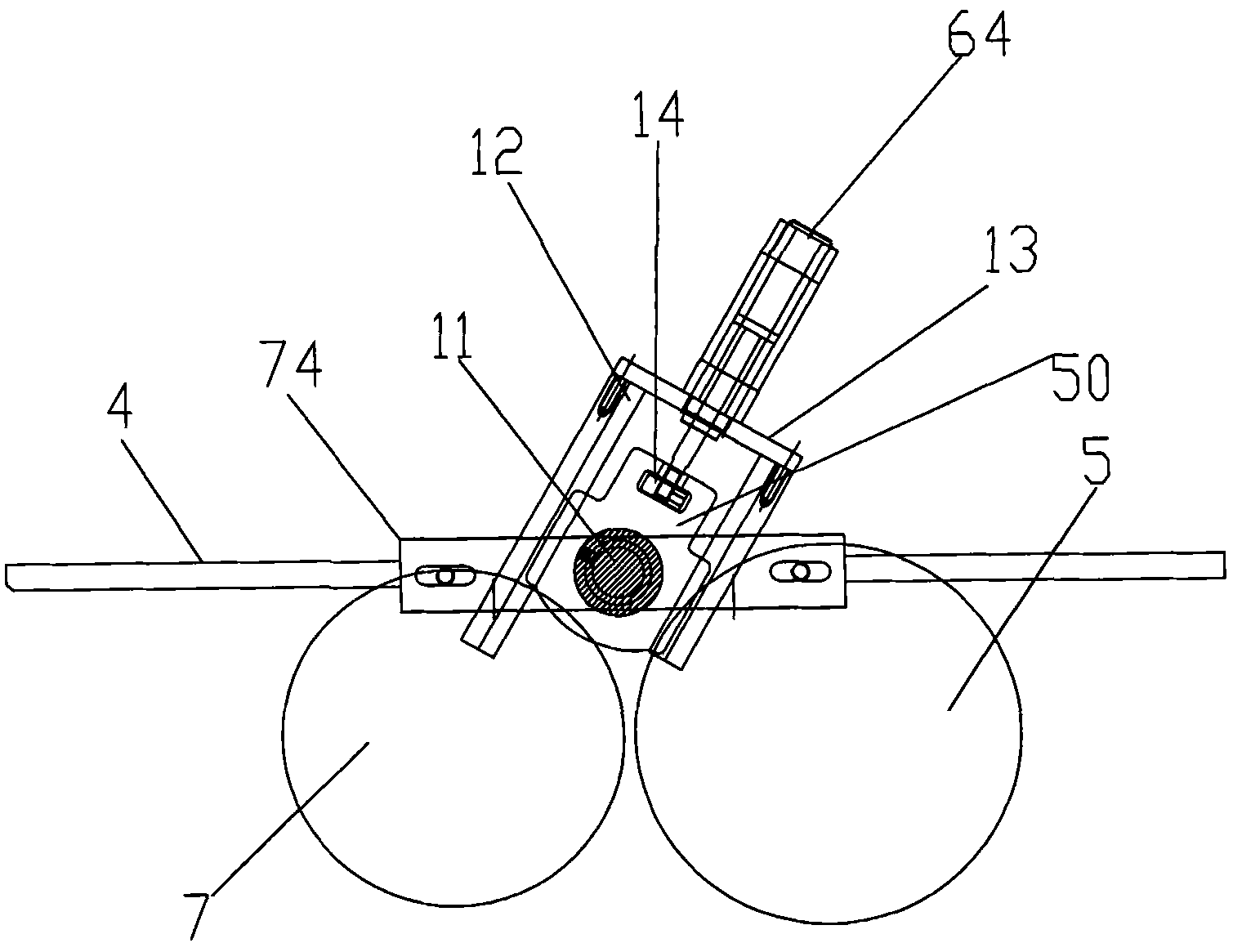

Wire feeder wire drive design

ActiveUS20120160897A1Restrict movementFilament handlingWelding/cutting auxillary devicesEngineeringMechanical engineering

A system and method of feeding wire is provided using at least one roller which is biased towards the wire. The at least one roller is permitted to deflect a limited amount during the wire feeding operation. The roller is permitted to deflect 50% or less than the wire diameter during feeding to prevent tangling.

Owner:LINCOLN GLOBAL INC

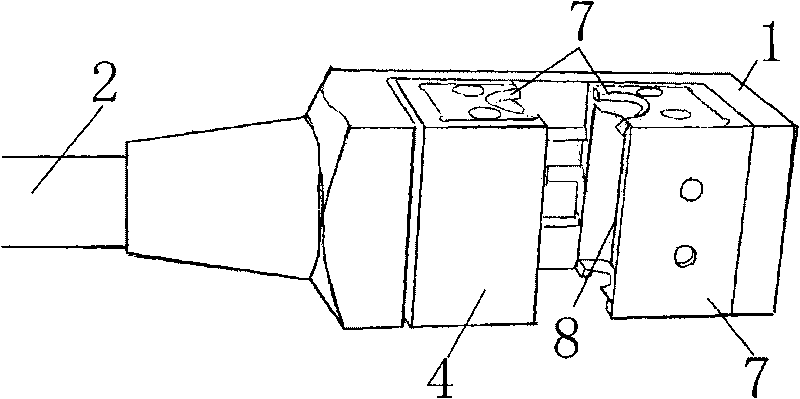

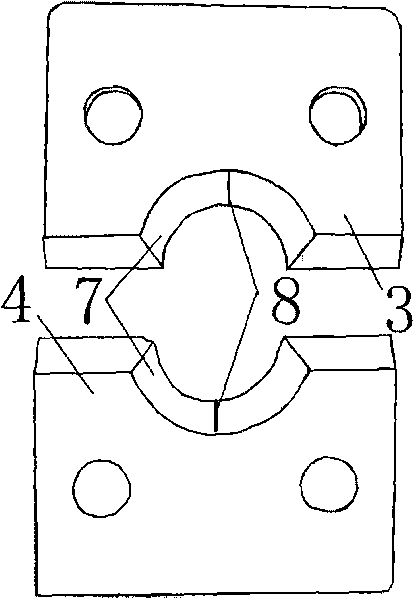

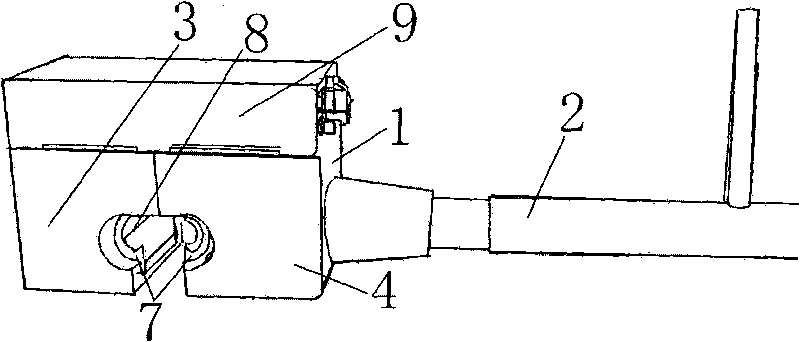

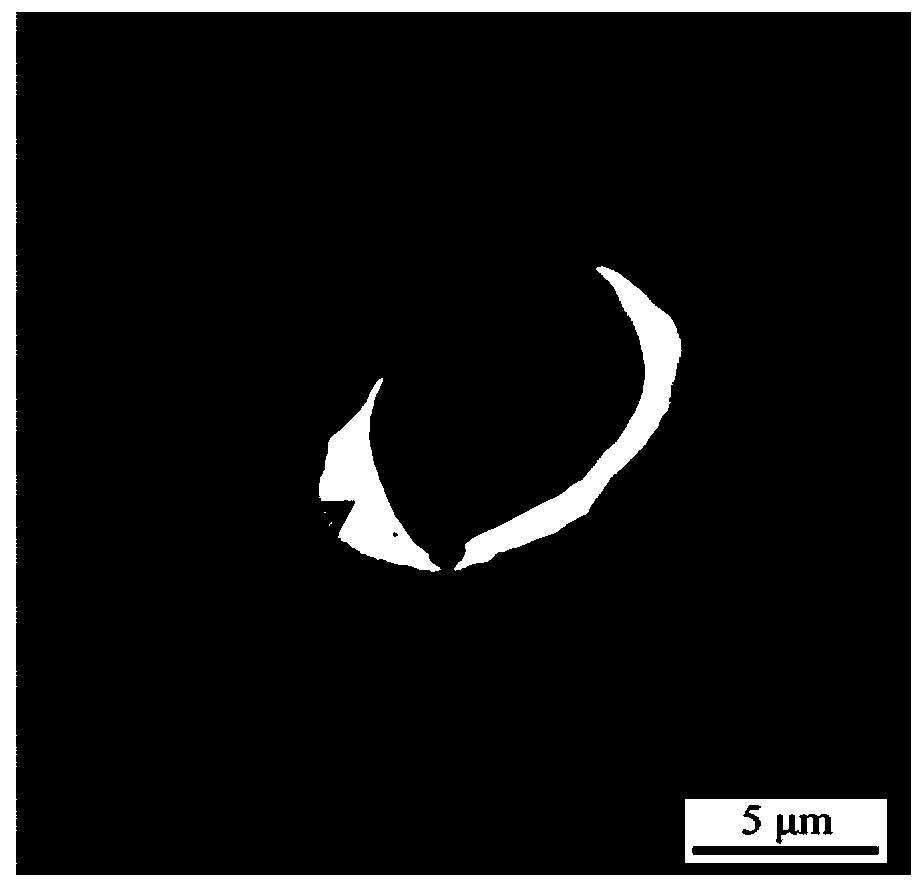

Peeling method of insulated lead of distribution wire and peeling knife thereof

The invention relates to a peeling method of an insulated lead of a distribution wire and a peeling knife thereof. The peeling method adopts a jaw vice-shaped peeling knife, wherein the inside of a knife block of the peeling knife is provided with an upper knife block and a lower knife block which are arranged oppositely in vertical direction and can move relatively; symmetrical cambered concave cutting knife edges are formed on the side mouths of both knife blocks; the inner side of each knife block is provided with a single cutting knife edge; the cutting knife edges are connected with an electric hot plate to perform direct-current preheating for 8 to 10 minutes, and the temperature is controlled between 95 and 125 DEG C; and finally, the cutting knife edges are sleeved on a to-be-peeled insulated lead and are fed simultaneously through screwing a handle to cut in an insulation layer of the insulated lead and peel off the insulation layer. The peeling method has the advantages that the method not only improves the knife structure, but also switches on a direct current power supply to heat the cutting knife edges and cut the insulated lead through rotary feed; and at the same time, the insulation layer of the insulated lead is heated and softened during feed and a rotary knife body separates the insulation layer from the core of the insulated lead, thereby reducing the hardness of the insulation layer and facilitating the feeding, cutting and peeling off.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

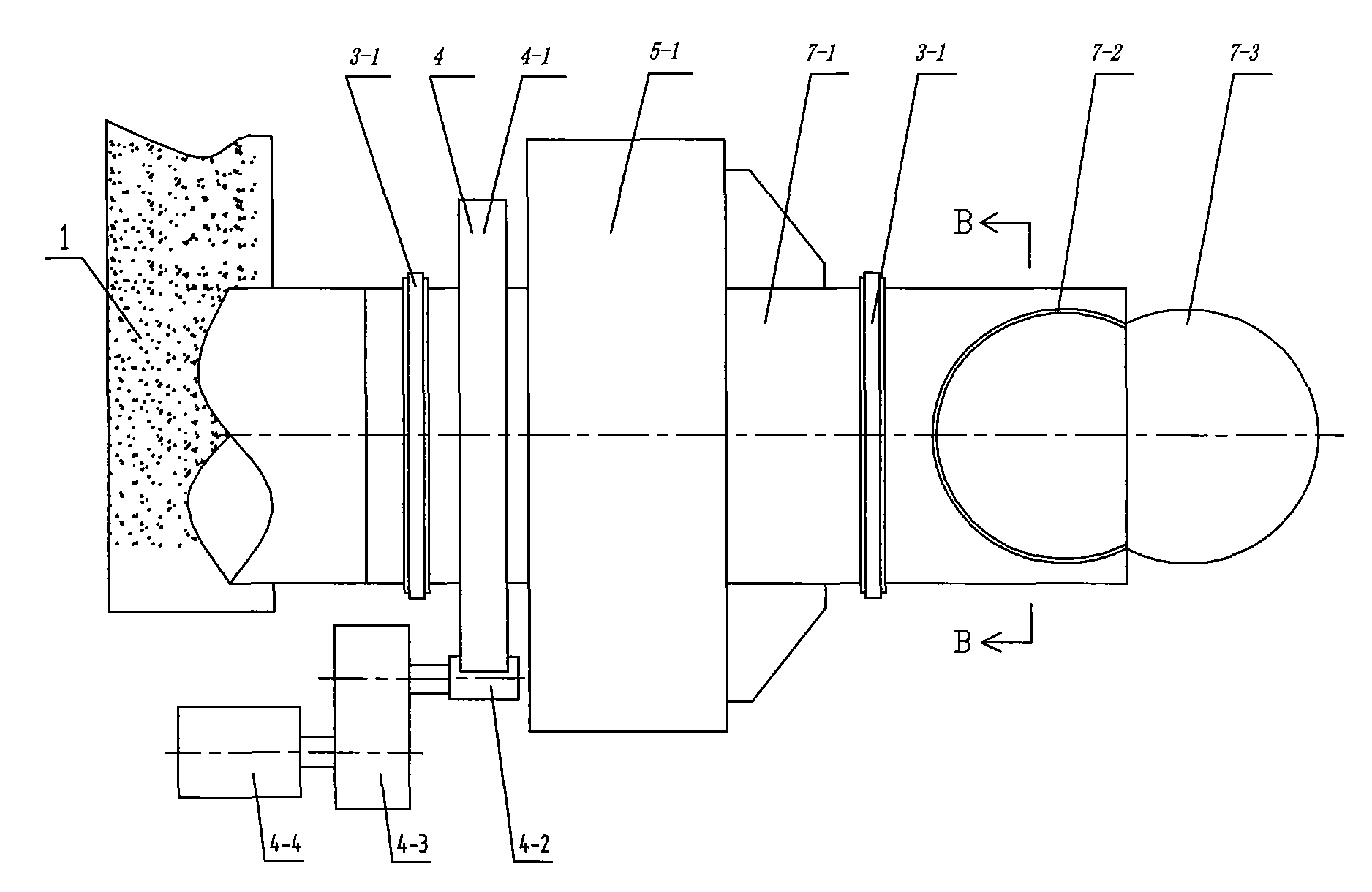

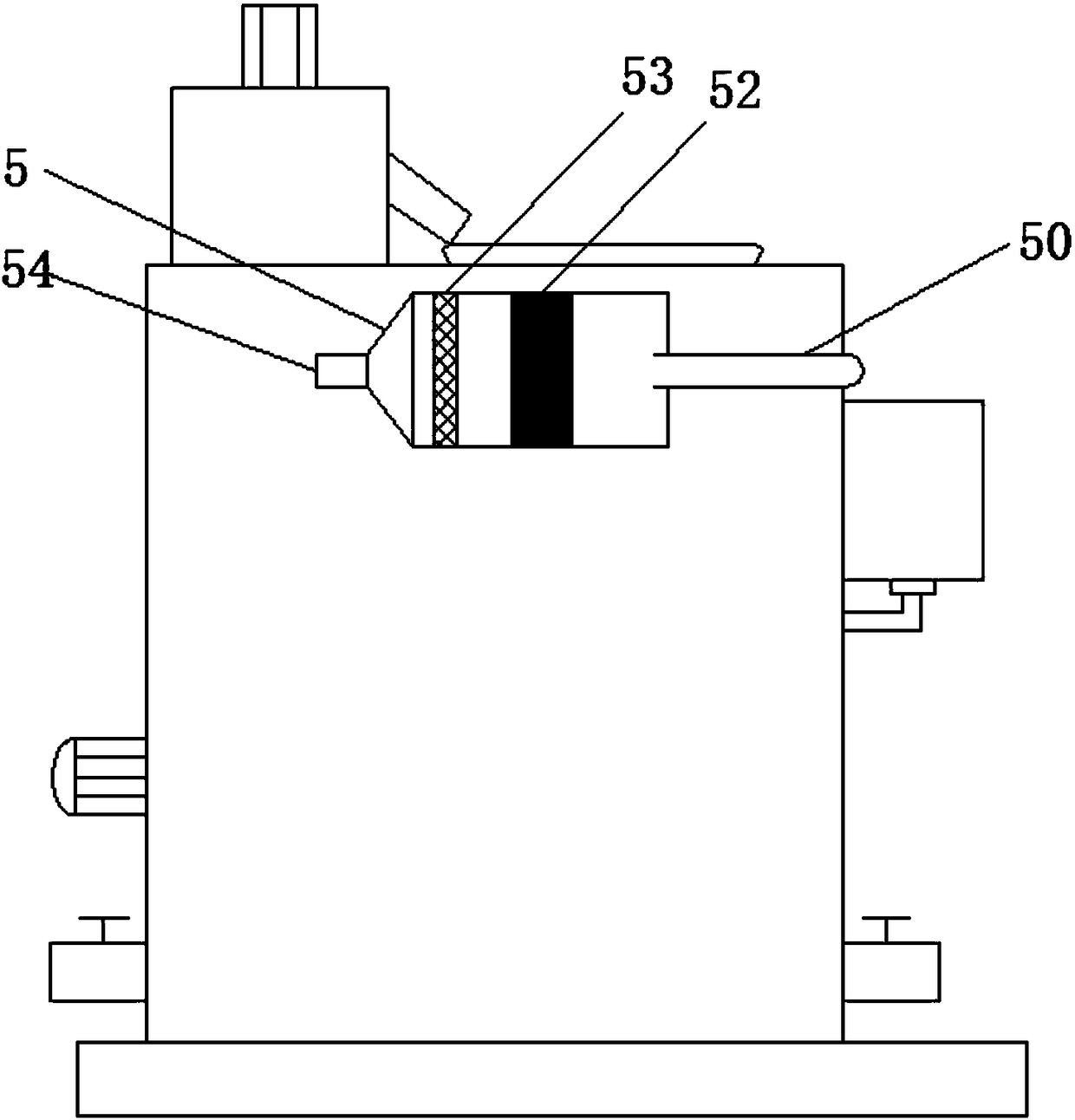

Steel pipe bending machine

The invention relates to a steel pipe processing device. A steel pipe bending machine comprises a frame, wherein a bending roller, a driving roller, a limiting roller and a motor for driving the driving roller are arranged on the frame; a resistance increasing layer is arranged on the surface of the driving roller; the resistance increasing layer is formed by vulcanizing 20% of steel particles and 80% of rubber together; the particle size of the steel particles is smaller than 1mm. The steel pipe bending machine is high in traction force during feeding; the problem of low traction force caused by high possibility of slippage of the driving wheel of the steel pipe bending machine in the prior art during driving can be solved.

Owner:ZHEJIANG HUXIN STAINLESS STEEL MFG

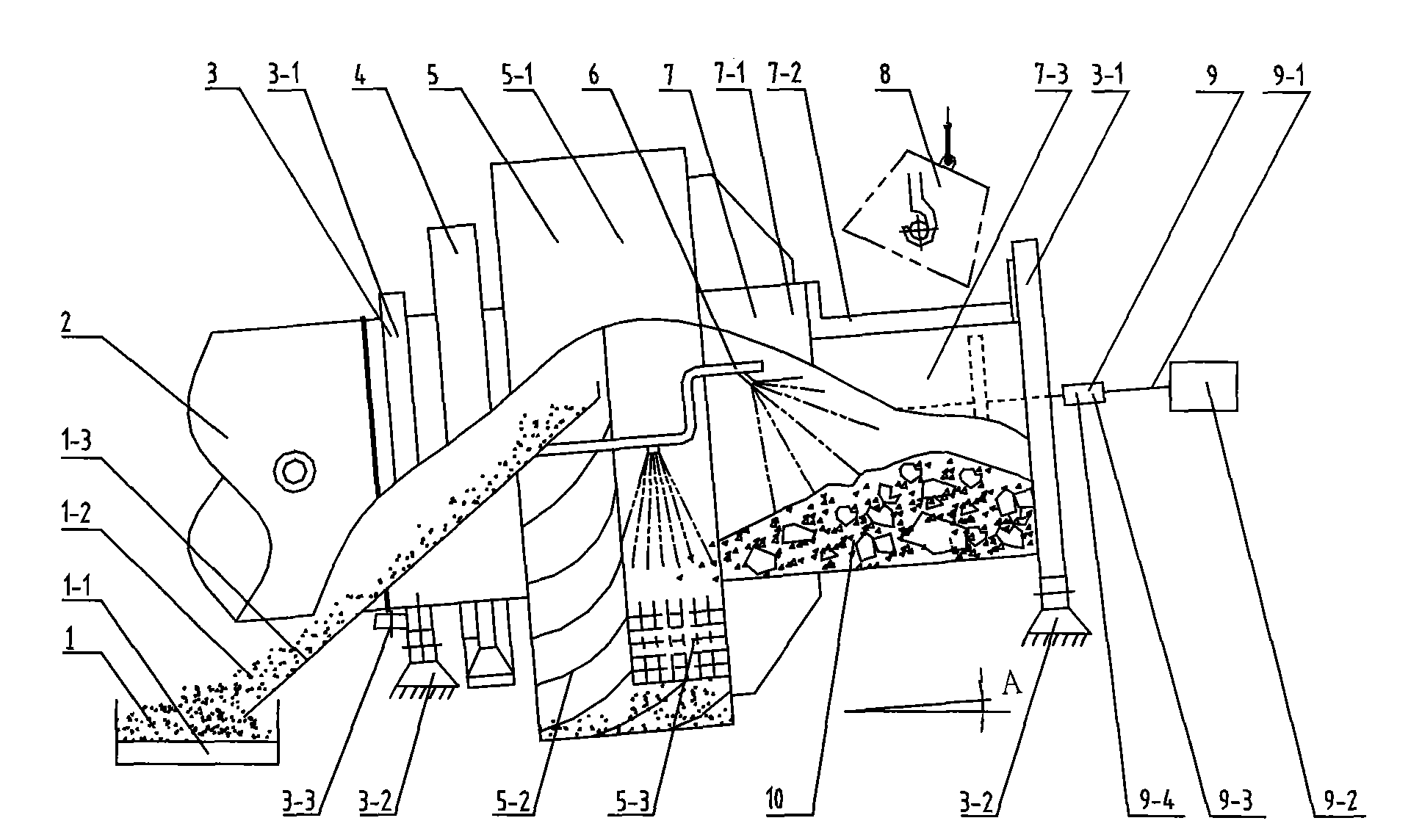

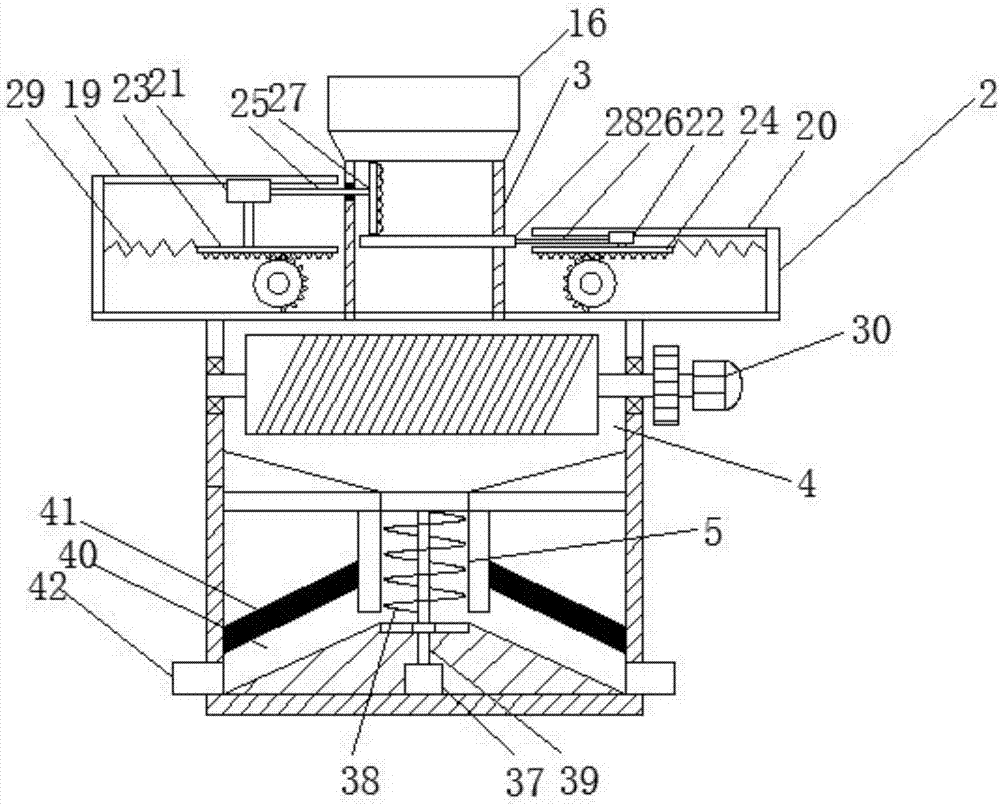

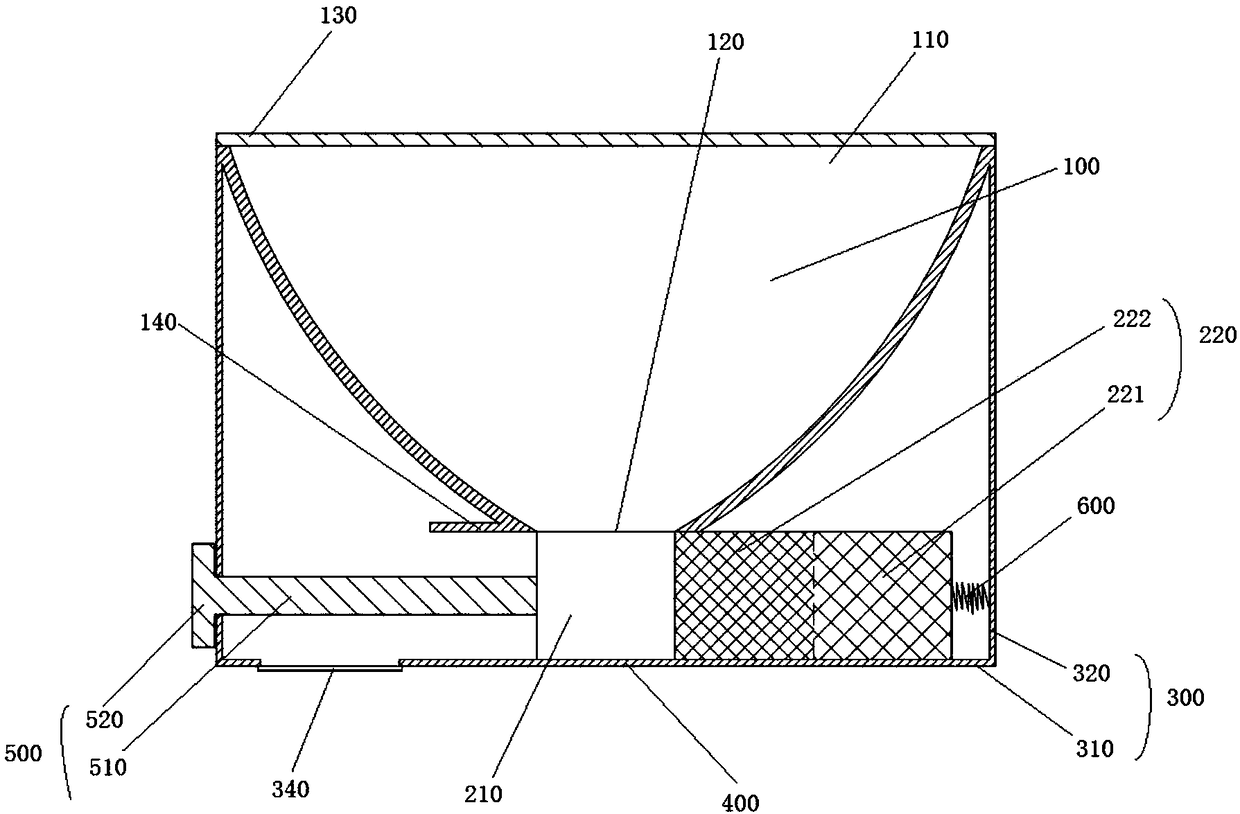

Processing method and device of high-temperature solid steel slag

The invention discloses processing method and device of high-temperature solid steel slag. In the processing method, the front of the traditional working cylinder is provided with a feed cylinder capable of containing a sufficient quantity of the high-temperature solid steel slag; the side surface or the end surface of the feed cylinder is provided with an automatic opening and closing door; the feed cylinder and the working cylinder are on a same axial line and rigidly fixedly combined together to form a large cavity, and the axial line forms a certain tilt angle outwards with a horizontal plane; the high-temperature solid steel slag is poured into the feed cylinder for one time during feed; a sealing door is automatically closed and locked after the feed is completed, the feed cylinder rotates according to set direction and speed under the action of a transmission device, and the high-temperature solid steel slag inside the feed cylinder gradually moves downwards with the rotation of the feed cylinder and feeds spirally to sequentially enter the working cylinder; the high-temperature solid steel slag inside the feed cylinder is continuously cooled and smashed with the rotation of the working cylinder, and finished product slag reaching certain granularity is delivered out of the working cylinder through an output device. The invention can realize the cleaning and efficient processing of the high-temperature solid steel slag.

Owner:BAOSHAN IRON & STEEL CO LTD

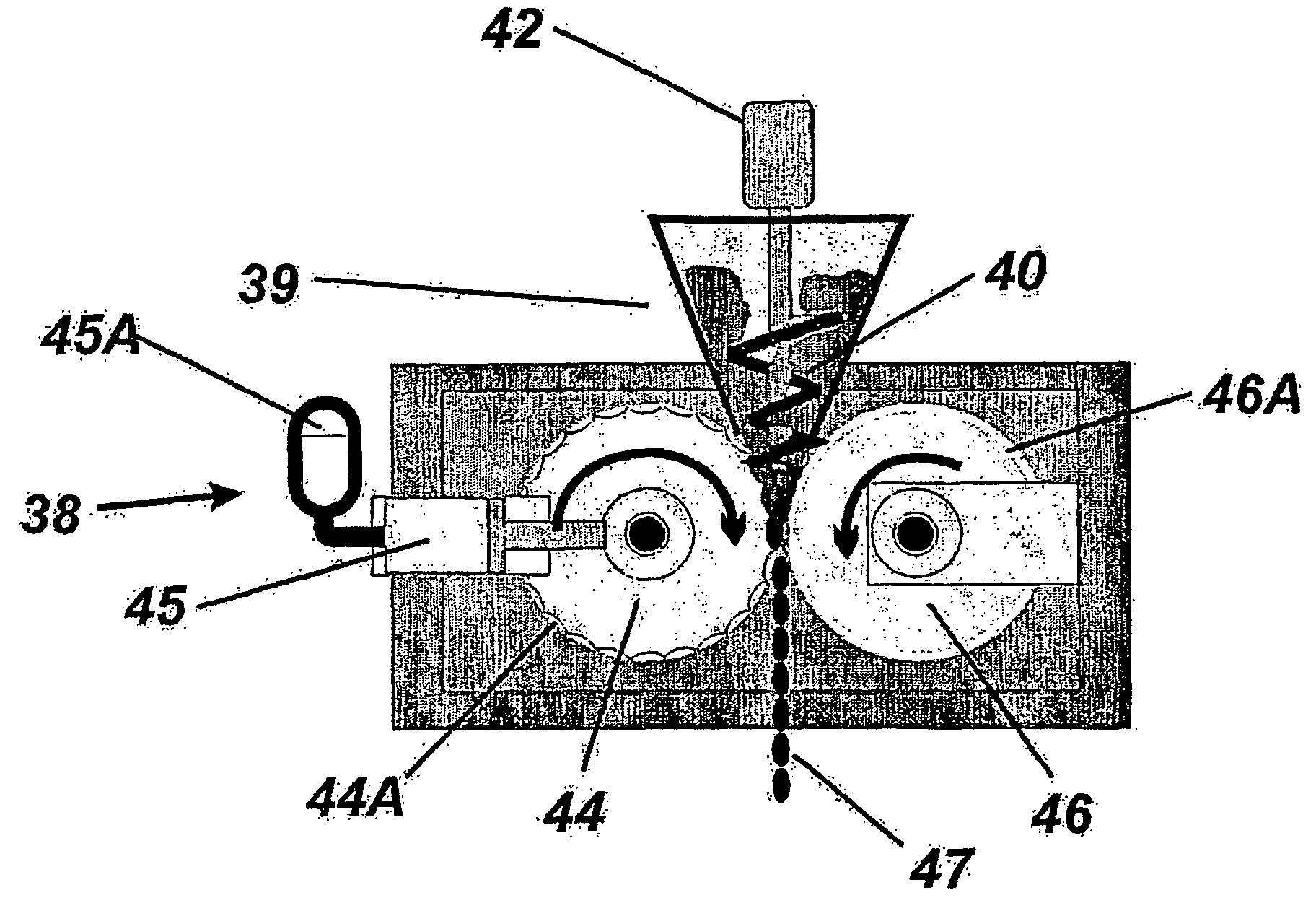

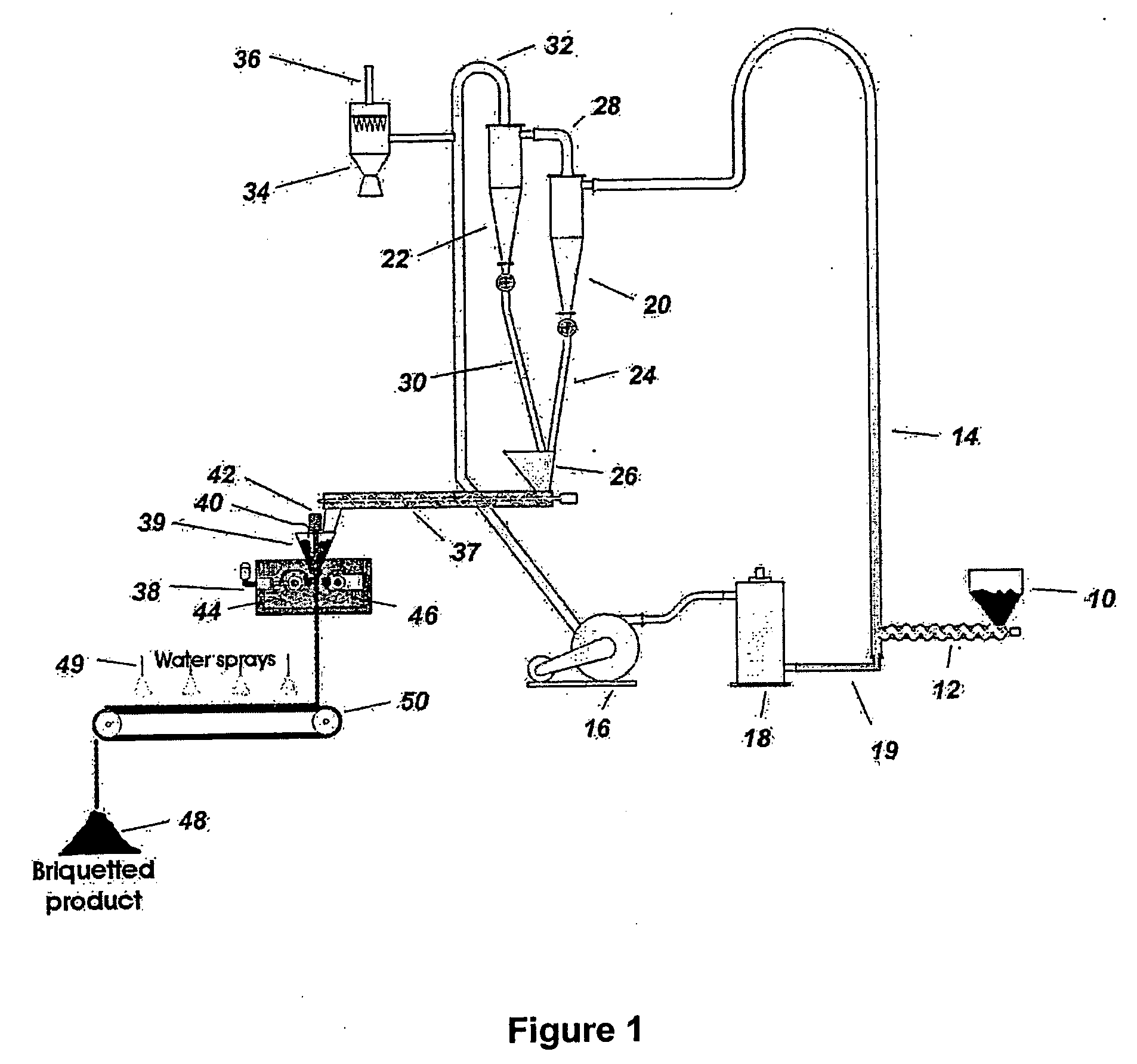

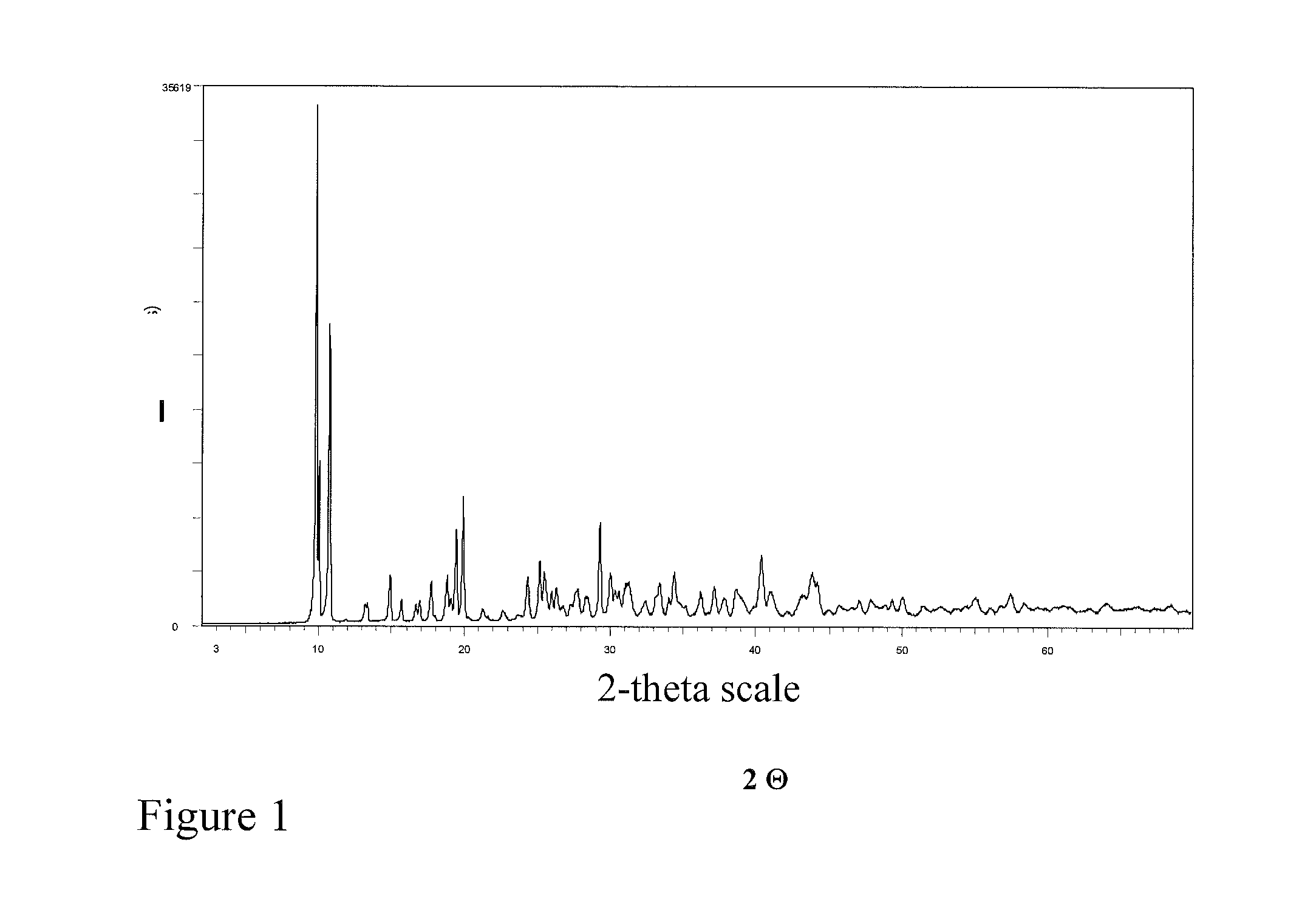

Briquetting process

ActiveUS20060112617A1Reducing pressure buildupLower the volumeConfectioneryBiofuelsParticulatesWater vapor

A process and system is provided for briquetting particulate matter such as moisture-containing bituminous and sub-bituminous coal. This process includes partially drying the particulate matter and feeding, the partially dried particulate matter to a briquetting apparatus under conditions such that water vapour is released from the particulate matter during feeding. The particulate matter is passed through briquette forming rollers to form briquettes. The released water vapour substantially displaces or prevents the ingress of a large proportion of other gaseous components from the atmosphere surrounding an / or intermixed with the particulate matter. The particulate matter that is fed to the briquetting apparatus is surrounded by and intermixed with a gaseous component containing 70 to 100% by volume of water vapour at the point where it enters the briquette-forming part of the briquetting apparatus, such that when the particulate matter is compressed during briquette formation, the water vapour liquefies and the pressure buildup of gaseous material in the thus-formed briquettes is minimised. This reduction in the pressure buildup of gaseous components also acts to reduce blow-back of gases as the coal fines are being formed into briquettes.

Owner:K R KOMAREK +3

Food and rink castoff feed processing method and culture medium and confecting method thereby

The invention discloses a method for processing the food waste to feed through adopting the microecology fermentation technology, which is characterized in that: two groups of the microecology preparation are used during treating; one group of the microecology preparation comprises yeast, lactobacillus and combined fungus of enterococcus faecalis; and the other group of the microecology preparation comprises bacillus cereus, bacillus subtilis, photosynthetic bacteria and actinomycetes. The method has the advantages that: the microecology preparation used as starter is added into the food waste, so as to remove the harmful microorganism such as pathogen through fermentation and realize full utilization and zero discharge of resources during feed processing; the consumption of energy is low; the equipment investment is low with simple and easy practice; and the produced microecology forage can replace the forage containing the antibiotic additive with green environmental protection. The invention also discloses a culture medium containing the component of seaweed, soybean sprout and sweet potato and a configuration process, the culture medium has the advantages of adapting to cultivation and proliferation of a plurality of probiotics and being beneficial to mass produce high-quality microecology preparation with low price and easy configuration.

Owner:JUNZHU DALIAN BIOLOGICAL IND CO LTD

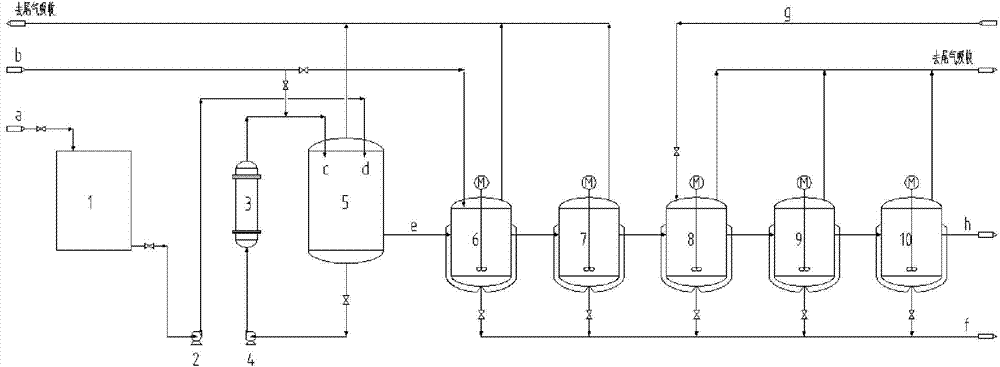

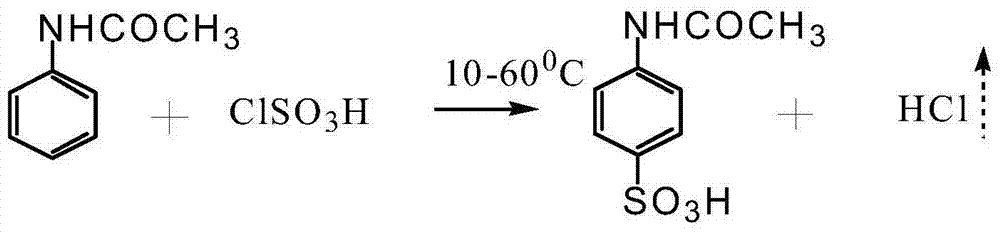

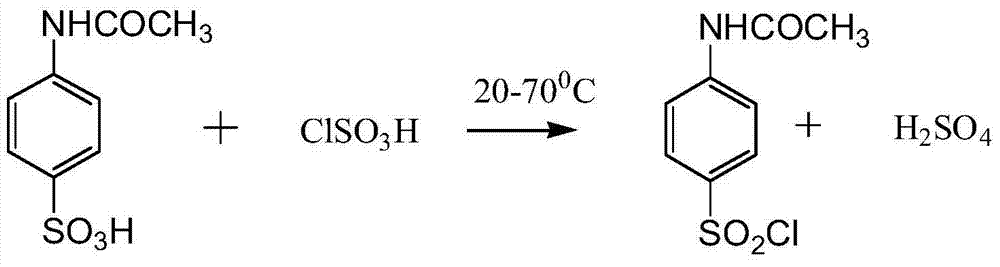

Continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate

ActiveCN104496866AImprove conversion rateThe reaction temperature is easy to controlSulfonic acid preparationMolten stateChlorosulfuric acid

The invention discloses a continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate. The process comprises the steps: performing reaction on chlorosulfonic acid and acetanilide which serve as raw materials; respectively atomizing chlorosulfonic acid and molten-state acetanilide and contacting with each other during feeding to perform reaction. According to the continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate, the molten-state acetanilide is used as a raw material, and the reaction on the acetanilide in an atomizing state and chlorosulfonic acid which is also in an atomizing state are carried out and the reaction temperature is easily controlled, so that the production of byproducts such as parachloroaniline is avoided, and the conversion rate of acetanilide serving as a raw material is high. The process is convenient to operate, short in production period, controllable in reaction process, less in labor demands, low in cost and easy for industrial production.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

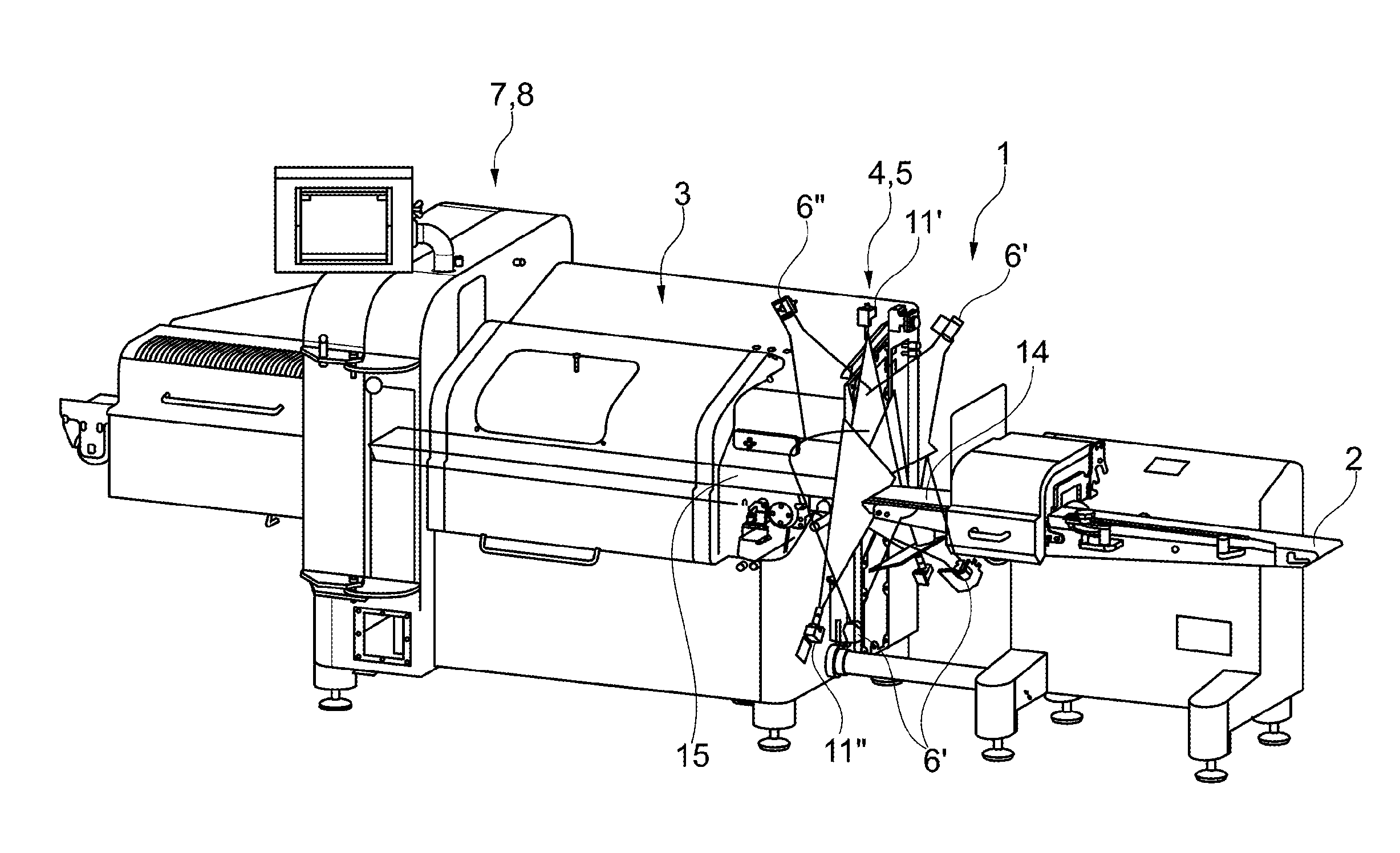

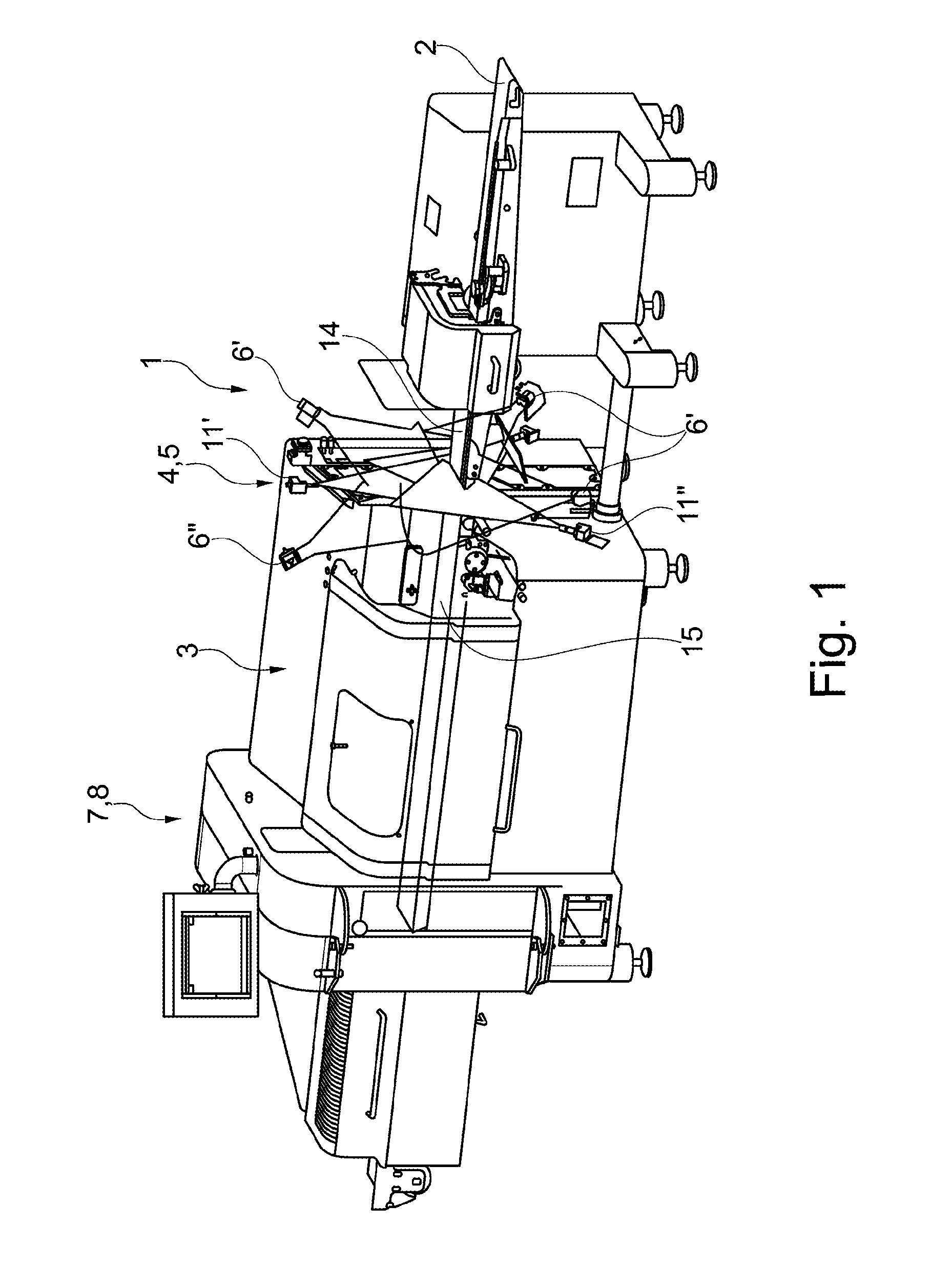

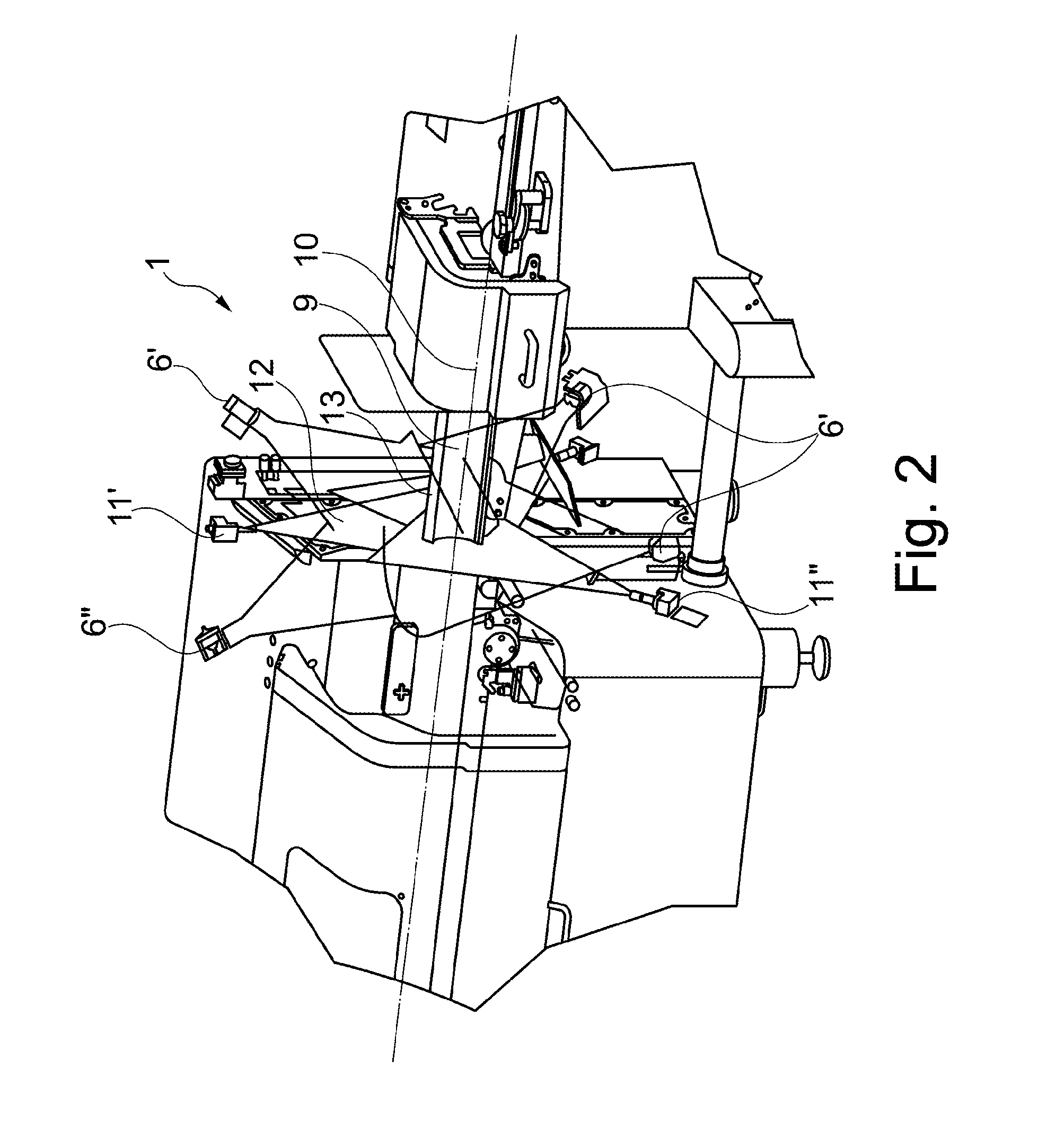

Method and device for weight precise cutting of a food strand

ActiveUS8758099B2Easy to detectImprove accuracyMeat processing plantsPoultry processingData controlMechanical engineering

Owner:REIFENHAEUSER UWE

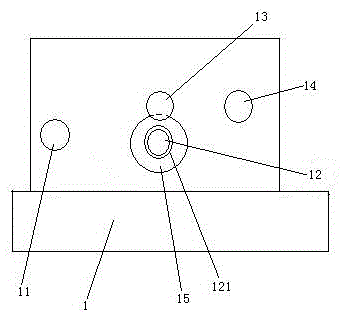

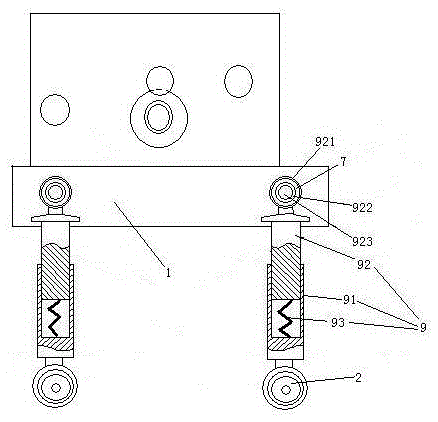

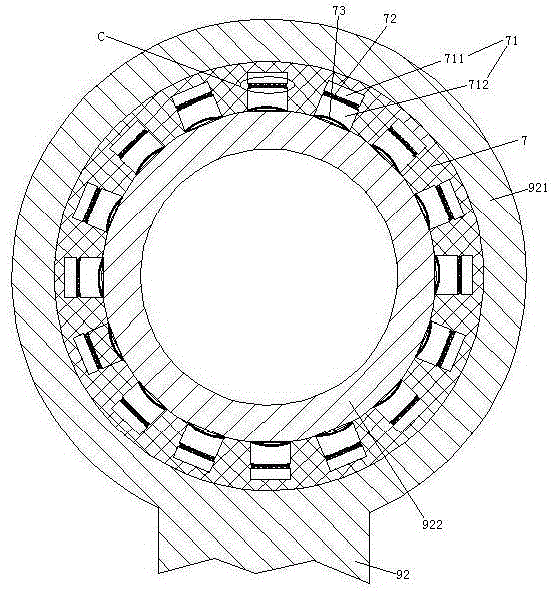

Cutting-off and chamfering integrated turning tool and one-step clamping, cutting-off and chamfering pipe cutter

InactiveCN103480872AStable structureFlexible operationAuxillary equipmentTurning toolsTool bitThrust bearing

The invention relates to a cutting-off and chamfering integrated turning tool and a one-step clamping, cutting-off and chamfering pipe cutter and belongs to pipe machining equipment. A main cutting edge is arranged on a front tool surface of the front of a tool handle, and two V-shaped grooves are symmetrically arranged in two auxiliary cutting edges, so that both cutting-off and chamfering can be performed, the operation is flexible, and exchanging of different turning tools during chamfering are avoided. The cutting-off and chamfering integrated turning tool is used by the pipe cutter, a thrust bearing, a tapered wedge thrust pipe and a plurality of tapered wedge pipes which are mounted on a cylindrical shaft successively are connected together, and a rotary feed pipe is clamped firmly by outward expansion of C-shaped rings under thrust of a clamping air cylinder piston and tapered heads. By means of the cutting-off and chamfering integrated turning tool mounted on a sliding shaft lathe tool rest, within the range of clearance grooves of the tapered wedge pipes, during feed pipe cutting-off tool withdrawn, and on a device, during once clamp of the inner diameter of a thin-wall round pipe, a plurality of feed pipes can be cut off by setting the length, and chamfering is performed on inner and outer edges of two end faces of notches.

Owner:柳燕明

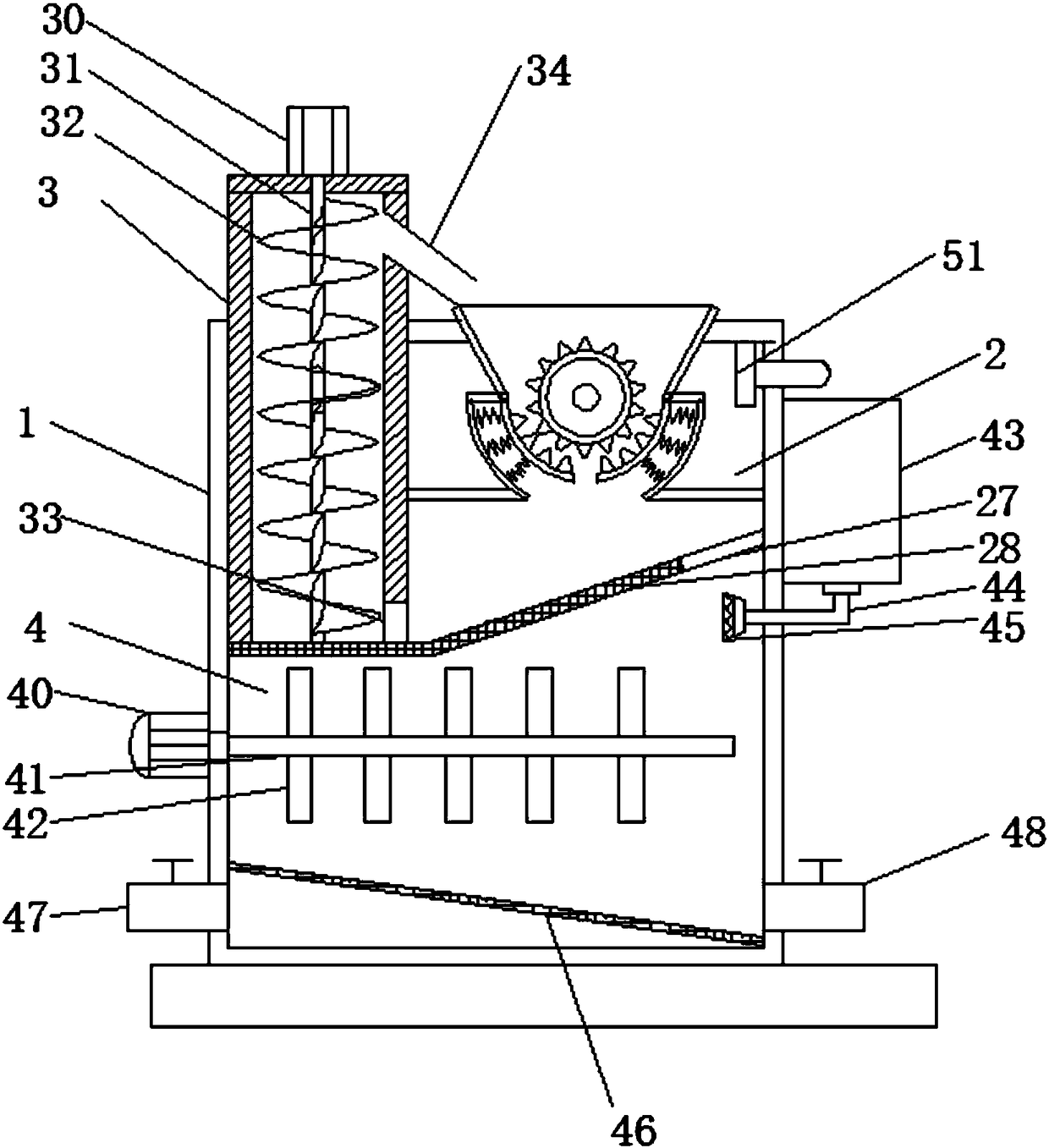

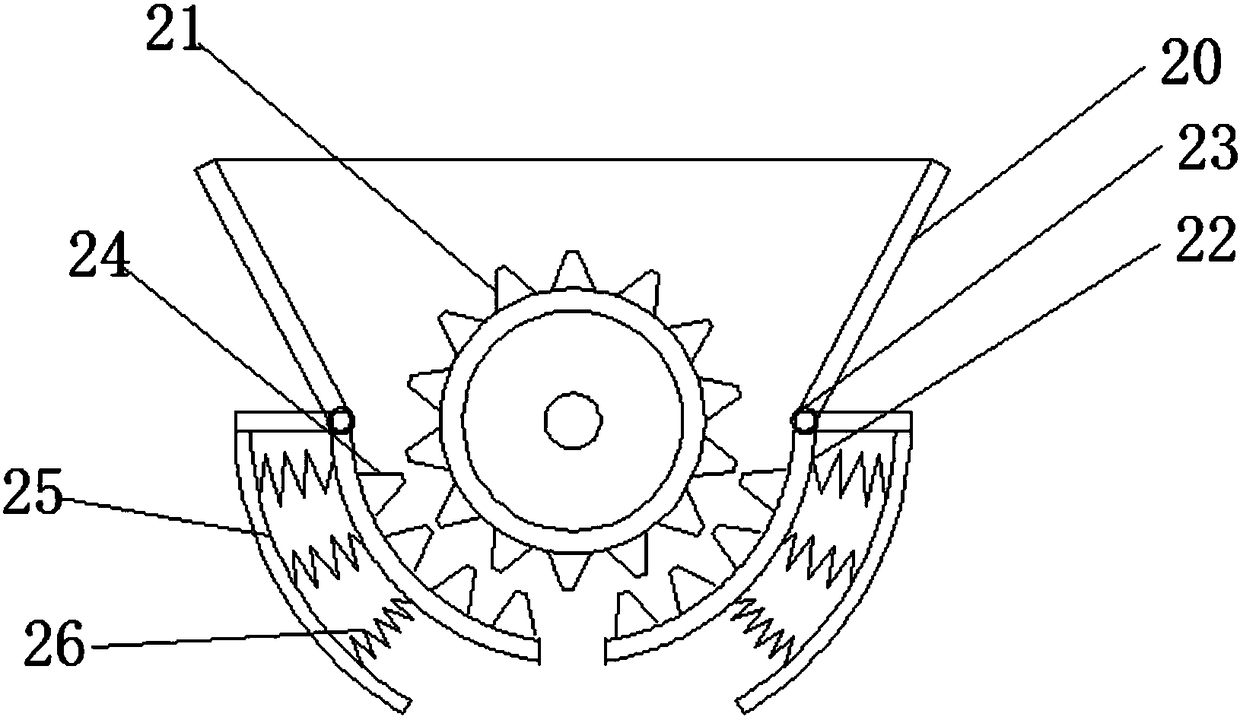

Recovery and crushing device for building materials

InactiveCN107457069AReduce pollutionAvoid wastingTransportation and packagingMixersSpiral bladeGround plane

The invention discloses a recovery and crushing device for building materials. The device comprises a chassis and a frame; the chassis is divided into a crushing cavity and a conveying cavity; and the conveying cavity is positioned below the crushing cavity. A third motor is mounted in the middle position of the ground plane of the chassis; a conveying rotating shaft is mounted at the top end of the third motor, and extends into the conveying cavity; spiral blades are mounted on the conveying rotating shaft; conveying grooves are respectively formed in the bottom ends of the left and right sides of the conveying cavity; electromagnetic plates are arranged at the bottom ends of the conveying grooves; and discharge ports are formed in the tail ends of the conveying grooves. The device has the following beneficial effects: through belt transmission and rack transmission mechanisms, during feeding, an impact block is driven to collide with materials, so that the materials are crushed during feeding.

Owner:李威

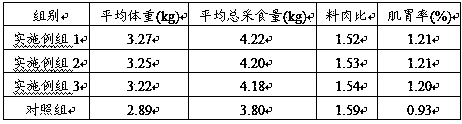

Integral-grain wheat-type chicken-in-meat compound feed and preparation method thereof

ActiveCN103392937AMeeting nutritional needsAddress nutritional needsFood processingAnimal feeding stuffGrape seedPeanut meal

The invention discloses integral-grain wheat-type chicken-in-meat compound feed and a preparation method thereof. The compound feed consists of the following raw materials: corn, integral-grain wheat, rice bran meal, soya-bean oil, 46% soybean meal, 46% peanut meal, stone flour, calcium hydrogen phosphate, dry powder of Chinese cabbage leaves, grape seed powder, liquid compound enzyme, bee pollen and premix. The preparation method comprises steps of crushing, mixing, pelletizing and spraying. The beneficial effects are that: the compound feed is scientific in ratio, economical and practical; by adding integral-grain wheat in daily ration of the chicken-in-meat, not only the nutritional requirement of the chicken-in-meat is fully satisfied, the problem of difficult digestion of integral-grain wheat is solved because of the ratio of the various raw materials, intestines and stomach are prevented from damage caused by superfine feed, but also the crushing energy consumption during feed processing is reduced and feed cost is reduced.

Owner:SHANDONG NEW HOPE LIUHE GROUP

Special feed for 50-150-day old mandarin fish

InactiveCN105394448AImprove farming productivityConvenient foragingFood processingClimate change adaptationAnimal sciencePrawn

The invention discloses special feed for 50-150-day old mandarin fish. The special feed comprises raw materials in parts by weight as follows: 40-80 parts of fish meal, 50-120 parts of krill meal, 30-50 parts of sandworm powder, 10-12 parts of cod liver oil, 0.5-2.5 parts of palm oil, 1.5-3.5 parts of corn oil, 5-18 parts of scallop skirts, 5-18 parts of sweet corn gluten meal, 10-16 parts of maize germ oil, 5-15 parts of cottonseed cakes, 10-18 parts of fermented bioprotein, 8-17 parts of black sesame powder, 10-38 parts of blood worms, 1-3 parts of radix aucklandiae, 1-3 parts of taurine, 0.5-1.5 parts of probiotics, 0.5-1.2 parts of methionine, 0.2-0.8 parts of threonine, 0.05-0.09 parts of compound enzyme, 0.01-0.03 parts of microelements, 2-5 parts of Chinese herbal medicines, 5-10 parts of a phagostimulant and 1-3 parts of vitamins. The product is used for the 50-150-day old mandarin fish, stress caused during feed changing can be reduced, transition between different kinds of feed is facilitated, the feed has good palatability and high nutritional value and is low in cost, the mandarin fish can grow fast if the mandarin fish is fed on the feed, and the fatality rate is small.

Owner:全椒县鮰鱼养殖专业合作社

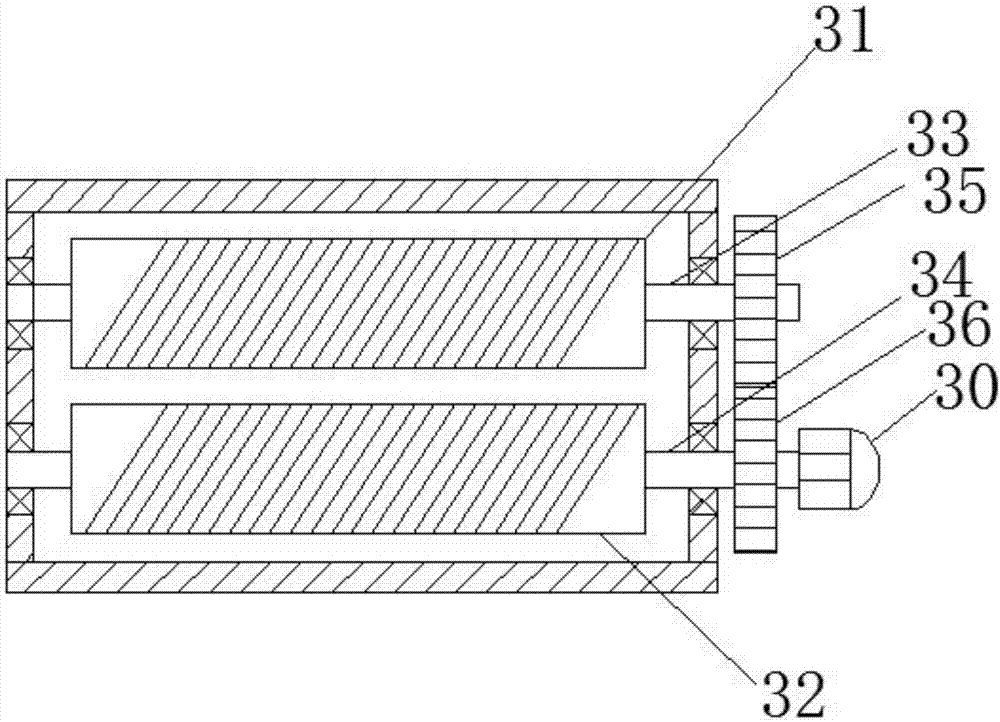

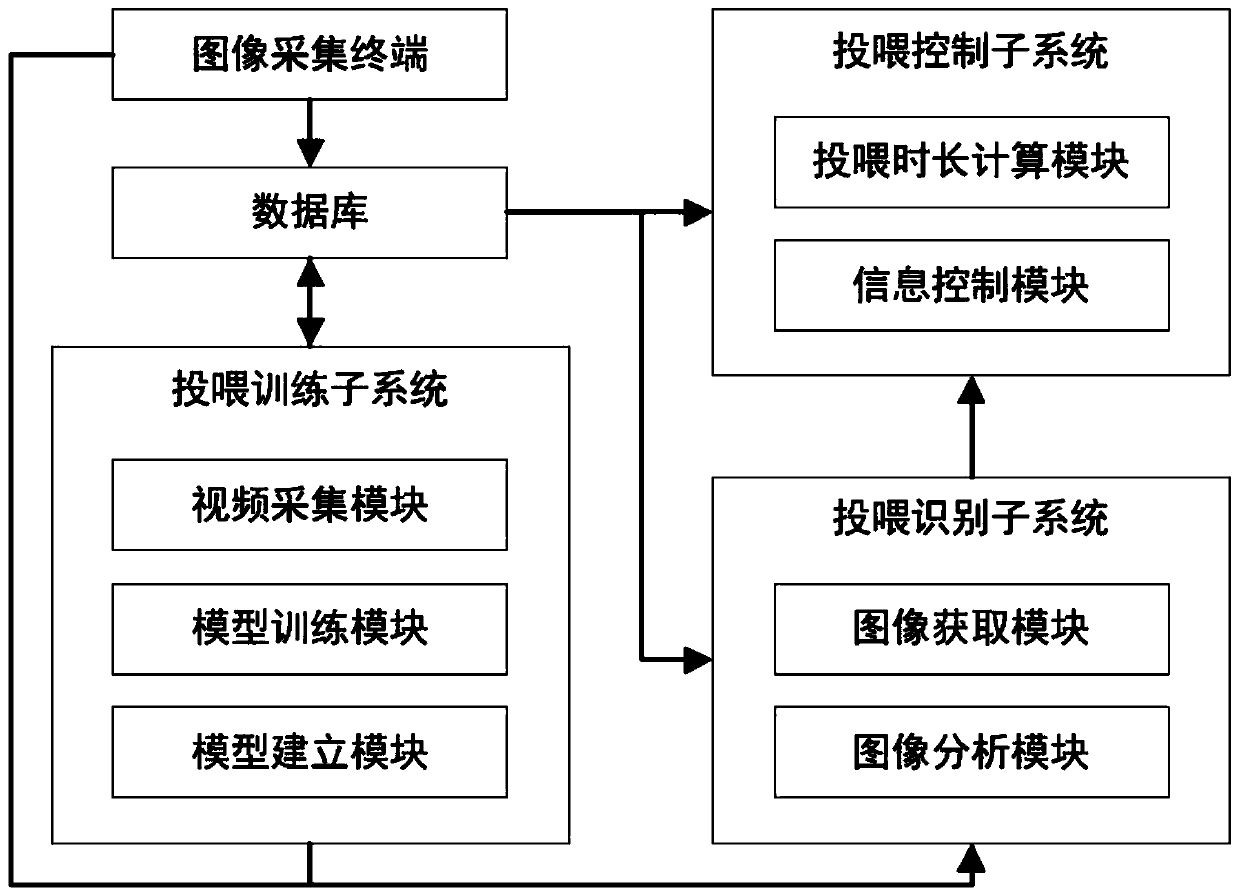

Fish, shrimp and sea cucumber breeding precise feeding system and device based on target detection and tracking

ActiveCN110583550APrecise feedingEasy to feed accuratelyClimate change adaptationPisciculture and aquariaFeeding durationShrimp

The invention relates to the technical field of feeding devices, in particular to a fish, shrimp and sea cucumber breeding precise feeding system and device based on target detection and tracking. Thesystem comprises a feeding training sub system used for acquiring eating videos and a training model and utilizing the eating videos for training the training model so as to generate a hunger analysis model, a feeding recognition sub system used for acquiring eating images during feeding and conducting image analysis on the eating images to generate hunger indexes, and a feeding control sub system used for generating feeding duration according to the hunger indexes and generating control information according to the feeding duration to control a feeding device to feed creatures. By adopting scheme, the feeding device can be controlled to feed the bred creatures according to the hunger states of the bred creatures, and precise feeding is achieved.

Owner:CHONGQING TECH & BUSINESS UNIV +1

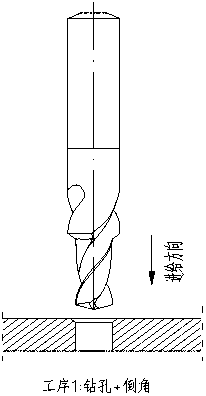

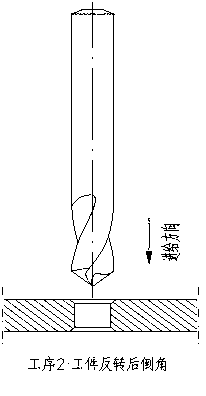

Positive-negative chamfering drilling bit used for processing of plate parts

InactiveCN103157836AImprove processing efficiencyGuaranteed machining accuracyTransportation and packagingTrepanning drillsEngineeringDuring feed

The invention relates to a positive-negative chamfering drilling bit used for processing of plate parts. The positive-negative chamfering drilling bit used for the processing of the plate parts comprises a handle portion, a neck portion and a head portion, the head portion, the neck portion and the handle portion are coaxial cylinder bodies taking the same central axis as the center, scrap discharge grooves are arranged on the head portion and the neck portion, an entity portion except the scrape discharge grooves is a tool back, a main cutting edge, a negative cutting edge and a positive cutting edge are respectively arranged at positions of the head end face, the middle and the tail end face of the scrape discharge grooves, the main cutting edge is used for drilling the plate parts by drilling a hole, the positive cutting edge processes the an inlet chamfer of a through hole during feeding for the first time, and after the inlet chamfer is processed, the tool is retracted to the position of the negative chamfer edge to mill an outlet chamfer of the through hole out. The positive-negative chamfering drilling bit used for the processing of the plate parts achieves composite processing of drilling, chamfering and negative-chamfering.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

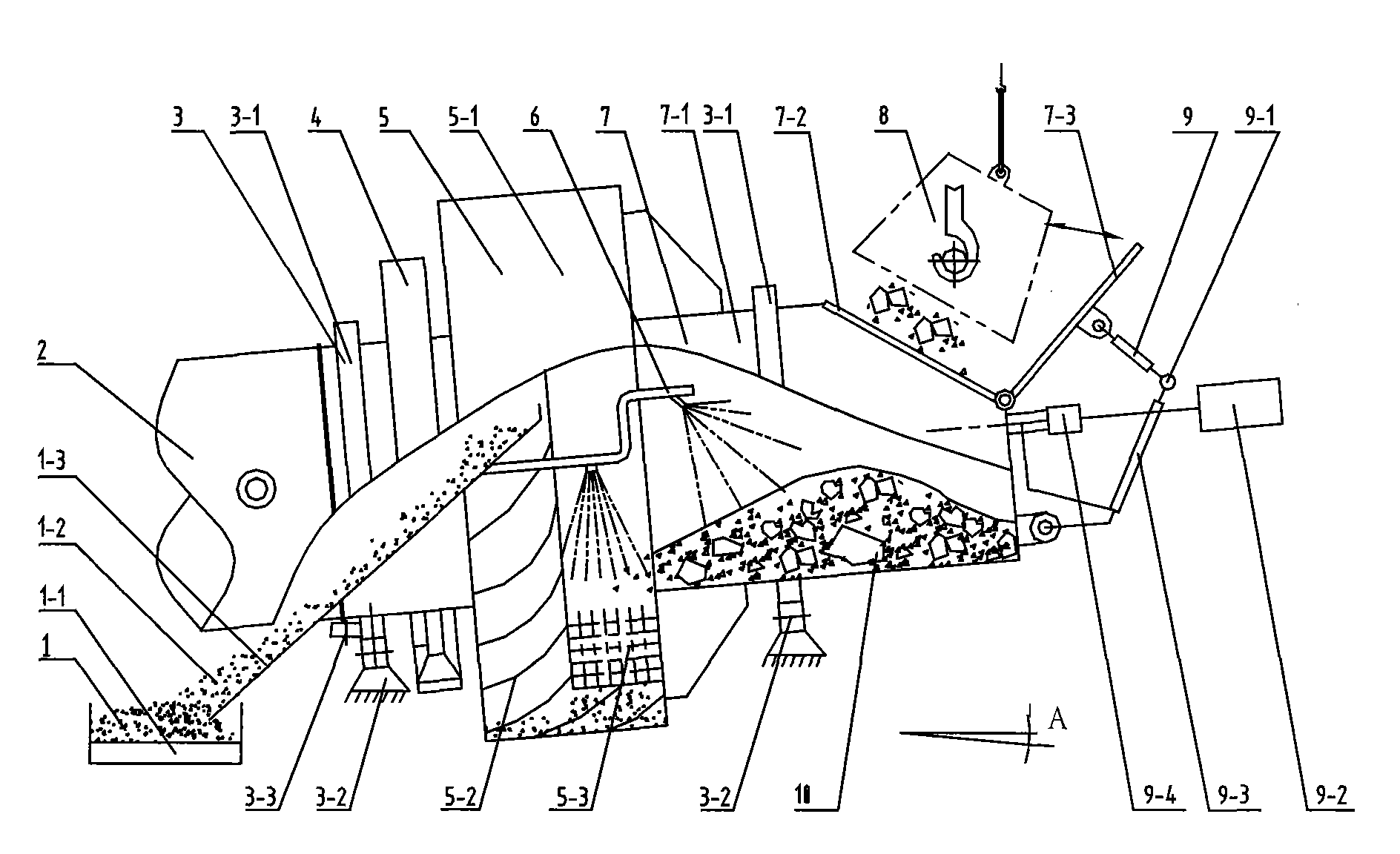

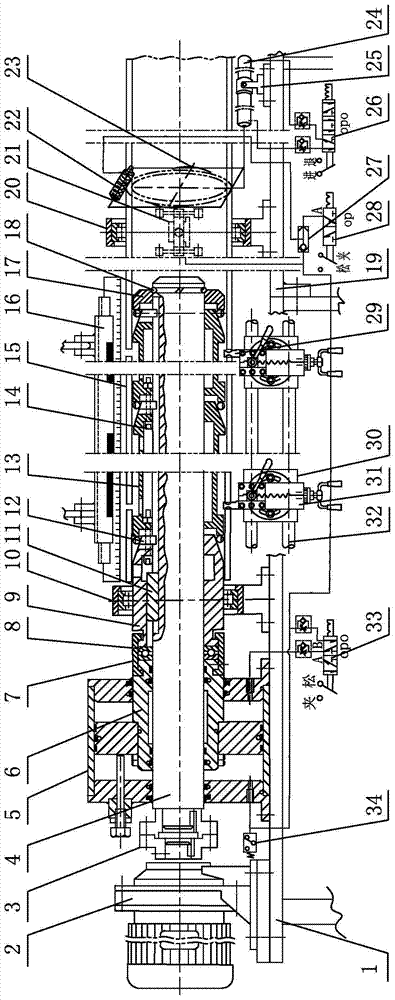

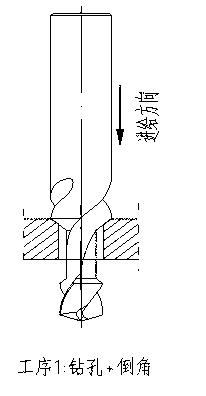

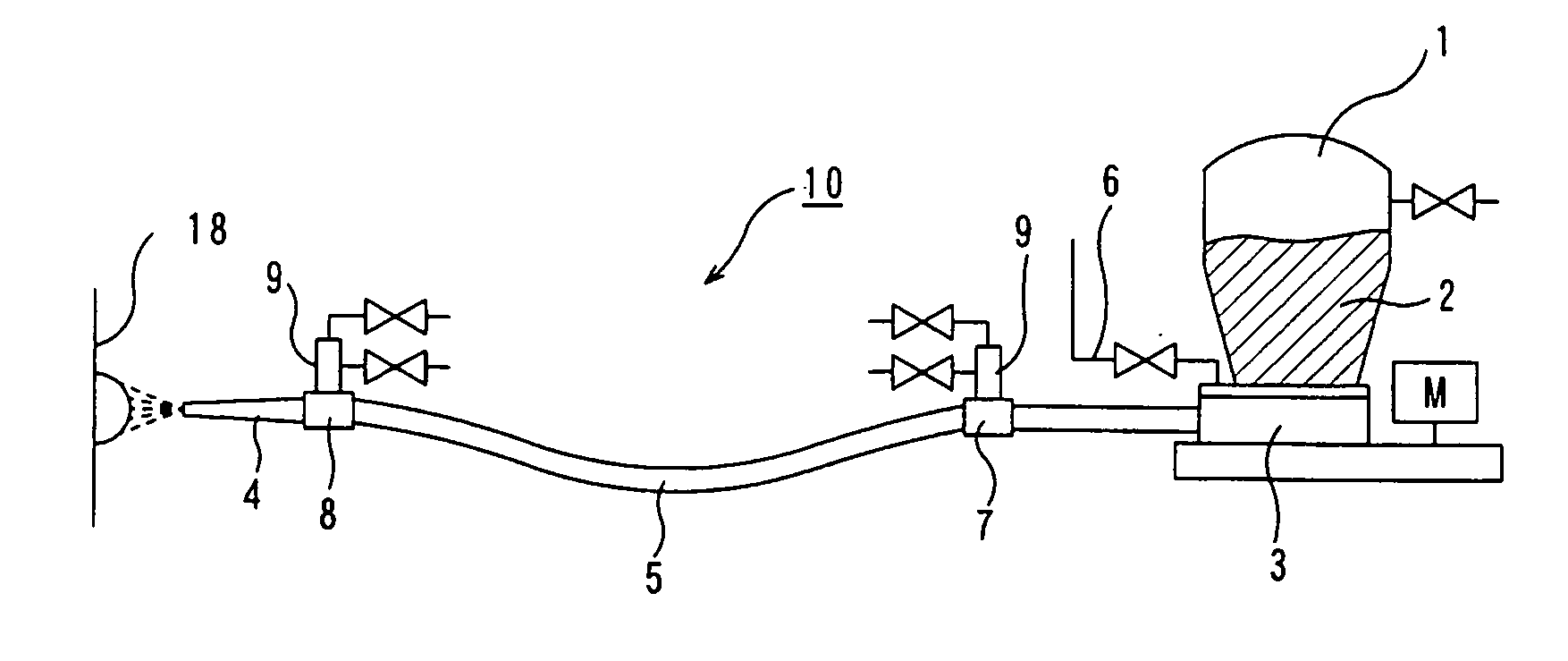

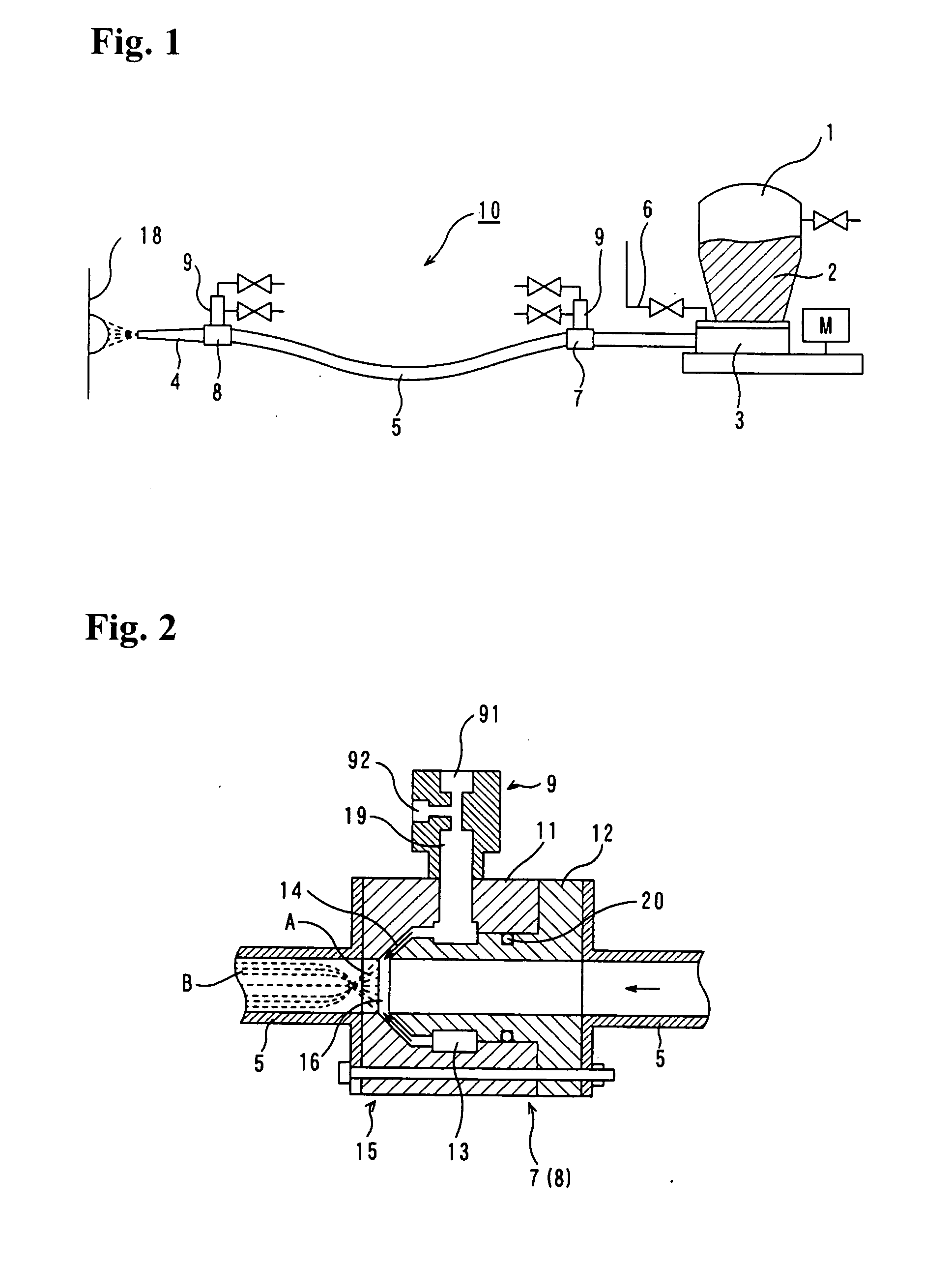

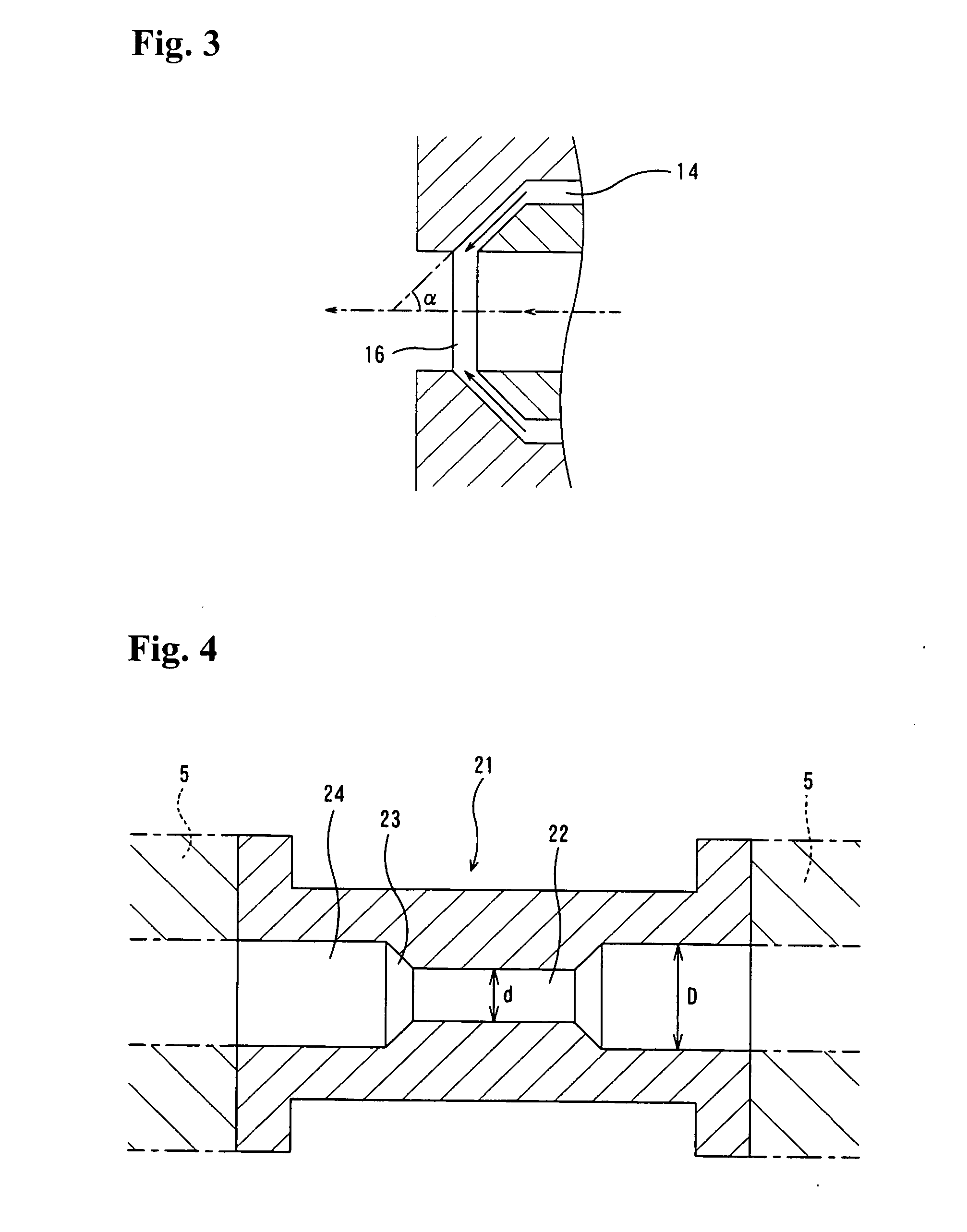

Method of Spray Application of Monolithic Refractory, Spray Material for Use Therein, and Application Apparatus

InactiveUS20070241204A1Improve kneading effectReduce variationFlow mixersAlkali metal silicate coatingsSpray nozzleRefractory

Disclosed is a method and apparatus for spray application of a monolithic refractory material, designed to add water to a powder material and knead the powder material during feeding. In the method and apparatus, a primary water injector 7 is arranged in a feed hose 5 extending from a spray-material supply device 1 to a distal spray nozzle 4, and a secondary water injector 8 is arranged in the feed hose at a position just before the distal spray nozzle 4. The primary water injector 7 is arranged on an upstream side of the secondary water injector 8 with a given distance therebetween. 10 to 50 mass %, preferably 15 to 40 mass %, of application water on the basis of the total application water required for the spray application is added from the primary water injector together with compression air in the form of water particles having an average particle size of 100 μm or less, to evenly wet a spray material during feeding to the extent capable of preventing the spray material from being slurried. Then, the remaining application water is injected from the secondary water injector together with compression air. The spray application method and apparatus of the present invention can achieve a high kneading effect by a low amount of application water while improving operational efficiency.

Owner:KROSAKI HARIMA CORP

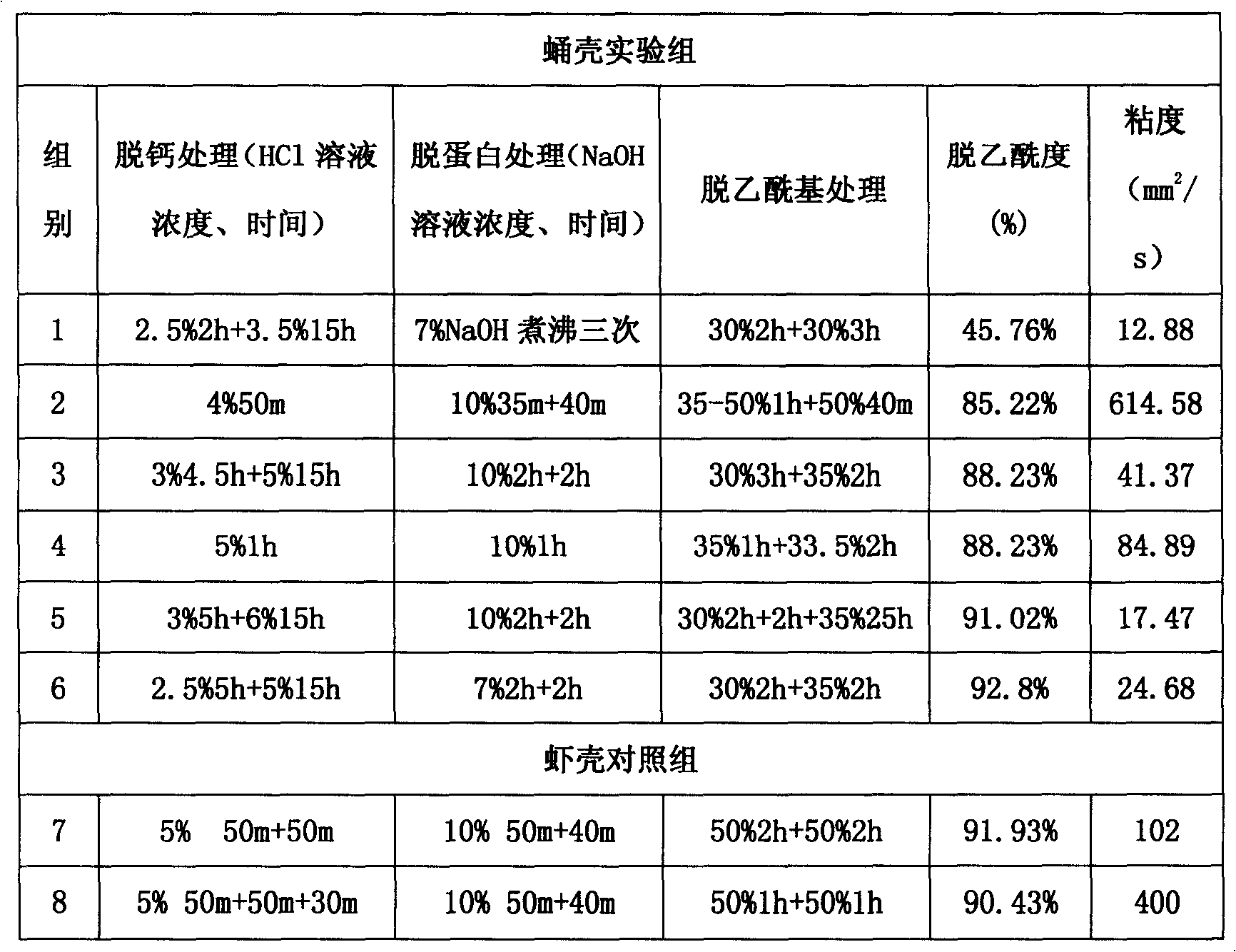

Method for extracting chitosan by employing flies

The invention relates to a method for extracting chitosan using fly, characterized in that the fly puparium is treated by acid alkaline process to obtain raw material. The raw material is subjected to decalcifying, deproteinizing, deacetylating, and then filtering, cleaning to be neutral to obtain the chitosan end product. The method can produce chitosan in enormous quantities using the high breeding property of fly, therefore the production rate of chitosan is increased. A product center combining raw material production and chitosan production together can avoid the inconvenience of raw material collection, therefore the production scale is greatly increased and the cost is reduced. During feeding the fly, the fly can be used for extract of protein feedstuff and antibiotic fly protein.

Owner:THE AFFILIATED HIGH SCHOOL OF SHANGHAI UNIV

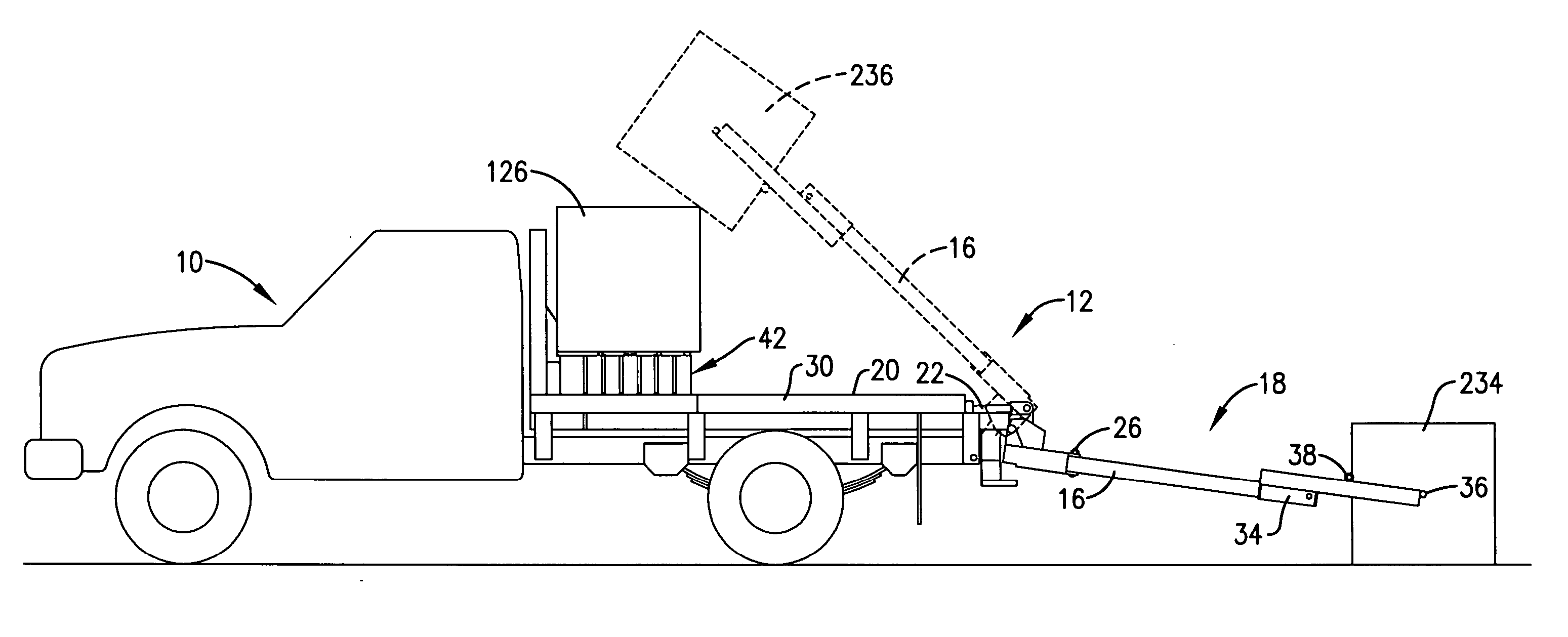

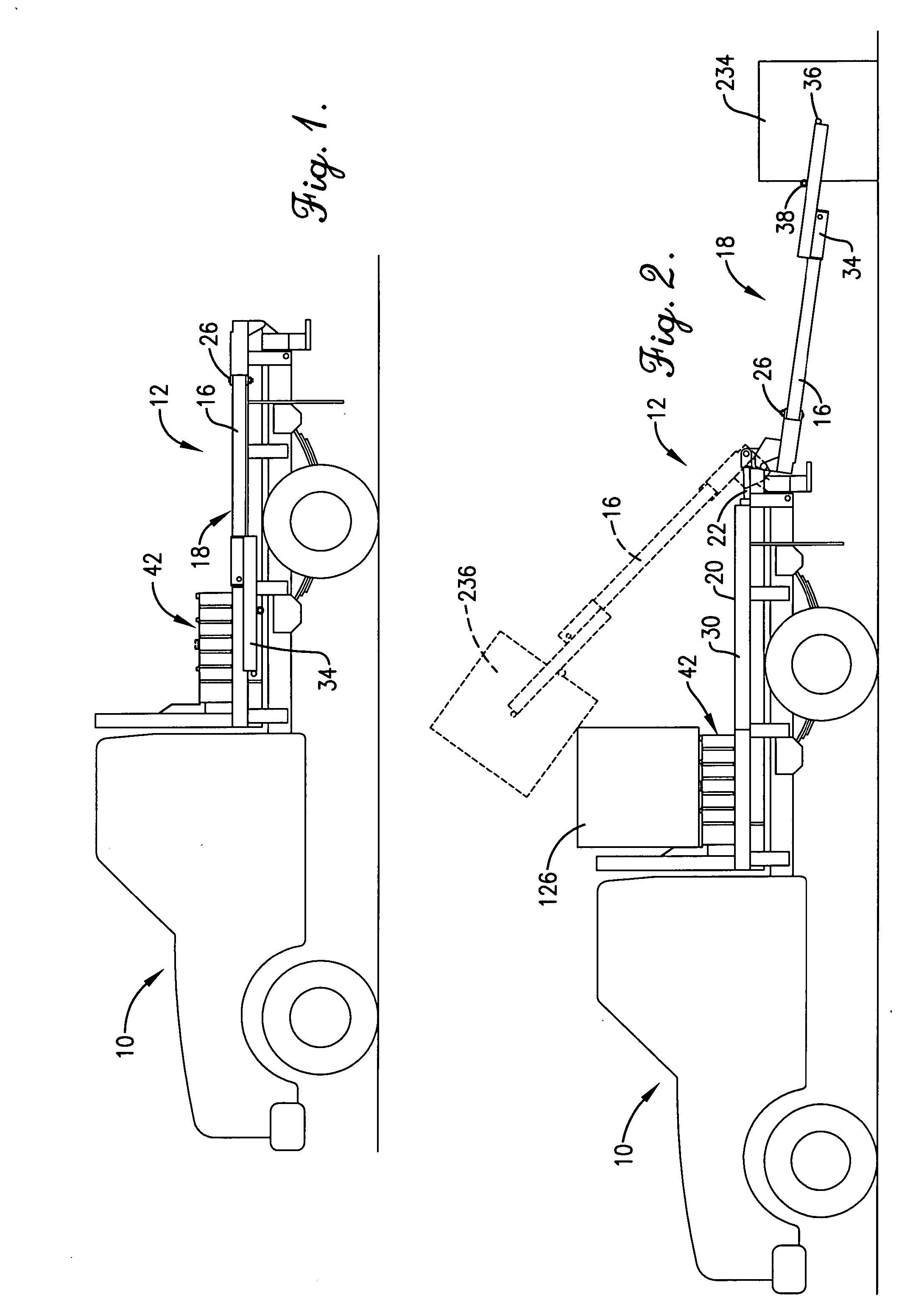

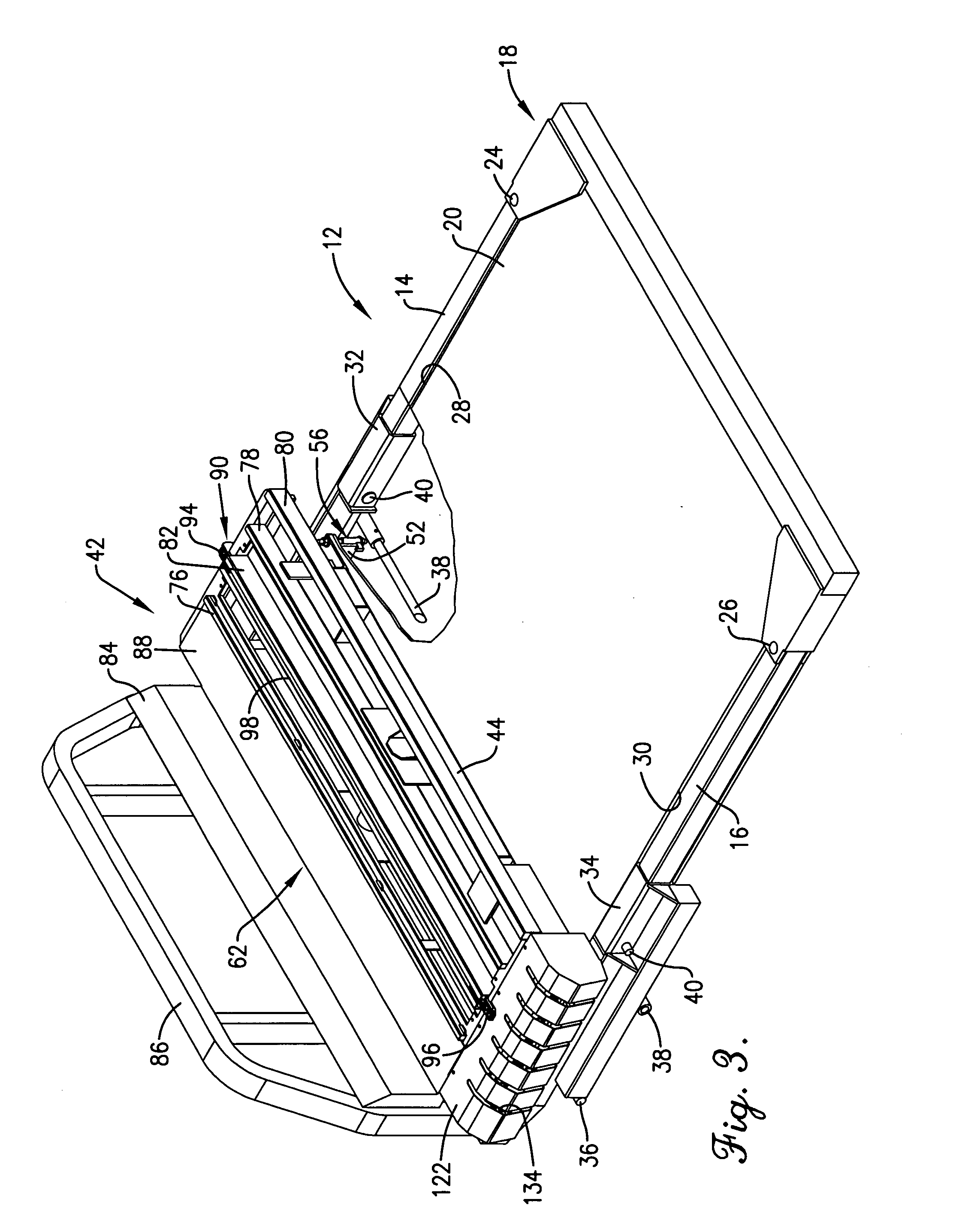

Square bale feeder attachment for flat-bed vehicles

InactiveUS20050220571A1Preventing more than one flakeVehicle with pivoted armsLoadersEngineeringTruck

Owner:ACKERMAN GALEN R +4

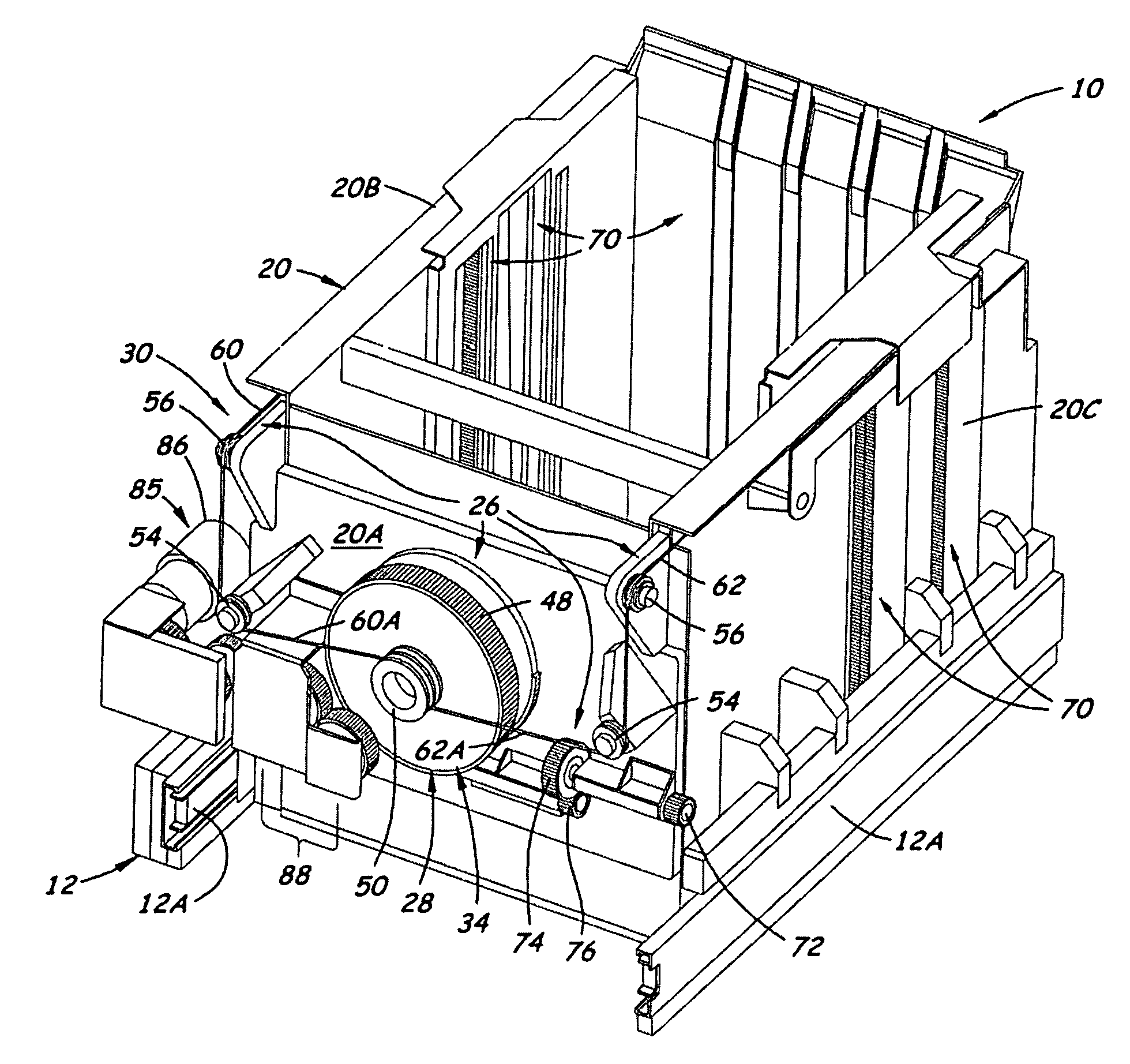

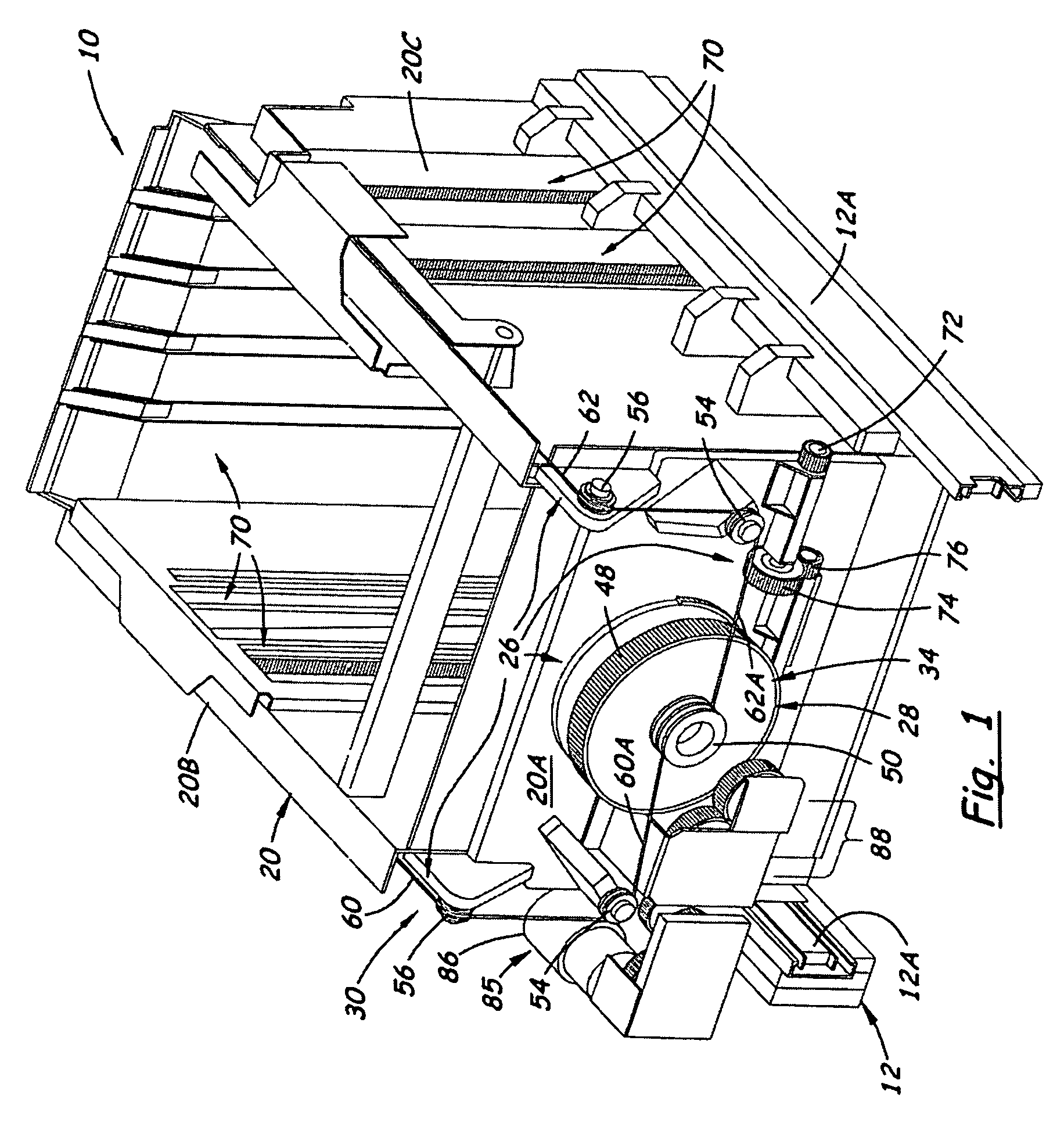

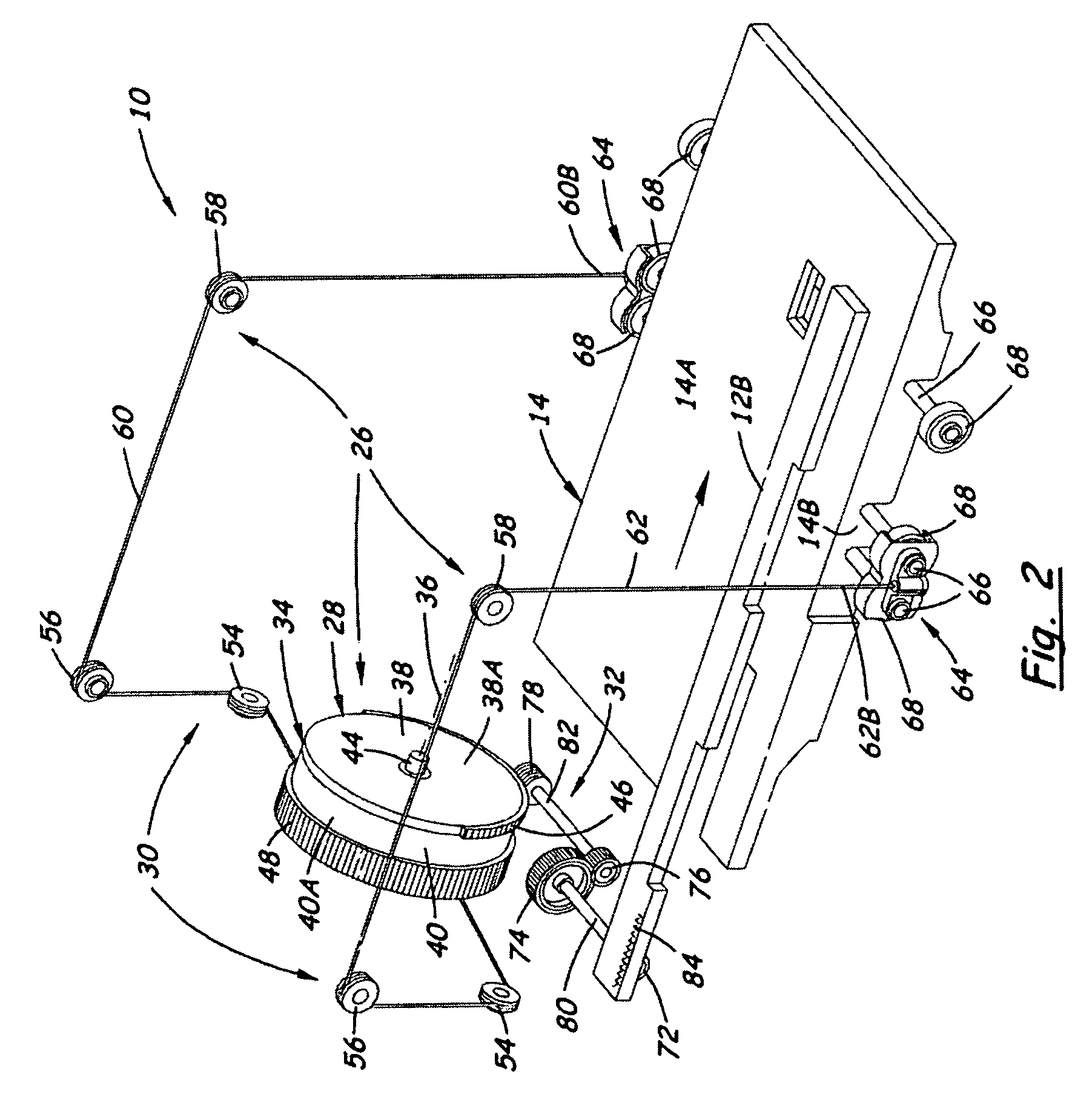

Media handling system for maintaining stack top within given range of pick positions during feeding sheets from stack top

InactiveUS7766320B2Required additionAvoid interferenceFunction indicatorsCurtain suspension devicesLower limitWeight decreasing

A media handling system includes a platform, a bin supporting the platform below and for undergoing movement toward and away from a sheet feeding position, a first motion transmitting assembly coupled between the platform and bin and tailored to counterbalance the weight of the platform and any stack such that as the weight decreases the platform is lifted toward the sheet feeding position to maintain the stack top below a lower limit position thereof, a control mechanism to sense the position of the stack top relative to a given range between the lower limit position to an upper home position, and a second motion transmitting assembly drivingly coupled to the platform via the first motion transmitting assembly and responsive to the control mechanism sensing to cause the first motion transmitting assembly to further lift the platform to and maintain the stack top position within the given range.

Owner:LEXMARK INT INC

Production method of cutting picks of coal mining machine

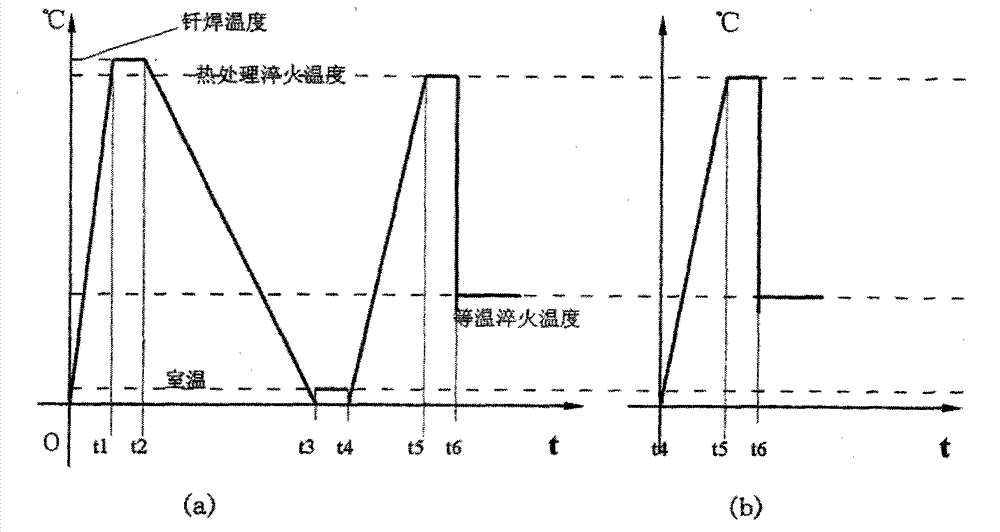

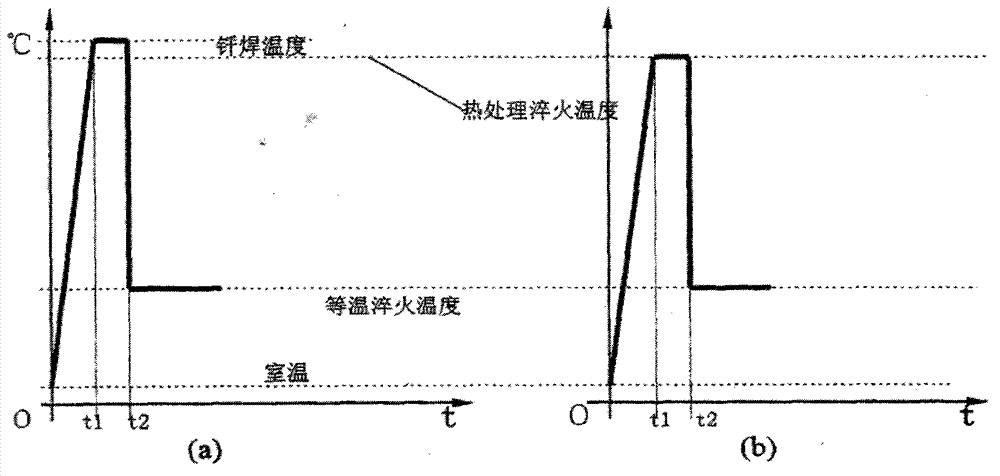

The invention discloses a production method of cutting picks of a coal mining machine. The production method comprises the following steps of: enabling the cutting picks which are well matched to sequentially enter a heating area of an inductor, and controlling the automatic feeding meter at 12 seconds-14 seconds; enabling the cutting picks to enter a welding area, firstly supplementing borax at the upper part of an alloy gear head, tightly shaking an alloy for a plurality of times after melting of copper, performing heat treatment when the temperature of an isothermobath is not less than 230 DEG C, gradually clamping out the well welded cutting picks, arranging into a hanging hook, rapidly lifting the hanging hook with the hand, immersing the cutting picks into a saline solution of the isothermobath, swinging left and right for 3 times, then hanging a cross rod, totally immersing the gear head alloy in the saline solution, and rapidly starting to supply water for cooling when temperature achieves 265 DEG C during feed-discharge balance; staying the cutting picks for not less than 30 minutes under the state that the variation in the isothermobath does not exceed a 20-DEG C constant temperature zone; and lifting out the cutting picks, performing salt leaching, and then washing and cooling. The difference between the production method disclosed by the invention and the prior art is that two times of heating are combined into a whole and can be completed once, thus the brazing quality is ensured, and the heat treatment quenching quality is also improved.

Owner:安徽省皖江机电设备制造有限公司

Preparation method and application of polymeric phosphorus ferric aluminum sulfate flocculating agent

InactiveCN103203212AHeating up fastPromote polymerizationEnergy based chemical/physical/physico-chemical processesWater/sewage treatment by flocculation/precipitationWater bathsChemical oxygen demand

The invention discloses a preparation method and an application of a polymeric phosphorus ferric aluminum sulfate flocculating agent. The preparation method comprises the following steps of: adding a certain amount of concentrated nitric acid to serve as an oxidant into polymeric aluminum sulfate and FeSO4.7H2O which serve as main raw materials, and then adding a disodium hydrogen phosphate solution to adjust the molar ratio of phosphorus to ferro-aluminum; putting the mixture into a microwave reactor for radiation and heating, and carrying out polymerization for 3-15 minutes; adding a NaOH or Na2CO3 solution under a water bath condition to adjust the degree of alkalization, and continuously reacting for a period of time; and finally, curing at normal temperature to obtain the polymeric phosphorus ferric aluminum sulfate. The polymeric phosphorus ferric aluminum sulfate can be widely used for treating source water, production wastewater and domestic sewage, and the function of the polymeric phosphorus ferric aluminum sulfate is superior to that of ordinary polymeric aluminum sulfate and polymeric ferric sulfate. During feed water treatment, the polymeric phosphorus ferric aluminum sulfate can effectively reduce the turbidity and UV254 of a water body; and when being used for treating the domestic sewage and industrial wastewater, the polymeric phosphorus ferric aluminum sulfate has a good effect of removing the turbidity, COD (chemical oxygen demand) and total phosphorus.

Owner:HUNAN UNIV OF SCI & TECH

Batch processing device for pharmaceutical wastes

InactiveCN108479933AImprove crushing effectAchieve reactivityDispersed particle filtrationSolid waste disposalBatch processingEngineering

The invention discloses a batch processing device for pharmaceutical wastes. The batch processing device comprises a machine box. The machine box is internally provided with a smashing cavity, a backflow cavity and a sterilizing cavity. A purifying box is mounted on the back side of the machine box. A feeding hopper is arranged at the top end of the smashing cavity. Grinding gears are mounted in an inner cavity of the feeding hopper. Moving base plates are mounted at the bottom end of the feeding hopper. The moving base plates are divided into two parts and are in an arc shape. The bottom endsof the moving base plates are connected with the bottom end of the feeding hopper through moving shafts. Fixed insections are arranged on the inner walls of the moving base plates. The fixed insections and insections on the surfaces of the grinding gears are arrayed in a staggered mode. Fixing seats are arranged under the moving base plates. A plurality of squeezing springs are arranged between the moving base plates and the fixing seats for connection. According to the batch processing device for the pharmaceutical wastes, the moving base plates can have a squeezing effect on materials whilemoving within a small range, so that the smashing effect of the materials is enhanced, and meanwhile blocking is avoided during feeding.

Owner:张荷友

Bismuth adding technological method of bismuth-containing free-cutting steel

The invention discloses a bismuth adding technological method of bismuth-containing free-cutting steel. In the last stage of refining, after other components except for bismuth are adjusted, adding ofa bismuth-containing cored wire is carried out. The method comprises the following specific steps of (1) control of production conditions before wire feed, wherein the slag layer, the temperature andthe oxygen activity of molten steel are controlled; (2) feed of the bismuth-containing cored wire; and (3) treatment after wire feed is finished. An intermittent wire feed method is adopted in the step (2), the bismuth-containing cored wire is intermittently fed by at least three times, the cored wire is 1 / n of the total quantity during feed of every time, n is the number of times, and the feed time interval ranges from 15 s to 20 s. The technological method has the following advantages that the wire feed process is stable, and severe splashing is avoided; the bismuth element yield is high and ranges from 15% to 40%, and the production cost is low; the forms of occluded foreign substances in the steel are good; and cutting performance is excellent. The bismuth adding technological methodis suitable for production of carbon free-cutting steel and free-cutting stainless steel and has quite large economic value in the field of the bismuth-containing free-cutting steel.

Owner:SHANGHAI UNIV

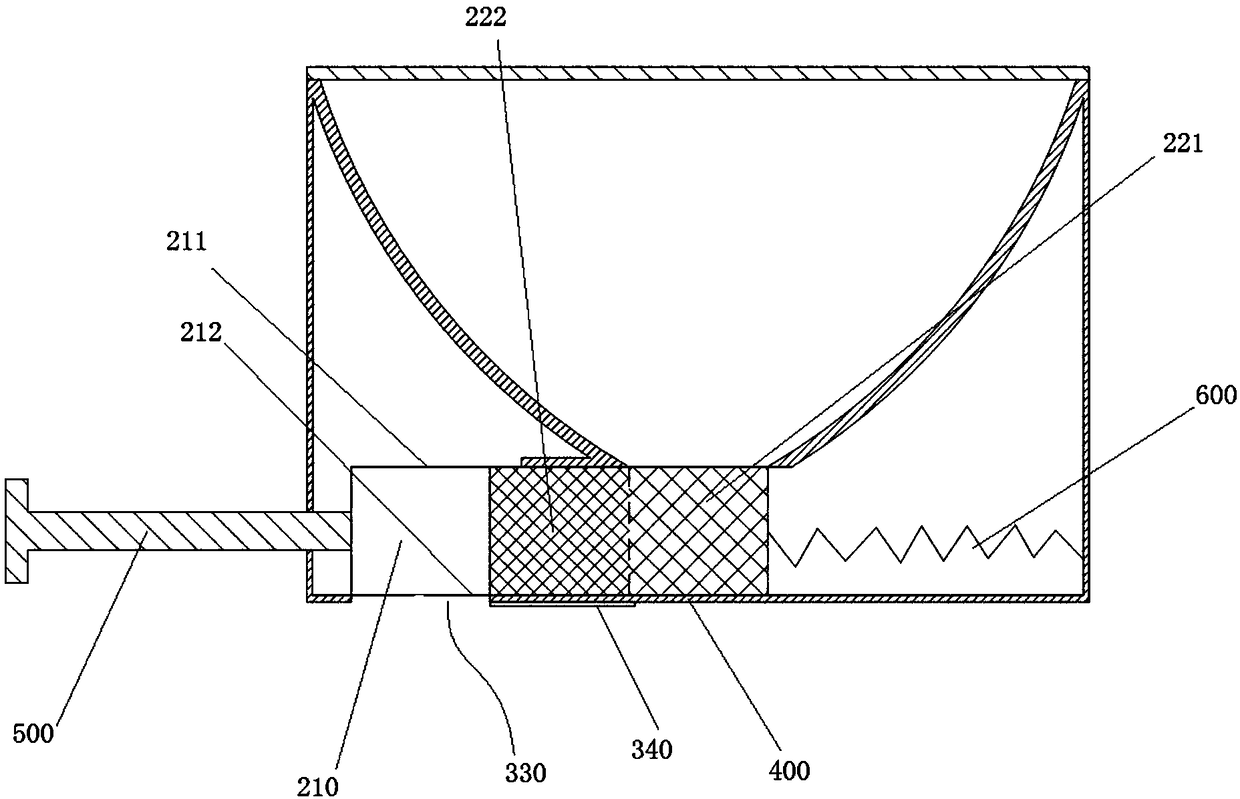

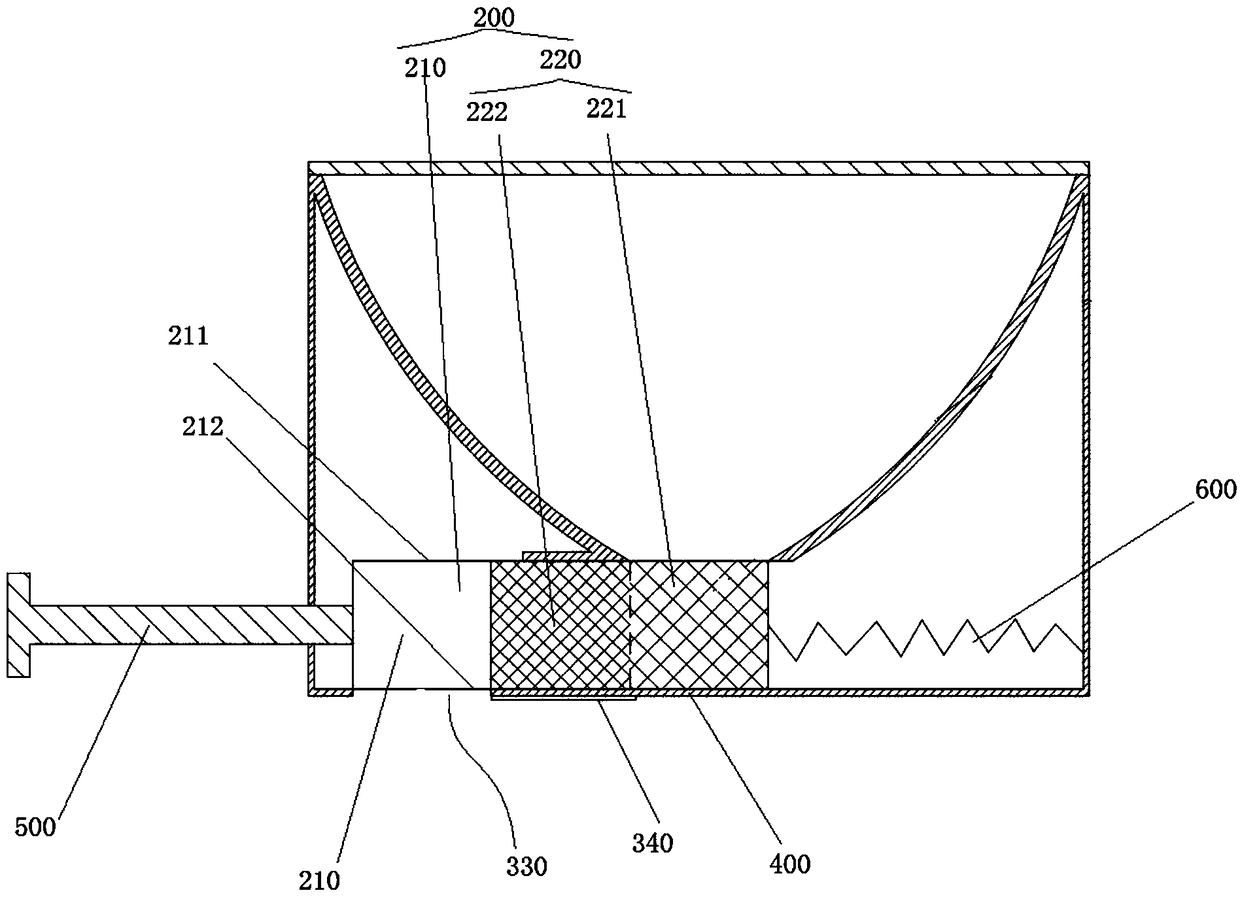

Quantifying vessel and quantifying milk powder box

PendingCN108438548AAchieve precise quantitationSimple structurePowdered material dispensingEngineeringDuring feed

The invention relates to a quantifying vessel and a quantifying milk powder box. The quantifying vessel comprises a storing bin, and a picking device which is connected to the storing bin, wherein thestoring bin is provided with a discharging port; the picking device comprises a picking bin at the left part, and a picking blocking plate at the right part; the picking bin is an empty chamber of which the upper end and the lower end are correspondingly provided with a material inlet and a material outlet; a sealing blocking plate is arranged below the picking bin; the length of the sealing blocking plate in the left and right direction meets that the material outlet is in a closed state during feeding materials into the picking bin and separating the material inlet of the picking bin from the discharging port; the length of the picking blocking plate in the left-right direction meets that the discharging port is in the closed state during separating the material inlet of the picking binfrom the discharging port and discharging the materials from the picking bin; the discharging port is blocked through the picking blocking plate; the material outlet of the picking bin is sealed andblocked by the sealing blocking plate; powdered or particular materials are not picked or stored while the picking bin is separated from the discharging port, thus accurate quantifying is achieved.

Owner:张星星

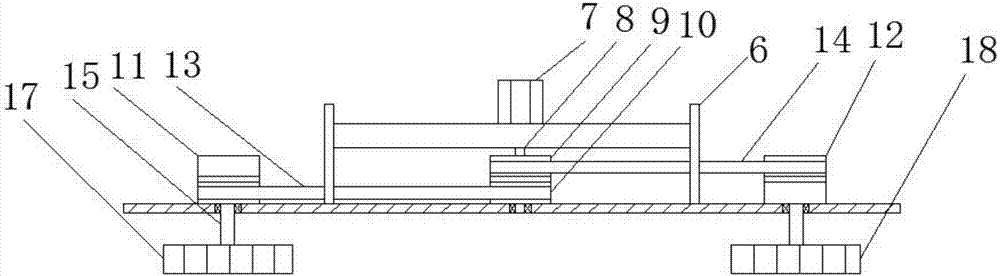

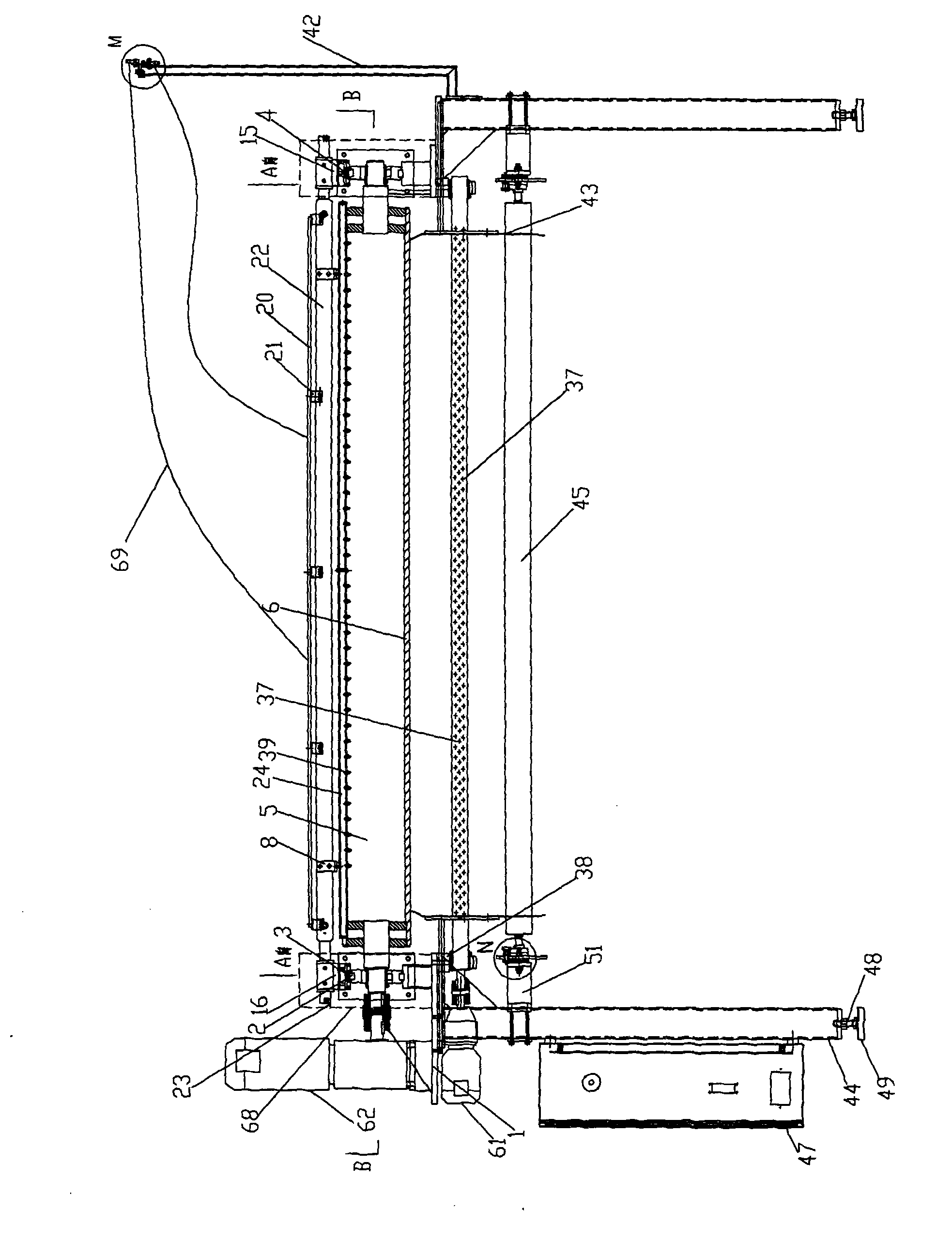

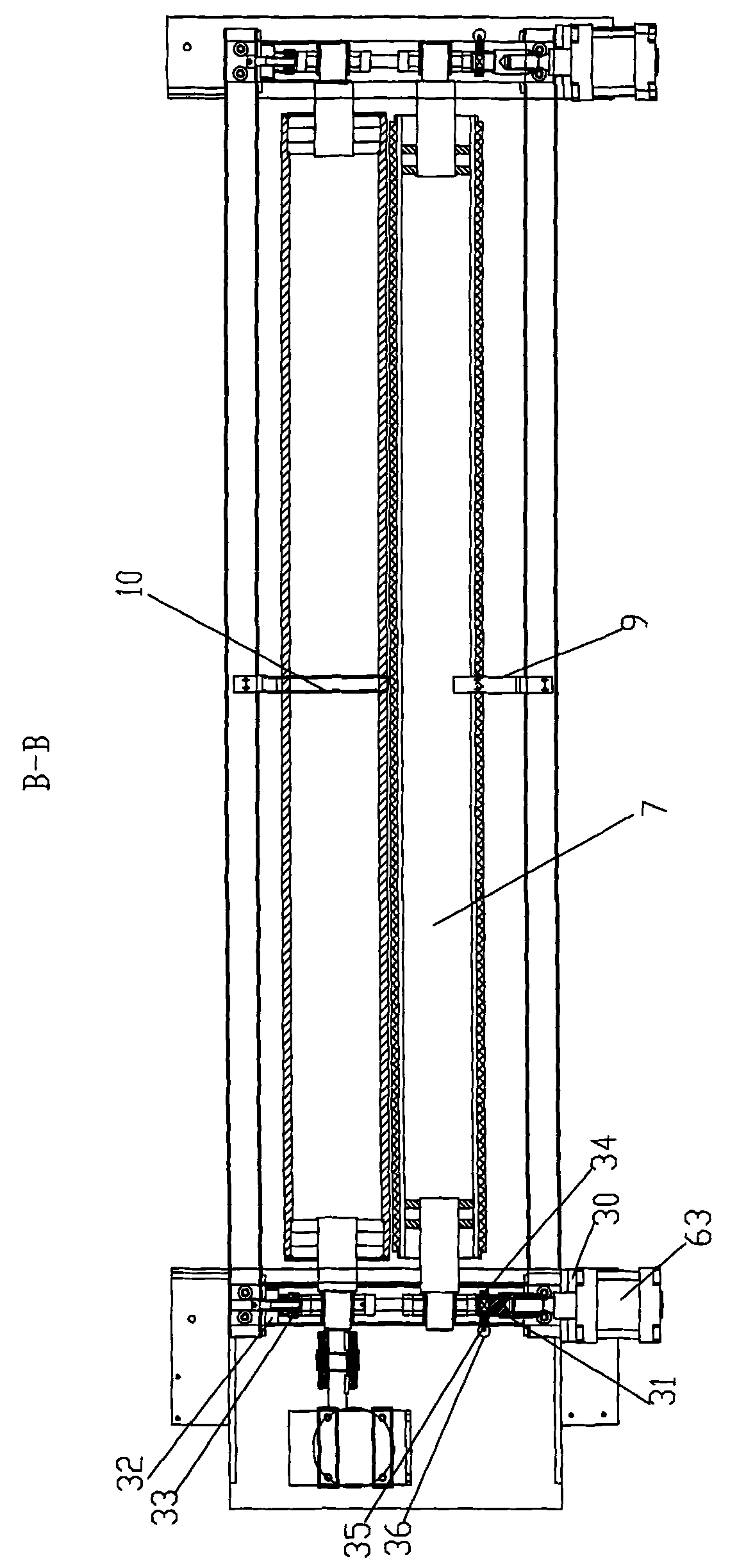

Yarn chopping device of biaxial warp knitting machine

ActiveCN101929031ARealize shuntTo achieve diversionWarp knittingSevering textilesGlass fiberDuring feed

The invention belongs to the field of glass fiber chopping devices, in particular to the yarn chopping device of a biaxial warp knitting machine, comprising a stand, support feet and an electric cabinet, wherein the stand is provided with a paying-off mechanism, a chopping mechanism and a dispersing mechanism, wherein the paying-off mechanism can be used for shunting and uniformly paying off the glass fiber yarns; a driving roller of the chopping mechanism is used for scissoring the glass fiber yarns; and the dispersing mechanism is used for uniformly dispersing the glass fiber yarns on roller cloth. The invention has the advantages of realizing the shunting and the diversion of glass fiber strands, preventing the glass fiber strands from being twisted together during feeding, ensuring high chopping efficiency and high speed, improving the production efficiency and reducing the production cost.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

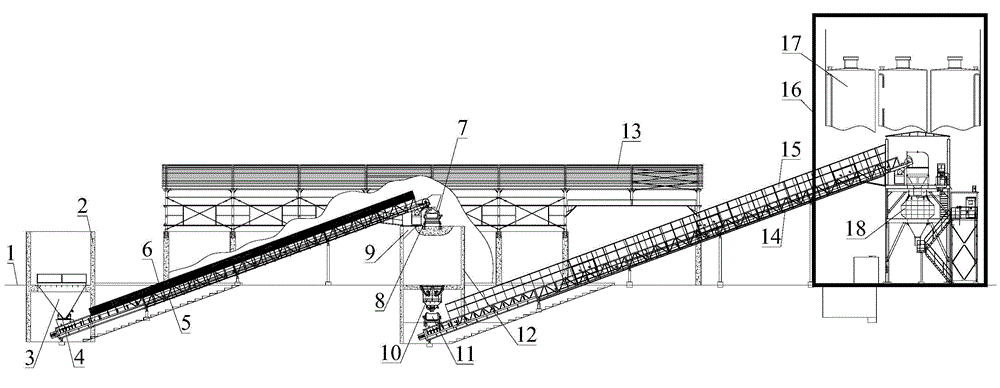

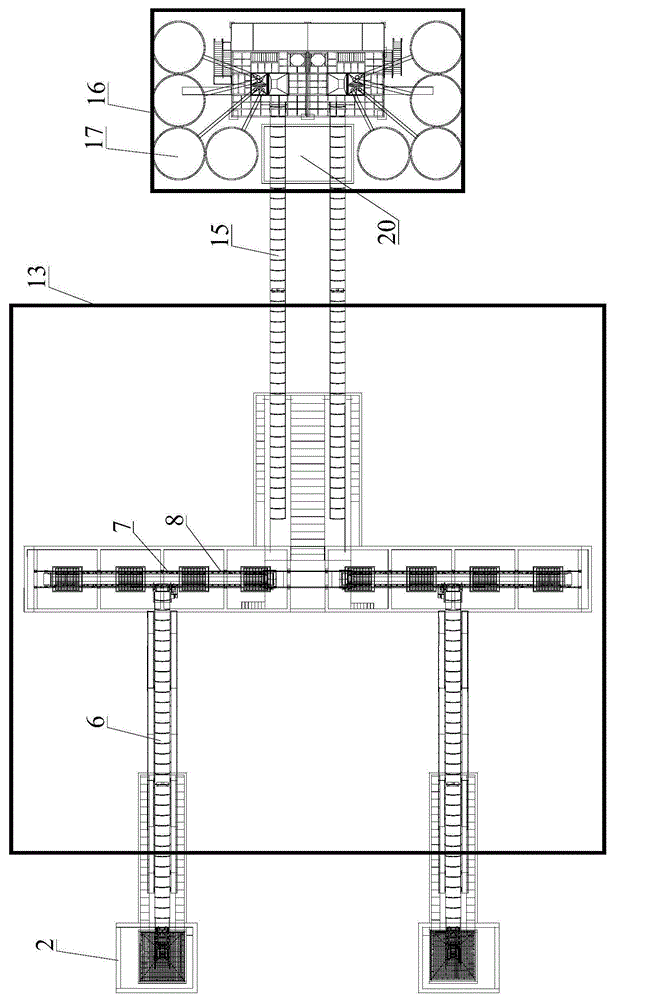

Automatic feeding system and mixing station

InactiveCN103600420AUse lessReduce manpowerMixing operation control apparatusSold ingredients supply apparatusMechanical engineeringAutomatic testing

The invention discloses an automatic feeding system and a mixing station. The automatic feeding system comprises a feeding bin, a first conveying mechanism, a burdening bin and a control unit; the feeding bin and the burdening bin are arranged at a interval, and the first conveying mechanism is arranged aslant; the first end of the first conveying mechanism is disposed below the discharging door at the bottom of the feeding bin, and the second end of the first conveying mechanism is disposed above the opening of the burdening bin; and the control unit controls the open-close state of the discharging door and the work state of the fist conveying mechanism according to the material position state of the burdening bin, so that sandstone materials are controlled to be conveyed to the burdening bin. The automatic feeding system helps to realize the automatic conveying of the sandstone materials; and compared with prior art, the automatic feeding system helps to effectively reduce the usage time of a loader during feeding process, and thus the automatic feeding system helps to save energy consumption, reduce labor and enable the feeding process to be relatively controllable and environment-friendly.

Owner:SANY AUTOMOBILE MFG CO LTD

Method of reducing the methane gas level and of increasing the total gas yield in animal feed

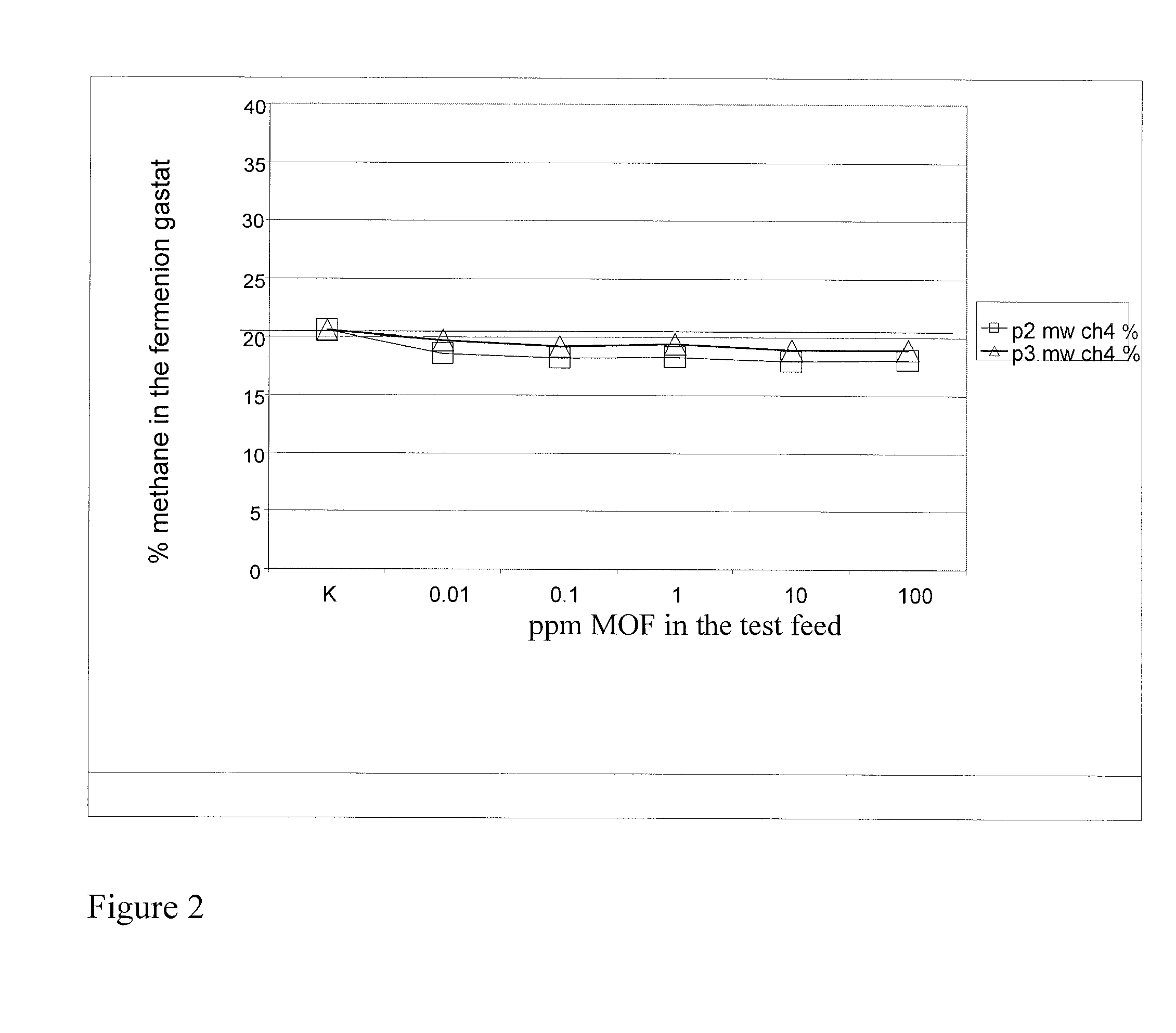

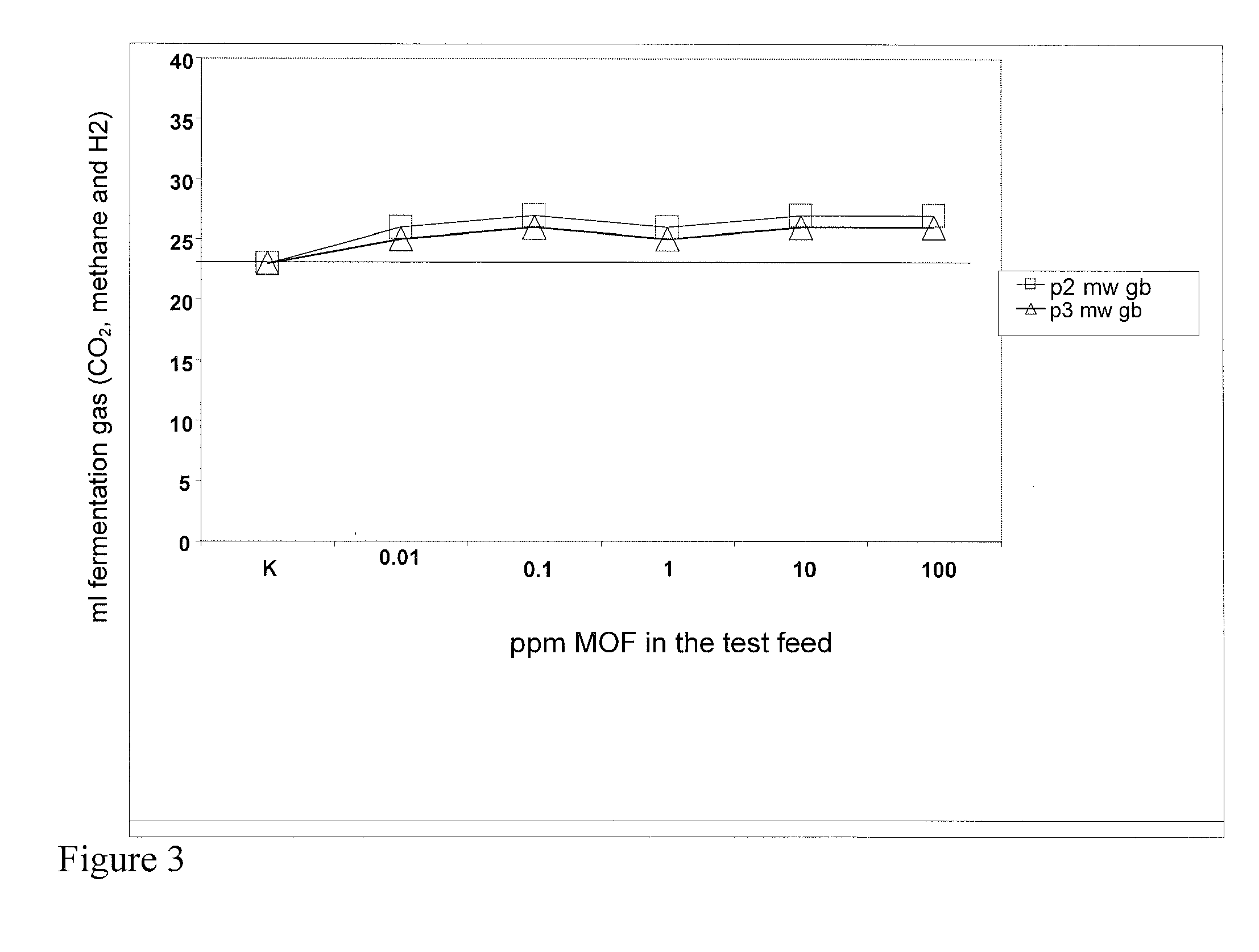

InactiveUS20110152375A1Reduce energy lossIncrease energy yieldBiocideDigestive systemDigestionMethane gas

The present invention relates to the use of at least one porous metal-organic framework material (MOF) comprising at least one first and, if appropriate, one second organic compound, where at least the first organic compound binds coordinatively to at least one metal ion in an at least partly bidentate manner, where the at least one metal ion is Mg(II) and where the first organic compound is derived from formic acid and the second organic compound from acetic acid, for reducing the methane level in the total gas produced, and to the use for increasing the total gas formation during feed digestion in ruminants as well as a method for reducing the methane level in the total gas produced and a method for increasing the total gas formation during feed digestion in ruminants.

Owner:BASF AG

Ecological pig raising method

The invention discloses an ecological pig raising method. The method comprises the following steps: feeding biological fermented feeds and local coarse cereals in peasant families to pigs twice every day in a timing manner, firstly feeding the biological fermented feeds and then feeding the local coarse cereals in peasant families later during feeding the pigs every time, and enabling the pigs which are fed for more than 10 months to become full-grown and ready for slaughter. The food consumption of the pigs is correspondingly adjusted according to the weight of the pigs in each stage, the daily food consumption of the pigs younger than 3 months is 5% of the weight of the pigs, the daily food consumption of the pigs of 3-6 months old is 4% of the weight of the pigs, and the daily food consumption of the pigs older than 6 months is 3% of the weight of the pigs. The biological fermented feed consists of 0.3-1 part by weight of fermented yeast, 1-2 parts by weight of brown sugar, 40-80 parts by weight of water, 200-330 parts by weight of corn, 80-120 parts by weight of wheat bran and 80-120 parts by weight of fine rice bran, wherein the fermented yeast consists of 20-30% microzyme, 15% of bacillus, 25% of lactic acid bacteria, 5% of bifidobacteria and 15% of cellulose decomposting bacteria. The pig raising method disclosed by the invention has the advantages that the growth cycle of the pigs is shortened, the lean meat percentage of the pigs which become full-grown and are ready for slaughter is high, the meat quality is fine and smooth, and the mouth feel is good.

Owner:乐至县诚舵农牧有限公司

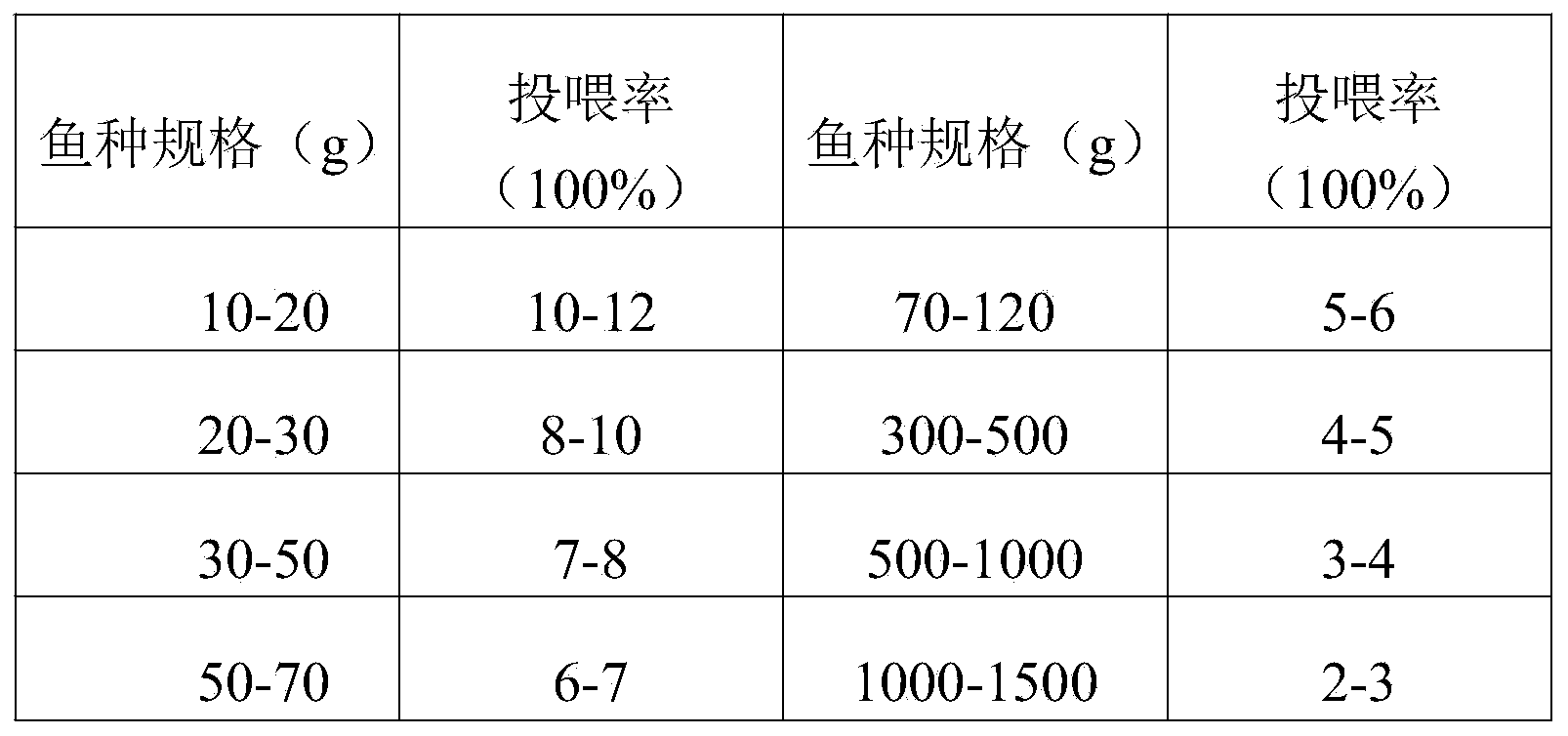

Sturgeon culturing method

InactiveCN103609487AImprove survival ratePromote digestion and absorptionClimate change adaptationAnimal feeding stuffAdditive ingredientChange control

The invention discloses a sturgeon culturing method and belongs to the field of fish culturing. The sturgeon culturing method includes the steps of flowing water pond disinfection, fingerling releasing, water changing control, feed feeding, pest prevention and control and the like. By disinfection of a flowing water pond before culturing and pest prevention and control during feed raising, survival rate of sturgeon fingerlings is greatly increased; by preparing feed with different nutritional ingredients for fingerlings and adult fishes, digestion and absorption at different stages of sturgeon are facilitated, and growing is prompted.

Owner:PUDING MINGRUI FISHERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com