Steel pipe bending machine

A technology of bending machine and steel pipe, applied in the field of steel pipe bending machine, can solve the problems of small feeding traction and easy slipping, and achieve the effect of increasing friction, increasing friction coefficient, and preventing slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

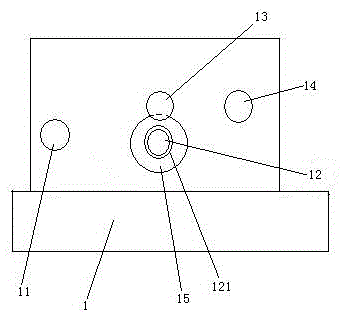

[0030] Embodiment one, see figure 1 , a steel pipe bending machine, including a frame 1. The frame 1 is provided with a bending roller 11, a driving roller 12, a second limiting roller 13, a first limiting roller 14 and a motor 15 for driving the driving roller. The surface of the driving roller 12 is provided with a resistance increasing layer 121 . The resistance-increasing layer 121 is composed of 20% steel particles and 80% rubber vulcanized together. The particle size of the steel shot is less than 1mm.

Embodiment 2

[0031] Embodiment two, the difference with embodiment one is:

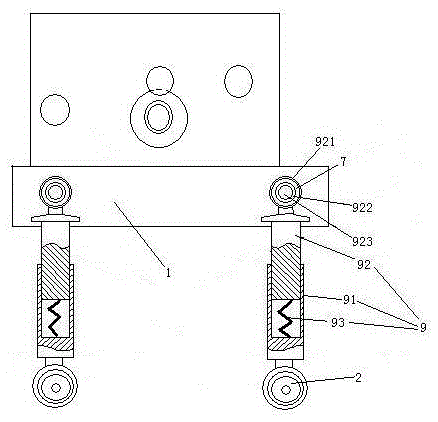

[0032] see figure 2 , Machine foot 1 is also provided with machine foot 9. The machine foot 9 includes a lower section 91 and an upper section 92 . The lower end of the lower section 91 is provided with a road wheel 2 . The upper end of the lower section 91 is slidably sleeved on the lower end of the upper section 92 . The lower section 81 is provided with a damping spring 93 supporting the upper section 92 . The upper end of the upper section 92 is provided with a connecting ring 921 . An inner ring 922 passes through the connecting ring 921 . The inner ring 922 is connected with the connecting ring 921 through the rubber ring 7 . The inner ring 922 is pierced with connecting pins 923 . The connecting pin 923 is connected with the frame 1 together.

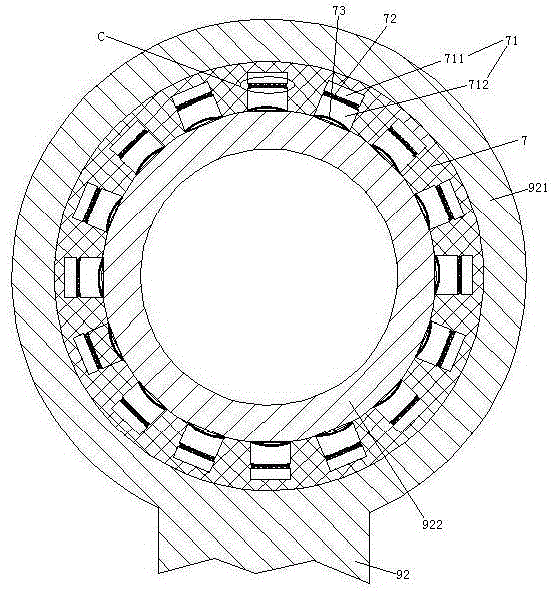

[0033] see image 3 , The inner peripheral surface of the rubber ring 7 is provided with several blind holes 71 distributed along the circumferential direc...

Embodiment 3

[0038] Embodiment three, the difference with embodiment two is:

[0039] see Figure 7 , the traveling wheel 2 comprises a spoke 222, a wheel rim 21 connected to the spoke, a pneumatic tire 23 connected to the wheel rim and an anti-puncture mechanism 29. The tire puncture prevention mechanism 29 includes a drum 291 , an air storage cylinder 292 , a threaded sleeve 293 , a screw mandrel 294 and a differential mechanism 295 . The rim 21 is provided with a pneumatic tire 23 . The roller 291 is coaxially fixed with the rim 21 . The roller 291 and the rim 21 are distributed along the axial direction of the rim 21 . The difference between the radius R1 of the tire minus the radius R2 of the drum is less than half the tire section height H and greater than 1 cm. The drum 291 is provided with an anti-rotation structure 2911 . The anti-rotation structure 2911 is a long hole disposed on the roller 291 and extending in the axial direction of the rim. The air storage cylinder 292 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com