Yarn chopping device of biaxial warp knitting machine

A technology of warp knitting machine and chopped yarn, which is applied in warp knitting, textiles, papermaking, knitting, etc. It can solve the problems of low chopping efficiency and unqualified products, achieve high cutting efficiency, improve production efficiency, and speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better illustrate the technical solution of the present invention, it will now be further elaborated in conjunction with specific implementation examples.

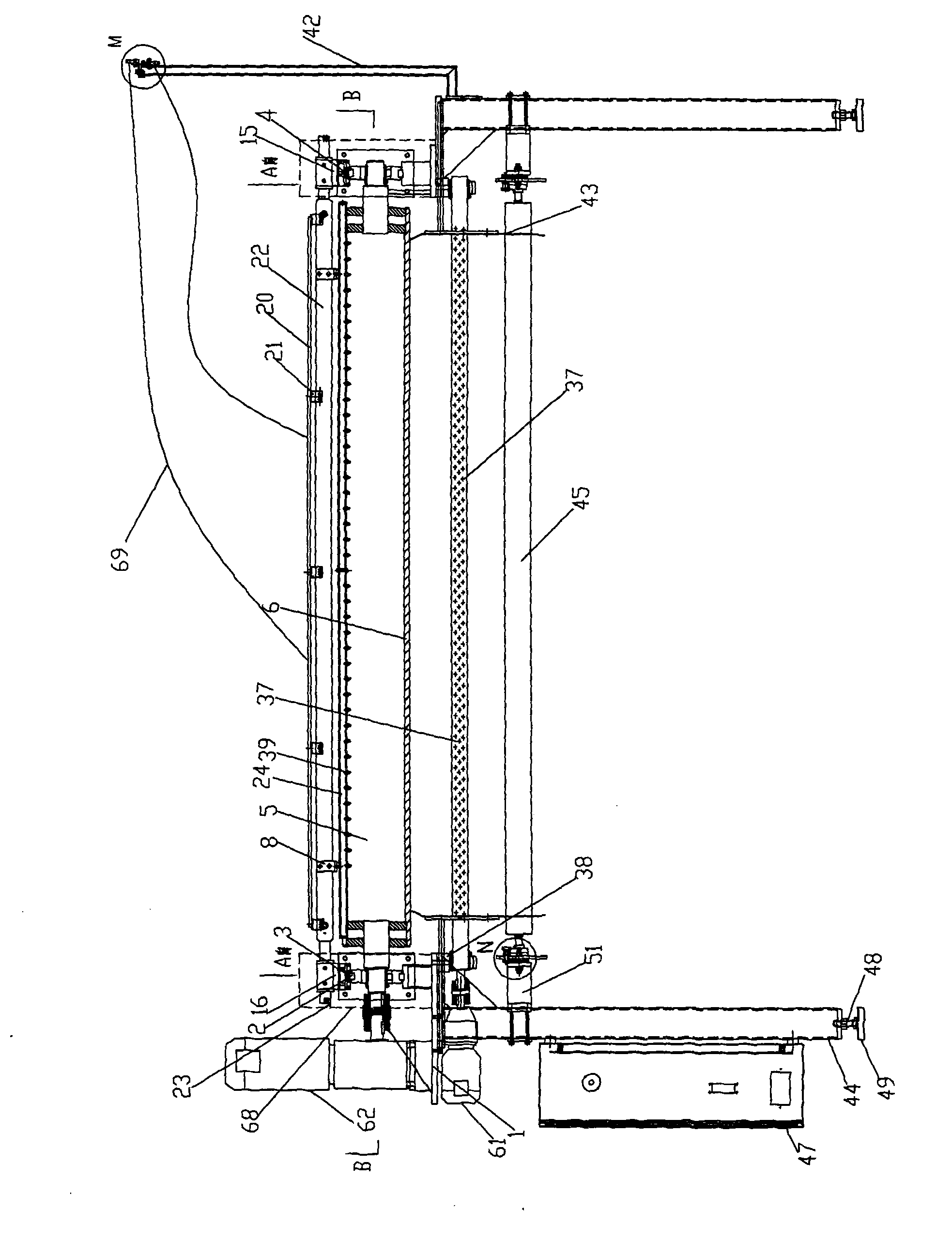

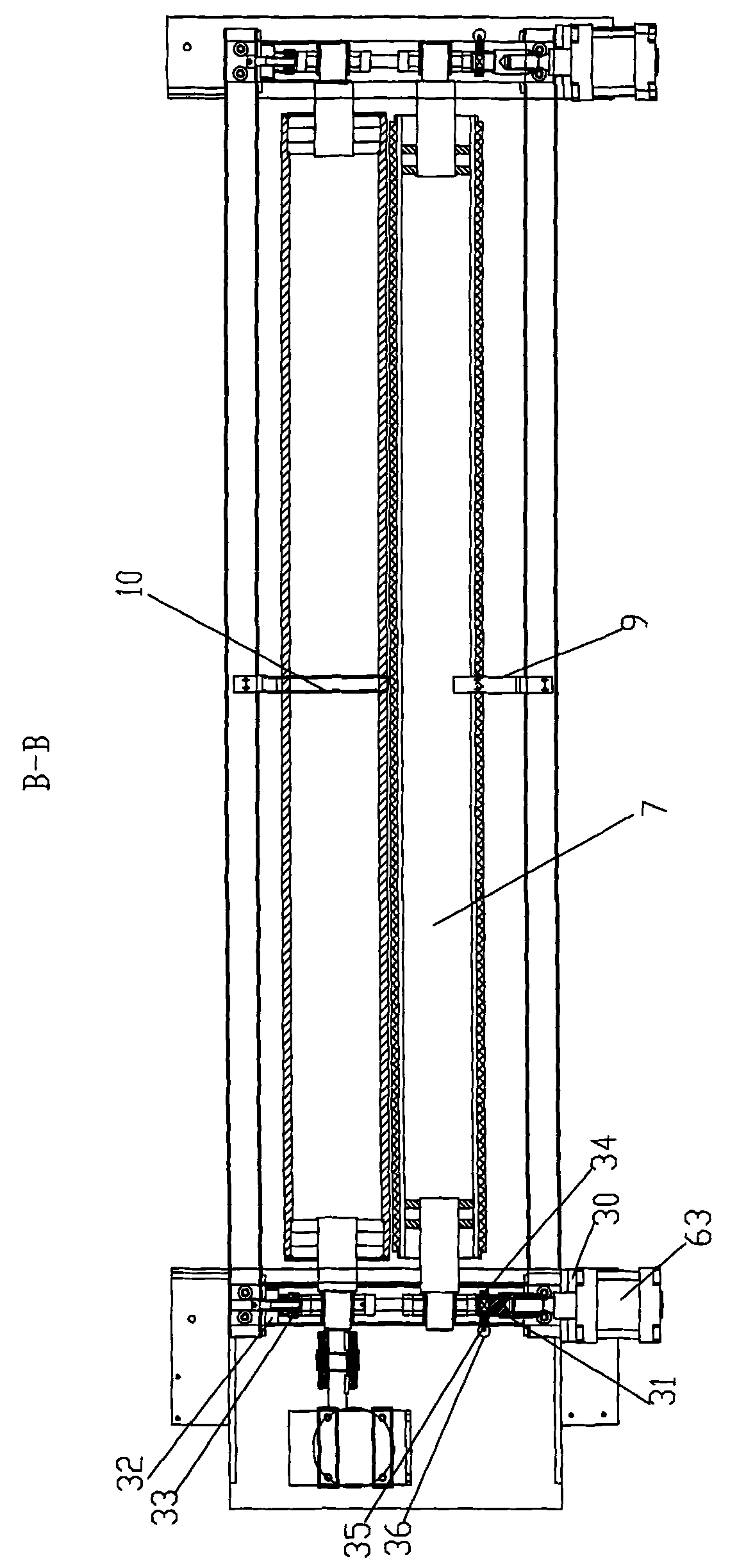

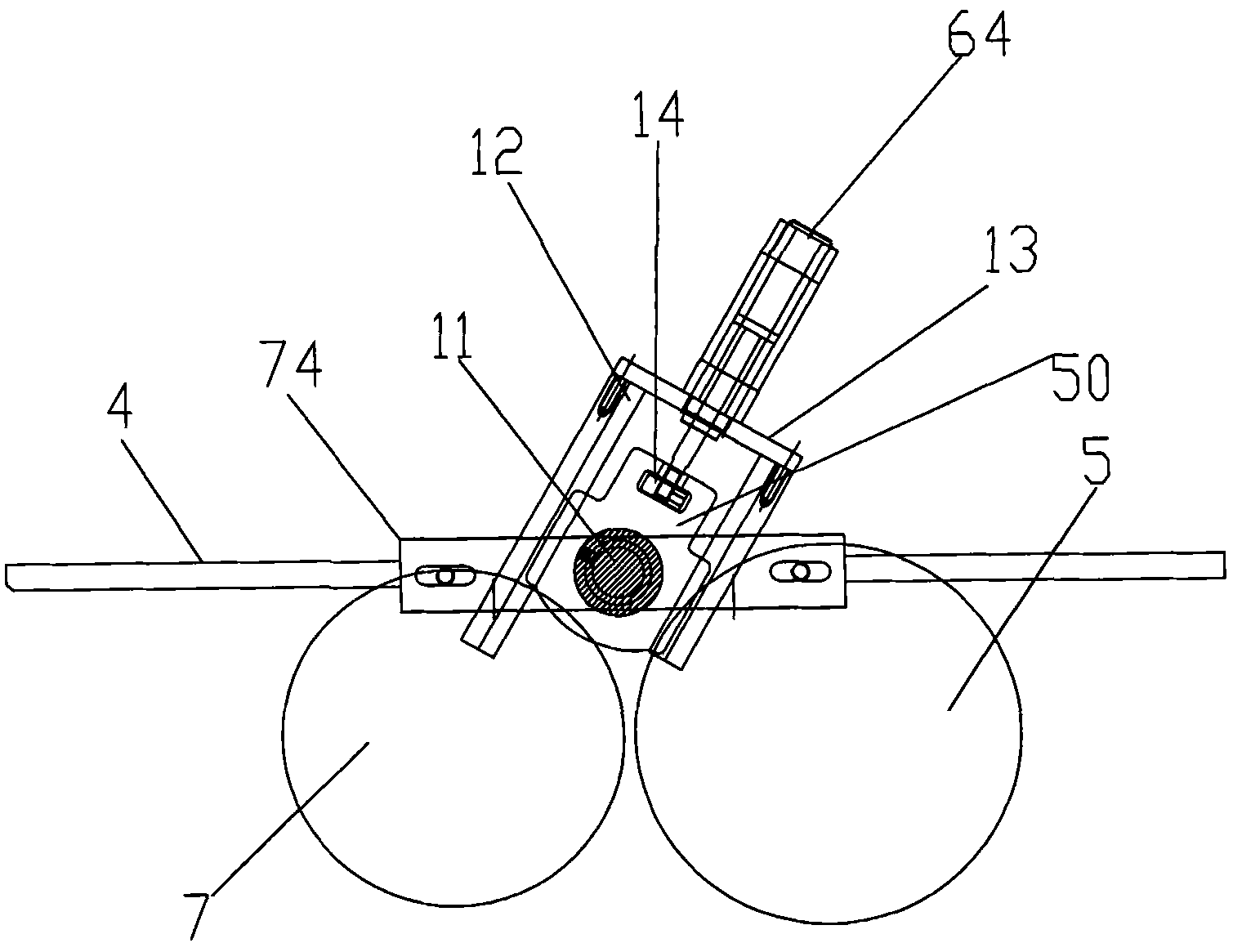

[0027] Such as figure 1 As shown, the chopped yarn device of the biaxial warp knitting machine includes a frame 1, a support leg 44 and an electric cabinet 47, and the four support legs 44 are respectively fixed around the frame 1, and the bottom of the support leg 44 is passed through an anchor screw An anchor 49 is fixed, and the electric cabinet 47 is fixed between the two support feet 44 through the electric cabinet mounting plate 46. The electric cabinet 47 is used for the circuit and air circuit control of the whole device. Cutting mechanism, dispersing mechanism and guiding mechanism. The guiding mechanism includes the support 68 fixed on both sides of the frame 1 and the guide rail 2 arranged in the bracket 68. The guide rails 2 on both sides are respectively provided with guide rail pressure pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com