Onboard anti-thunder antenna cover

A technology of radome and cover wall, which is applied to antennas, antenna parts, and antennas suitable for movable objects, etc., can solve the problems of large influence on antenna performance, achieve good appearance consistency, improve strength ratio and rigidity ratio, good chemical resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

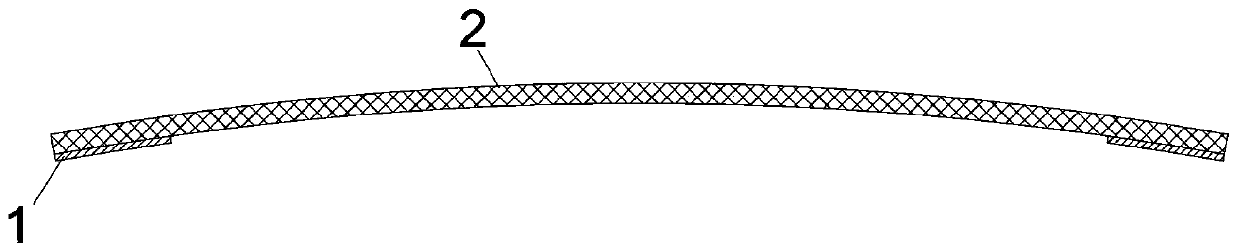

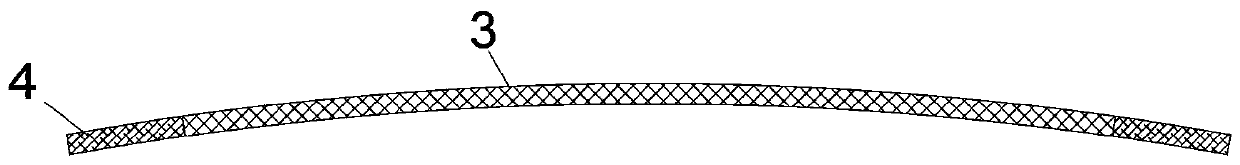

[0020] refer to Figure 1-Figure 6 . In the preferred embodiment described below, an airborne lightning protection radome includes: a radome shell 2 with the cover wall made into a curved shape, and a metal lap 1 fixedly connected to the inner edge of the radome shell 2 , wherein the material of the metal strap 1 is aluminum alloy. The radome shell 2 is a multi-layer composite material structure formed by integral thermocompression molding of the metal pattern layer 5 and the non-metallic fiber layer 6 . The radome shell 2 is divided into an intermediate wave-transmitting area 3 surrounding the peripheral external installation area 4 according to functions. The intermediate wave-transmitting area 3 is a multi-layer composite material sandwich structure, and one or more layers of metal pattern layers 5 are arranged in the sandwich structure. , the rest are non-metallic fiber layers 6, and the metal pattern layer 5 is a frequency selection pattern 7 of array characteristics in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com