Production method of cutting picks of coal mining machine

A production method and coal mining machine technology, applied in the direction of cutting machinery, etc., can solve problems such as low-temperature salt failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

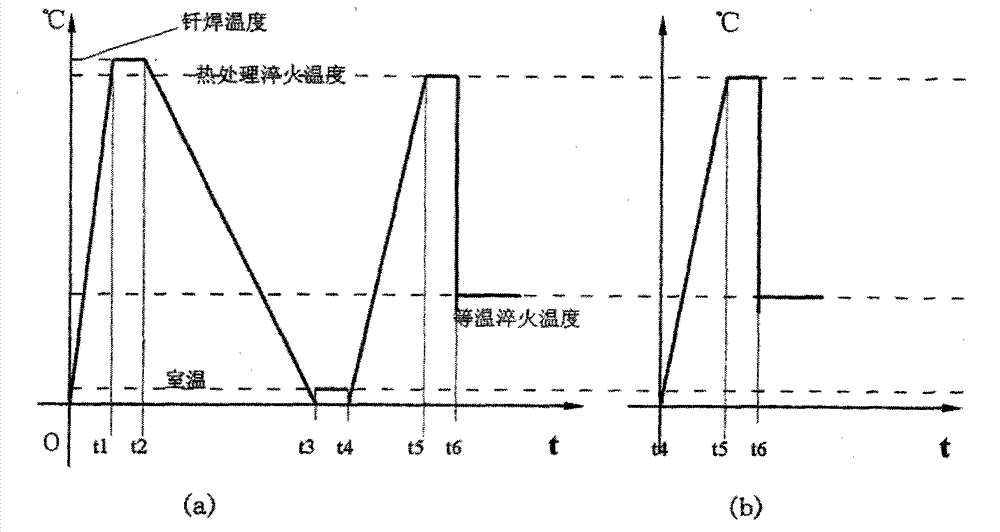

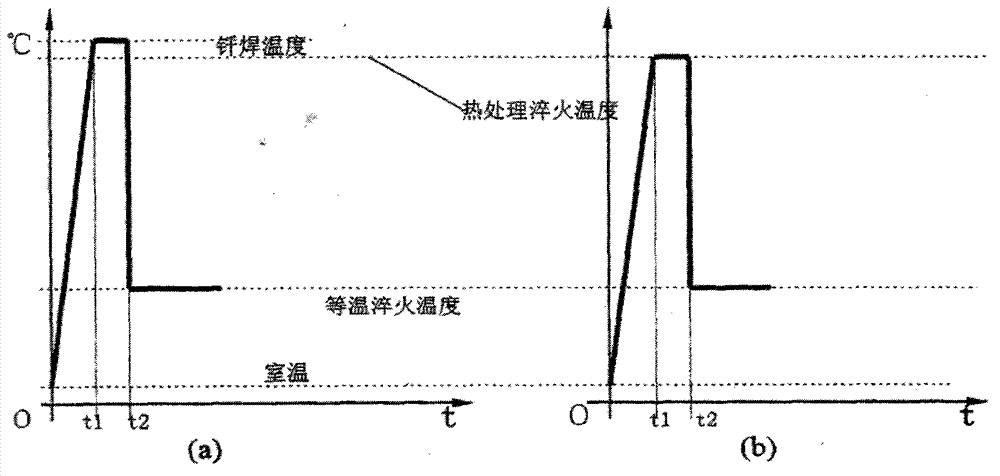

[0022] Embodiment 1: the production method of pickaxe tooth

[0023] 1. Preparation before welding

[0024] 1. Preparation before welding of tooth head alloy

[0025] a. Take the case as a batch unit to sample and measure the tolerance range of the outer diameter of the alloy. If it is greater than 0.1mm, all alloys should be sorted. Sorting grades are distinguished in units of 0.8mm. For example, less than 0.8mm; greater than or equal to 0.8mm and less than 0.16mm.

[0026] b. Take the box as a batch unit to take samples and check the carbon oxides on the surface of the alloy. After rubbing a few alloys by hand, observe whether there is gray or black on the surface of the palm of the hand. If so, the alloy needs to be surface treated.

[0027] c. Counting from the date of production, alloys that are more than two months old will be subjected to a physical tumbling process in addition to the inspection in item a. Tumble in the barrel for no less than two hours. After the...

Embodiment 2

[0045] Embodiment 2: the production method of knife-shaped tooth

[0046] 1. Preparation before welding

[0047] 1. Preparation before welding of tooth head alloy

[0048] a. Take the case as a batch unit to sample and measure the tolerance range of the outer diameter of the alloy. If it is greater than 0.1mm, all alloys should be sorted. Sorting grades are distinguished in units of 0.8mm. For example, less than 0.8mm; greater than or equal to 0.8mm and less than 0.16mm.

[0049] b. Take the box as a batch unit to take samples and check the carbon oxides on the surface of the alloy. After rubbing a few alloys by hand, observe whether there is gray or black on the surface of the palm of the hand. If so, the alloy needs to be surface treated.

[0050] c. Counting from the date of production, alloys that are more than two months old will be subjected to a physical tumbling process in addition to the inspection in item a. Tumble in the barrel for no less than two hours. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com