Continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate

A technology of p-aminophenyl and hydroxyethyl sulfone, which is applied in the field of continuous sulfonation process for synthesizing p-aminophenyl-β-hydroxyethyl sulfone sulfate, can solve the problem that the temperature is not easy to control, the production cycle is prolonged, and the reaction temperature is High problems, to achieve the effect of easy control of reaction temperature, easy industrial production, and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

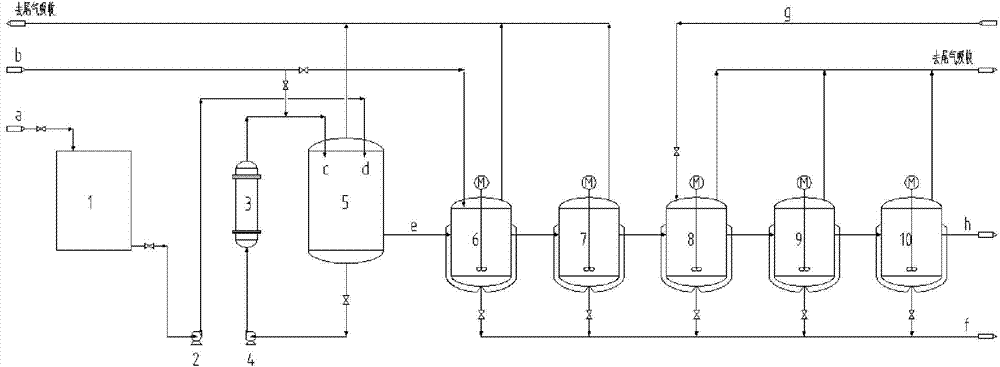

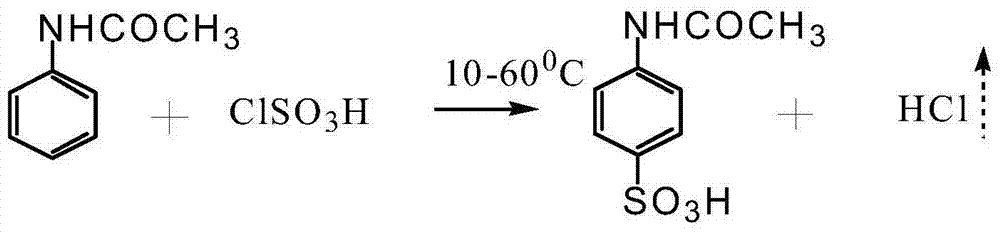

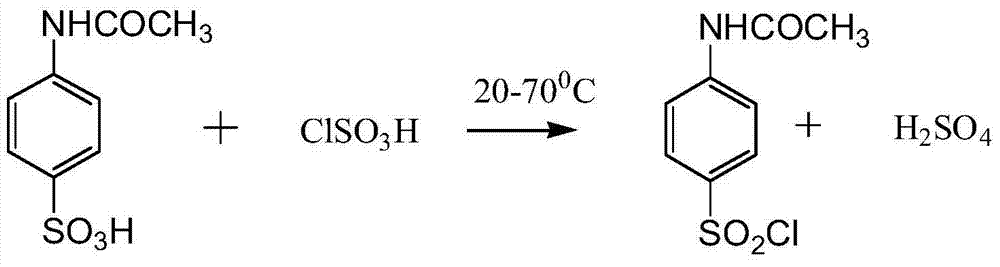

[0049] Turn on the sulfonation circulating pump 4, adjust the flow rate of chlorosulfonic acid to 1500kg / h, pump the chlorosulfonic acid feed pipe b from the chlorosulfonic acid transfer tank to the sulfonation batching kettle 5 through the feed pump, and enter the mouth of the sulfonation batching kettle Equipped with the first atomizing distributor c, it can instantly atomize the chlorosulfonic acid so that it is sprayed into the sulfonated batching kettle 5 in an atomized state, and at the same time, the flow rate of the molten acetanilide is adjusted to be 600kg / h, and the acetanilide is fed into the The material pipe a is transferred from the acetanilide transfer tank 1 to the sulfonation batching kettle 5 through the acetanilide feed pump 2, and the second atomization distributor d is installed at the mouth of the sulfonation batching kettle, which can instantly atomize the acetanilide, so that It is sprayed into the sulfonation batching kettle 5 in an atomized form, the ...

Embodiment 2

[0051] Turn on the sulfonation circulating pump 4, adjust the flow rate of chlorosulfonic acid to 1500kg / h, pump the chlorosulfonic acid feed pipe b from the chlorosulfonic acid transfer tank to the sulfonation batching kettle 5 through the feed pump, and enter the mouth of the sulfonation batching kettle Equipped with the first atomizing distributor c, it can instantly atomize the chlorosulfonic acid so that it is sprayed into the sulfonated batching kettle 5 in an atomized state, and at the same time, the flow rate of the molten acetanilide is adjusted to be 600kg / h, and the acetanilide is fed into the The material pipe a is transferred from the acetanilide transfer tank 1 to the sulfonation batching kettle 5 through the acetanilide feed pump 2, and the second atomization distributor d is installed at the mouth of the sulfonation batching kettle, which can instantly atomize the acetanilide, so that It is sprayed into the sulfonation batching kettle 5 in an atomized form, the ...

Embodiment 3

[0053] Turn on the sulfonation circulation pump 4, adjust the flow rate of chlorosulfonic acid to 2000kg / h, pump the chlorosulfonic acid feed pipe b from the chlorosulfonic acid transfer tank to the sulfonation batching kettle 5 through the feed pump, and enter the mouth of the sulfonation batching kettle Equipped with the first atomizing distributor c, it can instantly atomize the chlorosulfonic acid so that it is sprayed into the sulfonated batching kettle 5 in an atomized state, and at the same time, the flow rate of the molten acetanilide is adjusted to be 600kg / h, and the acetanilide is fed into the The material pipe a is transferred from the acetanilide transfer tank 1 to the sulfonation batching kettle 5 through the acetanilide feed pump 2, and the second atomization distributor d is installed at the mouth of the sulfonation batching kettle, which can instantly atomize the acetanilide, so that It is sprayed into the sulfonation batching kettle 5 in an atomized form, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com