Quantifying vessel and quantifying milk powder box

A container and silo technology, which is applied in the field of quantitative containers and quantitative milk powder boxes, can solve the problem of inaccurate quantification of portable powdery or granular materials, and achieve the effect of simple structure and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

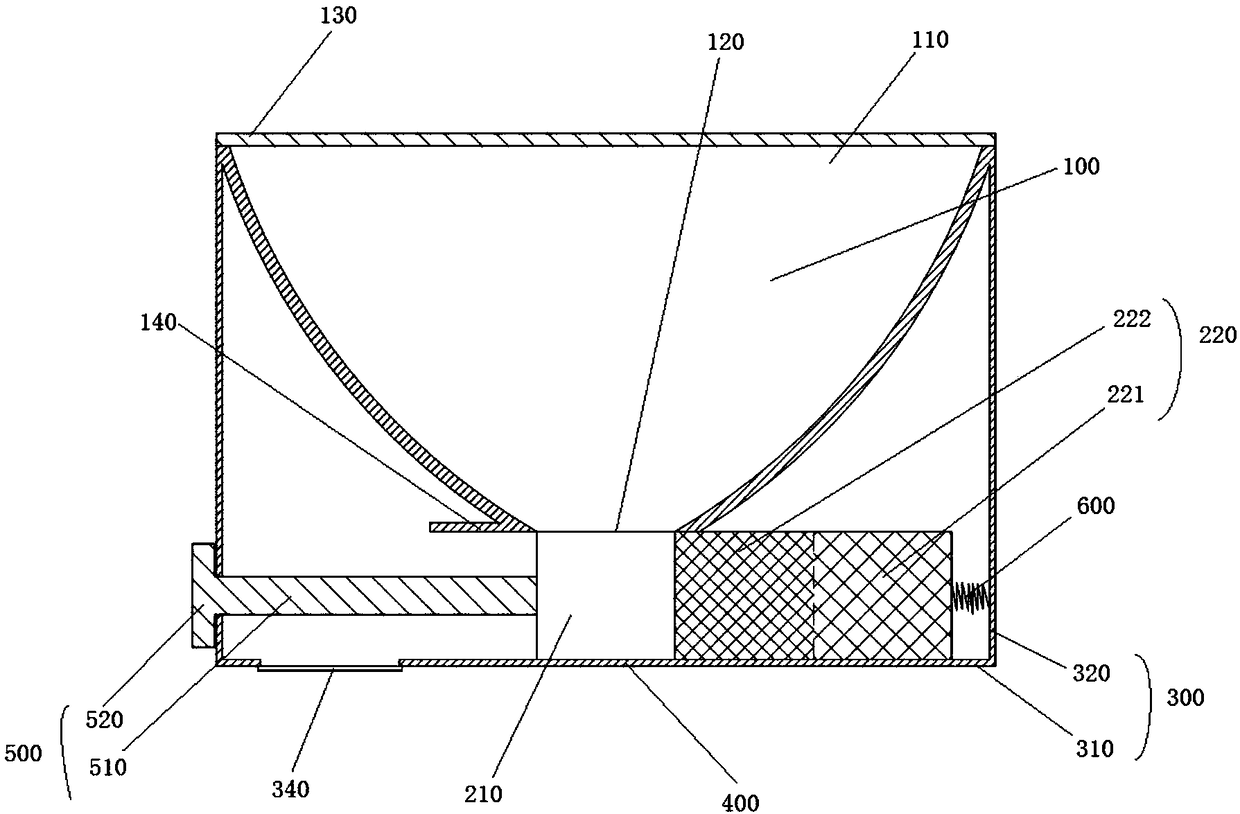

[0032] The quantitative container of the present embodiment comprises a storage bin 100, a retrieving device 200 connected with the storage bin 100, the storage bin 100 is provided with a feed port 110 for adding materials to the storage bin and is used to discharge the material to the retrieving device. Material discharge port 120. The feeding port 110 is provided with a cover 130 for closing the storage bin to prevent the material from being damp in the powder storage bin 100 . The material retrieving device 200 can move back and forth below the discharge port. The discharge port is a square discharge port. A retrieving shell 300 for sealing the retrieving device is arranged below the storage bin 100 . The retrieving shell 300 can seal the retrieving device 200 to seal the material and prevent the material from being damp or polluted. The retrieving shell includes an integrally formed bottom plate 310 and a retrieving shell side plate 320 . The side plate 320 of the retr...

Embodiment 2

[0039] The quantitative container described in this embodiment has a general structure consistent with that of Embodiment 1, but is different from Embodiment 1 in that the size of the feed port of the retrieving bin 210 is larger than the size of the discharge port of the storage bin. The bottom of the storage bin is provided with a cover plate for covering the upper part of the feeding bin. The cover plate and the storage bin are integrally formed. The cover plate is located on both sides of the discharge port, and is used to cooperate with the scraper to quantify the feeding bin.

Embodiment 3

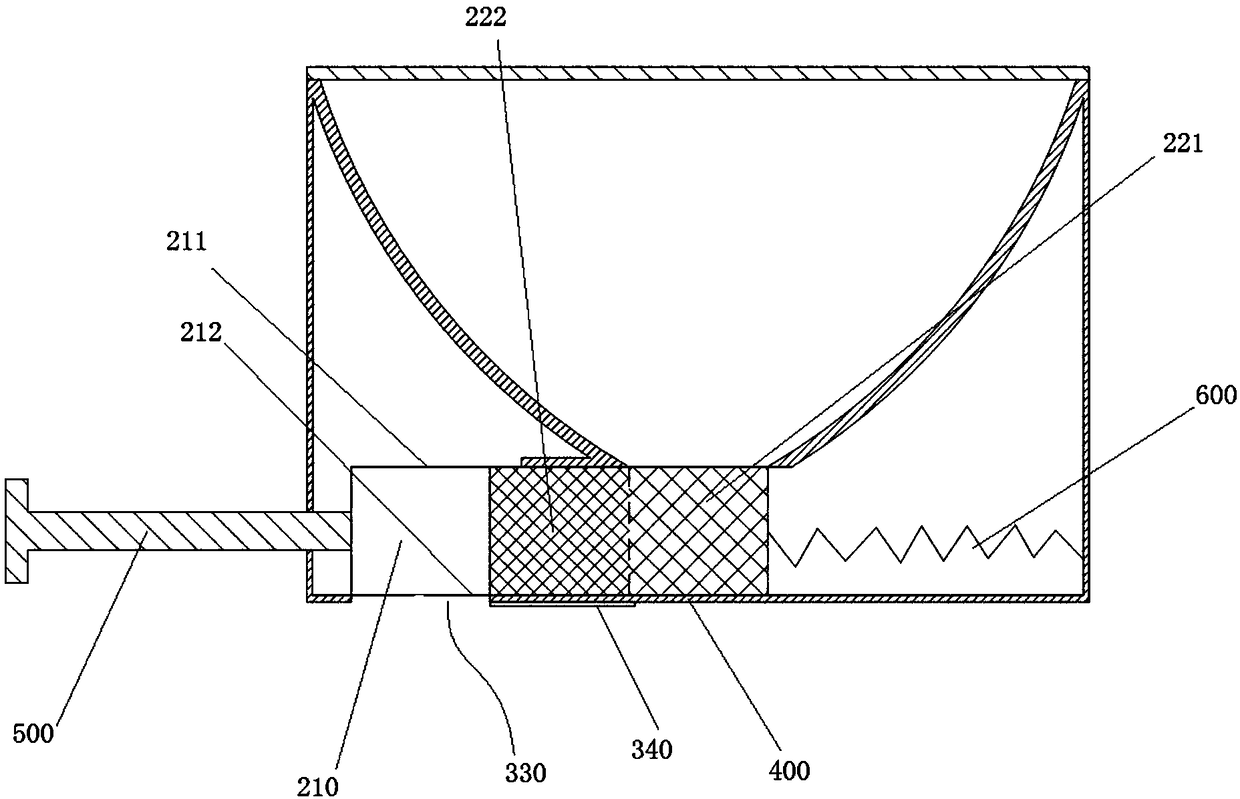

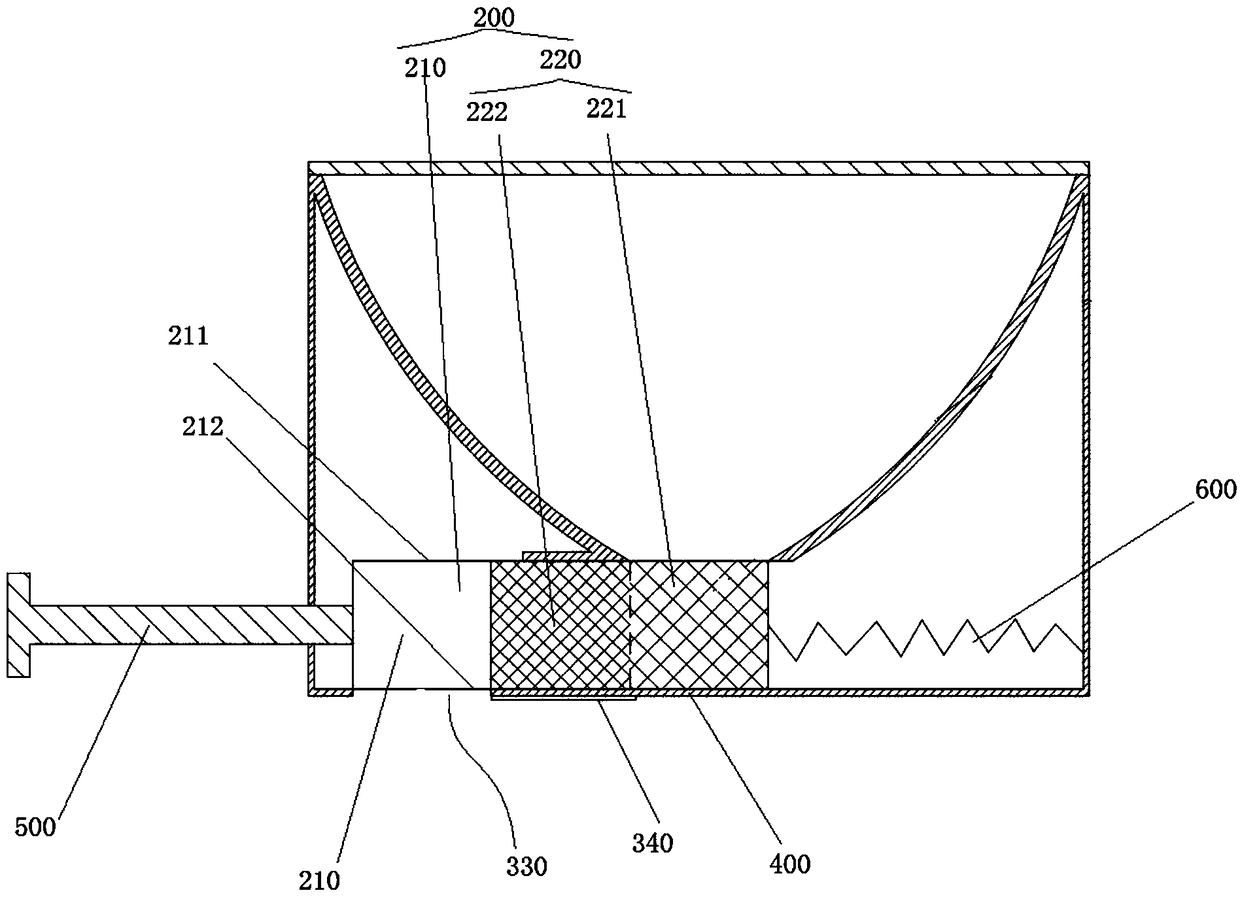

[0041] The general structure of the quantitative container described in this embodiment is consistent with that of Embodiment 1, but the difference from Embodiment 1 is that the size of the feed port 211 of the retrieving bin 210 is larger than the size of the discharge port 212 . The side plate of the feed bin is an inclined plate. The feeding bin is a trumpet-shaped structure with a large top and a small bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com