Positive-negative chamfering drilling bit used for processing of plate parts

A technology for machining parts and plates, which is used in the field of high-efficiency, high-speed and precision tools to improve machining efficiency, optimize structure, and ensure machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

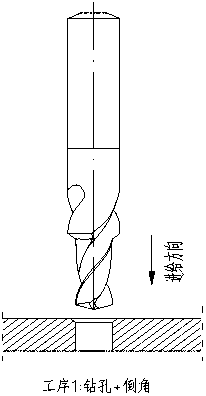

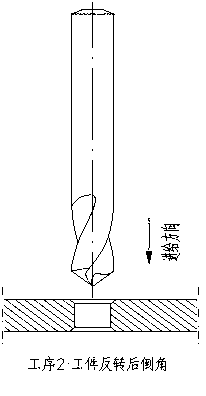

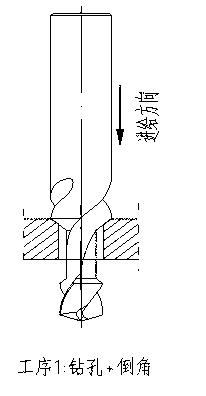

[0024] According to the technical requirements of double-sided chamfering for plate parts, the positive and negative chamfering compound drill is designed to reduce the process and improve the processing efficiency. The drill can be clamped at one time to complete the three processes of drilling, entrance chamfering and exit chamfering. Compared with the traditional process, it can reduce one clamping, improve processing efficiency, and reduce machine tool occupation time.

[0025] Such as Figure 5 As shown, the front and back chamfering drill bit used for processing plate parts includes a shank 1, a neck 2 and a head 3, and the head 3, neck 2 and shank 1 are coaxial cylinders centered on the same central axis body, the shank 1 is a section of cylinder with high cylindricity, the collet clamps the shank to transmit the power of the machine tool, so that the tool rotates and has cutting ability, the head 3 and the neck 2 are provided with chip removal grooves 4, The solid par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com