Peeling method of insulated lead of distribution wire and peeling knife thereof

A technology for insulated wires and power distribution lines, which is applied in the direction of dismantling/armoured cable equipment, etc. It can solve the problems of damage to the metal part of the wire, hidden dangers, and difficult work of the wire stripper, so as to reduce the hardness and facilitate cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

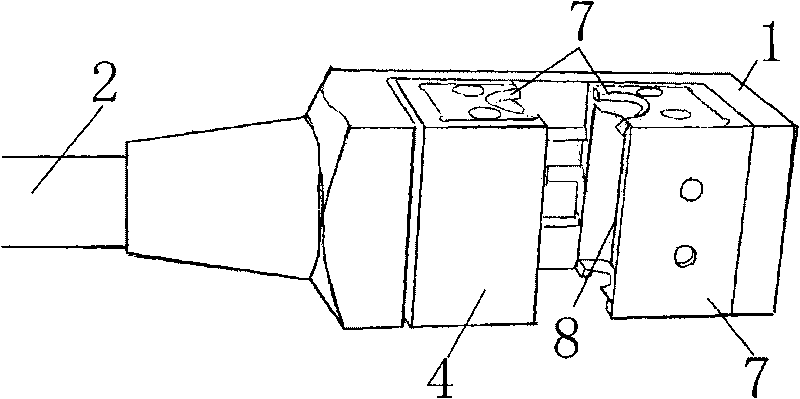

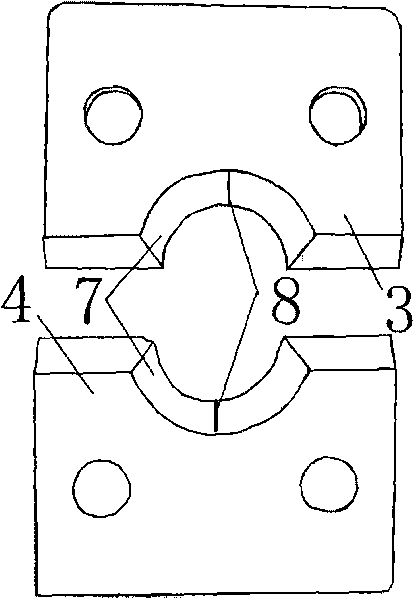

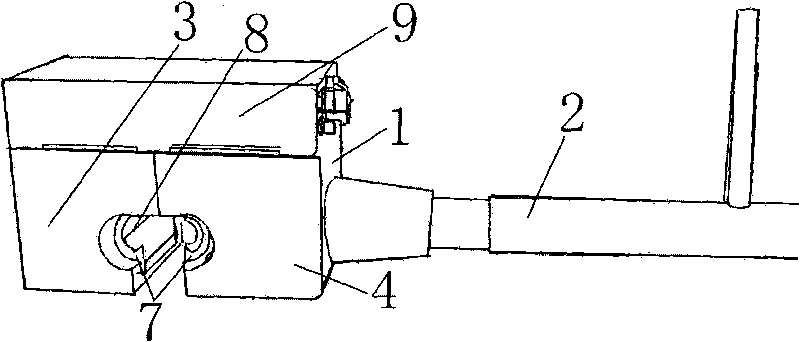

[0050] First, an insulated wire stripping knife is prepared, and the insulated wire stripping knife also includes: a "ㄇ" groove-shaped stripping knife frame 1 and a stripping knife seat handle 2 connected with the frame. The "ㄇ" groove-shaped peeling knife frame is provided with up and down opposite, relatively movable upper and lower two knife seats 3, 4, and the above-mentioned two upper and lower knife seats 3, 4 form a vise shape. The middle of the upper and lower two knife seats 3 and 4 is used to place the wire 5 to be stripped of the insulation layer, and the edge of the upper and lower two knife seats is formed with a symmetrical arc-shaped concave cutting knife blade 7, which is used for cross-cutting the wire foreskin 6 direction of feed.

[0051] In the inner side between the two arc-shaped inner notch cutters 7 and 7 of the upper and lower two knife seats, a single cutter blade 8 is arranged, which is used to feed the lead wire foreskin in the longitudinal directio...

Embodiment 2

[0074] Except that described insulated wire stripping knife is covered with a heat preservation cover during use, in order to heat stably, other is the same as embodiment 1, makes and uses insulated wire stripping knife.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com