Automatic feeding system and mixing station

An automatic feeding and mixing station technology, which is applied in mixing plants, sales raw material supply devices, clay preparation devices, etc., can solve the problems of physical and mental health hazards of workers, flying dust at the work site, low work efficiency, etc., and achieve the goal of feeding process Controllable, humanized and environmentally friendly working environment, and the effect of reducing the use of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

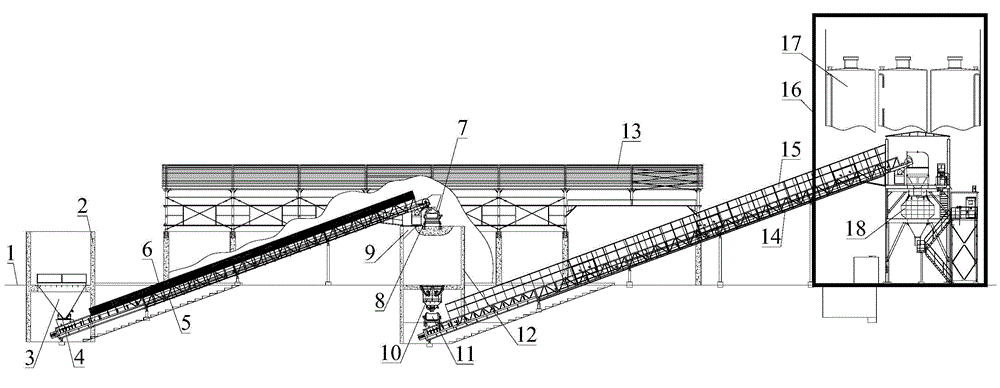

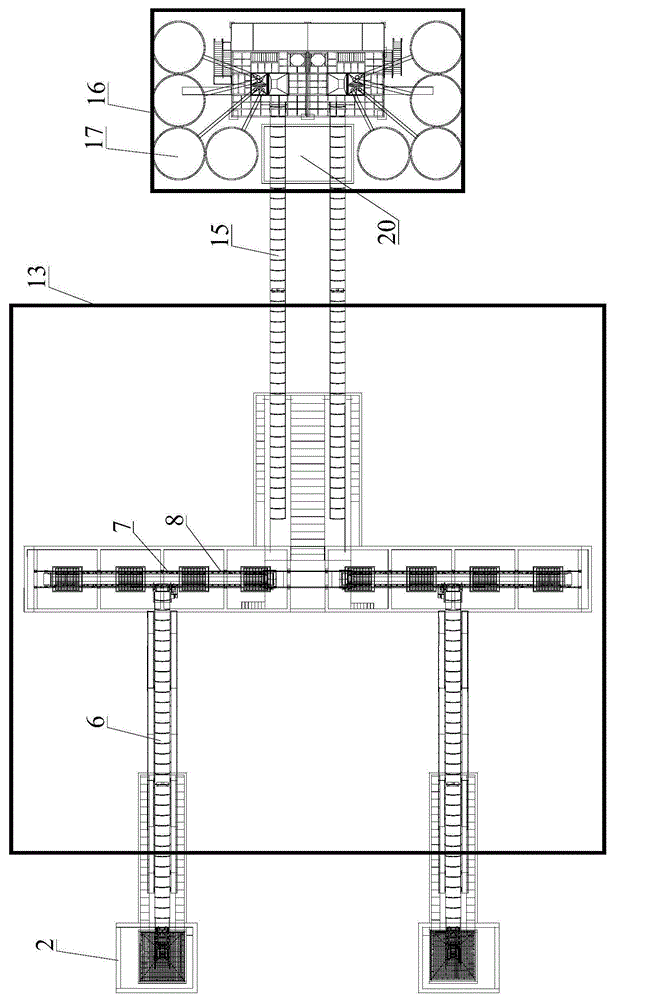

[0043] Please also refer to figure 1 with figure 2 , the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] As shown in the figure, the mixing station of the embodiment of the present invention at least includes an automatic feeding system, a main mixing building 18 , a powder tank 17 and a third conveying mechanism 14 .

[0045] Wherein, the automatic feeding system may include a feeding bin 2, a first conveying mechanism 5, a second conveying mechanism 7, a walking guide rail 8, a batching bin 12 and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com