Method for making MOS having light doped drain electrode

A technology of oxide semiconductor and lightly doped drain, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as narrow process range, difficult control, and unfavorable actual production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

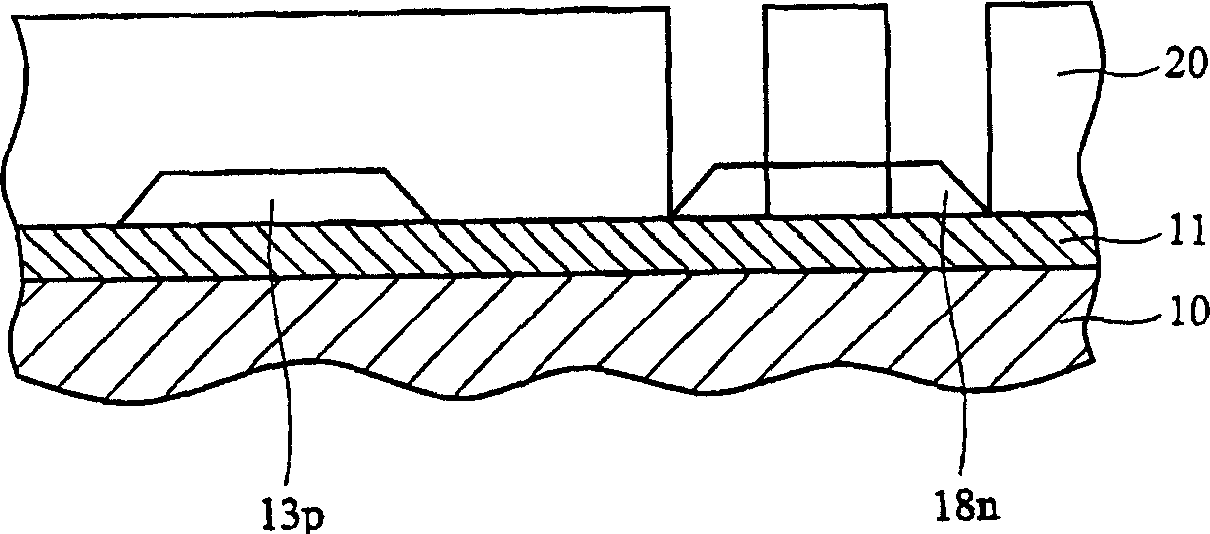

[0028] The invention provides a metal oxide semiconductor manufacturing method with a lightly doped drain, which can effectively reduce the number of photomasks used in the thin film transistor process, reduce process complexity and increase yield. The metal oxide semiconductor with lightly doped drain is applied to a thin film transistor liquid crystal display. The following is an example of a preferred embodiment of the method for fabricating a lightly doped drain metal oxide semiconductor according to the present invention, which is described in detail with reference to the accompanying drawings:

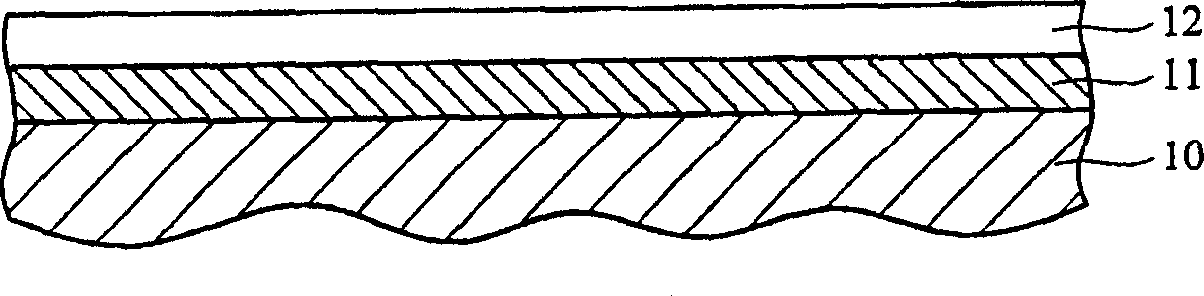

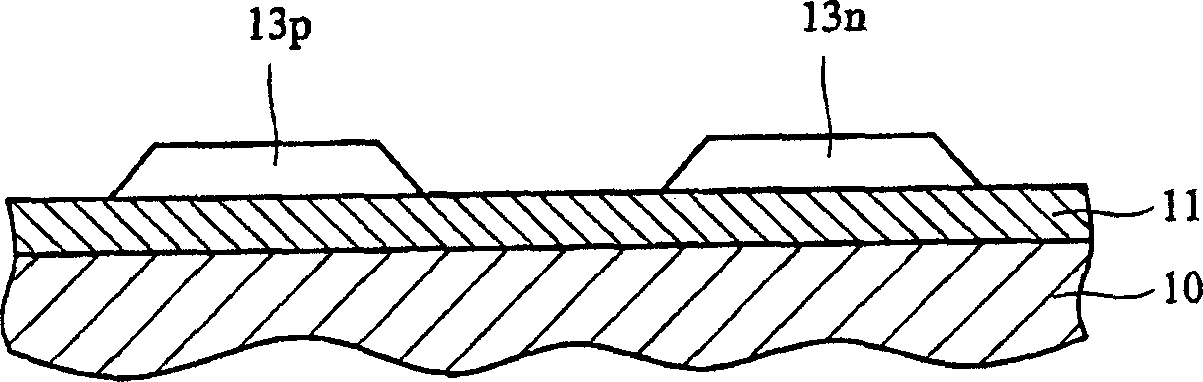

[0029] First, see Figure 3a , providing a substrate 200, which may be, for example, a suitable substrate for a liquid crystal display, and the substrate 200 includes a P-type metal oxide semiconductor region P and a lightly doped drain region LDD. Next, a buffer layer 202 and a semiconductor layer are sequentially formed on the substrate 200 . Next, using a first photomask and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com