Processing method and device of high-temperature solid steel slag

A processing device and processing method technology, applied in the direction of recycling technology, etc., can solve the problems such as the inability to realize the cleaning treatment of tank bottom slag, the inability to process the steel slag, and the lack of fluidity, so as to reduce infrastructure investment, improve depth and level, The effect of removing influences and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

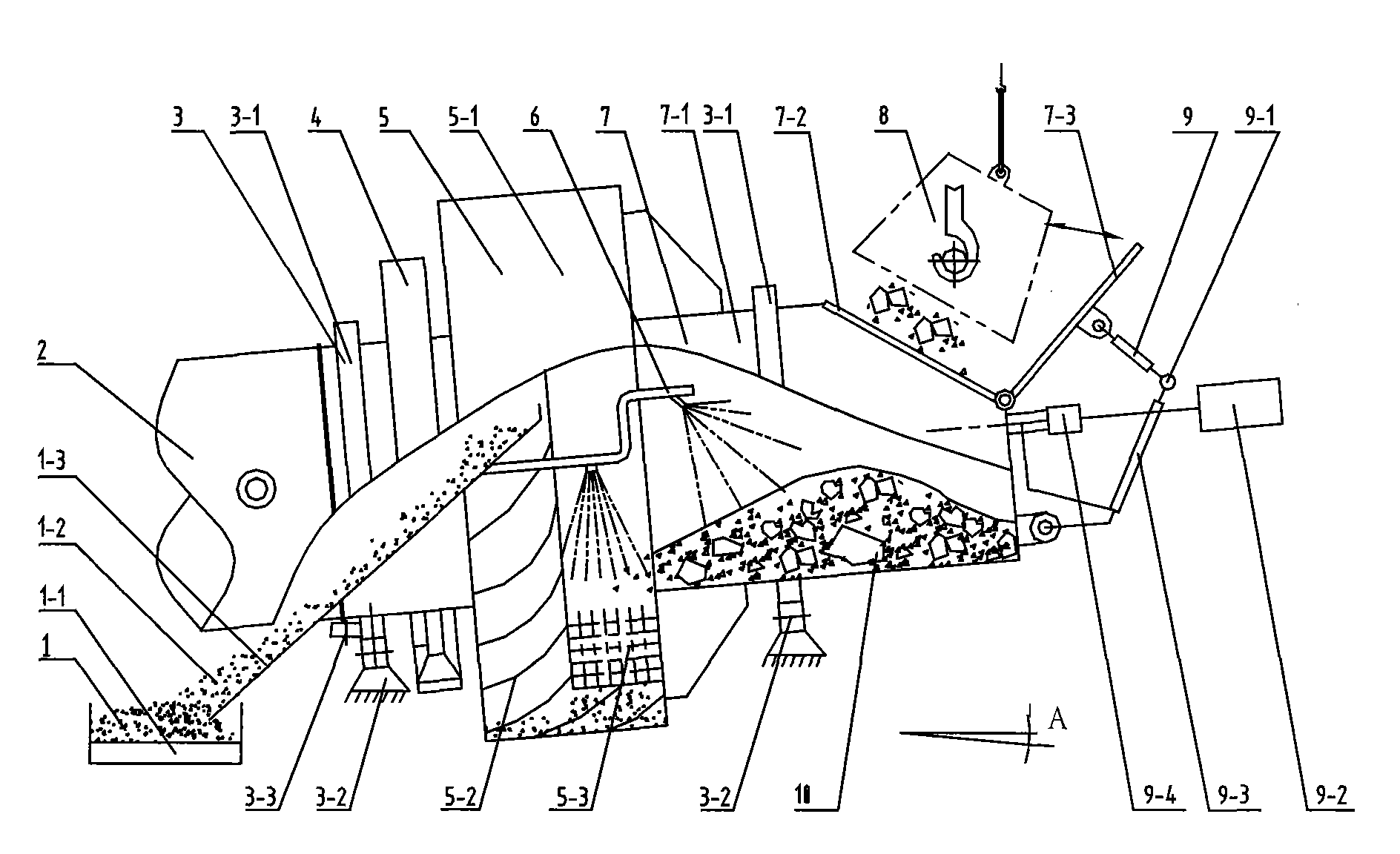

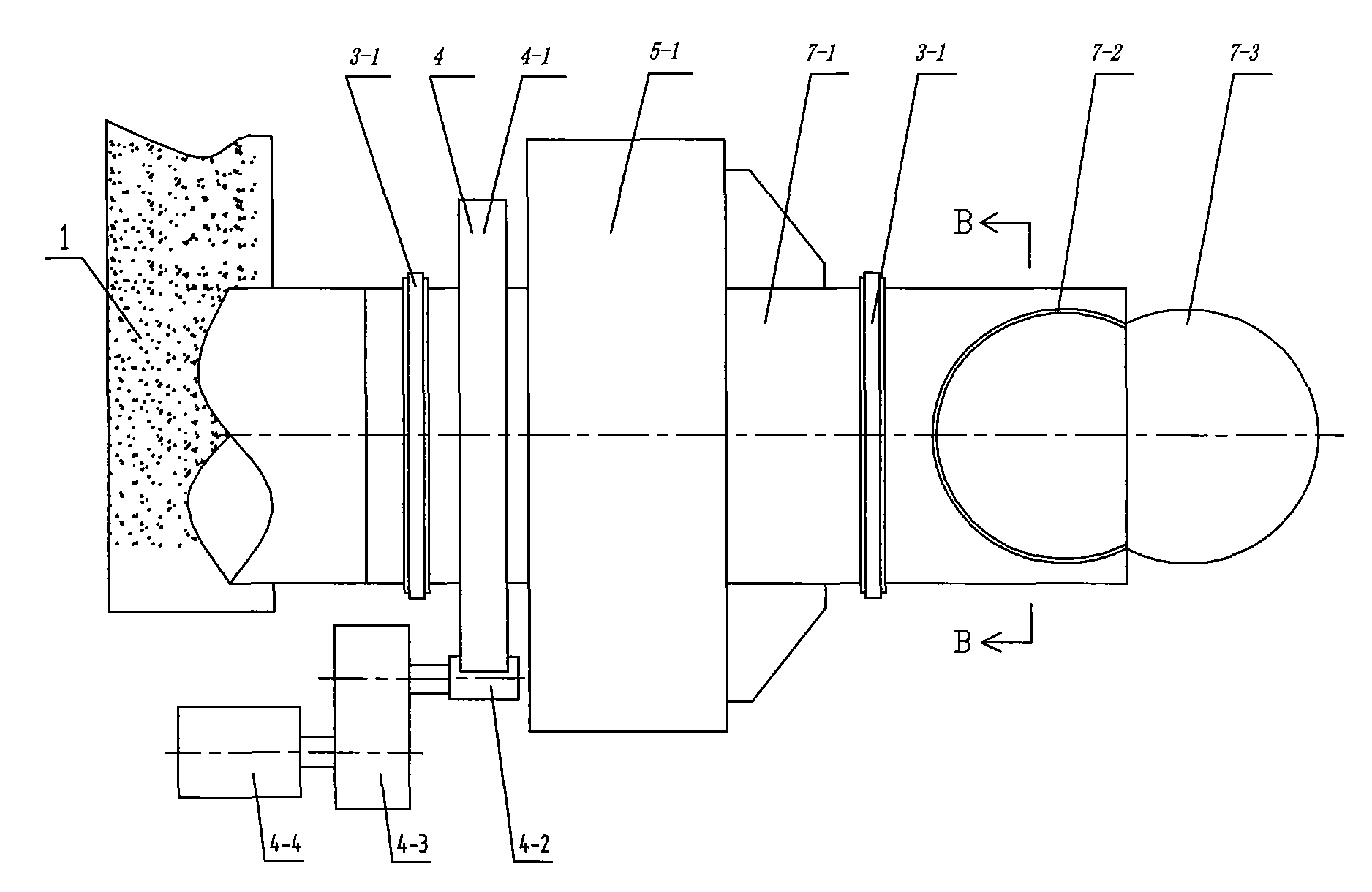

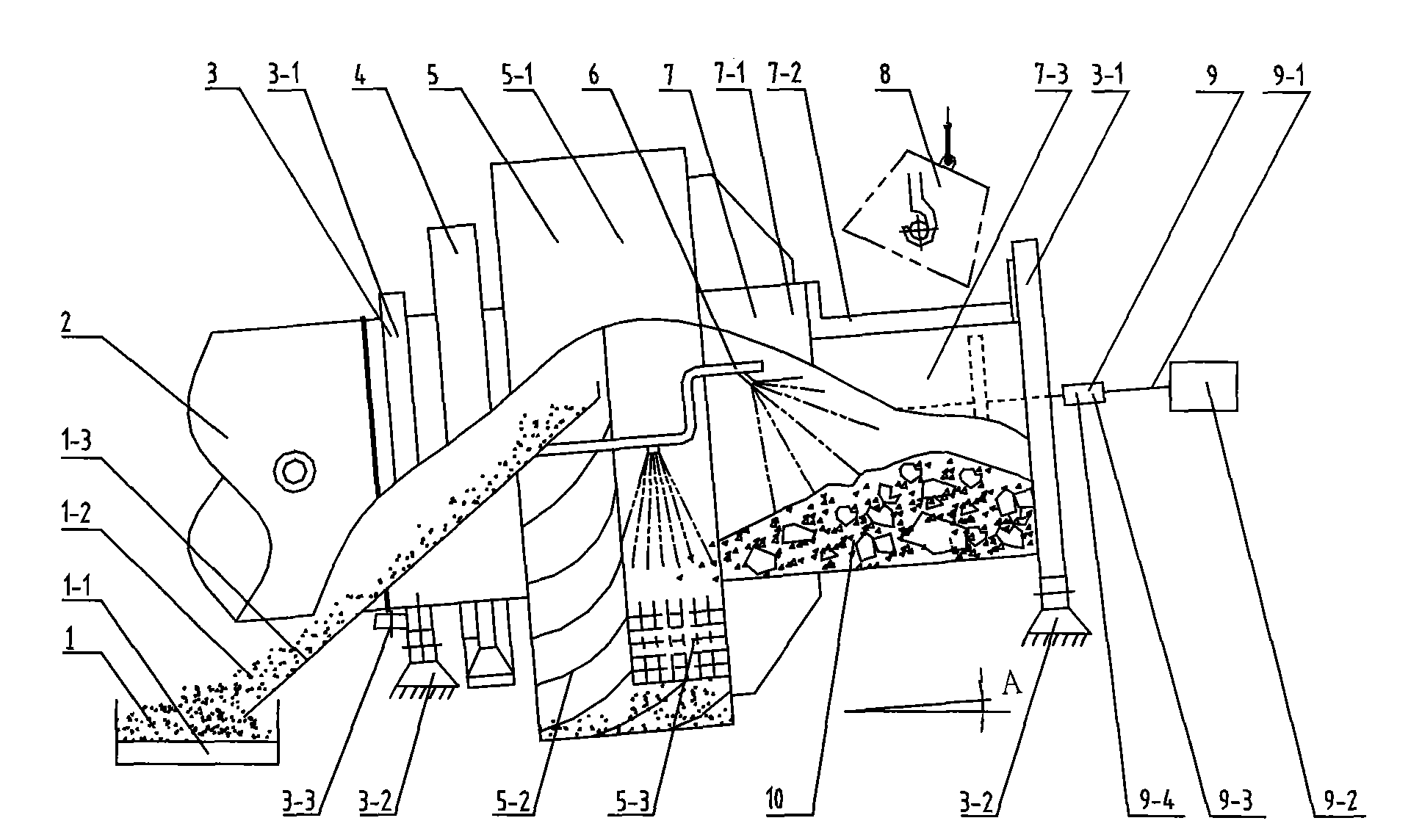

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] see figure 1 , figure 2 , Image 6, a treatment method for high-temperature solid steel slag, is to install a feed cylinder 7 capable of holding a sufficient amount of high-temperature solid steel slag in front of the existing working cylinder 5, and a feed cylinder 7 is provided on the side or end surface of the feed cylinder 7. The feed port 7-2 and the sealing door 7-3 that can be opened and closed automatically, the feeding cylinder 7 and the working cylinder 5 are coaxially and rigidly consolidated together, and the axis and the horizontal plane form a certain inclination angle A; between 0° and 20°;

[0036] The working cylinder 5 is provided with a cooling and crushing medium 5-3, that is, steel balls, which rapidly cools and crushes massive high-temperature steel slag; the cooling water sprayed by the spray cooling system 6 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com