Square bale feeder attachment for flat-bed vehicles

a flat-bed vehicle and feeder technology, applied in the field of agricultural equipment, can solve the problems of difficult for one person to do the job effectively, unsound economic situation for many small farmers and ranchers to obtain single-purpose equipment, etc., and achieve the effect of preventing more than one flak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is susceptible of embodiment in many different forms. While the drawings illustrate and the specification describes certain preferred embodiments of the invention, it is to be understood that such disclosure is by way of example only. There is no intent to limit the principles of the present invention to the particular disclosed embodiments.

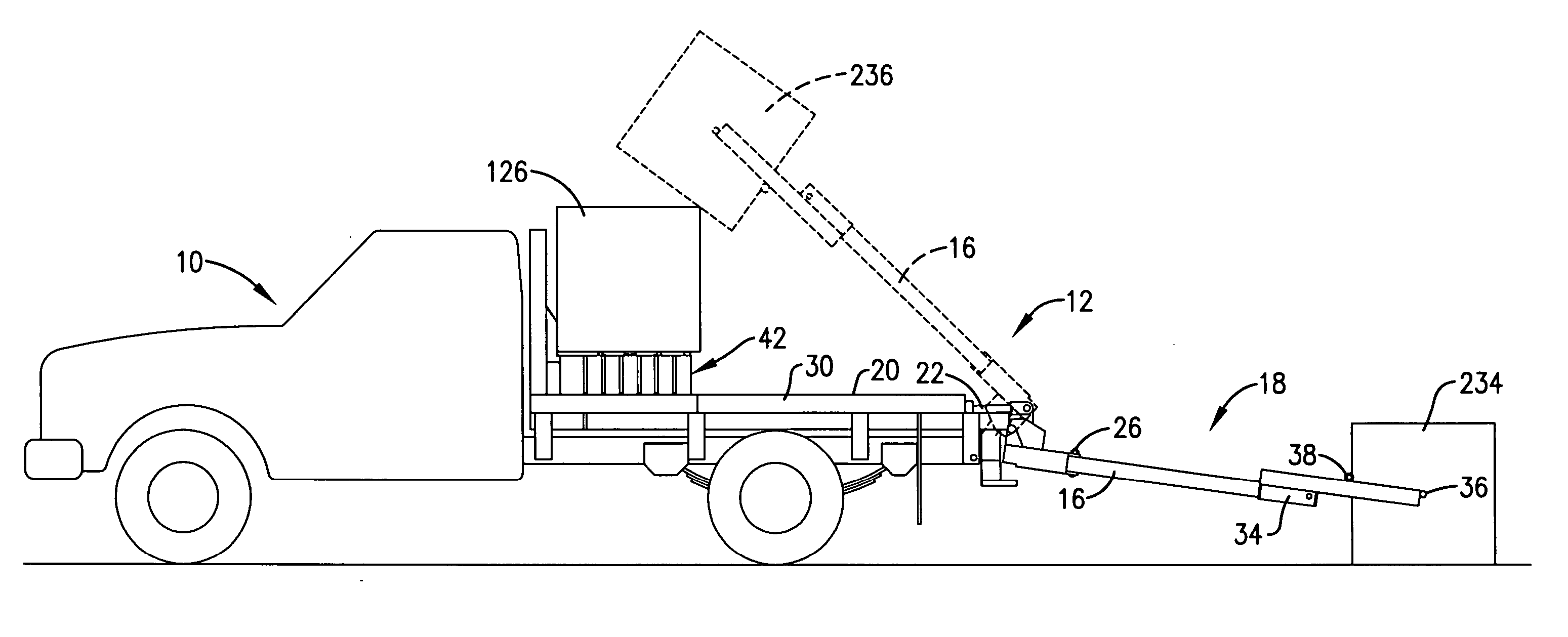

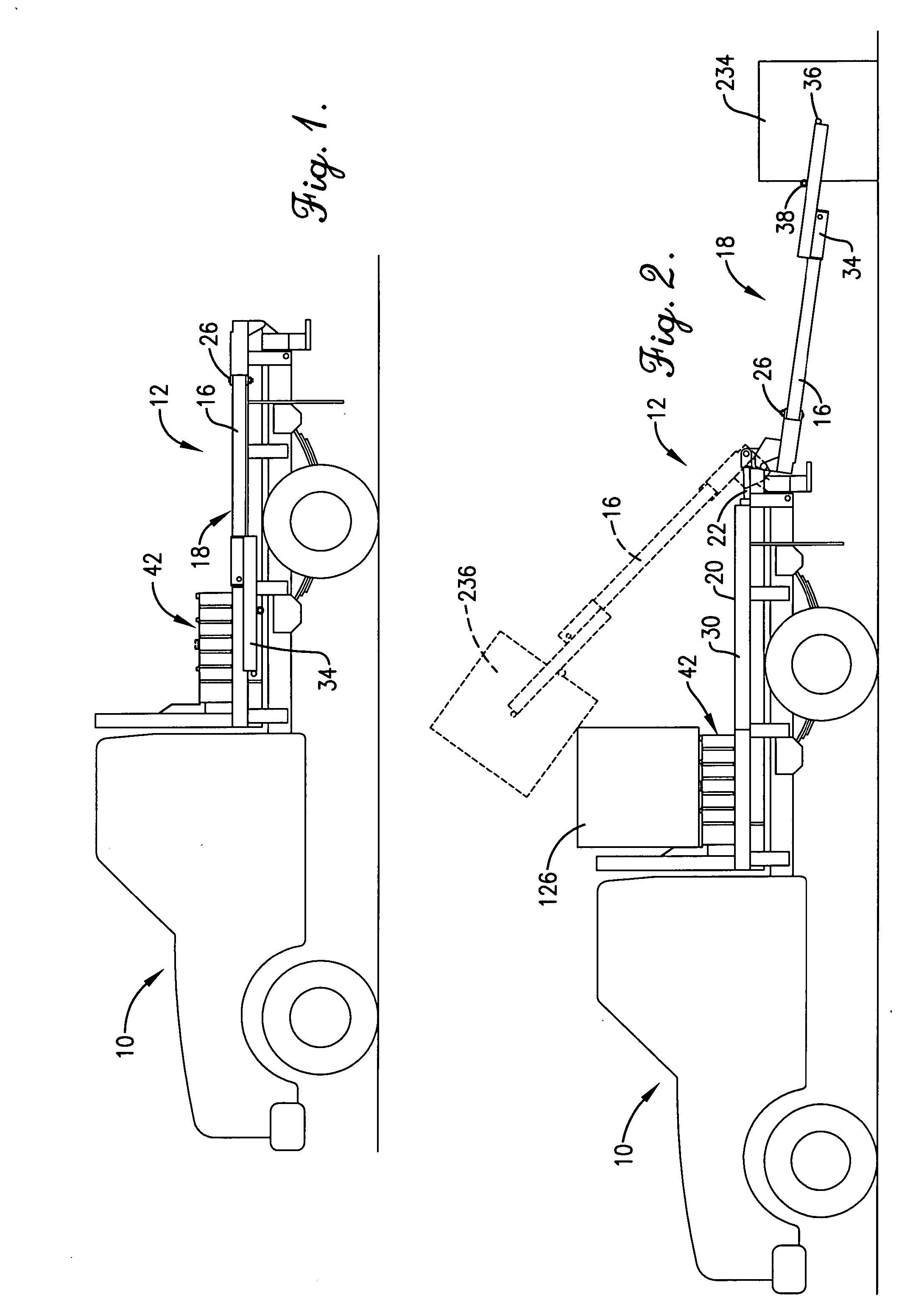

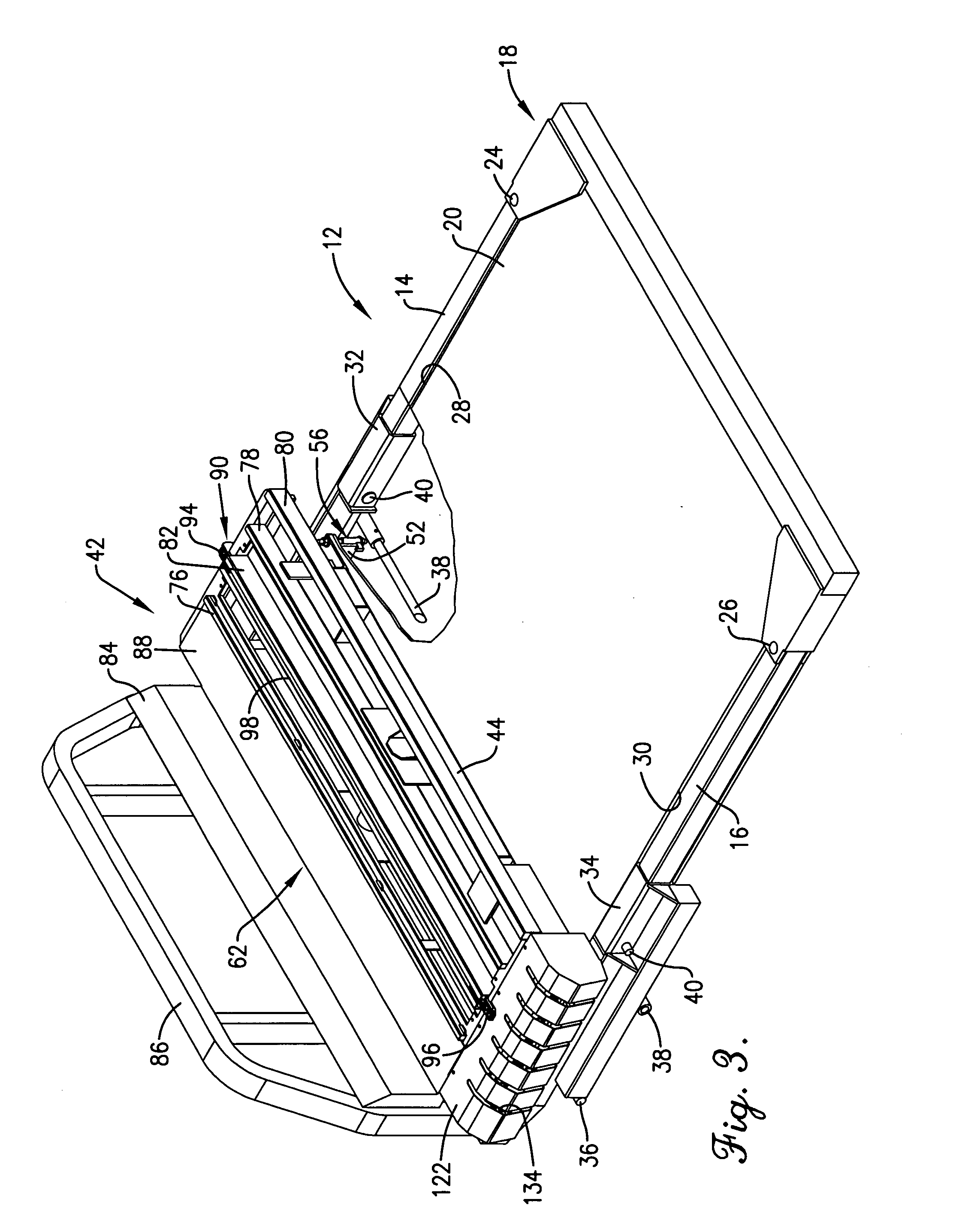

[0024] Apparatus for handling and feeding big square bales in accordance with the present invention broadly includes a flat-bed vehicle 10 and a bale handling and feeding bed assembly 12 mounted on the chassis of vehicle 10. In many respect, bed assembly 12 corresponds closely to the bed assembly as disclosed and claimed in U.S. Pat. No. 4,564,325, the disclosure of which is hereby incorporated by reference into the present specification. Accordingly, reference may be had to the '325 patent for a complete understanding of the nature and operation of lift arms 14 and 16 of a bale retriever 18 forming a part of bed ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com