Double-shaft rocking sieve

A technology of sieve plate and rotating shaft, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of material fluidity affecting the screening efficiency, affecting the operation reliability, occupying the area of the sieve plate, etc., to achieve good screening effect, The effect of stable swing and large screening area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

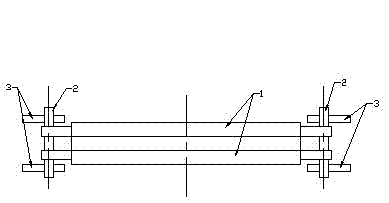

[0009] As shown in the figure, the double-shaft swinging screen includes multiple layers of parallel sieve plates 1, the sieve plates are flexibly suspended on a fixed frame, and a rotating shaft 2 is installed on each side of the sieve plate 1 to pass through each sieve plate. Weight block 3 is installed. A bias weight 3 is respectively installed at the two ends of each rotating shaft. The two rotating shafts 2 are synchronously driven by the same motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com