Misfueling preventing apparatus

a technology of misfueling and preventing apparatus, which is applied in the direction of vehicle components, propulsion parts, transportation and packaging, etc., can solve the problems of reducing the mechanical strength, limiting the hardness of the annular ring, and known misfueling preventing apparatuses adapting the annular member, etc., to facilitate the elastic deformation of the flapper, reduce the car manufacturing cost, and facilitate the effect of handling and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

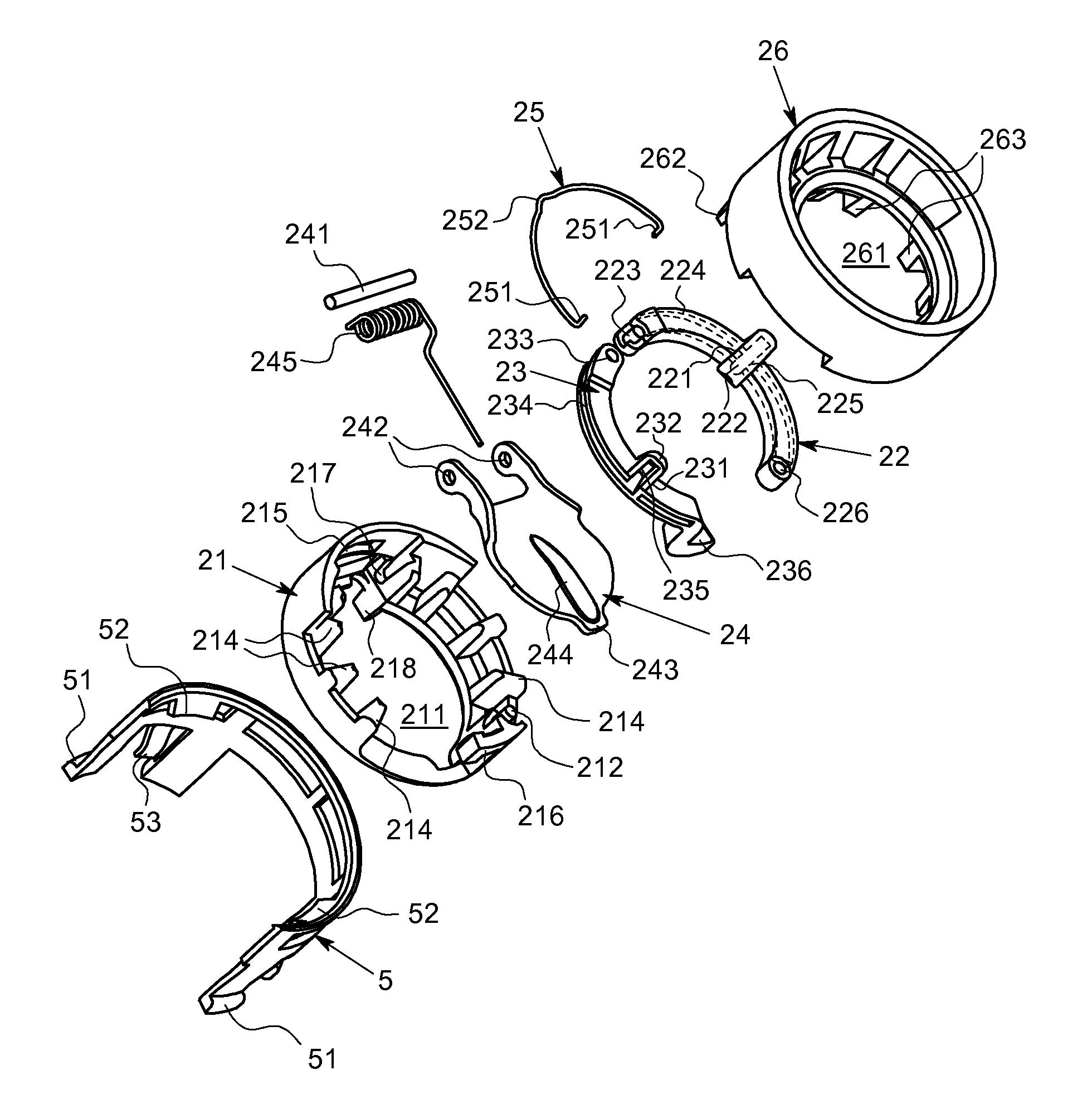

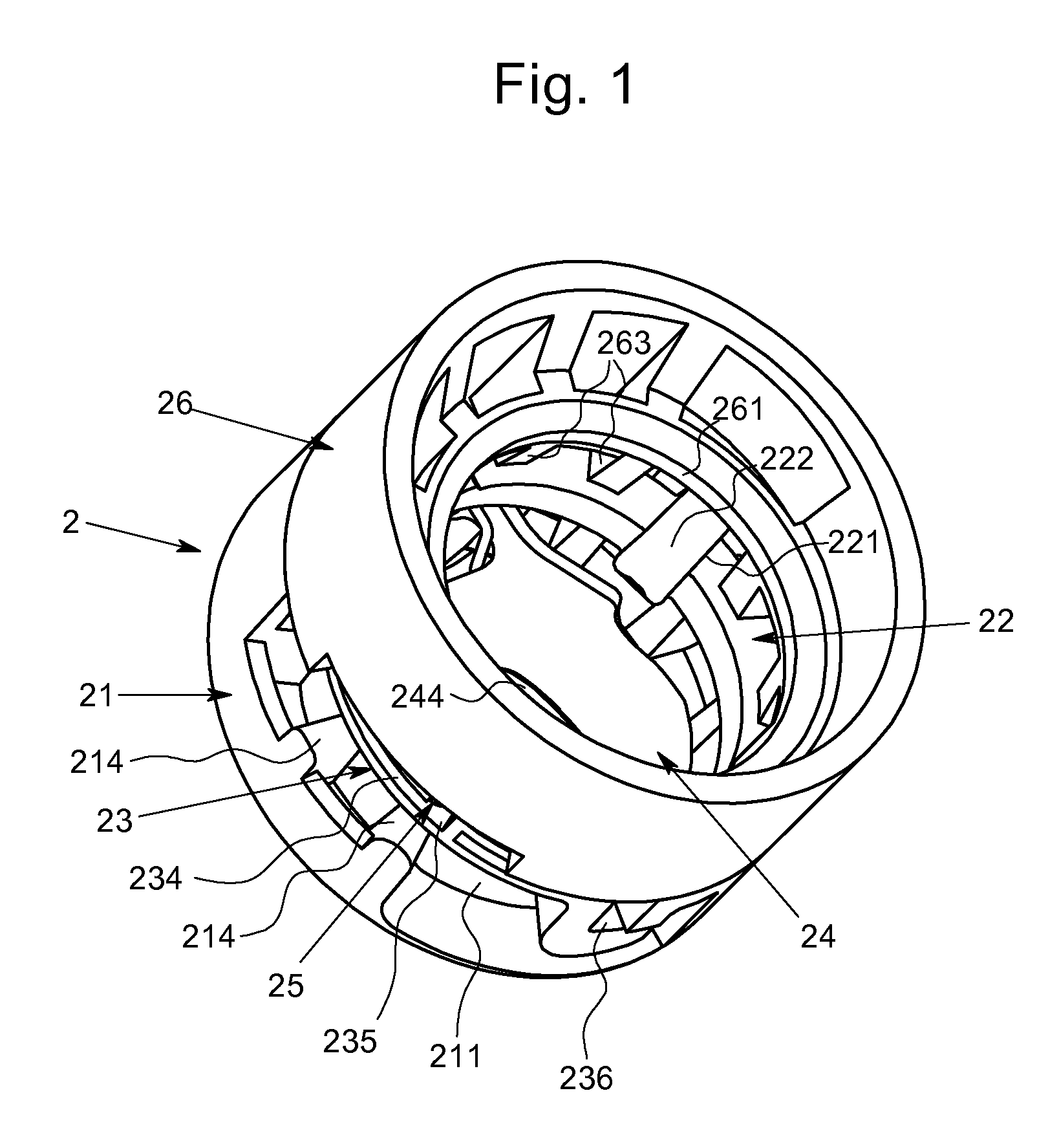

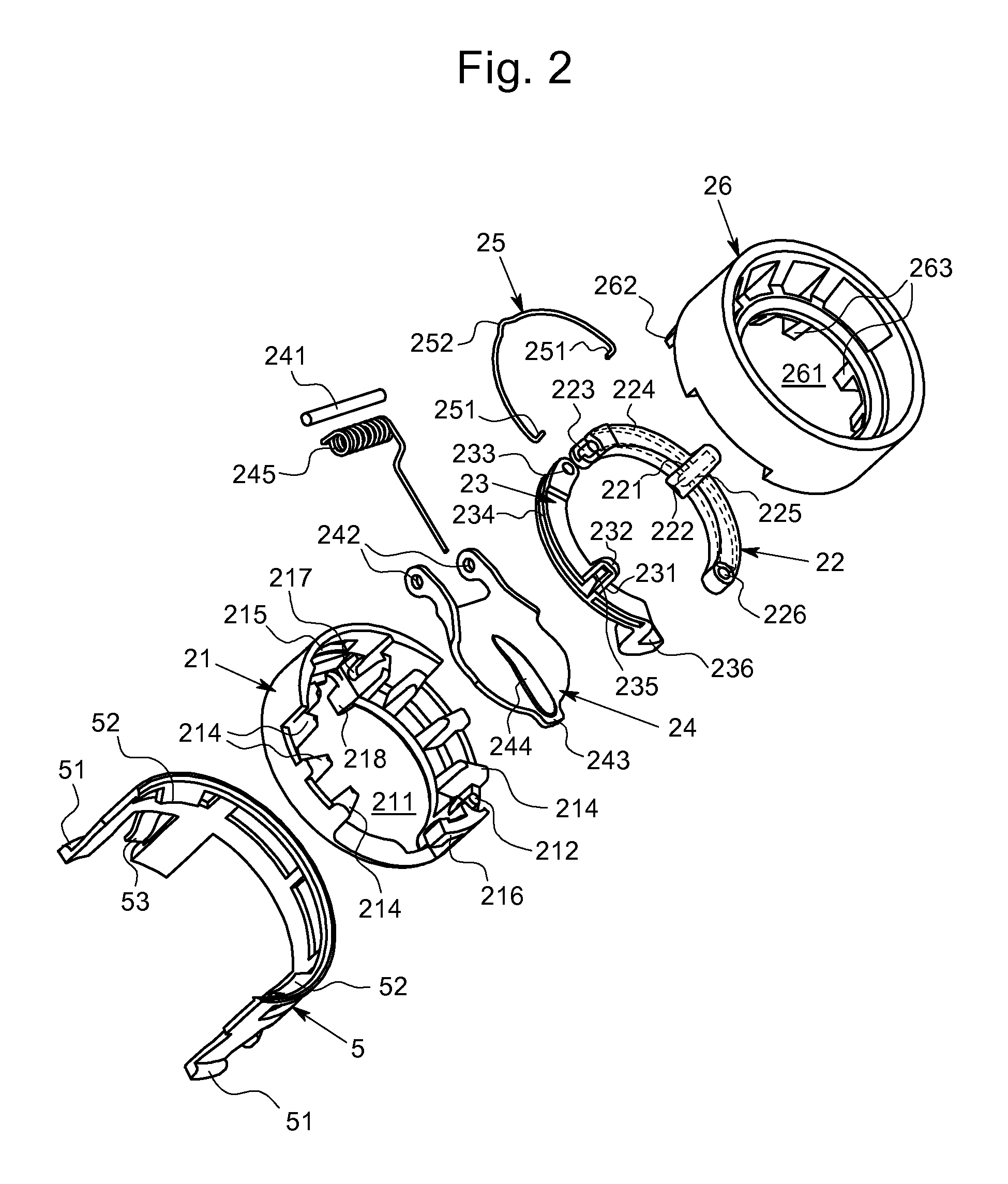

[0037]Embodiments of the present disclosure is explained with reference to Figs. For a convenience of explanation, a direction to which a fuel filler nozzle 3 or 4 is inserted is referred to as “lower side”. The opposite direction to the lower side is referred to as “upper side”. Direction to which a first link arm 22 is located in a plain view, such as FIGS. 5, 8, 9, 14, 16, 18, 20, is referred to as “right side”. Direction to which a second link arm 23 is located in a plain view of a misfueling preventing apparatus 2, such as FIGS. 5, 8, 9, 14, 16, 18, 20, is referred to as “left side”. FIGS. 1 to 6 and FIGS. 10 to 21 illustrate an embodiment of the present disclosure. FIG. 7 illustrates another embodiment of the present disclosure. FIG. 8 illustrates still another embodiment of the present disclosure. FIG. 9 illustrates still another embodiment of the present disclosure.

[0038]The embodiment illustrated in FIGS. 1 to 6 and FIGS. 10 to 21 is explained in the following. A misfueling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com