Automatic sludge processing device and method

An automatic sludge treatment technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve problems such as undiscovered fast and convenient methods, and achieve screening Good effect, avoid secondary mixing, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

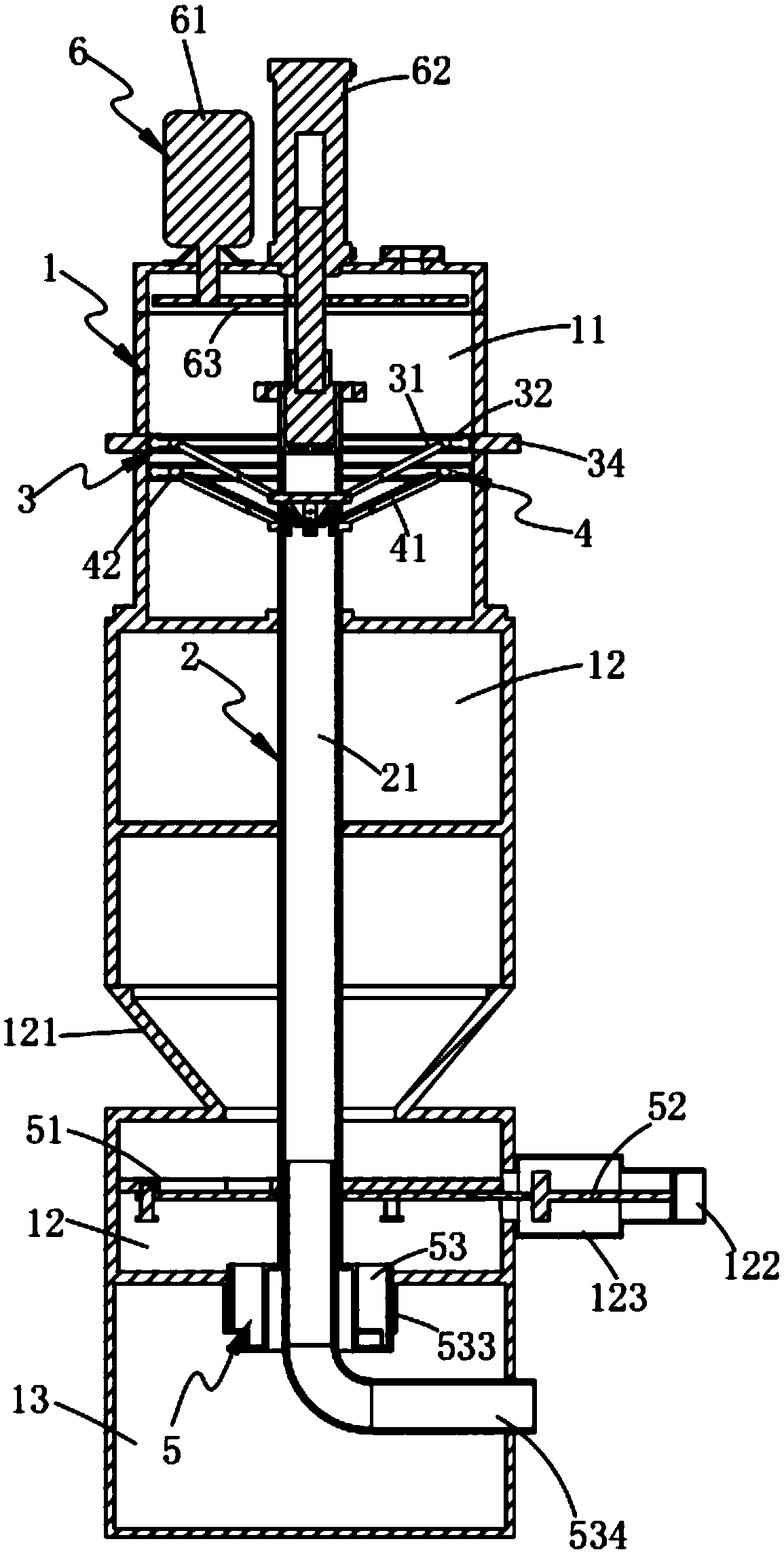

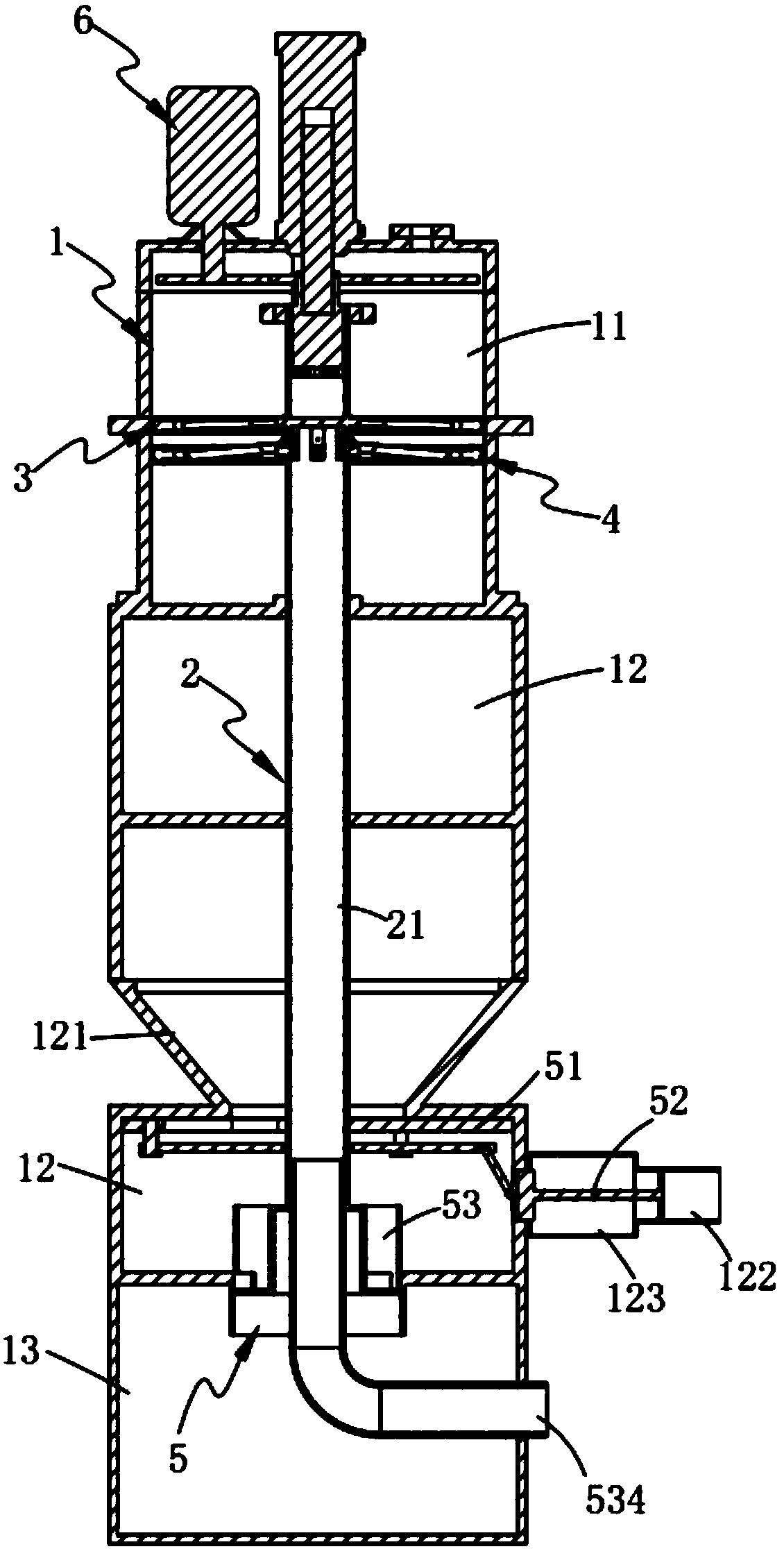

[0069] Such as figure 1 versus figure 2 As shown, an automatic screening and dewatering device for sludge impurities includes a processing box 1, which is divided into a sieve zone 11, a stratification zone 12, and an output zone 13 from top to bottom, and further includes:

[0070] The main shaft 2, the main shaft 2 is vertically rotatably arranged in the processing box 1, and is hollowed out, and a channel 21 is provided inside;

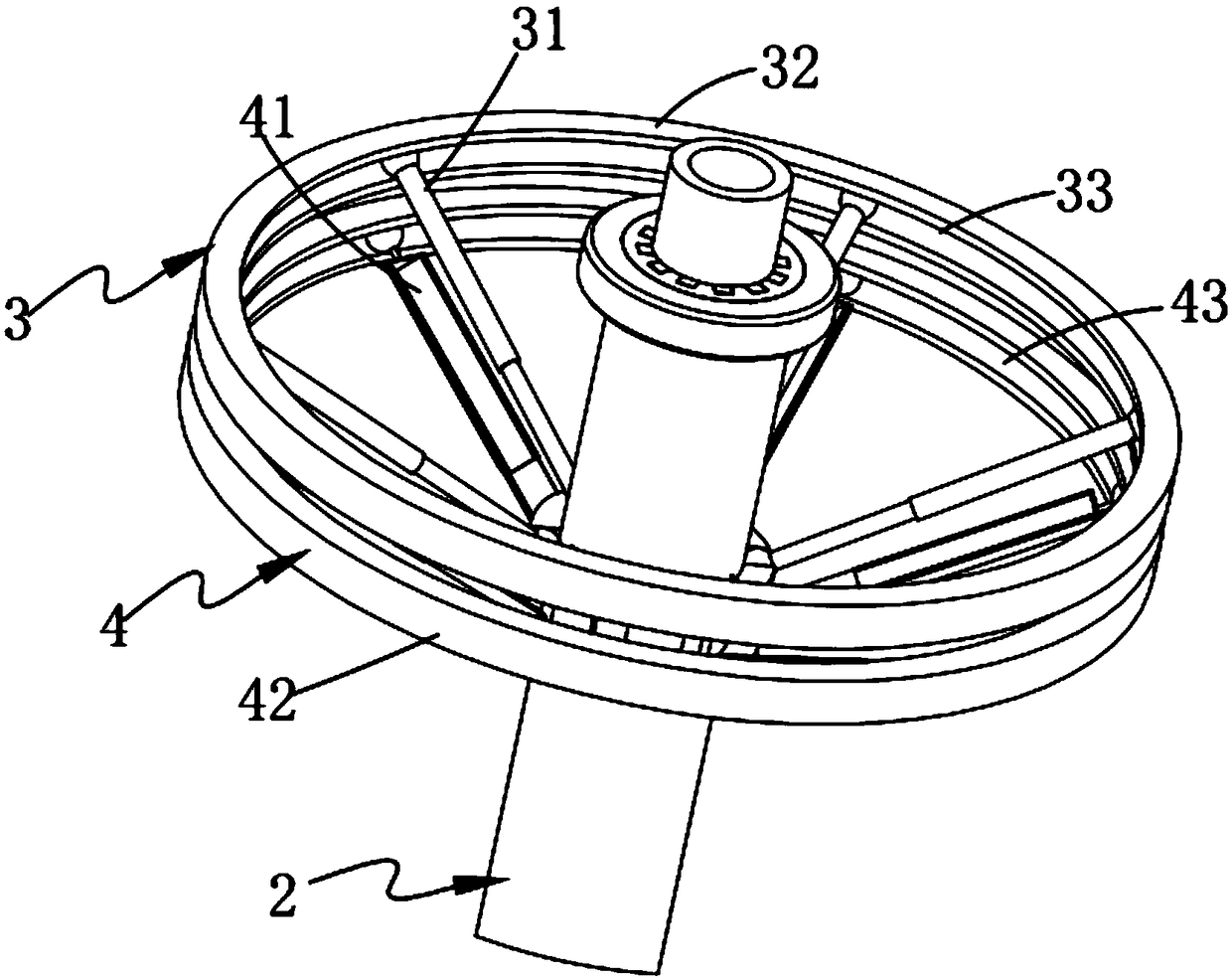

[0071] The screening mechanism 3 is arranged in the screening zone 11 and includes a number of screening rods 31 for screening sludge impurities, and the screening rods 31 are all along the central axis of the main shaft 2 The sieving rods 31 are arranged at equal intervals on the circumference, and the screening rods 31 are hinged to the main shaft 2;

[0072] The conveying mechanism 4, the conveying mechanism 4 is arranged in the screen zone 11, which is located below the screening mechanism 3, and it includes a number of conveyors that correspond one-...

Embodiment 2

[0102] Figure 7 It is a schematic structural diagram of Embodiment 2 of an automatic sludge impurity screening and dewatering device of the present invention; Figure 7 As shown, the components that are the same as or corresponding to the first embodiment use the reference numerals corresponding to the first embodiment. For simplicity, only the differences from the first embodiment are described below. The second embodiment and figure 1 The difference of the first embodiment shown is:

[0103] Such as Figure 7 versus Figure 8 As shown, an automatic screening and dewatering device for sludge impurities, the closed assembly 44 includes:

[0104] A sealing plate 441, the sealing plate 441 is disposed at the discharge port 22, and the top of the sealing plate 441 is rotatably connected with the main shaft 2; and

[0105] A limit hook 442, the limit hook 442 is located at one end of the feed trough 41 and the main shaft 2 hinged, the limit hook 442 is arranged in the channel 21, and it...

Embodiment 3

[0108] Picture 9 It is a schematic structural diagram of Embodiment 2 of an automatic sludge impurity screening and dewatering device of the present invention; Picture 9 As shown, the components that are the same as or corresponding to the first embodiment use the reference numerals corresponding to the first embodiment. For simplicity, only the differences from the first embodiment are described below. The second embodiment and figure 1 The difference of the first embodiment shown is:

[0109] Such as Picture 9 versus Picture 10 As shown, an automatic sieving and dewatering device for sludge impurities is provided on the top of the processing box 1 is provided with a feed pipe 14, the feed pipe 14 is provided with a valve 141, and the valve 141 is also provided with a control mechanism 5. , The control mechanism 8 includes:

[0110] A gear 81, which is connected to the main shaft of the valve 141 and is located outside the feed pipe 14; and

[0111] The rack 82 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com