Potato harvesting machine

A harvester and potato technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems that the shovel teeth are easy to damage the potato skin and poor screening effect, and achieve good screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

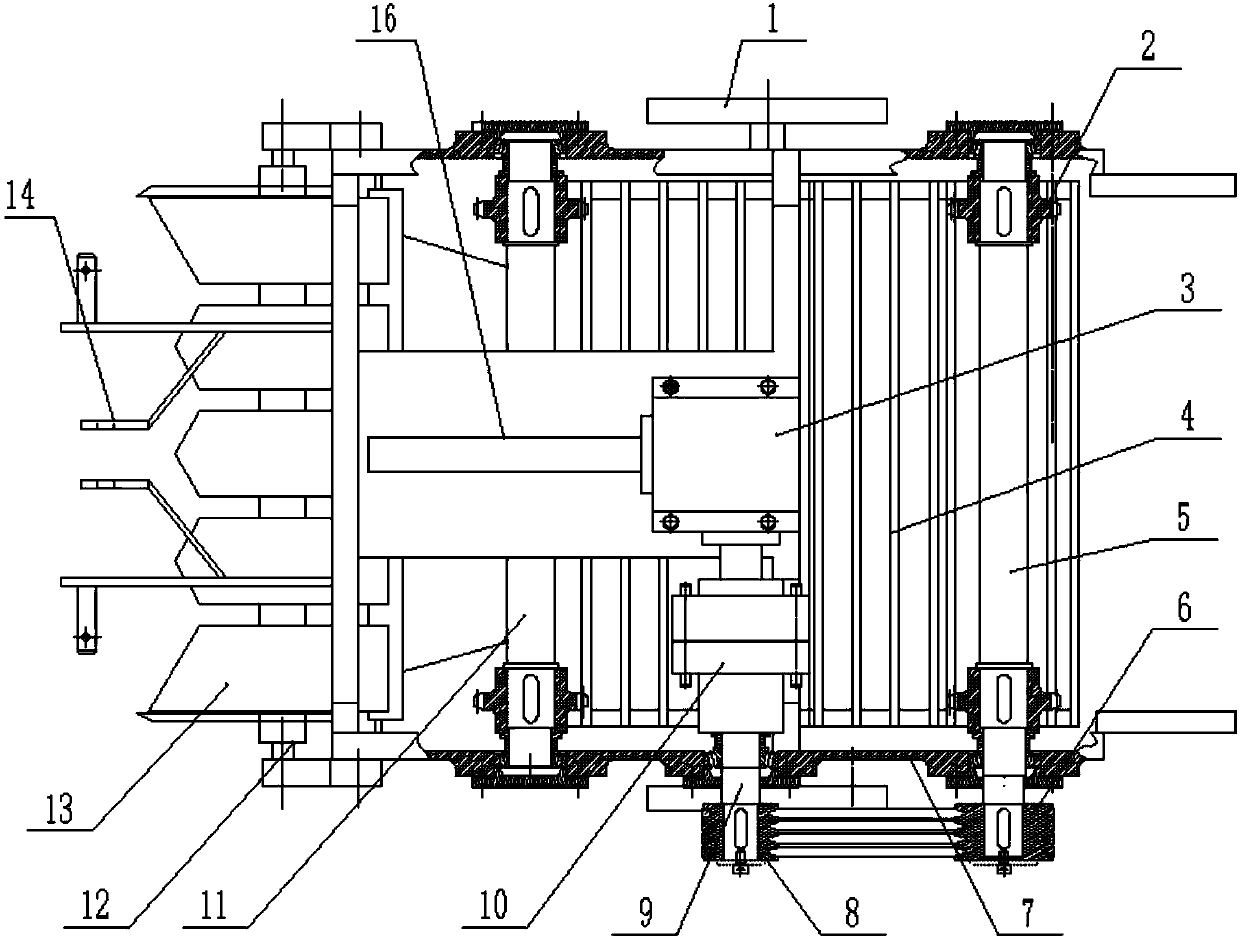

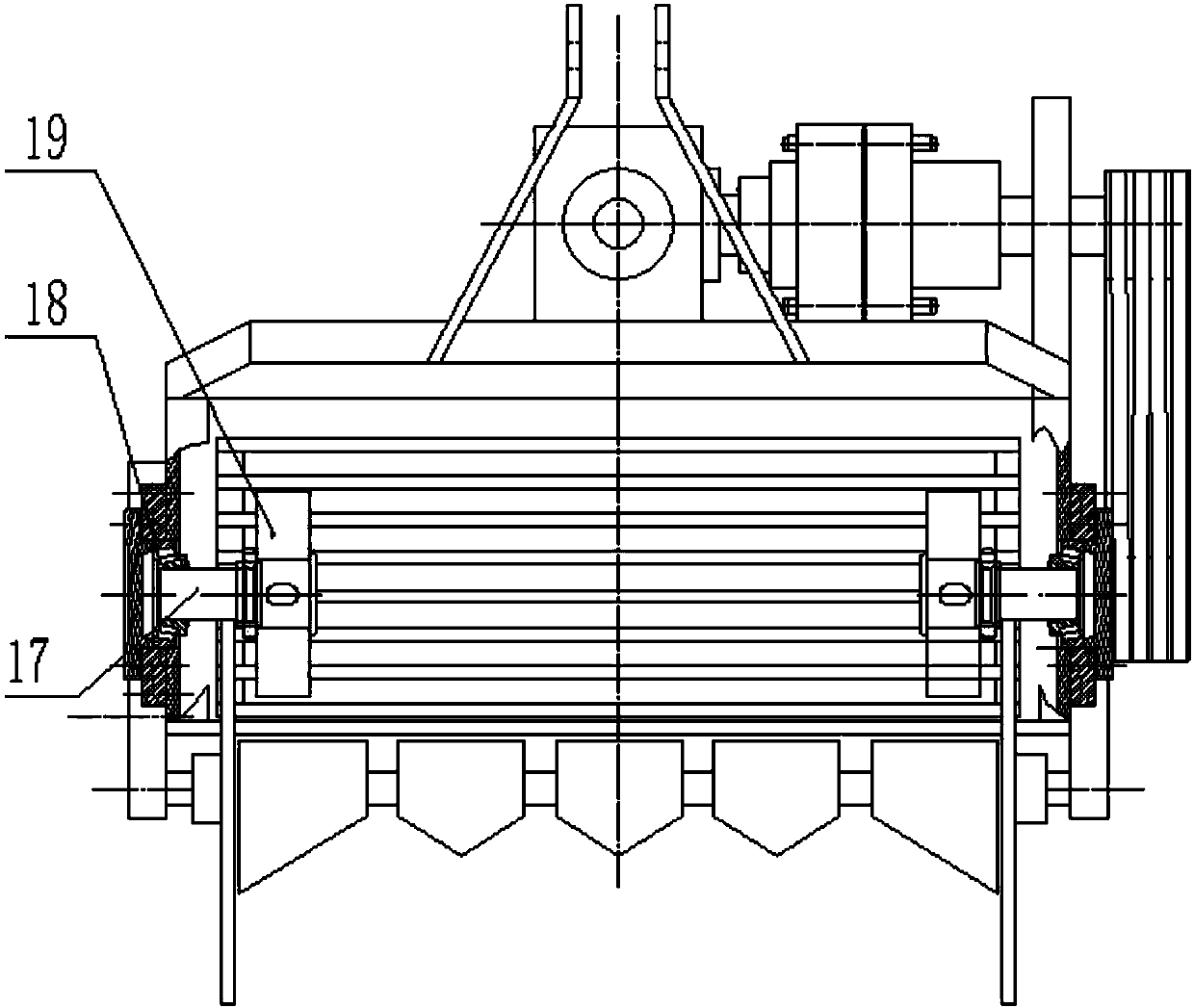

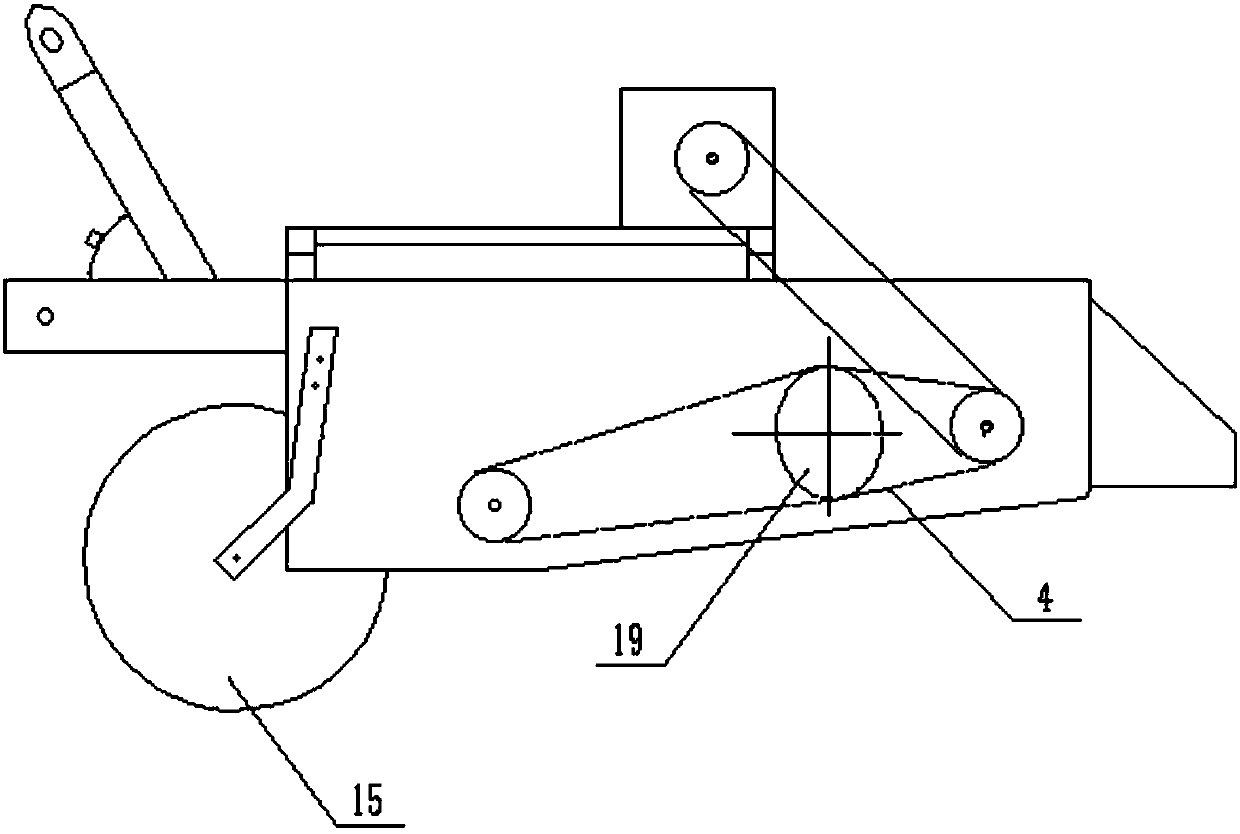

[0028] Embodiment 1: as Figure 1-3 , 5, the potato harvester includes a frame 7, the frame 7 is provided with a bucket portion, a lifting portion, a driving portion and a shaking portion, and the bucket portion is fixed on the front end of the frame 7, and the To shovel out the potatoes in the field ridge, the rear end of the bucket part contacts the lifting part; the lifting part includes a driven sprocket mounted on the front end of the frame 7 and a driving chain mounted on the rear end of the frame 7 Wheel 2, the driven sprocket and the driving sprocket 2 are connected through the lifting chain 4, and the lifting part is used to transport the potatoes shoveled out from the bucket part; Eccentric wheel 19, described eccentric wheel 19 is positioned between driving sprocket 2 and driven sprocket, and described eccentric wheel 19 is provided with gear teeth, and eccentric wheel 19 contacts and supports lifting chain 4 by gear teeth; The driving part is installed on the top ...

Embodiment 2

[0031] Embodiment 2: as figure 1 , 2 , shown in 4 and 5, the potato harvester includes a frame 7, the frame 7 is provided with a bucket portion, a lifting portion, a driving portion and a shaking portion, and the bucket portion is fixed on the front end of the frame 7 , used to shovel out the potatoes in the field ridge, the rear end of the bucket portion is in contact with the lifting portion; the lifting portion includes a driven sprocket mounted on the front end of the frame 7 and a The driving sprocket 2, the driven sprocket and the driving sprocket 2 are connected through the lifting chain 4, and the lifting part is used to transport the potatoes shoveled out from the bucket part; The eccentric wheel 19 in the middle, the eccentric wheel 19 is located between the driving sprocket 2 and the driven sprocket, the eccentric wheel 19 is provided with gear teeth, the eccentric wheel 19 contacts and supports the lifting chain 4 through the gear teeth; The driving part is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com